Patents

Literature

70 results about "Armor-piercing shell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An armor-piercing shell, AP for short, is a type of ammunition designed to penetrate armor. From the 1860s to 1950s, a major application of armor-piercing projectiles was to defeat the thick armor carried on many warships. From the 1920s onwards, armor-piercing weapons were required for anti-tank missions. AP rounds smaller than 20 mm are typically known as "armor-piercing ammunition", and are intended for lightly-armored targets such as body armor, bulletproof glass and light armored vehicles. The classic AP shell is now seldom used in naval warfare, as modern warships have little or no armor protection, and newer technologies have displaced the classic AP design in the anti-tank role.

Non-expanding modular bullet

InactiveUS20070017409A1Lower requirementLow costAmmunition projectilesProjectilesArmor-piercing shellMarine engineering

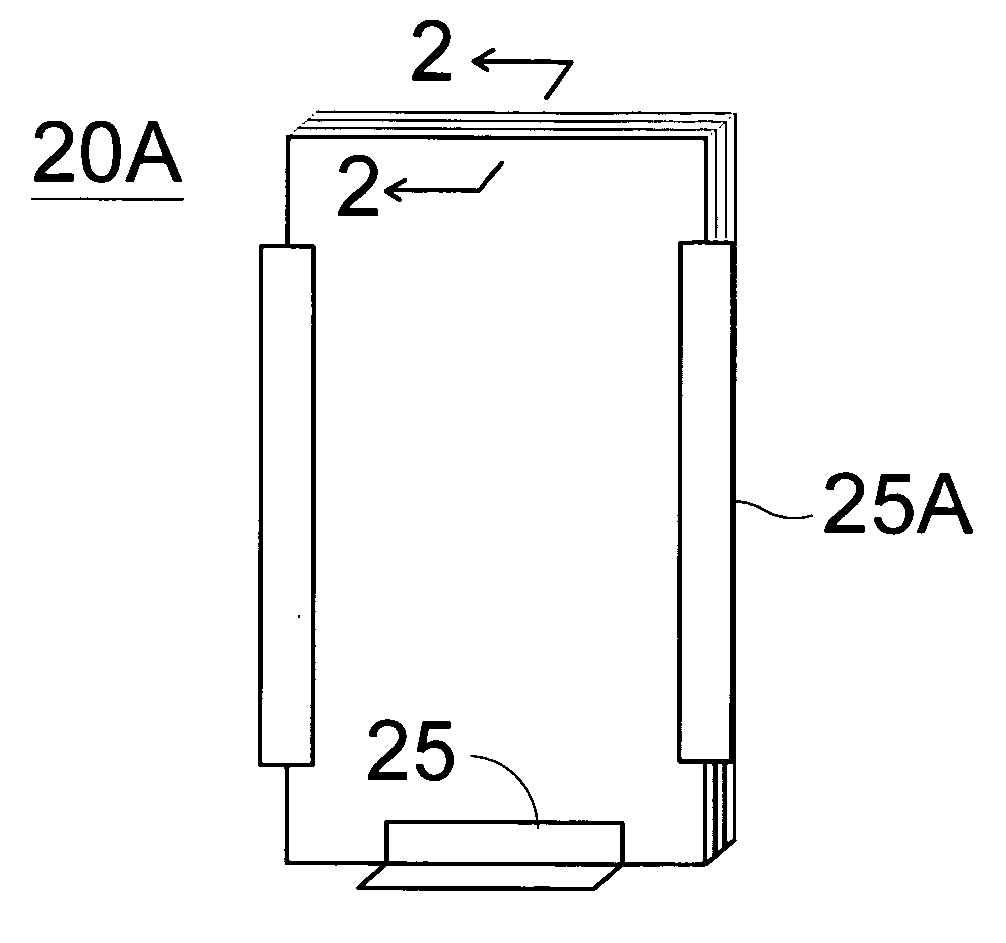

A non-expanding bullet platform may comprise a modular jacket having an internal nose cavity and an internal heel cavity. The cavities may be separated by a divider. The cavities may be filled with suitable materials to produce various types of non-expanding bullets, such as military ball, trace, armor piercing, etc. Inventive non-expanding bullets may comprise full metal jacketed bullets or may have exposed material. The inventive bullets may be non-expanding, wherein the diameter of the bullet does not substantially increase upon impacting soft tissue.

Owner:ALLIANT TECHSYST INC

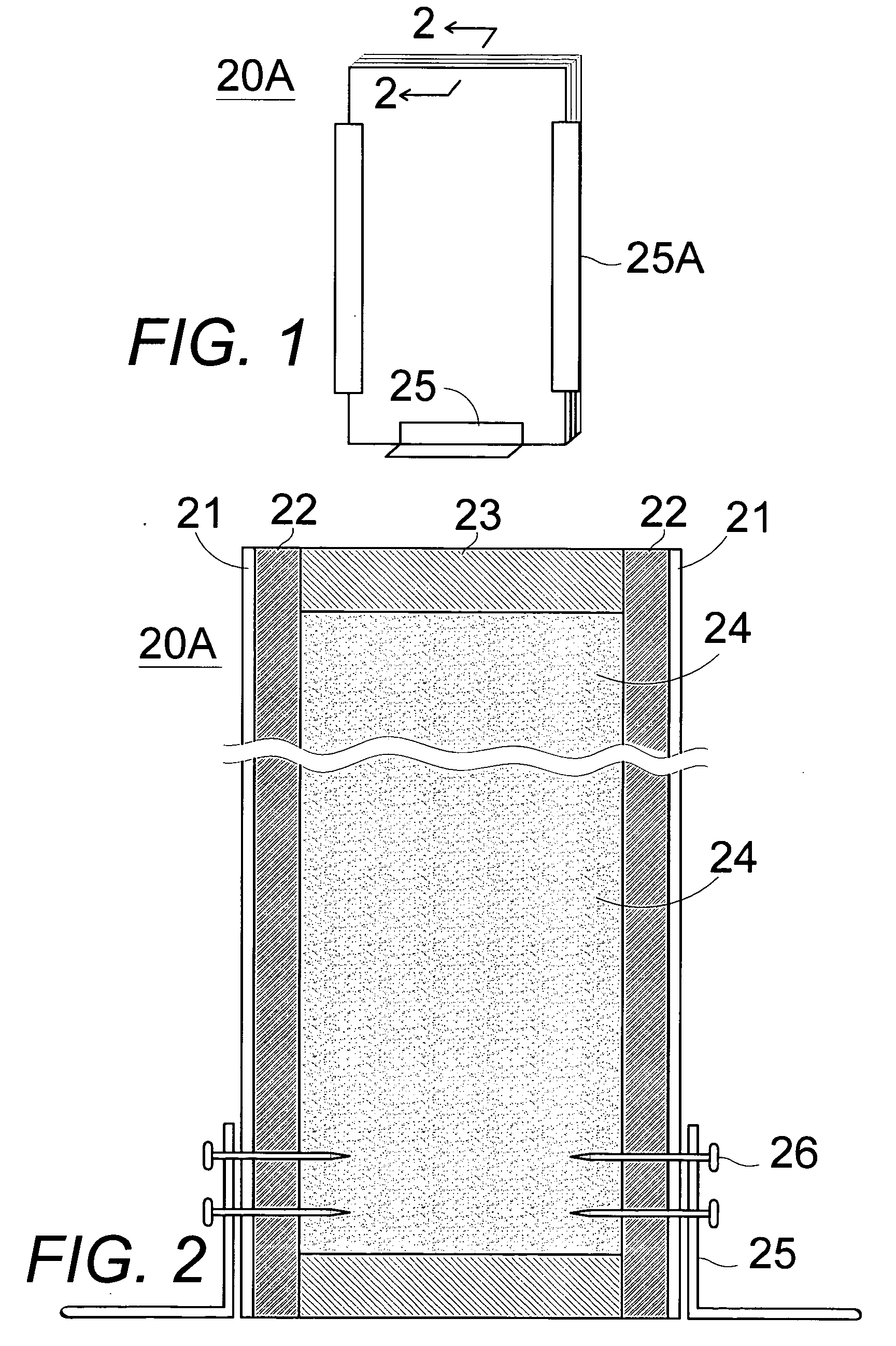

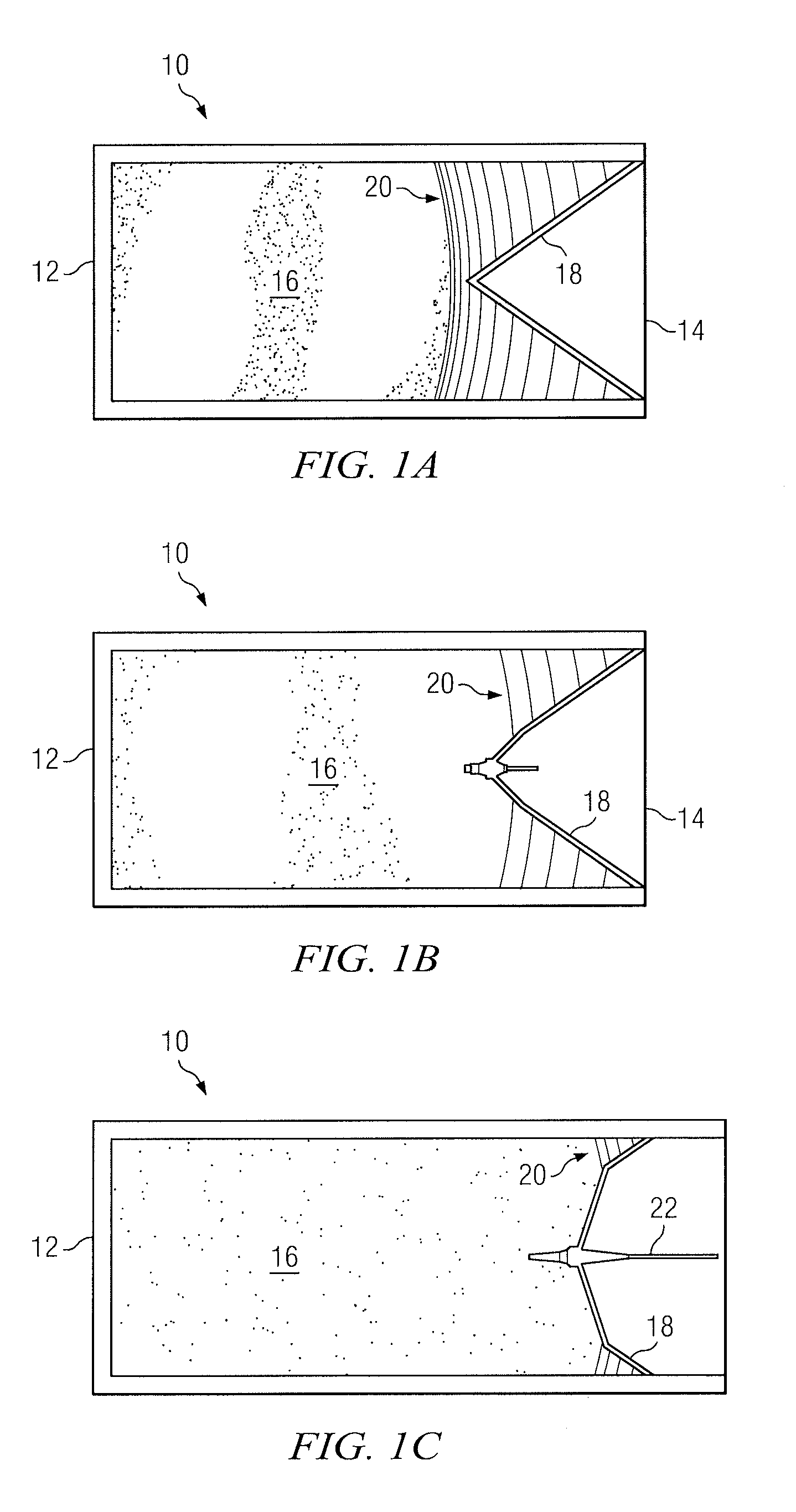

Ballistic barrier system and method

InactiveUS20060248827A1Immediate inexpensive and effective protection against attacks inside a structureAvailable materialBuilding componentsProtective buildings/sheltersArmor-piercing shellStructural engineering

A ballistic barrier wall is constructed of a pair of spaced vertical surfaces connected by 2×4 s, 2×8 s or other boards and filled with sand. The outside is spray-coated on both vertical sides with an elastomeric polymer mixture. Panels or walls are connected to other panels and to floor or wall surfaces by straight brackets and angle brackets. The multiple vertical layers of the panel trap bullets, armor piercing shells, bomb shrapnel or other ballistic elements in the wall.

