Cartridge holder clamping petal of carbon fiber composite armor-piercing bullet and forming method and forming die thereof

A composite material and the technology of the carrier flap, which is applied in the field of the armor-piercing projectile carrier, can solve the problems of low tooth efficiency, easy damage, and difficult covering of the carrier, so as to reduce the negative mass, enhance the strength of the teeth, The effect of shortening laying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is not limited to the following specific embodiments. Those skilled in the art can implement the present invention in various other specific embodiments according to the disclosed content of the present invention, or make simple changes or All changes fall within the protection scope of the present invention. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention is described in further detail below in conjunction with embodiment:

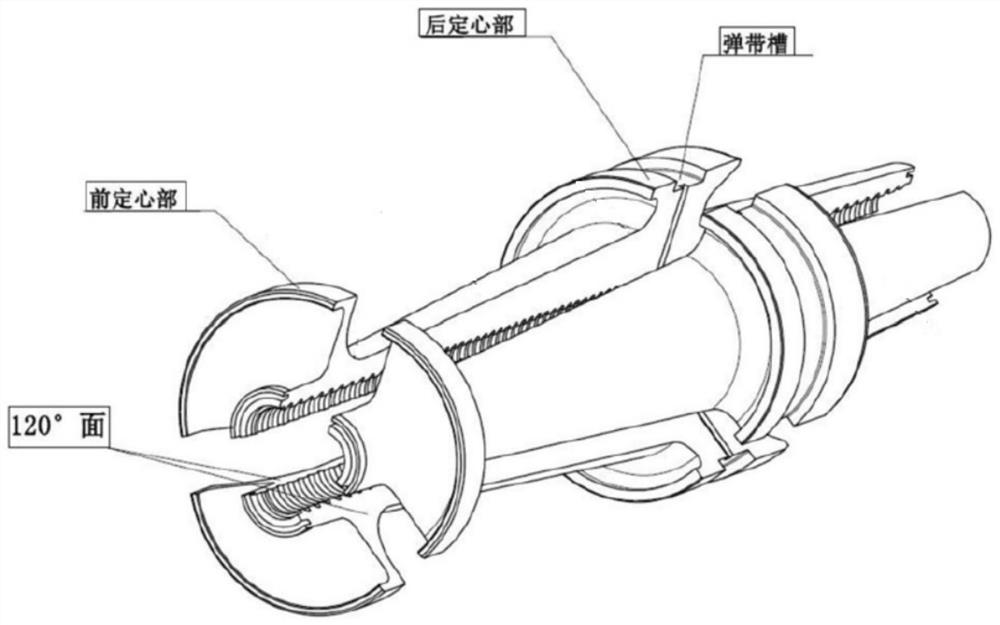

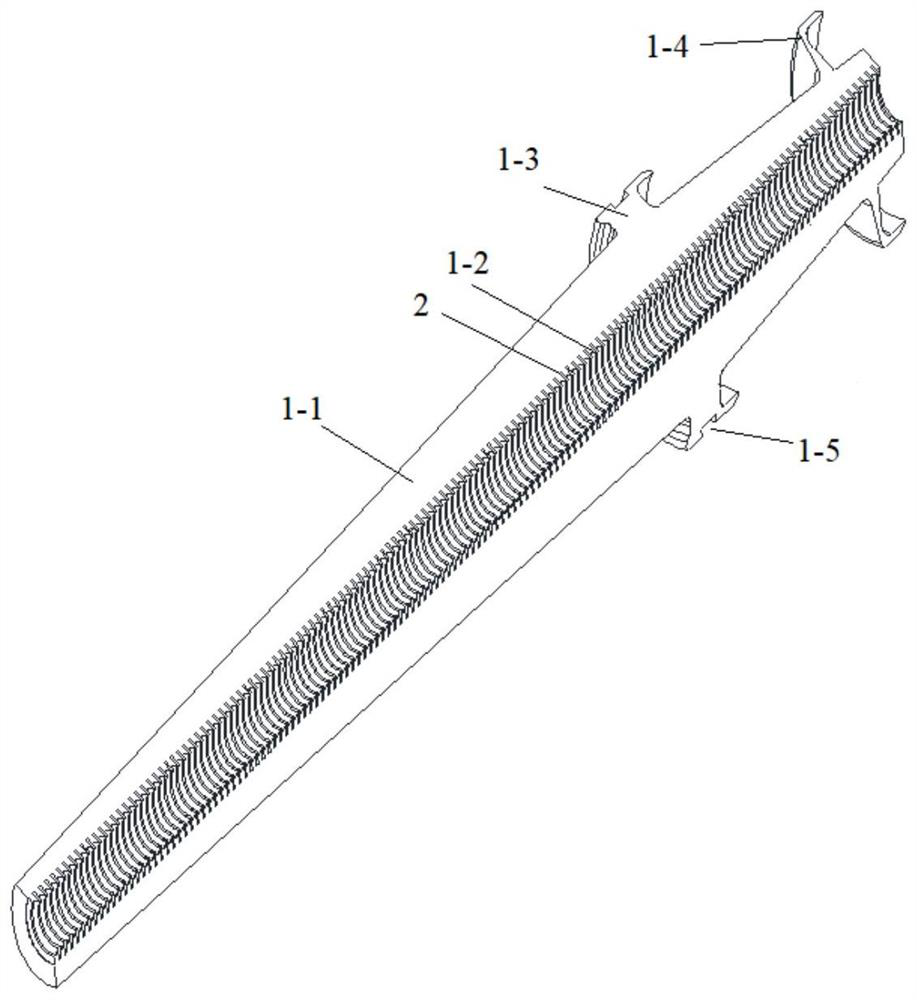

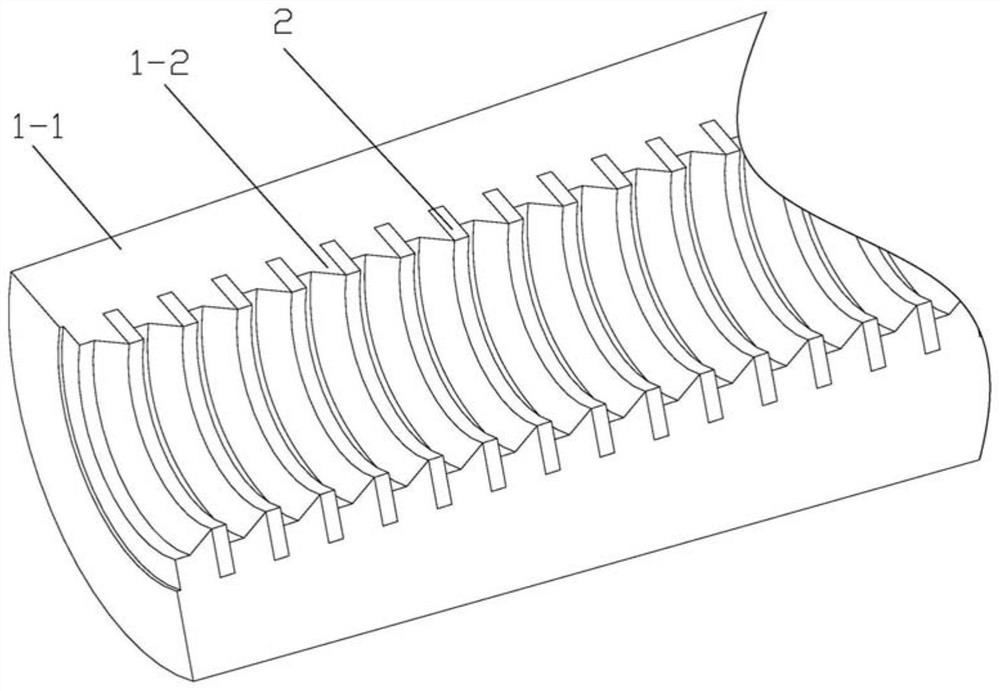

[0025] The carrier flap of the carbon fiber composite armor-piercing projectile of this embodiment, the carrier flap includes a shell and a fan-shaped tooth reinforcement plate 2, the shell is integrally molded by chopped carbon fiber prepreg, and includes a shell with a fan-shaped cross section 1-1. A plurality of ring-shaped teeth arranged uniformly and at intervals along the axia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com