Conveying and reversing device for catalyst slurry

A technology of reversing device and catalyst slurry, which is applied in the directions of liquid distribution, conveying or transfer device, distribution device, transportation and packaging, etc., can solve problems such as the decline of catalyst quality and effect, the decline of slurry purity, and the decline of slurry transportation efficiency. , to achieve the effect of maintaining high-efficiency transportation for a long time, improving yield and quality, and ensuring high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

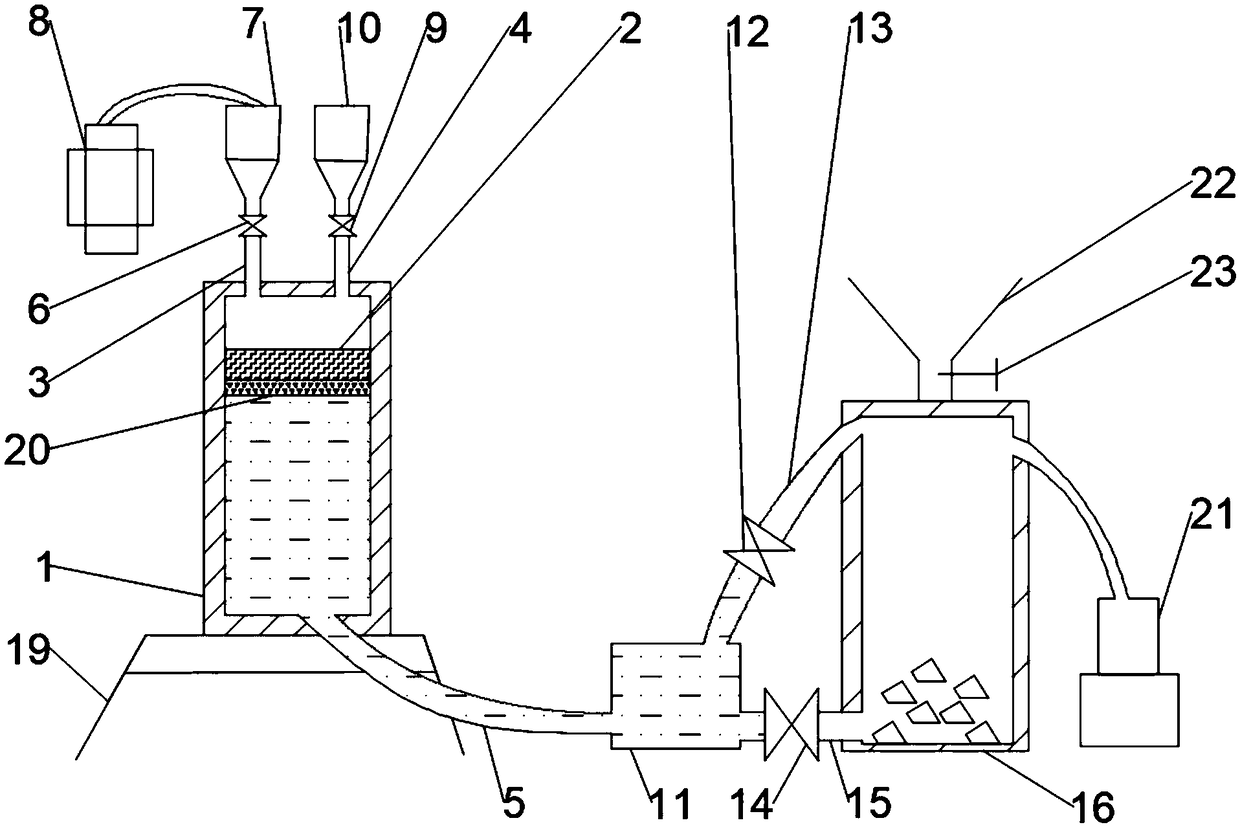

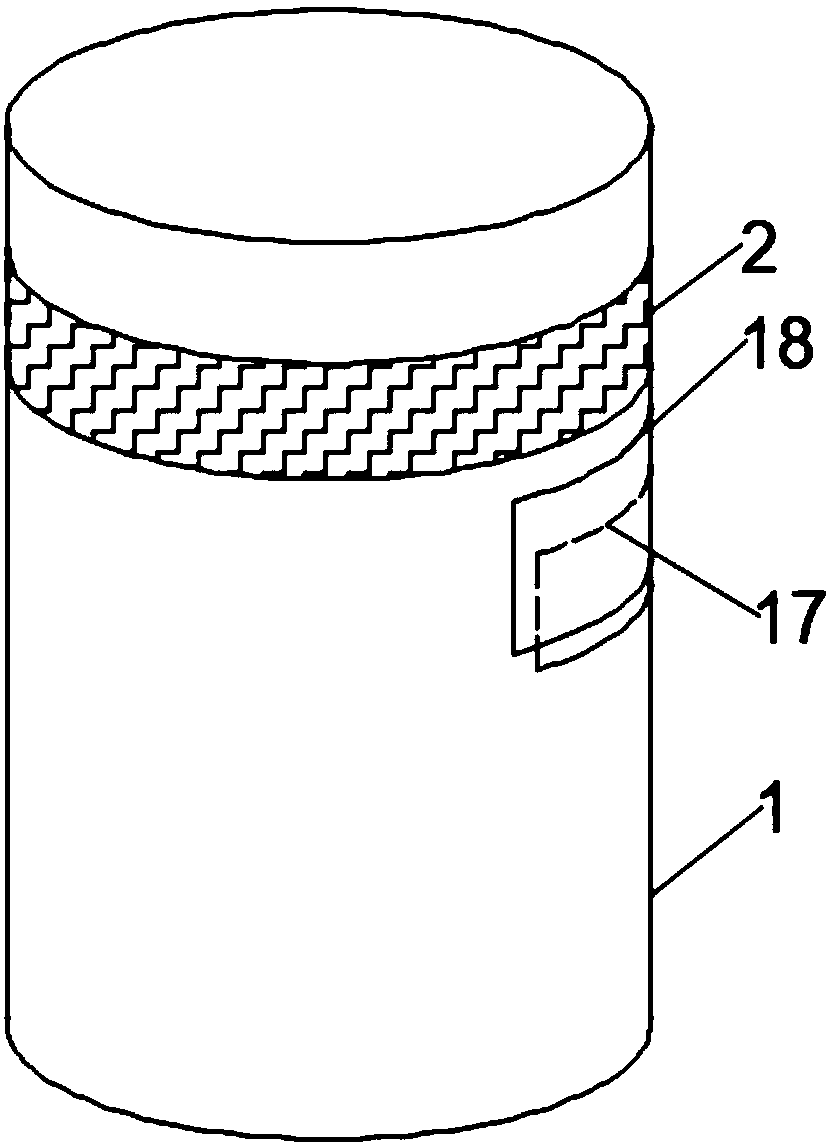

[0024] Such as figure 1 with figure 2 As shown, the present invention provides a reversing device for catalyst slurry delivery, including a piston cylinder 1, a bracket 19 is provided at the bottom of the piston cylinder 1, and the bracket 19 supports the piston cylinder 1, and the bracket 19 makes the piston cylinder 1 Conveying the slurry is more stable. The side of the piston cylinder 1 is provided with a feed port 17, and a sealed door 18 is installed on the outside of the feed port 17. The sealed door 18 covers the feed port 17, and the feed port 17 is convenient for catalyst The slurry enters the piston cylinder 1 and is transported. Here, the feed port 17 is set under the piston 2, that is, when the piston 2 is in a balanced state, the piston 2 is located above the feed port 17, so that the slurry can only fill the space under the piston 2. , the sealing door 18 is a part that seals the piston cylinder 1 after the slurry is filled, so as to avoid that the kinetic ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com