Owner:MEEKER JAMES R

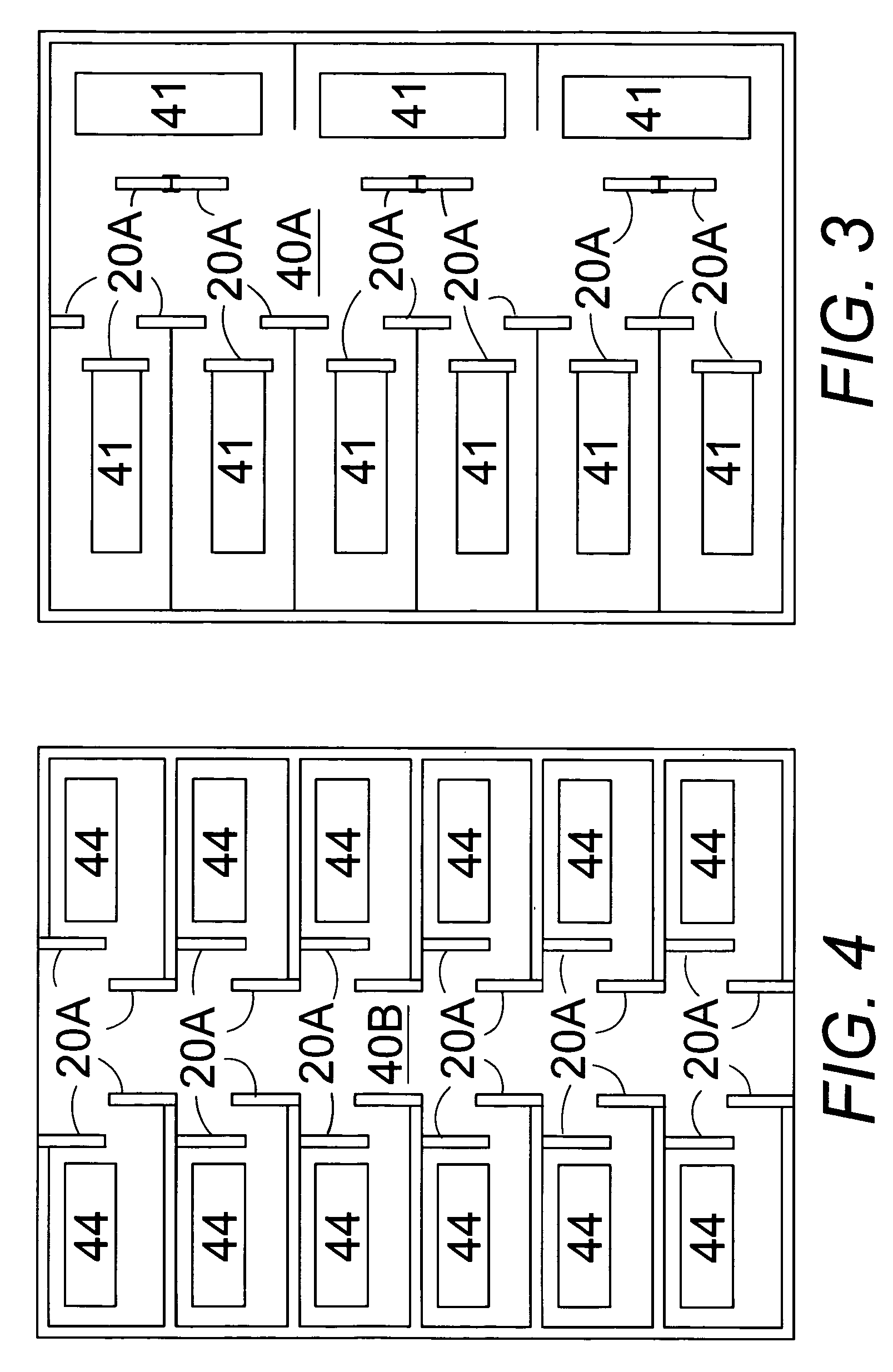

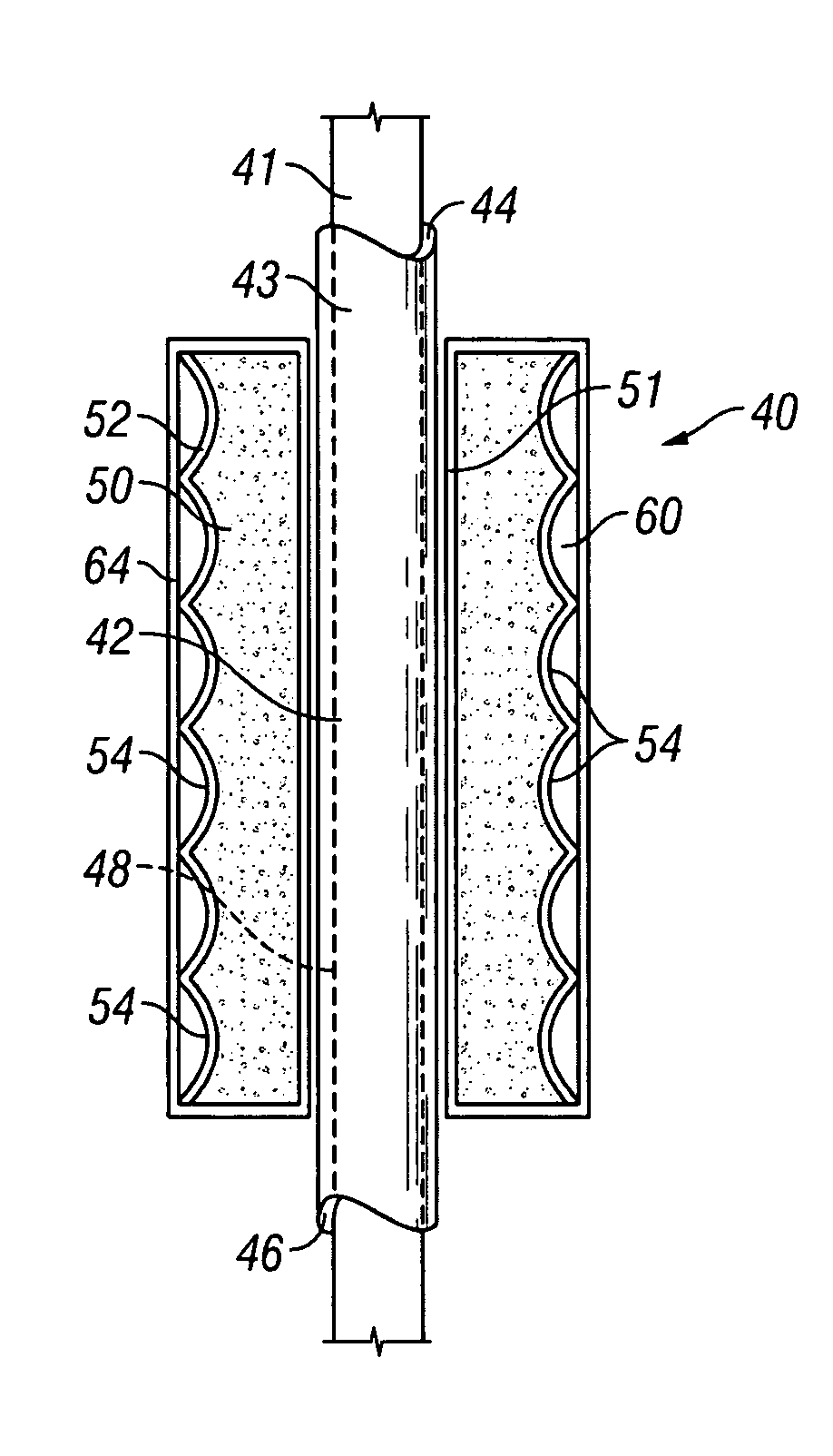

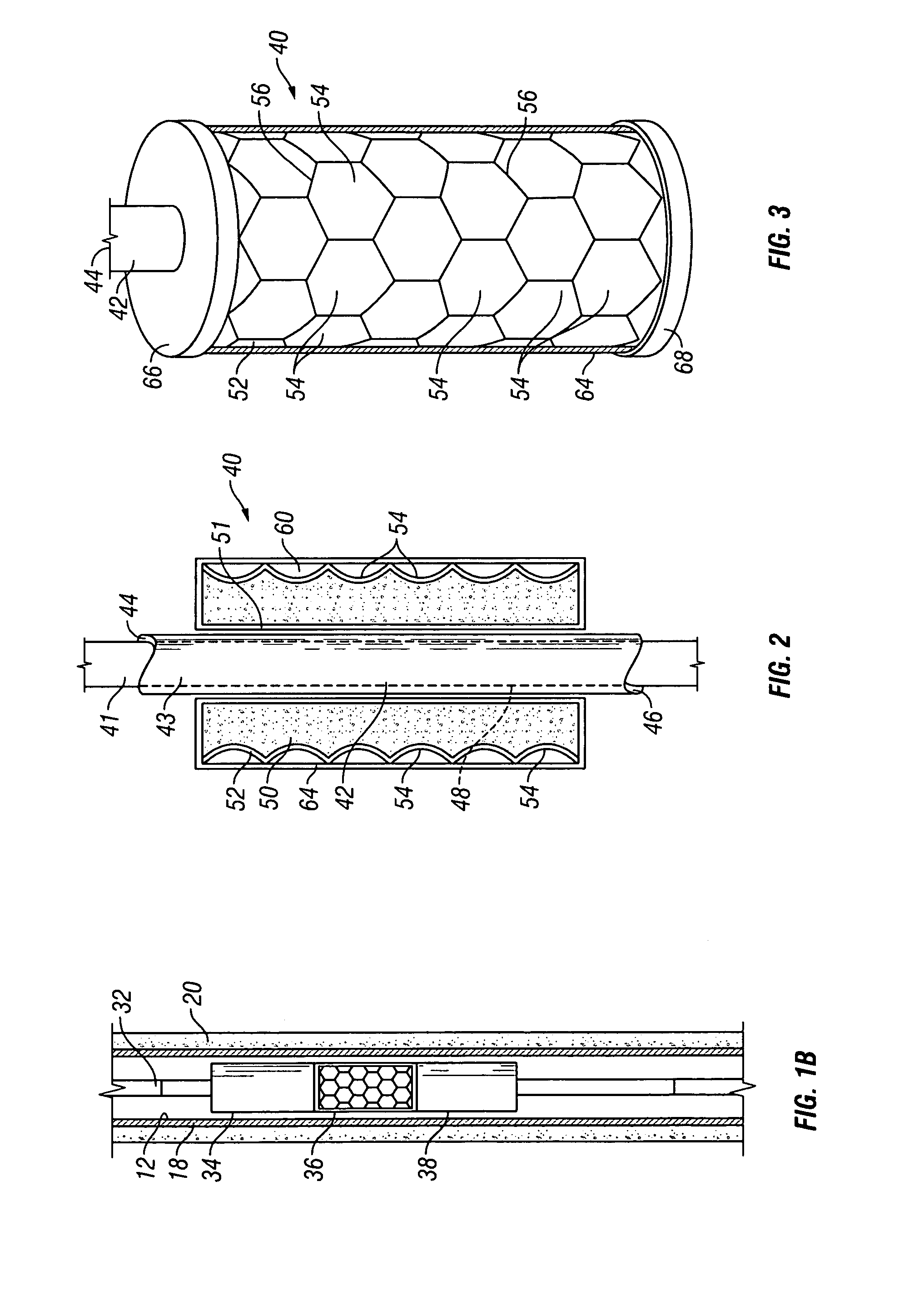

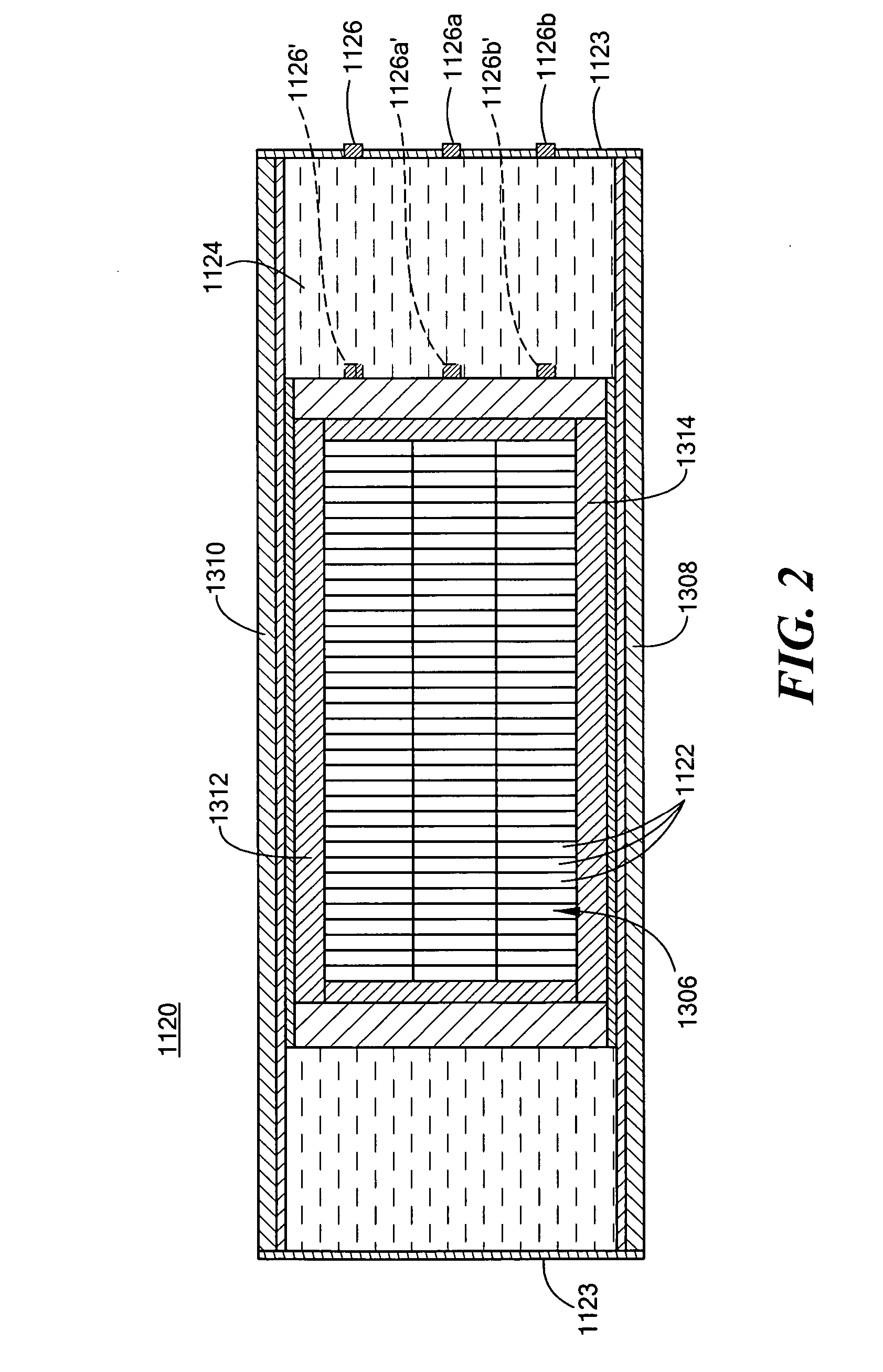

High density perforating gun system producing reduced debris

InactiveUS20070240599A1Amount of debris resulting from the detonation is reduced or eliminatedExplosive chargesFluid removalArmor-piercing shellDetonation

A perforating system has a perforating module comprising a unitary body of explosive. The explosive is contained within a non-explosive casing, or liner, having formed indentations and a cover thereover. The indentations, which will transform into explosively formed penetrators (EFP's) upon detonation, have a perimeter shape that allows for improved packing density, e.g., a hexagonal perimeter, which results in relatively little “dead space” wherein no perforating penetrators are generated. In operation, the module provides a relatively dense shot pattern and substantially reduced amount of post-detonation debris that could clog the perforations and / or require remedial clean-up or repeat perforation.

