In-situ repair system and method for deep layer stirring-hot air injection of polluted soil

A technology of polluted soil and deep mixing, applied in the restoration of contaminated soil, etc., can solve the problems of poor repair efficiency and pollutant removal effect, and achieve the effects of shortening the repair cycle, expanding the application range, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

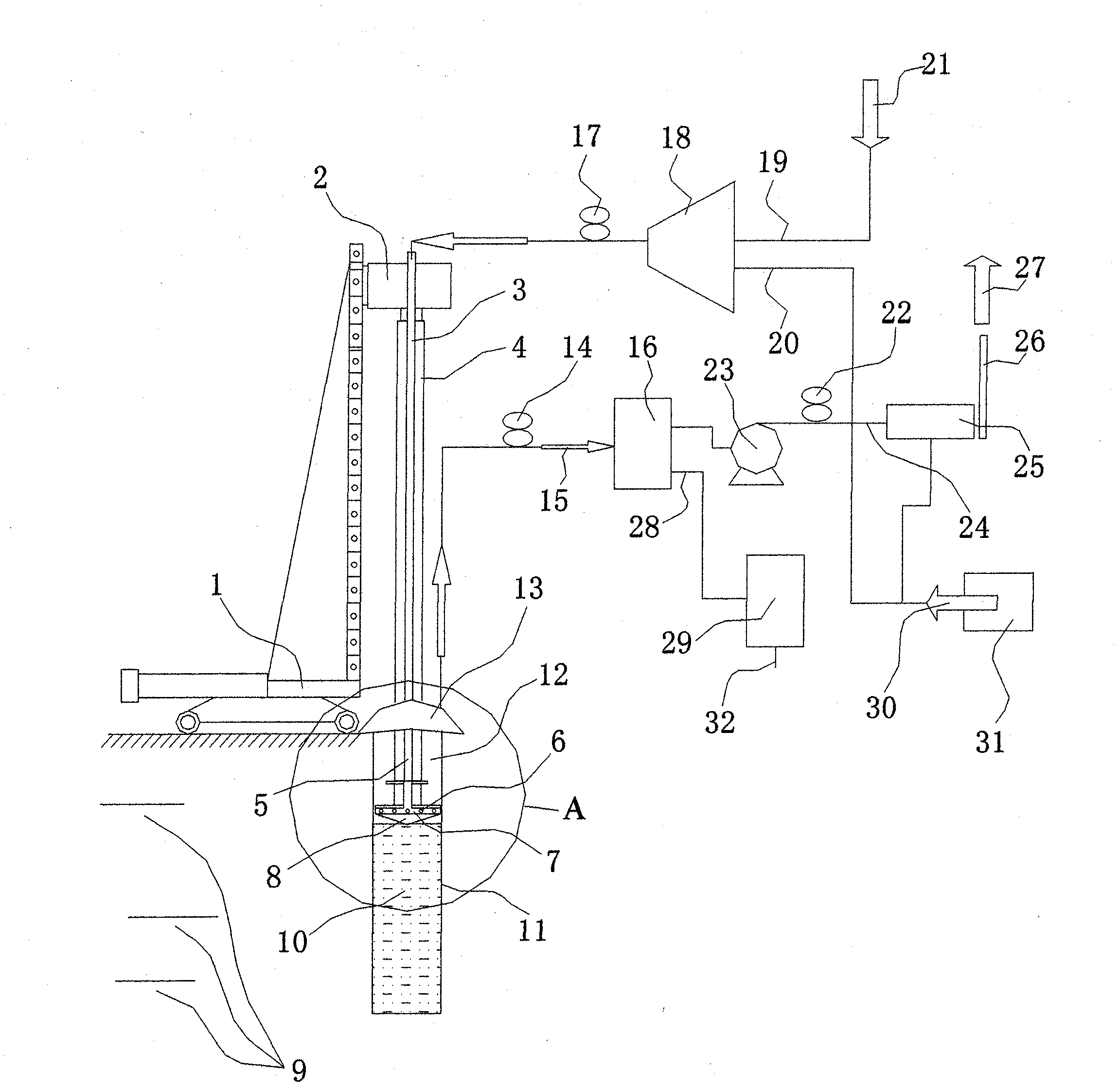

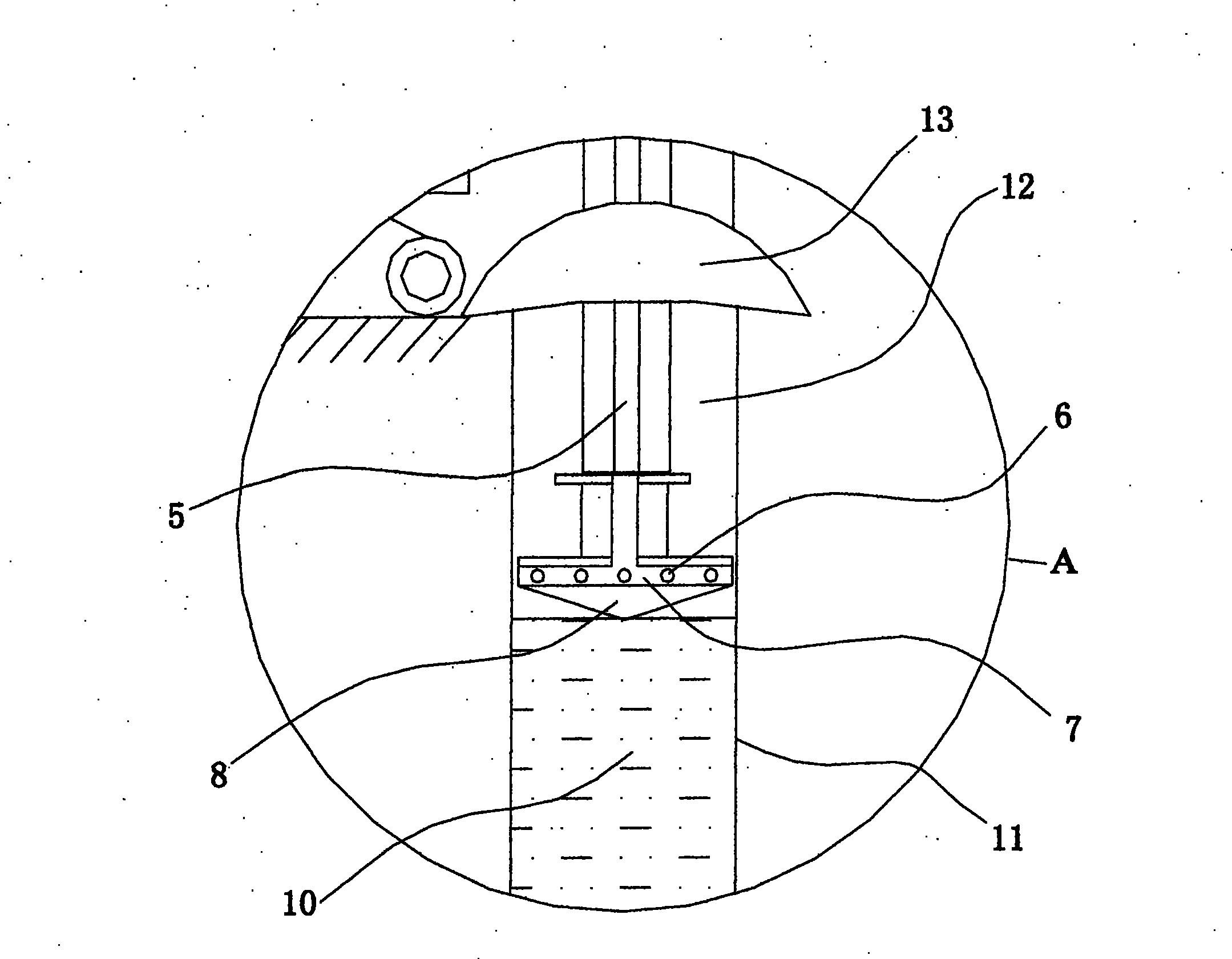

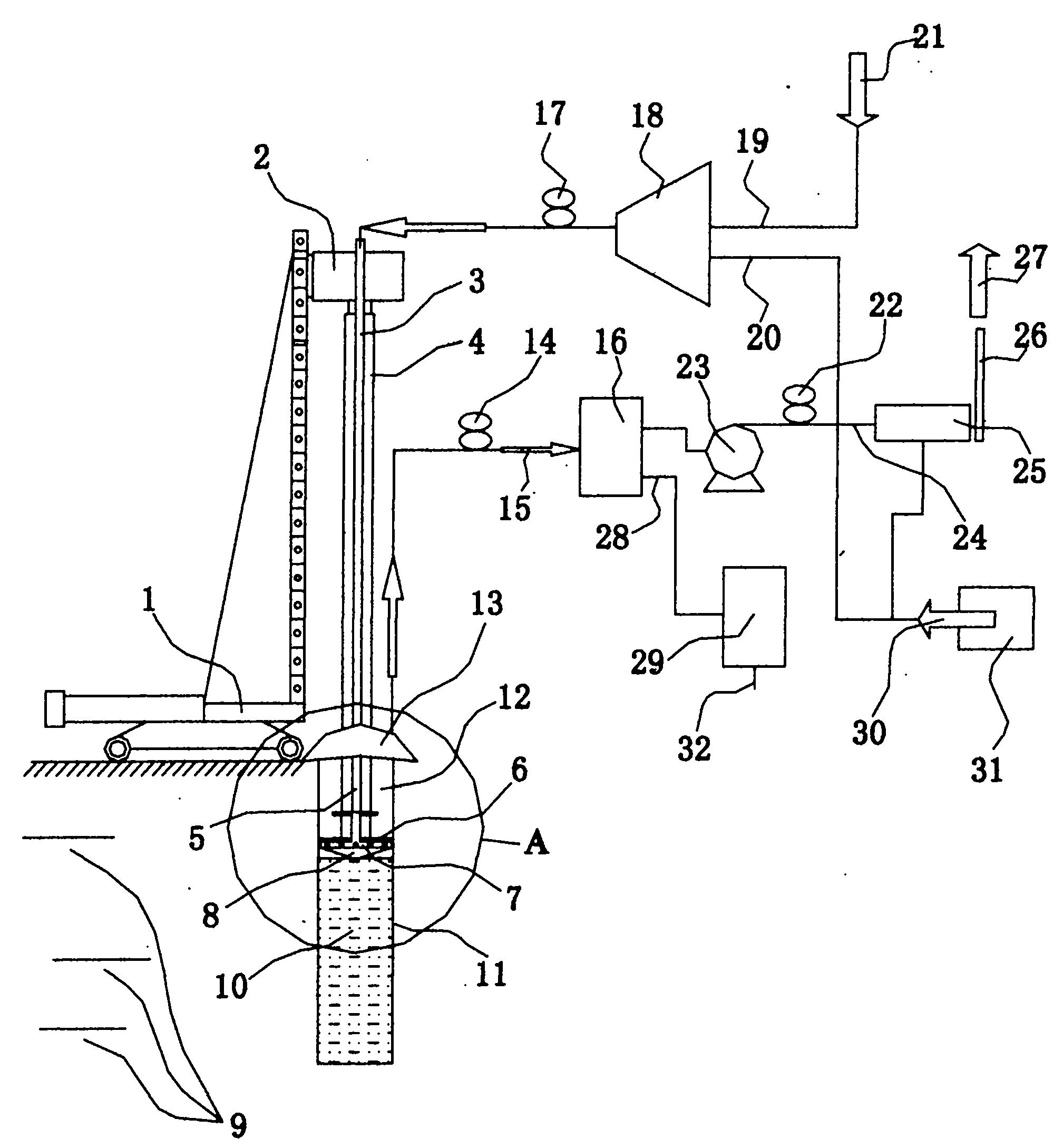

[0026] like figure 1 and figure 2As shown, an in-situ remediation system for deep stirring-hot air injection involved in this embodiment includes: long auger drill 1, power head 2, hot air injection pipe 3, drill pipe 4, drill bit body Core pipe 7, drill bit 8, cover 13, mixed gas-liquid pipeline 15, gas-liquid separator 16, hot air compressor 18, vortex exhaust fan 23, gas phase processor 25, liquid phase conveying pipeline 28, waste liquid treatment device 29 and power source 31, the power head 2 is arranged on the long screw drilling machine 1, the upper end of the drill rod 4 is connected with the power head 2, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com