Owner:OWEN OIL TOOLS

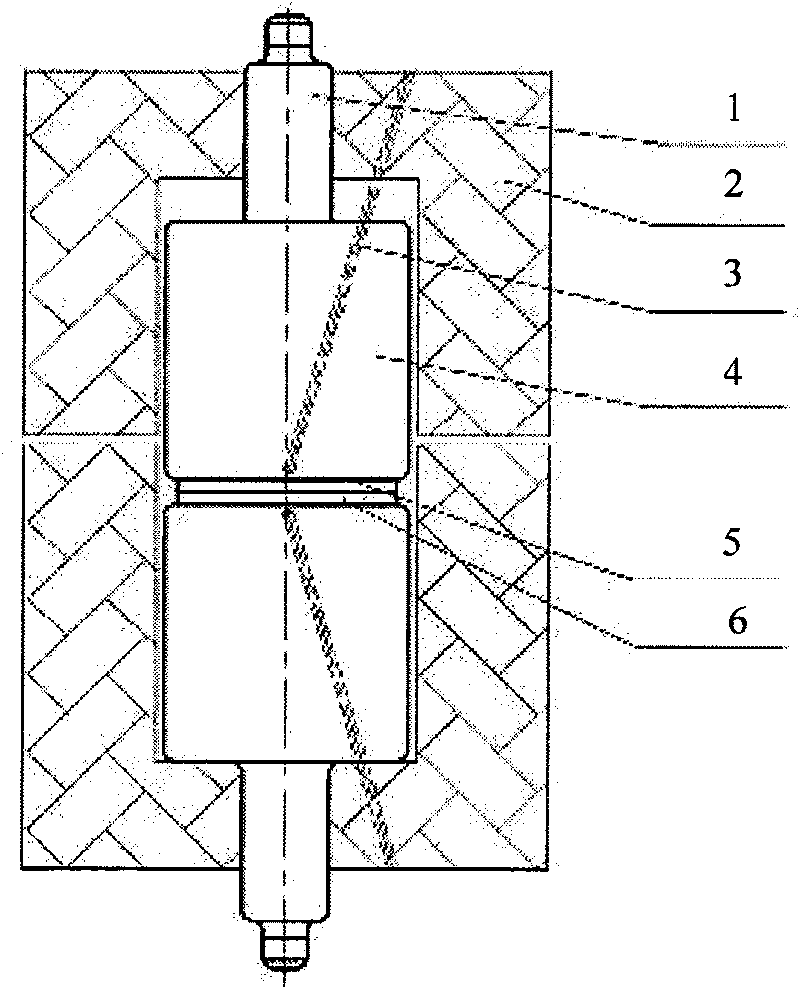

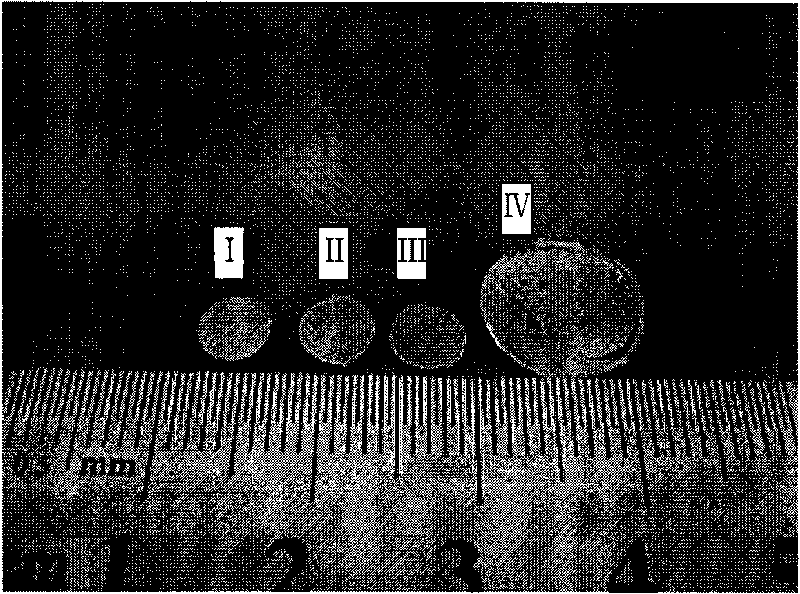

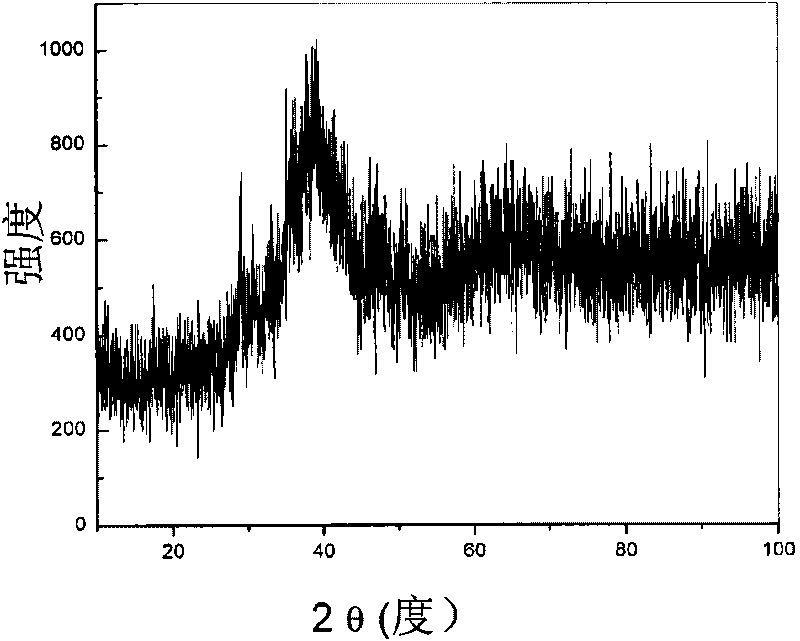

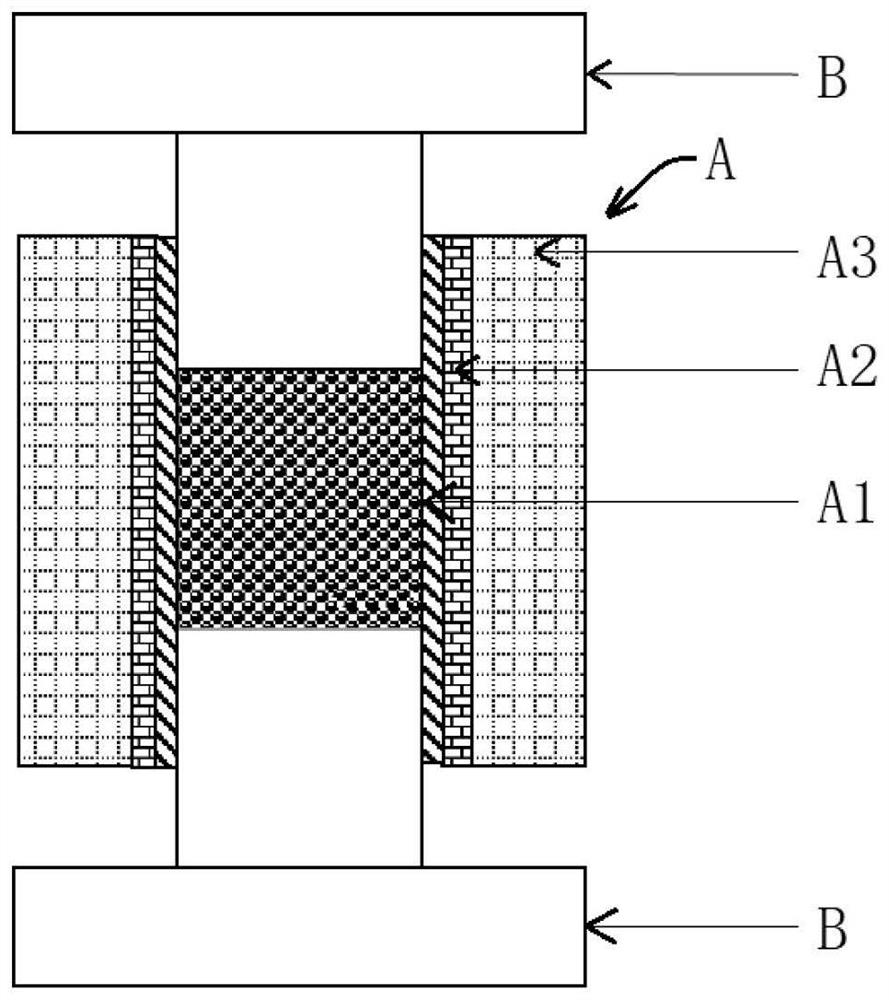

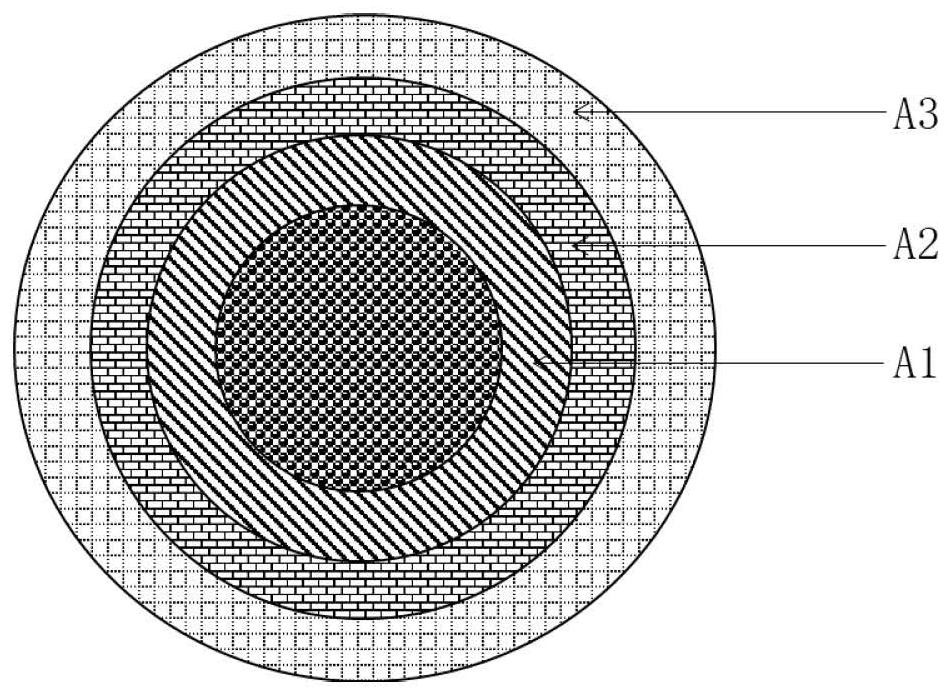

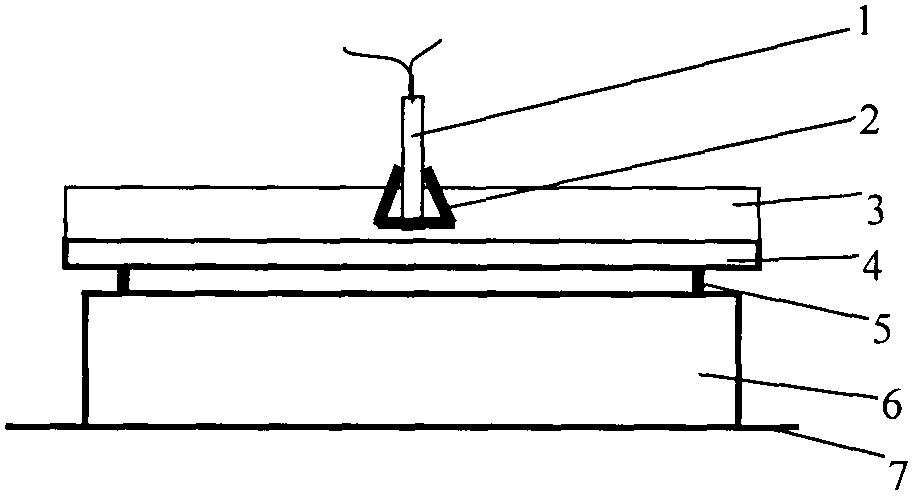

Method and device for preparing large-size bulk amorphous composite materials

The invention provides a method for preparing large-size bulk amorphous composite materials, which belongs to the field of preparing amorphous alloy (metallic glass) and composite materials thereof. The method applies to superplastic diffusion bonding of bulk amorphous substances and fiber, and is characterized in that the bulk amorphous substances and the fiber are arranged in a certain mode (such as a layered mode and the like), put into a mold, pressurized and thermally insulated under gas protection or vacuum for superplastic diffusion bonding; pressure is released after a certain period of time; and workpieces are taken out of the mold. The invention also provides a novel device for preparing large-size bulk amorphous, fiber / amorphous composite materials through superplastic diffusion bonding. The device consists of a heating system, a heat insulation system, a mold system, a loading system, a gas protection system and a cooling system. The method and the device have the advantages of reinforcing the fiber, enabling the shape of amorphous alloy-base composite materials to be designed, enabling the volume of the fiber in the composite materials to be controlled and enabling the fiber to be used in other various amorphous alloy systems low in amorphous formation capability, and are applicable to armor boards, armor-piercing shells and the like.

Owner:UNIV OF SCI & TECH BEIJING

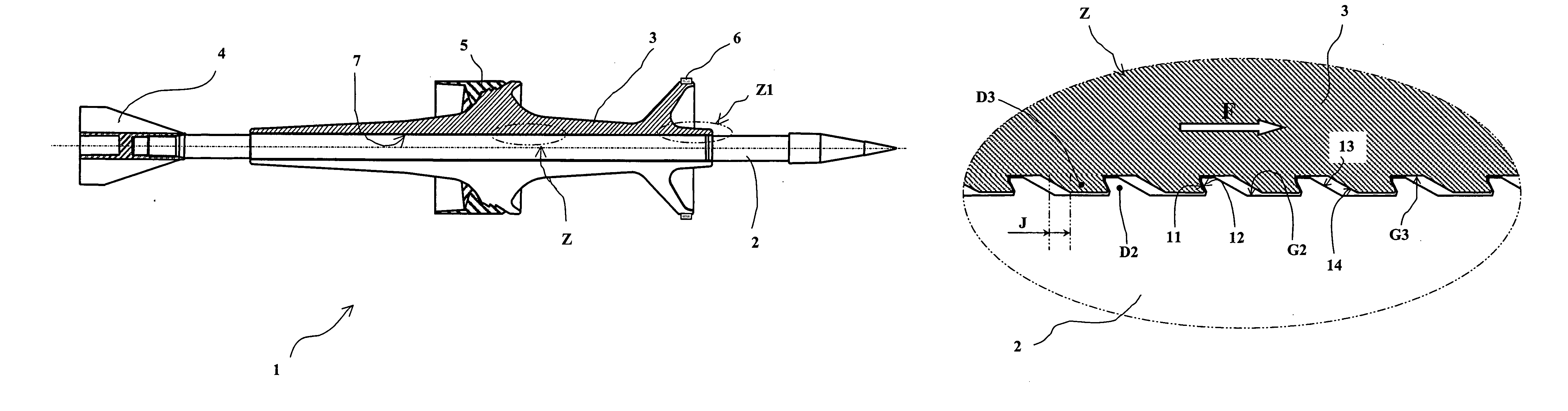

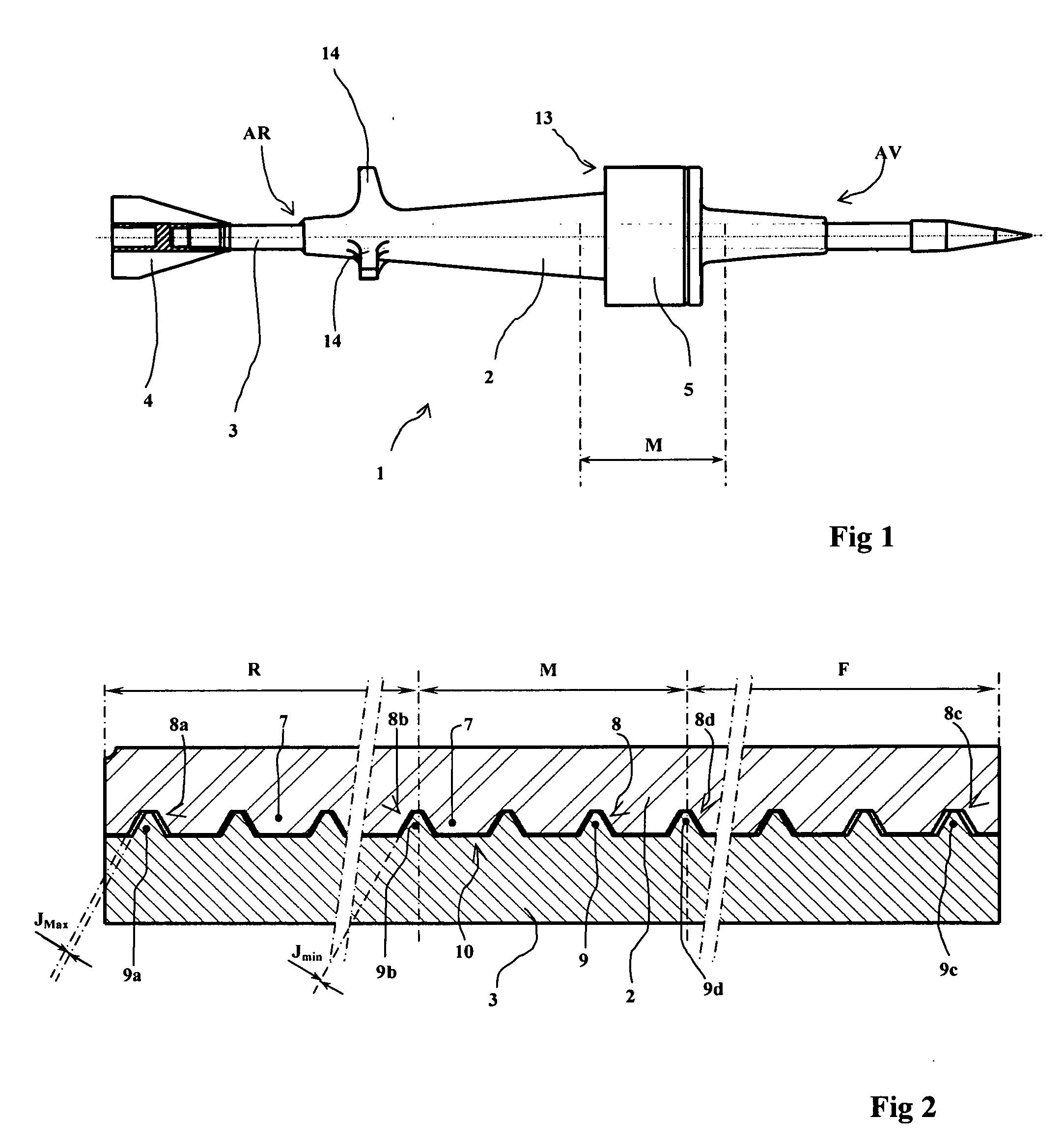

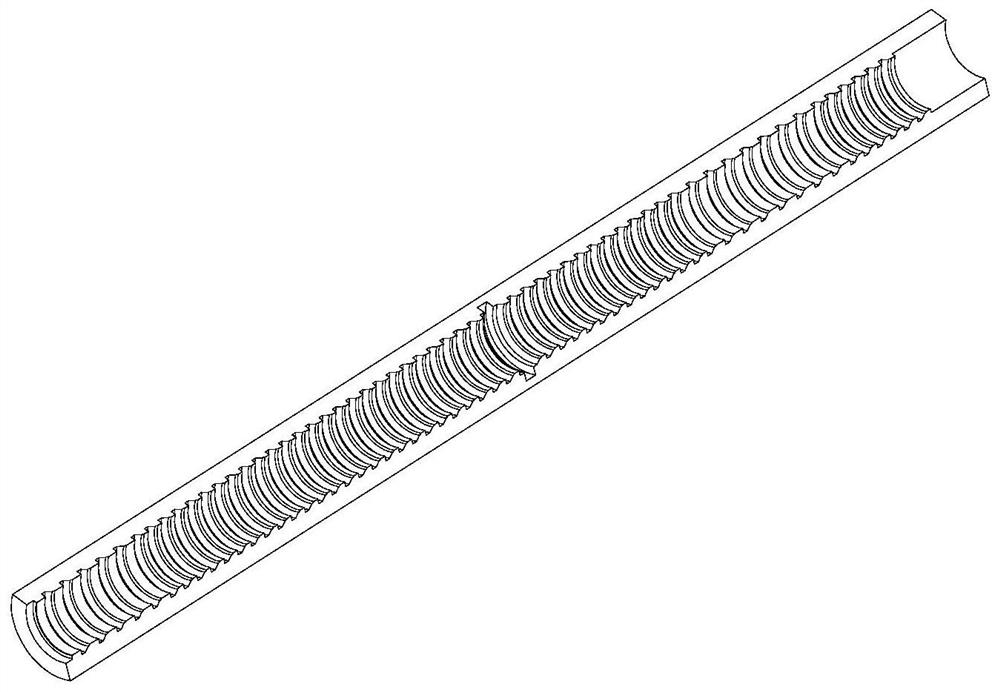

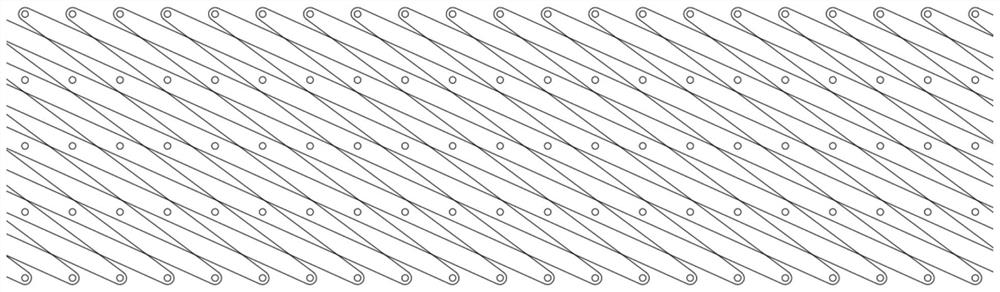

Sub-caliber projectile, penetrator and sabot enabling such a projectile

InactiveUS20050011397A1Better flexion-resistance of the sabotHigh retention rateAmmunition projectilesProjectilesAxial displacementArmor-piercing shell

A sub-calibre projectile incorporating a penetrator and a sabot formed of several segments, the penetrator and sabot incorporating profiles that cooperate with one another so as to ensure the axial drive of the penetrator by the sabot when the projectile is being fired, such projectile wherein there is axial play (J) between the profile on the sabot and that on the penetrator so as to enable a limited relative axial displacement of the sabot with respect to the penetrator, means being provided to ensure the radial locking of the sabot segments by the penetrator in the foremost position of the sabot with respect to the penetrator, this locking no longer being ensured in the rearmost position of the sabot with respect to the penetrator.

Owner:NEXTER MUNITIONS

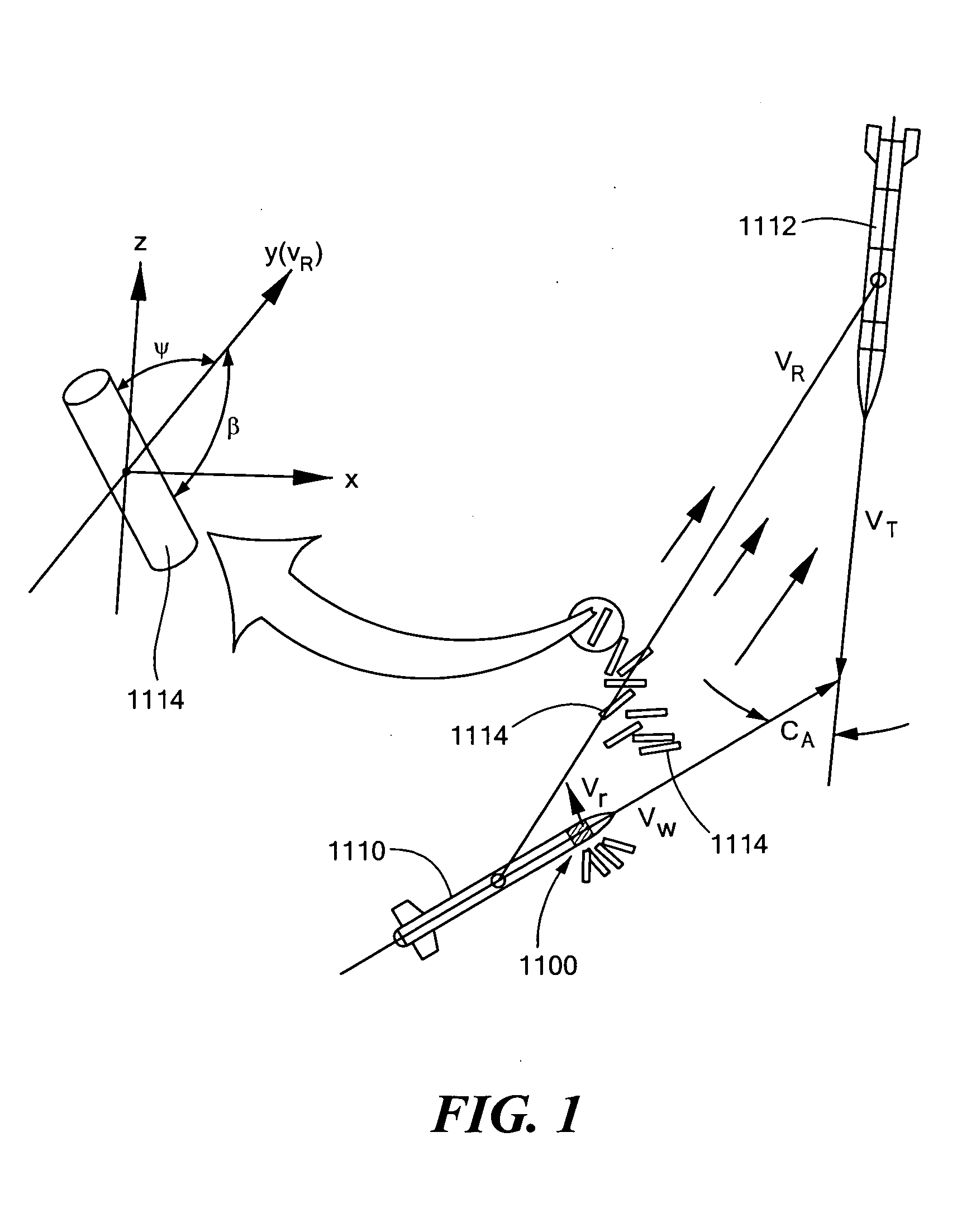

Kinetic energy rod warhead with self-aligning penetrators

InactiveUS20060283348A1Good chanceImprove permeabilityAmmunition projectilesDefence devicesDetonatorArmor-piercing shell

A kinetic energy rod warhead with self-aligning penetrators includes a plurality of rods, an explosive for deploying the rods, and a detonator for detonating the explosive. A stabilizer is attached to all or selected rods for aligning said rods to strike a target at an optimal strike angle.

Owner:RAYTHEON CO

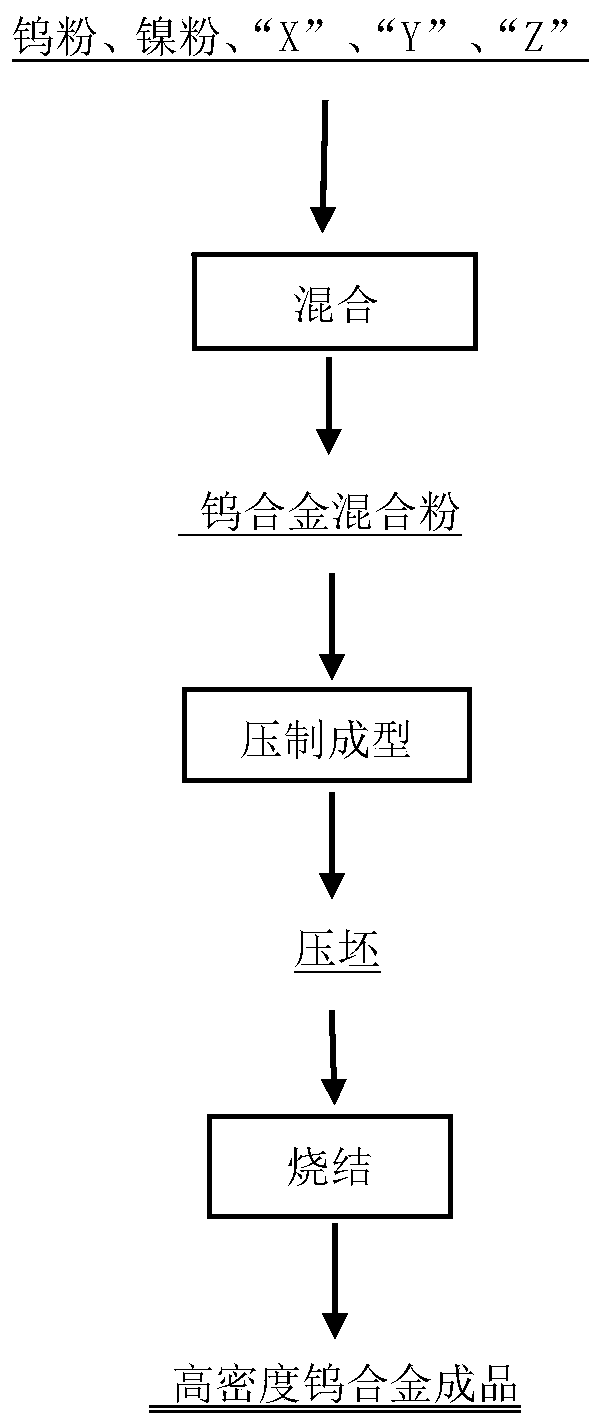

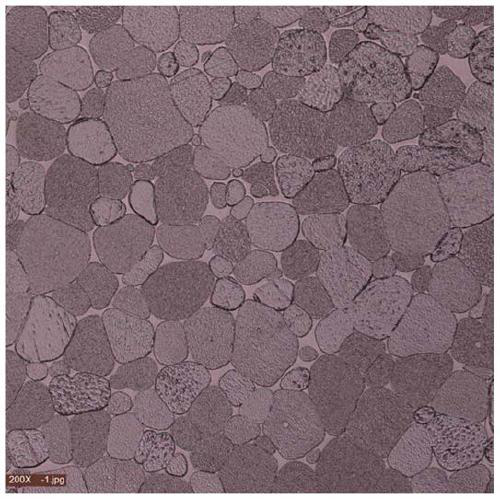

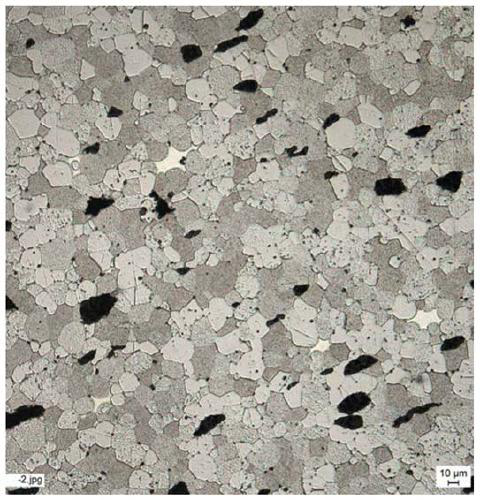

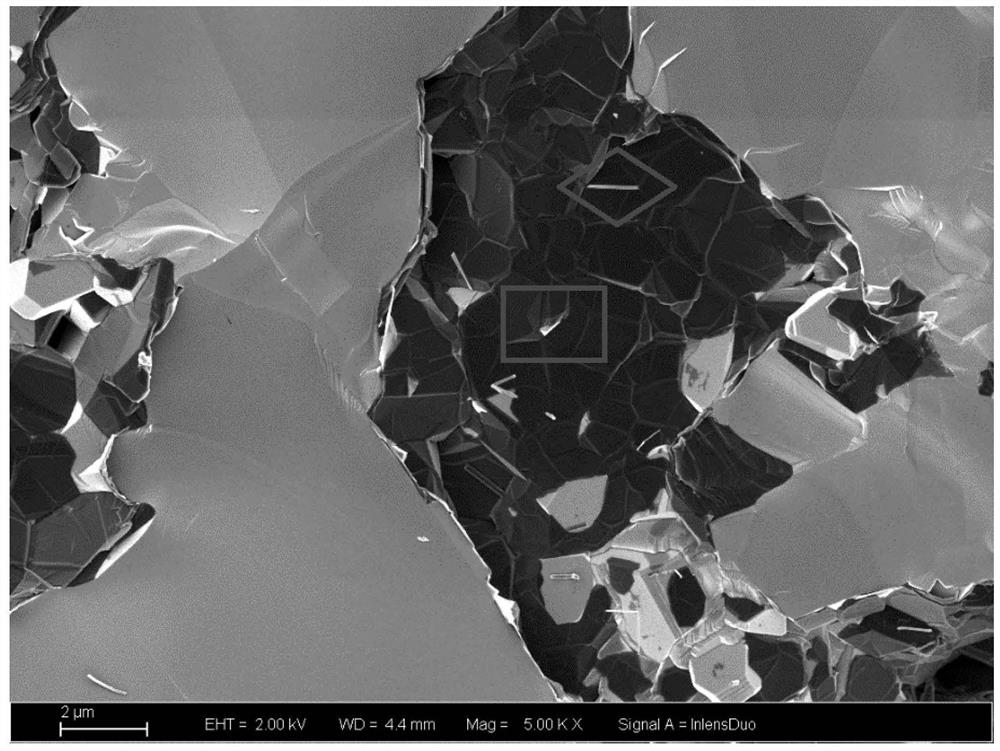

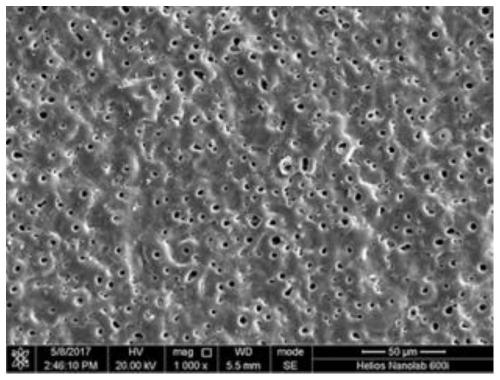

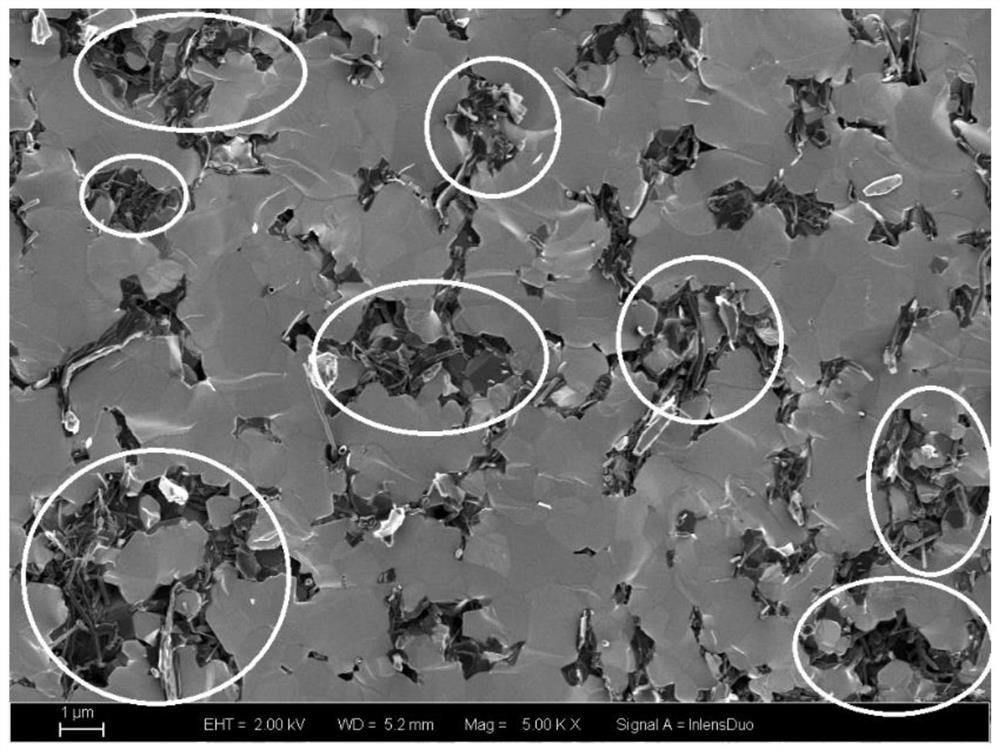

Tungsten alloy and preparation method thereof

ActiveCN111057926ASolve the problem of not being able to have good armor-piercing power at the same timeSolve the problem of a large number of fragments after armor piercingArmor-piercing shellHigh density

The invention belongs to the technical field of powder metallurgy, and relates to a tungsten alloy and a preparation method thereof. The tungsten alloy comprises components in the specific expressionof W100%-tNiaXbYcZd. Due to the reasonable composition proportion and strict control over process parameters of all steps, the tungsten alloy material has the physical and mechanical properties of high density, high hardness and high compressive strength. Used as a armour-piercing bullet core, the good armour piercing power is achieved, meanwhile, due to the facts that the low plasticity is achieved, a brittle phase is distributed in the tissue structure, holes are distributed, and proper porosity is formed, cracks are formed when the bullet core pierces an armour and is impacted by stress waves, so that the bullet core becomes a fragment breaking source, and finally a large number of broken pieces are formed after the armour is pierced. The alloy has the characteristics of being good in armour piercing power and large in number of broken pieces after the armour is pierced, and wider space is provided for design and application of new-generation armour-piercing bullets in China.

Owner:ZIGONG CEMENTED CARBIDE CORP

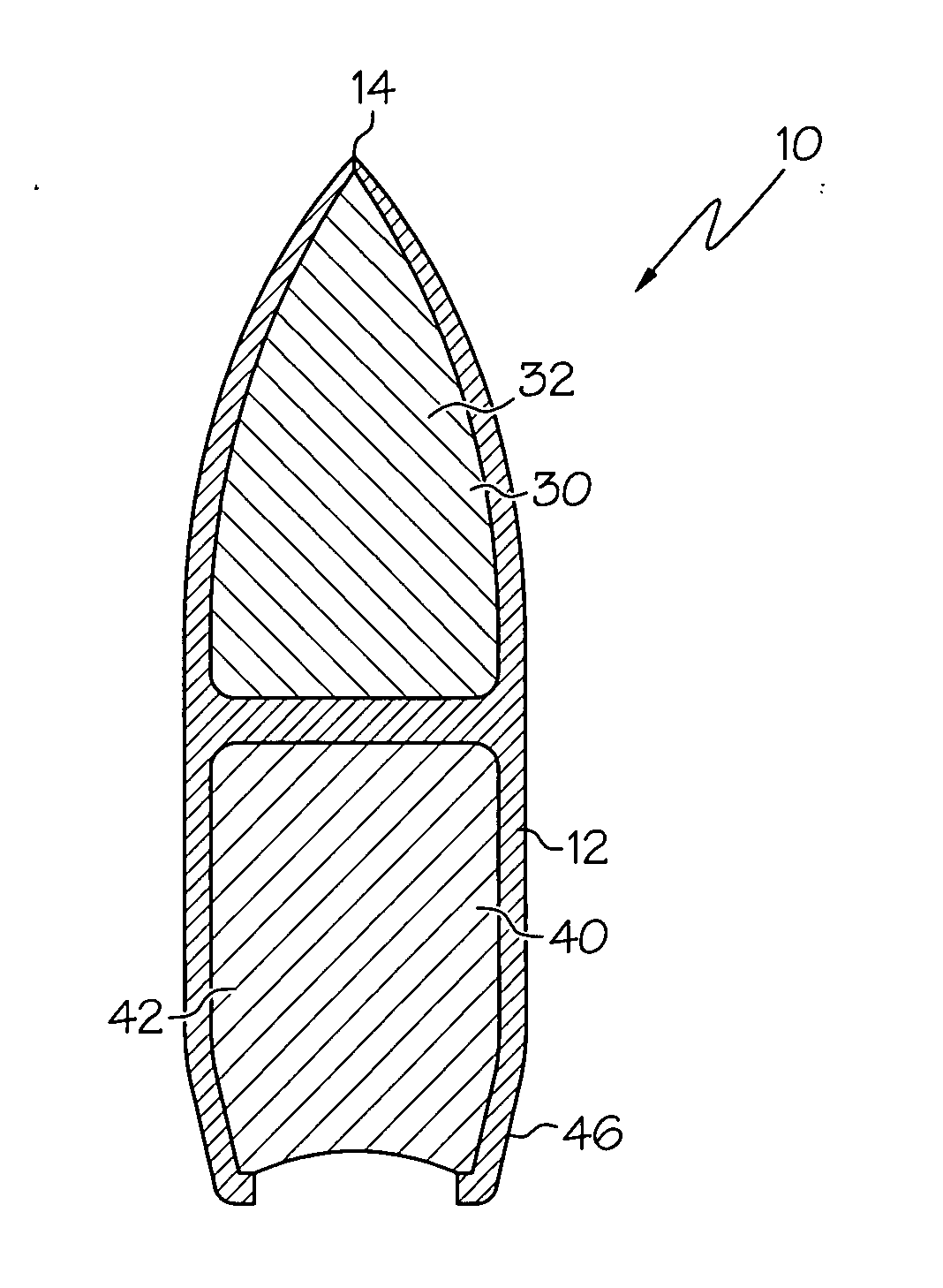

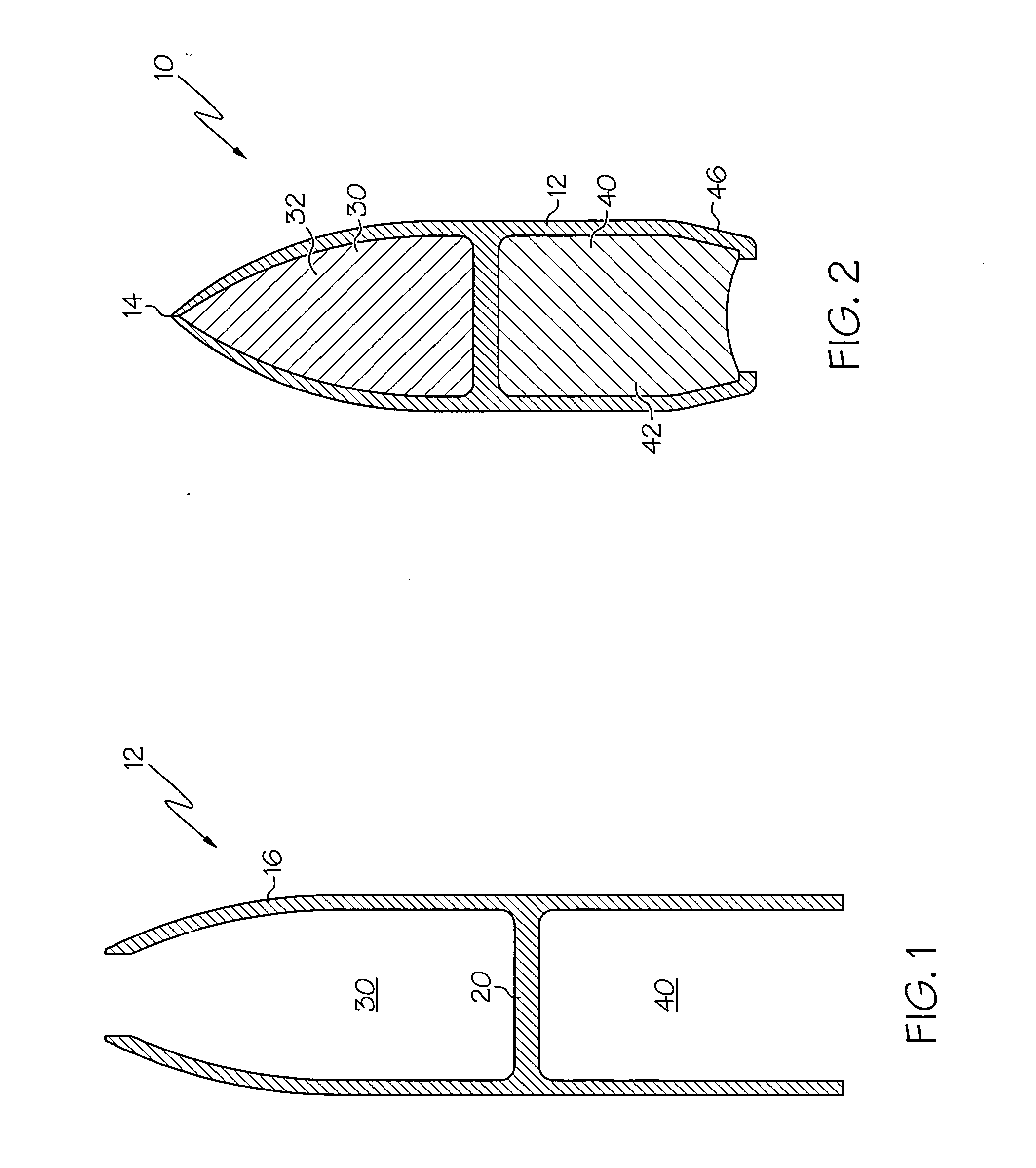

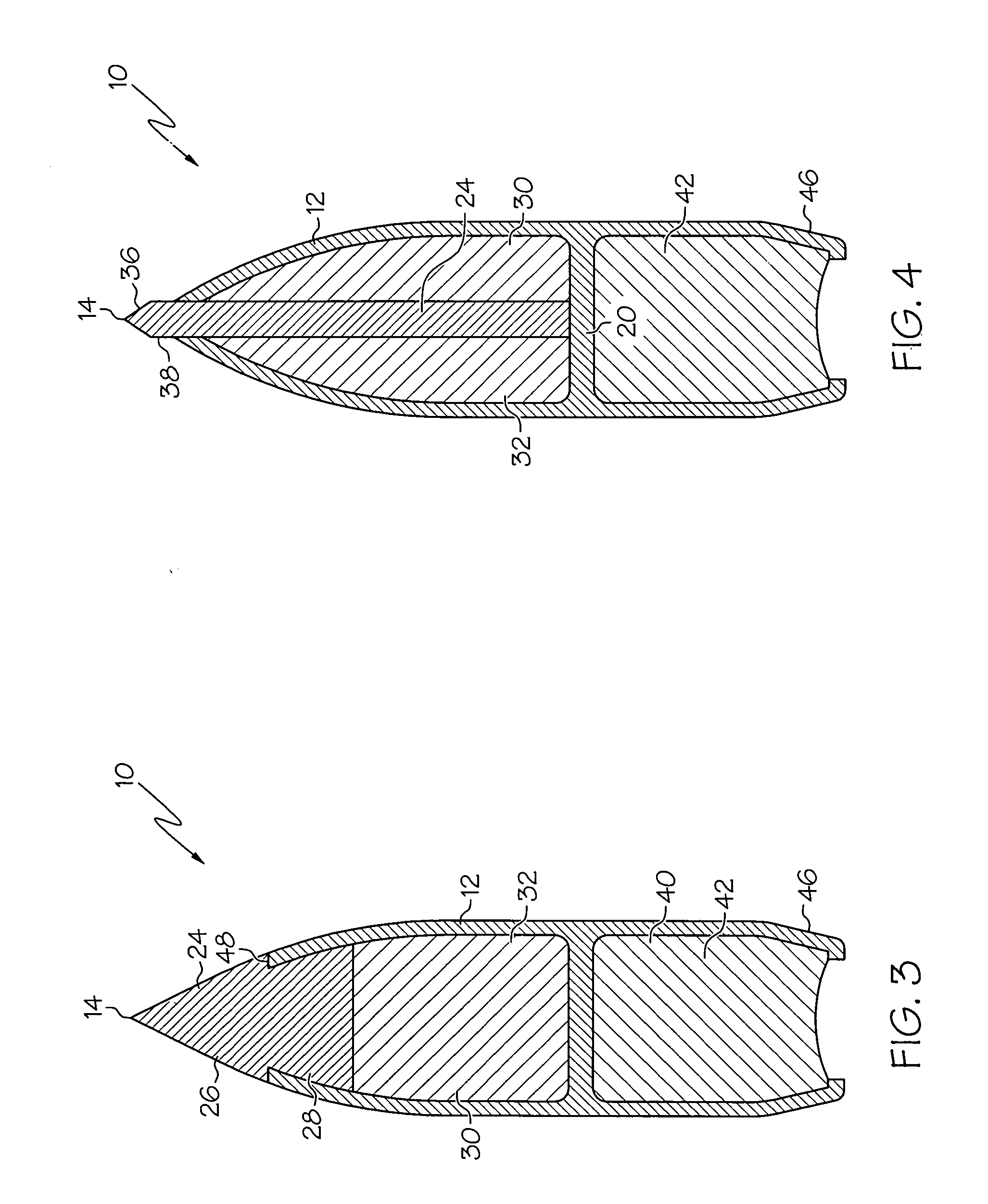

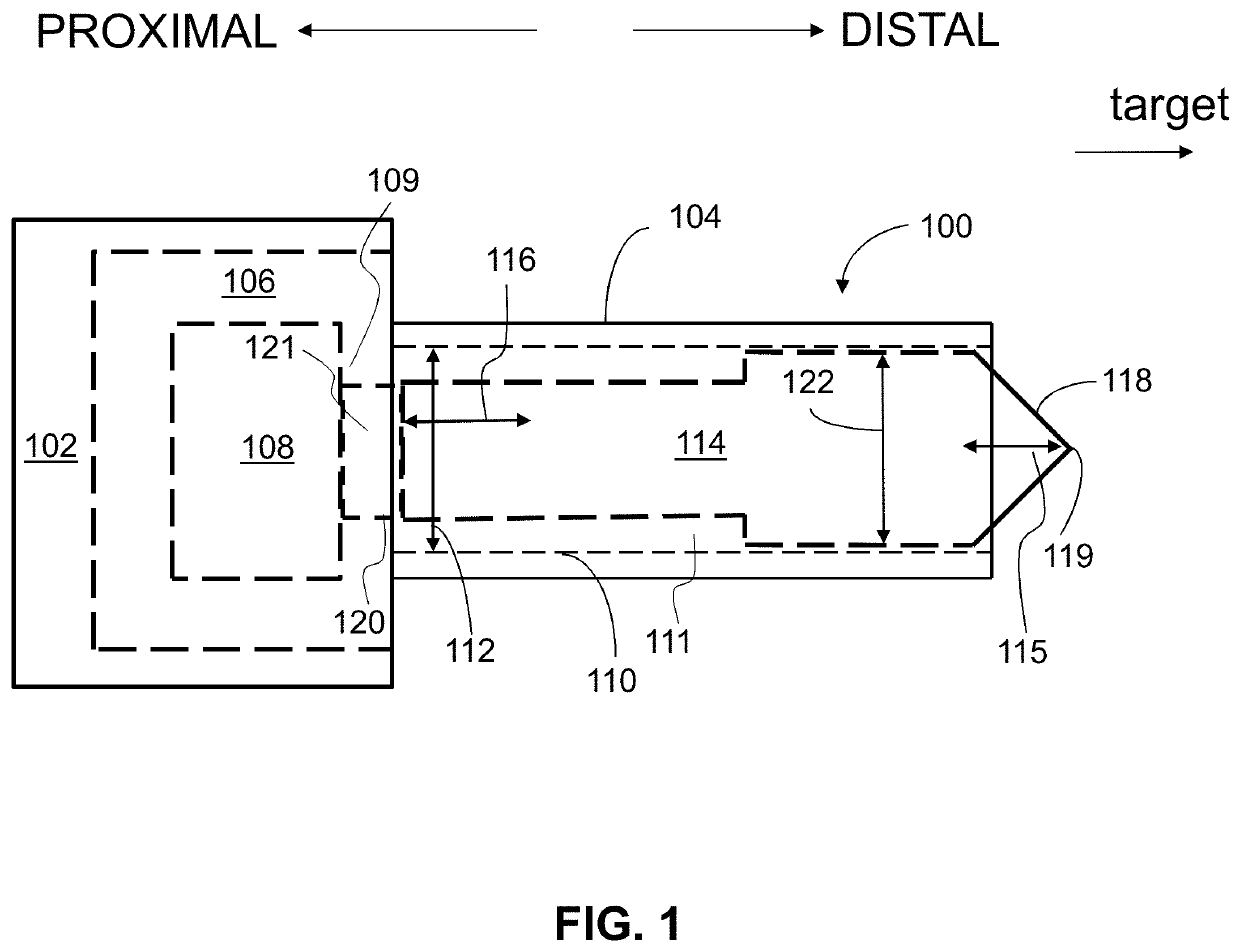

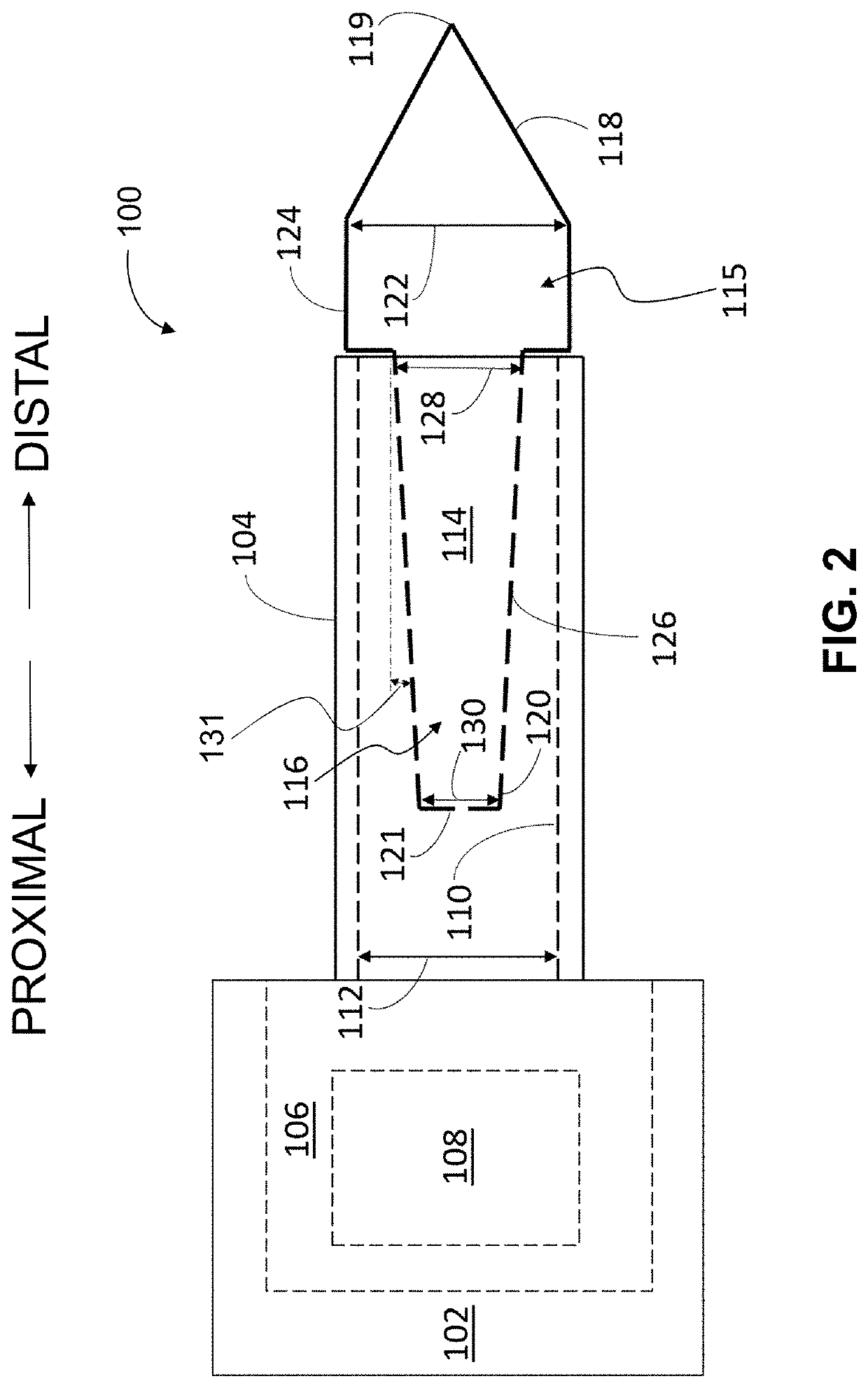

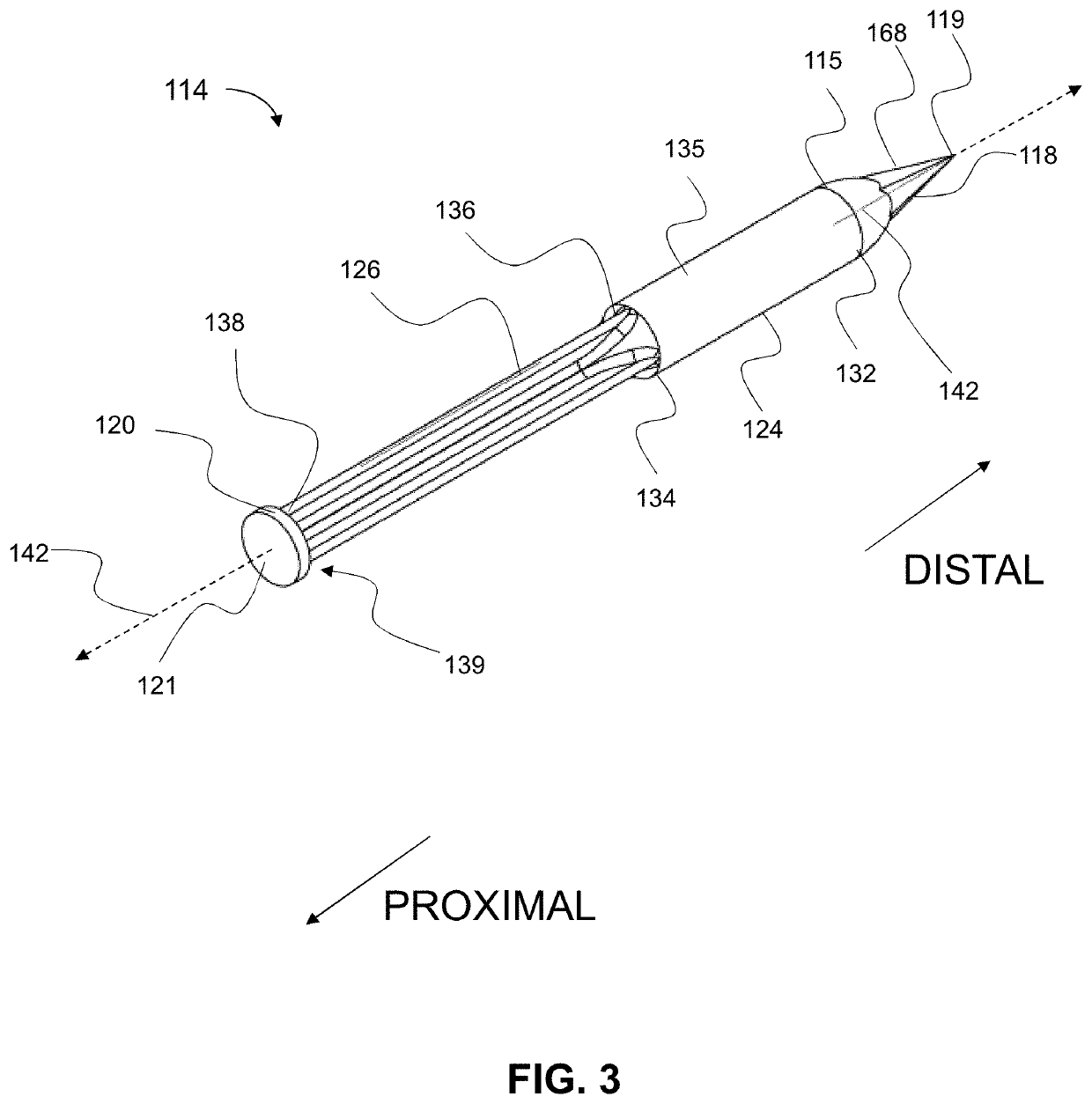

Penetrator Projectile for Explosive Device Neutralization

ActiveUS20200173761A1High precisionMinimal fragmentationAmmunition projectilesBlastingArmor-piercing shellExplosive Agents

Provided herein are penetrator projectiles for use with explosive ordnance disposal disrupters, and related methods of making and using. The penetrator projectile has a tip, neck, shaft and base, wherein the geometry and composition of the different elements are selected to ensure the projectile is ballistically stable after firing to provide improved free-flight characteristics and corresponding explosive ordnance disruption.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE FEDERAL BUREAU OF INVESTIGATION DEPT OF JUSTICE

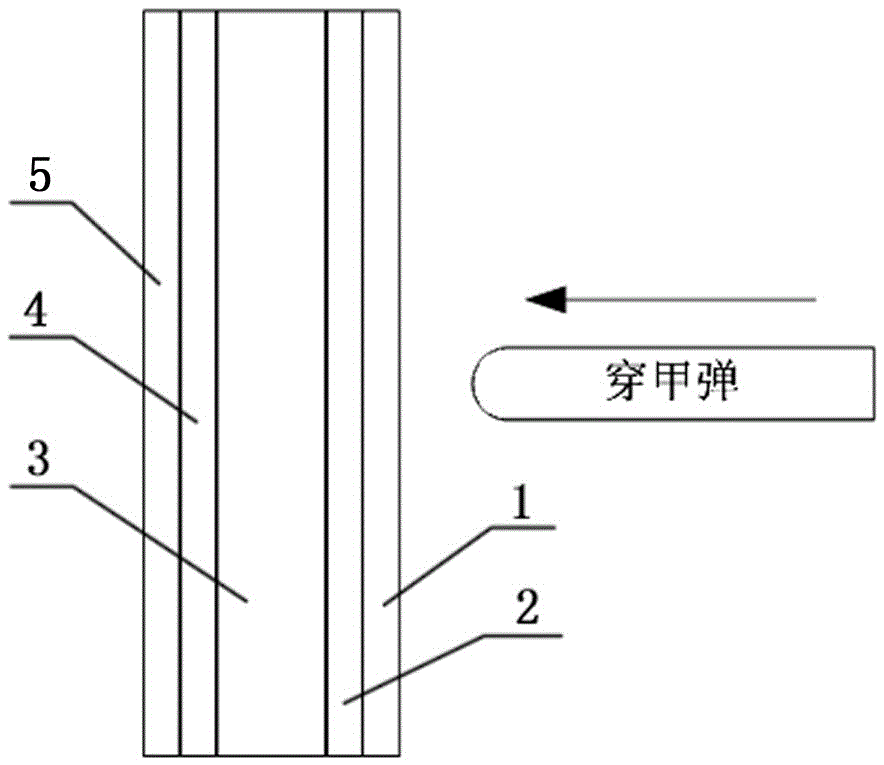

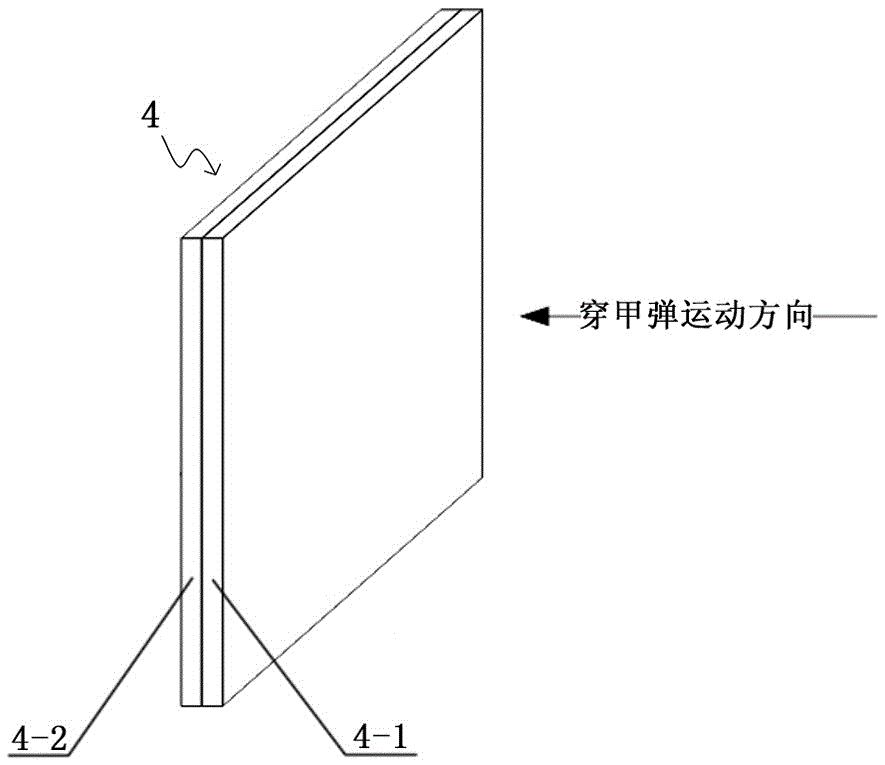

Protection method for resisting penetration of high velocity armour piercer

InactiveCN105890458ADestructive penetrationReduce damage effectDefence devicesArmour platesArmor-piercing shellHigh density

The invention provides a protection method for resisting penetration of a high velocity armour piercer. The protection method comprises the step of arranging an armour protective device formed by sequentially stacking a deformation development layer, a high density high extension layer, an explosive layer, an induced detonation array layer and an explosion protection layer outside a protected object; when the high velocity armour piercer penetrates, the deformation development layer is firstly penetrated and penetration range is expanded; the high density high extension layer forms a conical hopper at a penetration position under the action of the deformation development layer; the induced detonation array layer determines the penetration position by inducing distance from the high density high extension layer, and explosive in the explosive layer is exploded at the penetration position; and energy converged after the explosive is exploded reacts on the armour piercer, so that penetration effect of the armour piercer is destroyed, and damage of the armour piercer on the protected object is reduced or avoided. By adopting the protection method provided by the invention, a high-value object can be effectively protected to resist penetration of the high velocity armour piercer, so that armour protection effect is improved.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

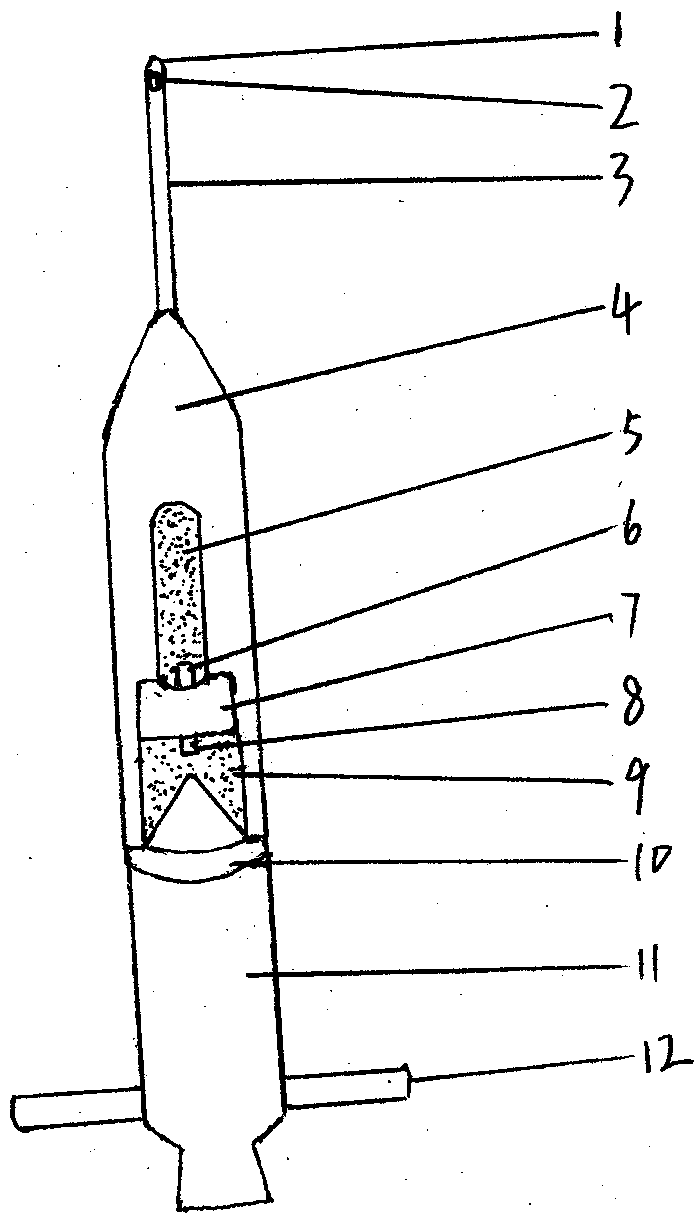

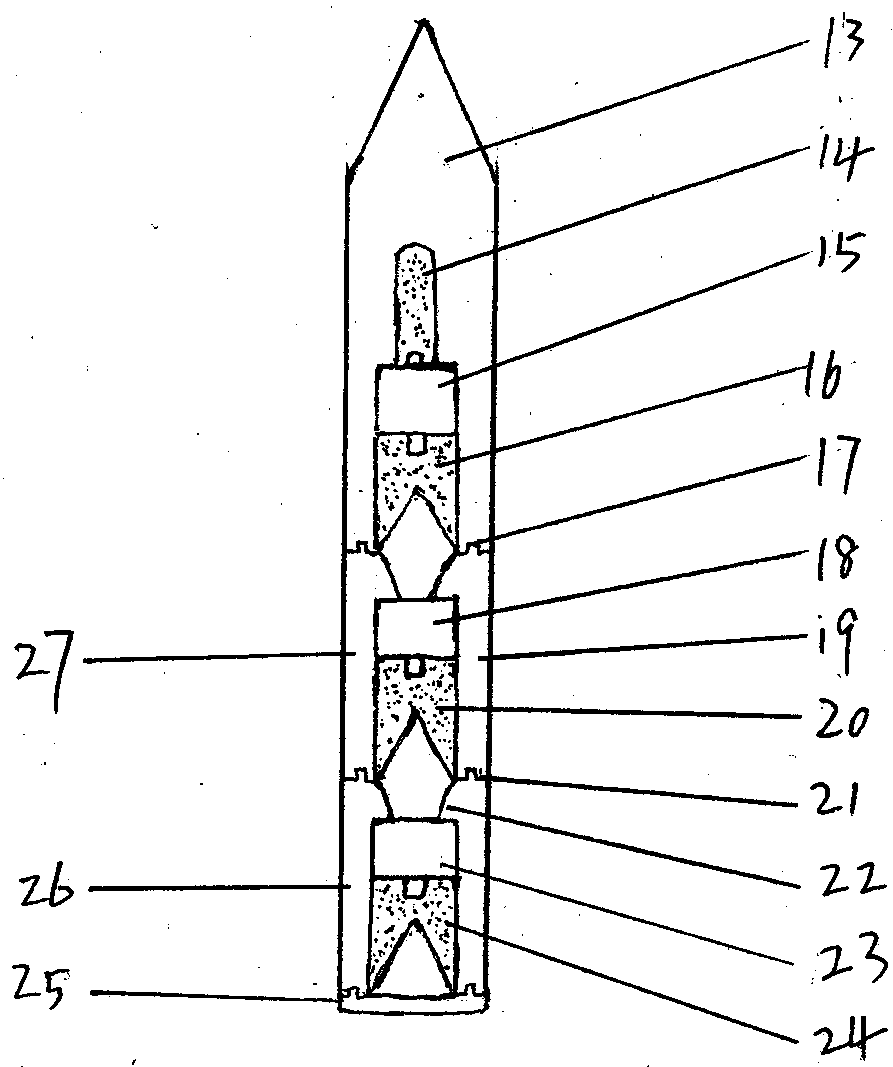

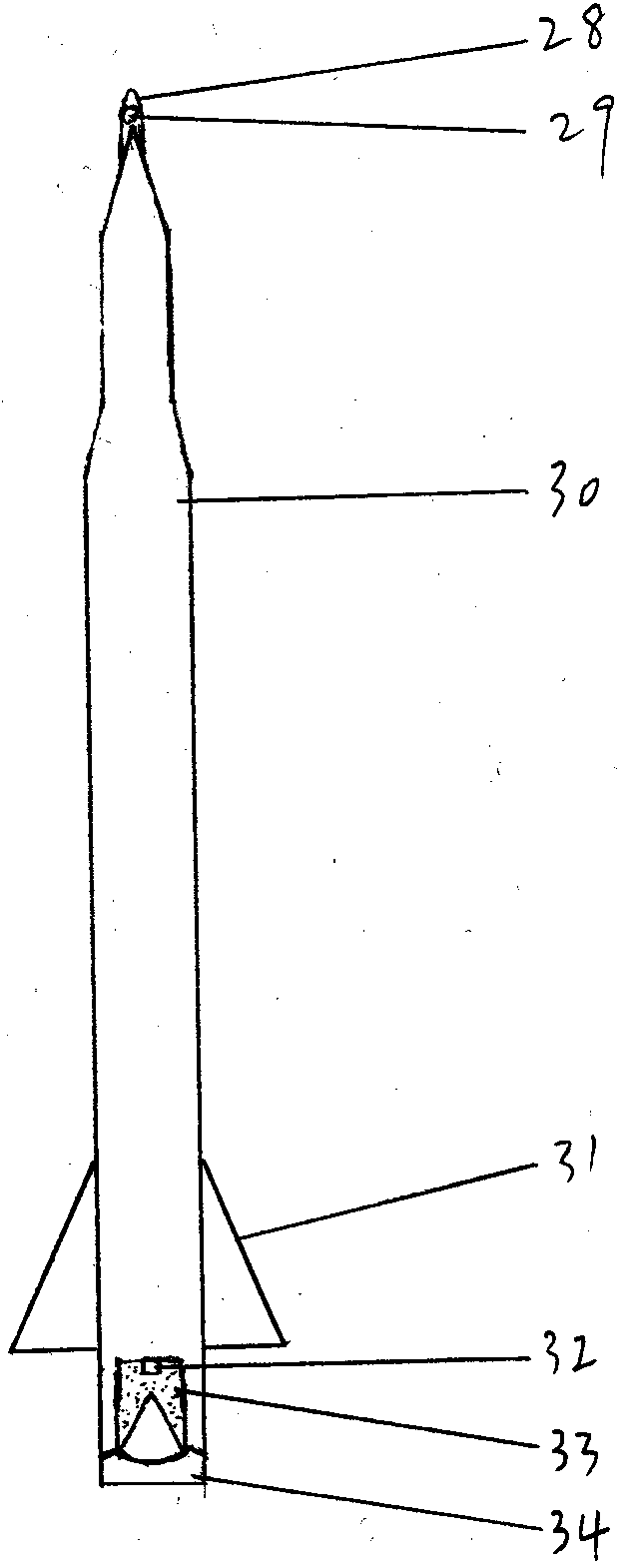

External ballistic trajectory tail section bottom explosion speed-increasing penetration armor-piercing projectile

InactiveCN110906806APenetration effect is goodHigh speedAmmunition projectilesProjectilesArmor-piercing shellExternal ballistics

The invention discloses an external ballistic trajectory tail section bottom explosion speed-increasing penetration armor-piercing projectile. According to the external ballistic trajectory tail section bottom explosion speed-increasing penetration armor-piercing projectile, a plurality of delivery modes such as missile, rocket, artillery, air drop, unmanned aerial vehicle and manual layout delivery modes are adopted. The external ballistic trajectory tail section bottom explosion speed-increasing penetration armor-piercing projectile is characterized in that a shaped charge is additionally arranged at the rear portion of a penetration warhead; a proximity fuse is additionally arranged at the front end of the warhead; and when the warhead is a certain distance away from the surface of a target, the fuse controls the shaped charge at the rear portion of the penetration warhead to be detonated, so that shaped charge jet flow is jetted backwards to generate an instantaneous reaction force, so that the penetration warhead is pushed to greatly increase speed in an extremely short time and within an extremely short distance, and is ejected to and penetrates the target; the warhead can obtain high penetration capacity without a bulky and huge barrel artillery or the long-distance acceleration of a rocket; and series multi-stage shaped charges can also be used, so that the warhead canobtain higher speed.

Owner:长沙深蓝未来智能技术有限公司

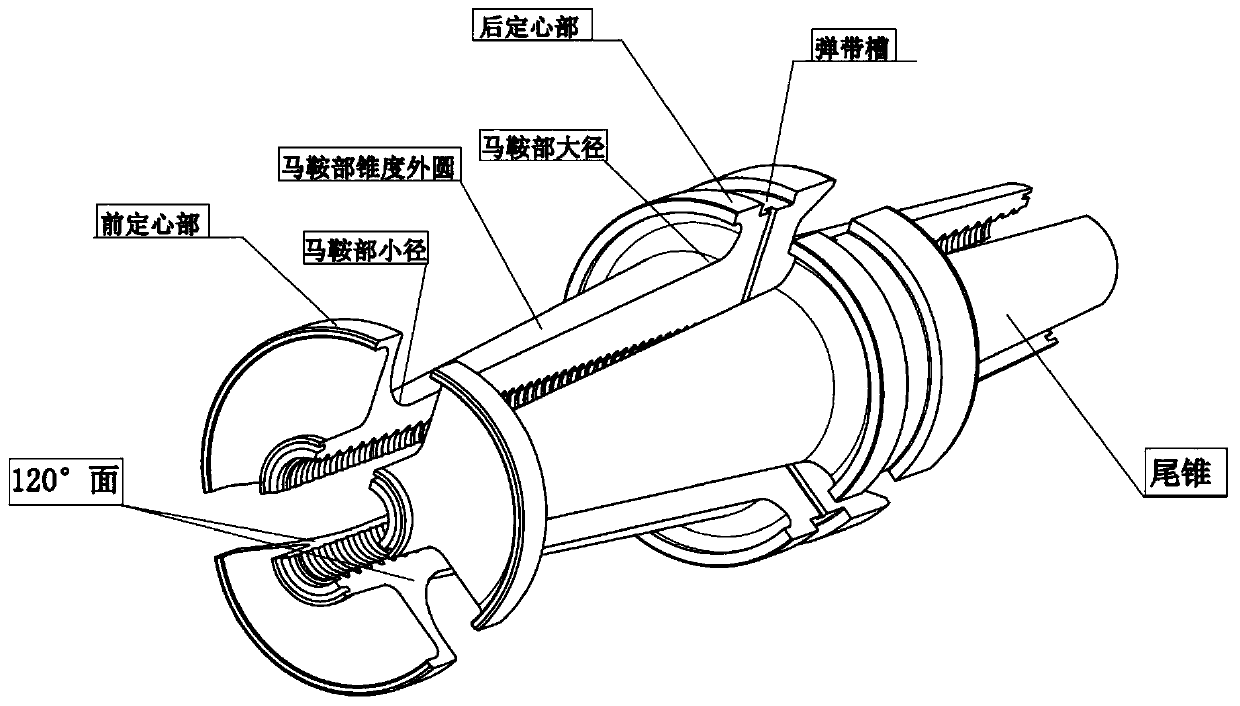

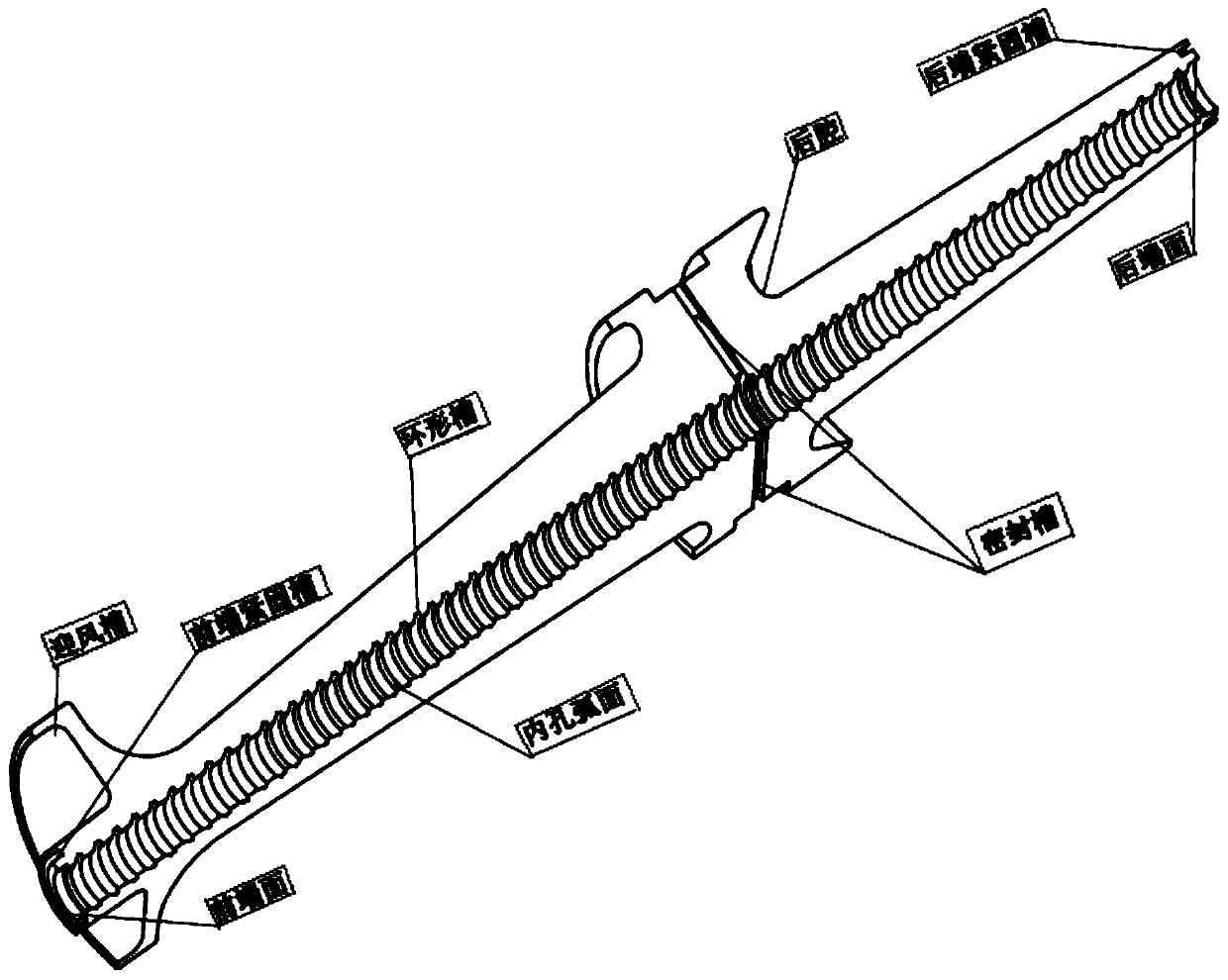

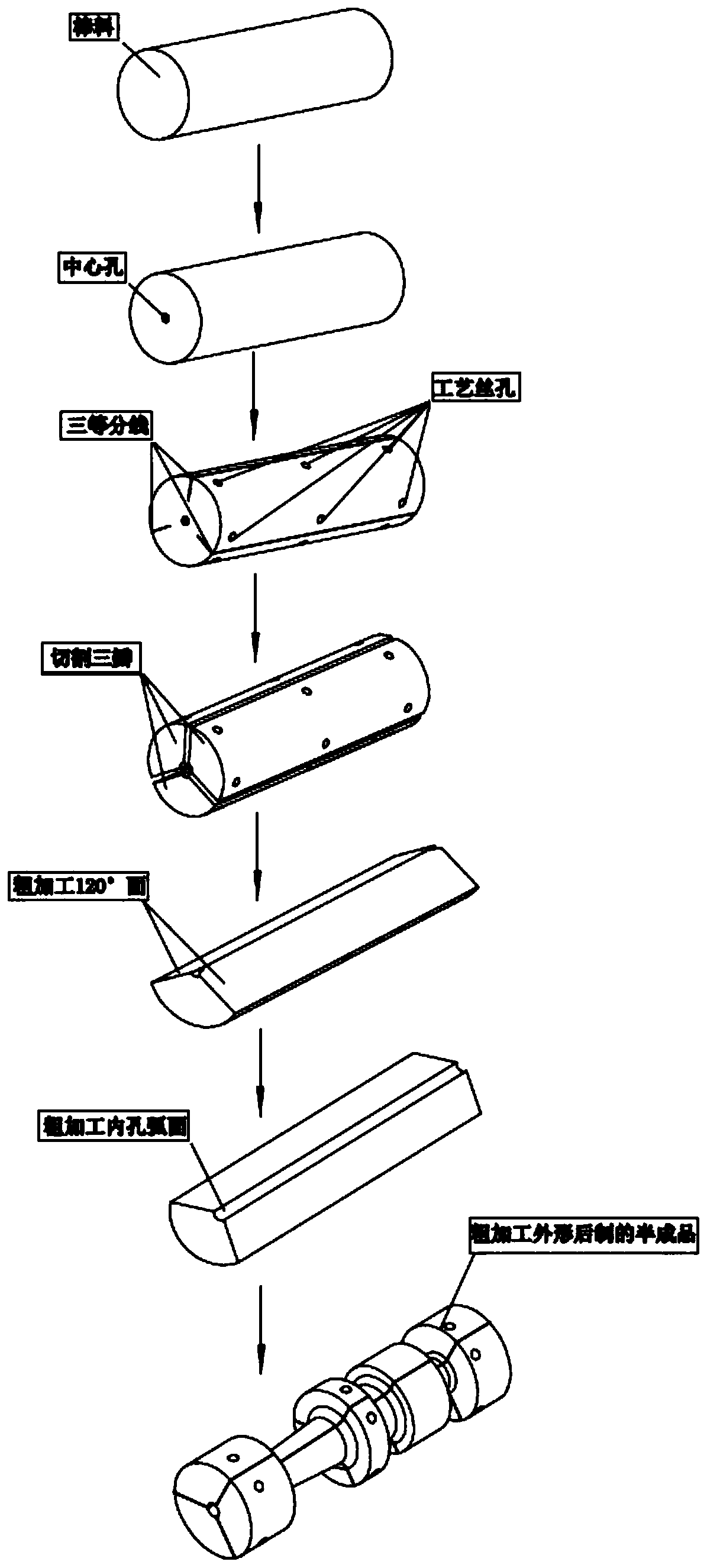

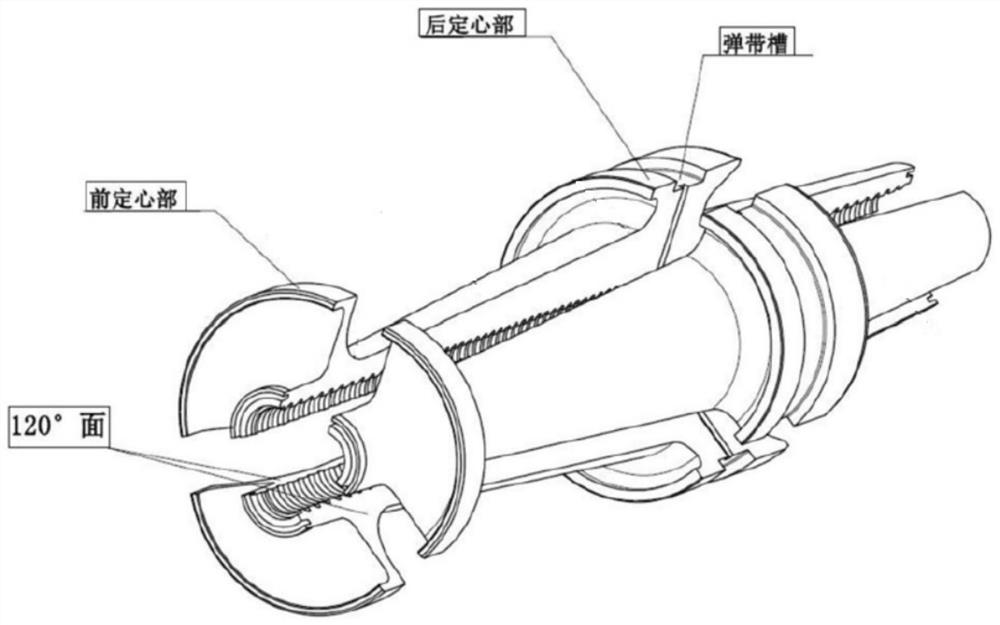

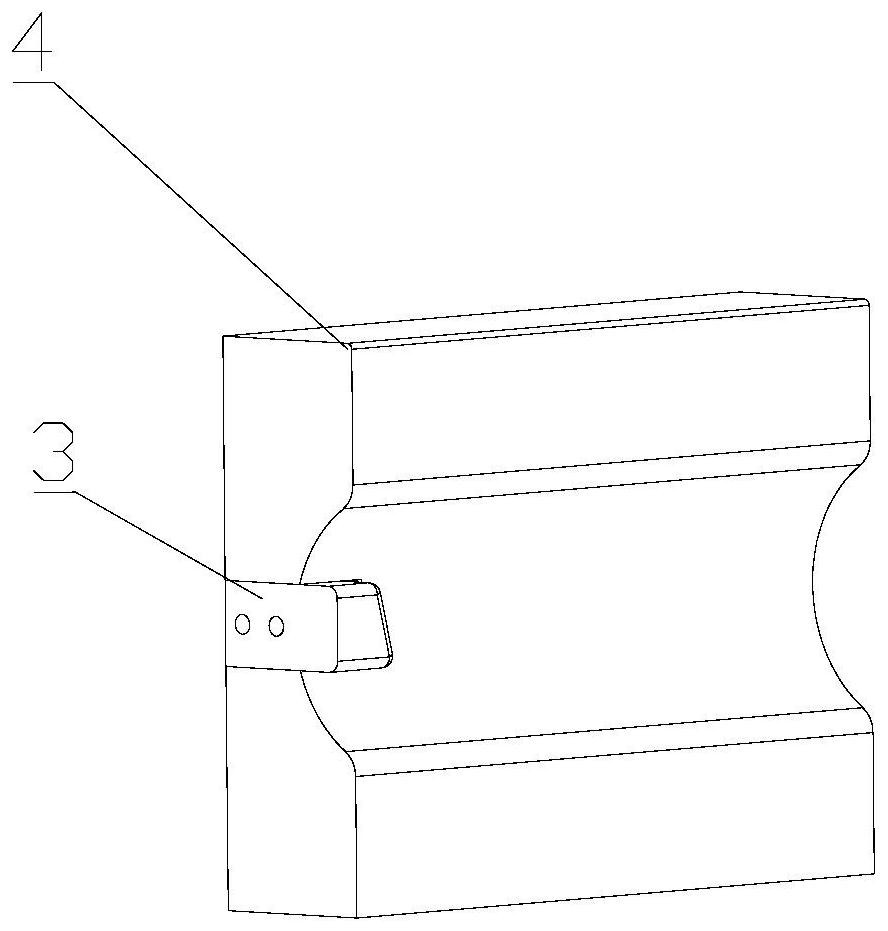

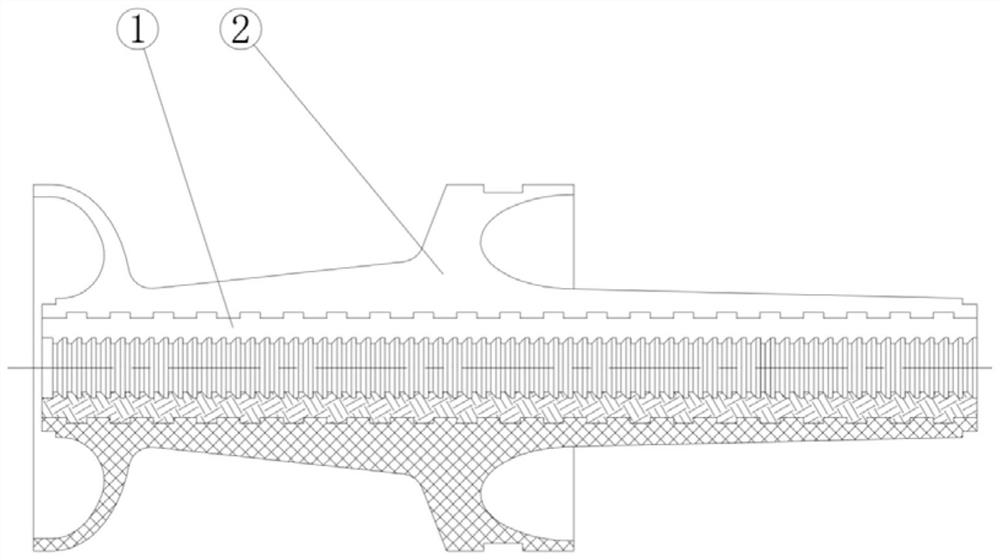

Machining process of sabot of armor-piercing discarding sabot with large length-to-diameter ratio

The invention discloses a machining process of a sabot of an armor-piercing discarding sabot with a large length-to-diameter ratio. The machining process comprises the following steps of (1) manufacturing a blank; (2) carrying out rough turning outer circle and perforating a center hole; (3) dividing trisection petal position lines and drilling and tapping process screw holes; (4) saw-cutting three petals for machining; (5) carrying out rough machining of general milling at 120 degrees; (6) carrying out rough machining of general milling of an inner bore cambered surface; (7) rough turning a contour shape; (8) carrying out ageing treatment; (9) carrying out finish machining of continuous grinding at 120 degrees; (10) carrying out finish machining of general milling of the inner bore cambered surface; (11) carrying out semi-finish turning on the contour shape; (12) carrying out rough milling on an annular groove; (13) carrying out straightening; (14) carrying out finish turning on the annular groove; (15) carrying out finish milling on a sealing groove; (16) carrying out finish turning on the contour shape; (17) carrying out finish machining on an end surface and a fastening annulargroove; (18) carrying out straightening; (19) carrying out detection after burring and finishing unqualified products; and (20) marking and packaging detected qualified products. In this way, the sabot with the large length-to-diameter ratio being in a range of 22-27 mm can be manufactured, so that the sabot is high in quality and wide to apply.

Owner:SIPING BOLT TECHN EQUIP

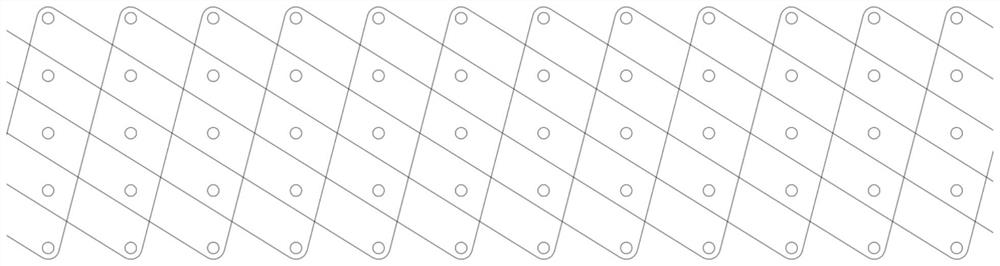

Bulletproof composite armor and manufacturing method thereof

ActiveCN111272016AFast sinteringImprove qualityProtective equipmentSynthetic resin layered productsFiberArmor-piercing shell

The invention discloses a bulletproof composite armor and a manufacturing method thereof, and belongs to the technical field of ceramic and metal based composite material preparation. The manufacturing method for the bulletproof composite armor comprises the following steps: step 1 of uniformly mixing B4C powder with nano carbon fibers to obtain a mixture, putting the mixture into a regularly hexagonal mould, and quickly sintering the mixture into regularly hexagonal ceramic sheets through plasma discharge sintering; step 2 of splicing the regularly hexagonal ceramic sheets into a ceramic basematerial, filling splicing seams with micro-level copper foils, and performing vacuum hot-pressing sintering to obtain a ceramic deck; and step 3 of performing hot-isostatic pressing compounding on the ceramic deck and a bulletproof back board to obtain the bulletproof composite armor. The high-toughness composite ceramic bonded by the copper based metal material is compounded with the bulletproof back board to manufacture the bulletproof composite armor, so that multi-time impact resistance ability of armor-piercing bullets and armor-piercing incendiary ammunitions of the composite armor isgreatly improved.

Owner:SUZHOU FIRST ELEMENT NANO TECH

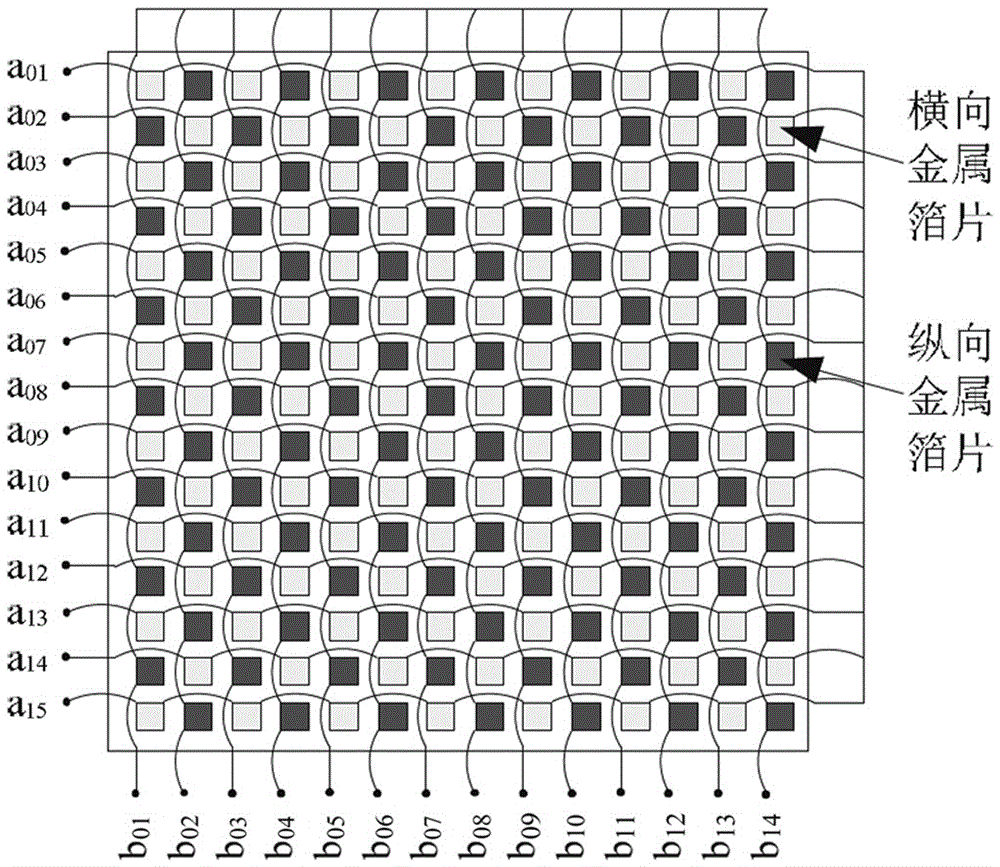

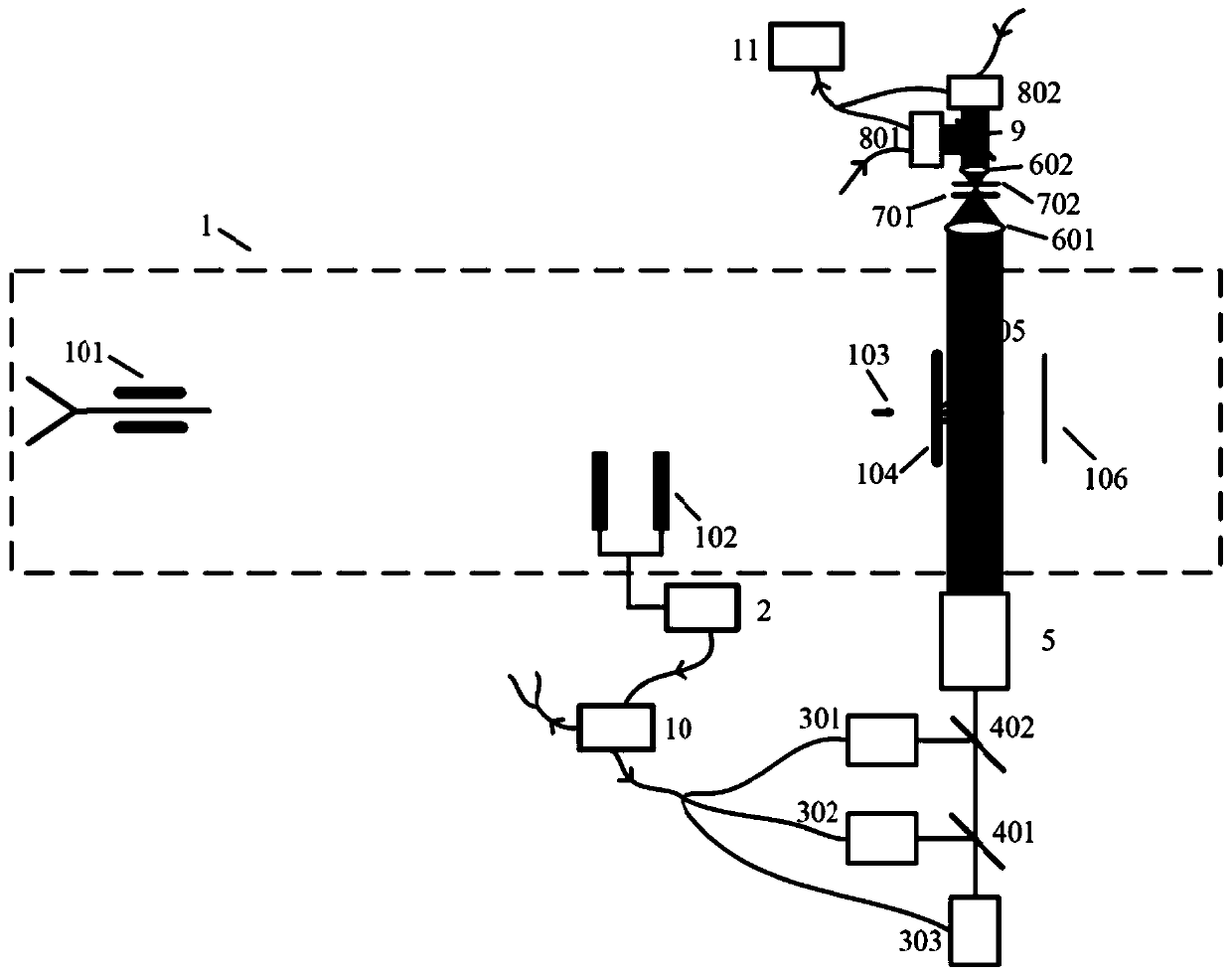

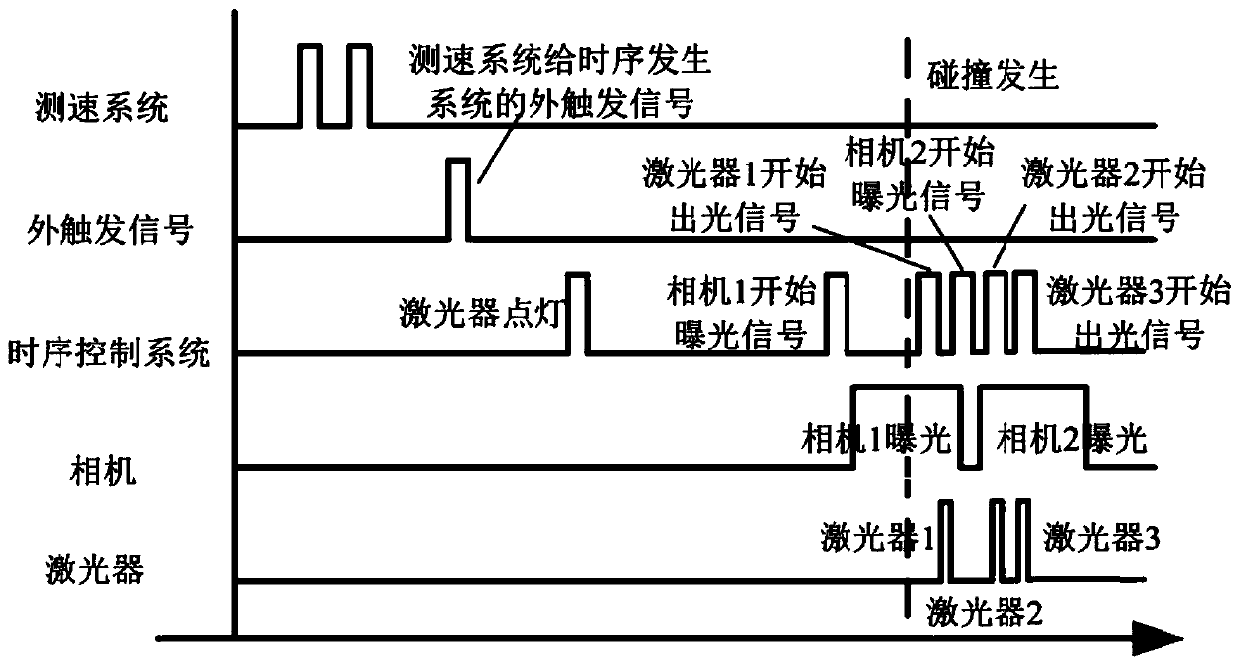

Multi-parameter measurement system and method for fragile type armor-piercing projectile dynamic target experiment fragment

The invention discloses a multi-parameter measurement system and method for a fragile type armor-piercing projectile dynamic target experiment fragment, and belongs to the technical field of fragile type armor-piercing projectile dynamic target experiment fragment parameter measurement. The measurement system includes a ballistic gun for firing a fragile type armor-piercing projectile, an armoredsteel plate, an experimental target, a speed measurement module which measures the speed of the fragile type armor-piercing projectile, a pulsed laser module which emits laser towards the fragment, aCCD camera group for recording holograms of the fragment at different moments, a timing control module and a calculation module. The fragile type armor-piercing projectile hits the armored steel plateto form the fragment. The timing control module is used for receiving a voltage signal of the speed measurement module and sending out a pulsed laser light-emitting voltage signal and a CCD camera exposure-starting voltage signal according to preset timing. The calculation module is used for collecting the holograms of the fragment recorded by CCD cameras and reconstructing software by using theholograms to obtain the size, shape, three-dimensional speed and acceleration parameters of the fragment. The size, shape, three-dimensional speed and acceleration parameter information of the fragment can be obtained.

Owner:ZHEJIANG UNIV

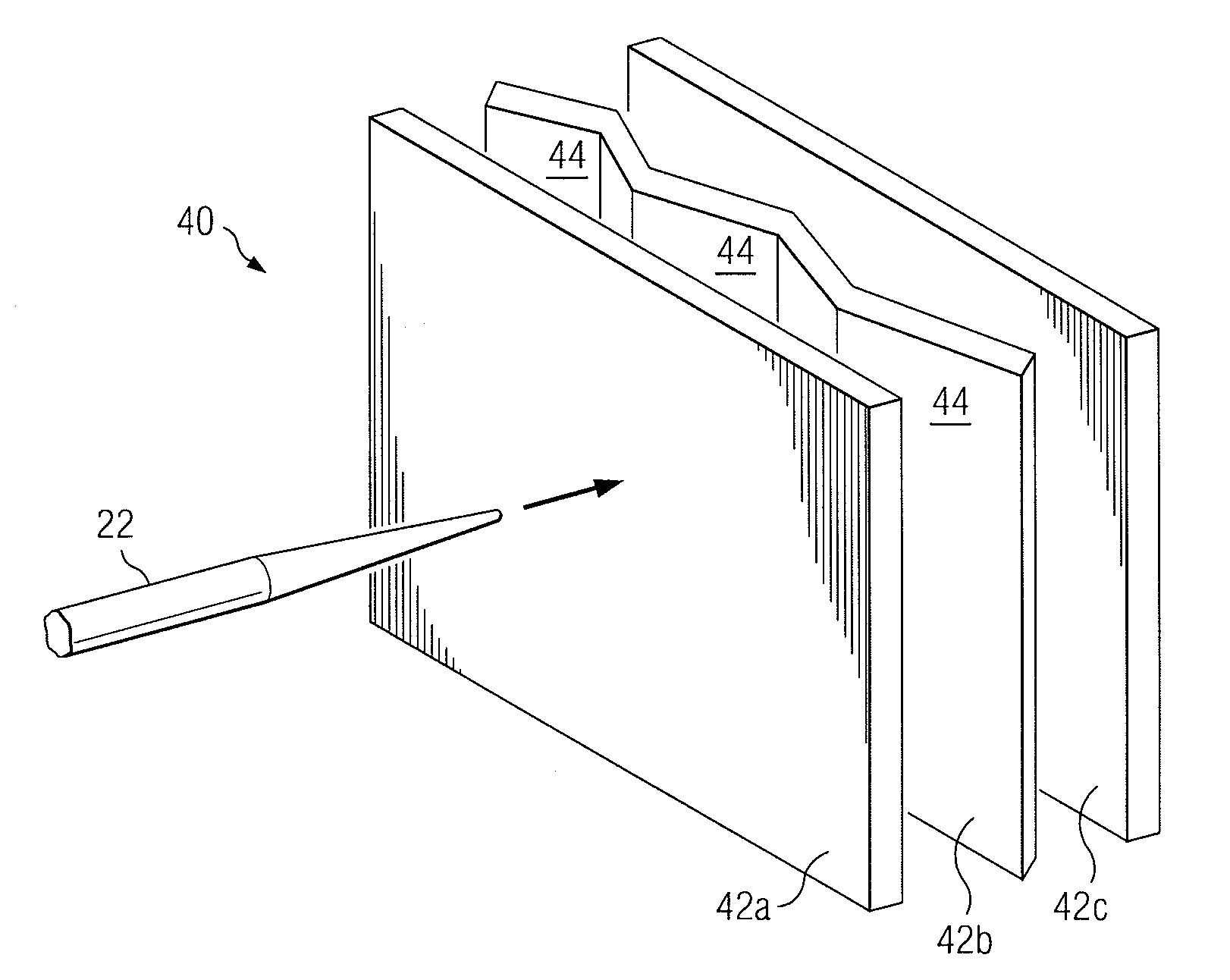

Shaped charge resistant protective shield

ActiveUS20110308380A1Decrease energyLight weightDoor/window protective devicesDomestic articlesEngineeringHardness

In one embodiment, a protective armor system includes first and second armor layers separated by a gap. The second armor layer has a hardness that is less the first armor layer. The protective shield is configured to disperse energy of a shaped charge, such as the energy within a penetrator generated by an explosively formed penetrator (EFP).

Owner:RAYTHEON CO

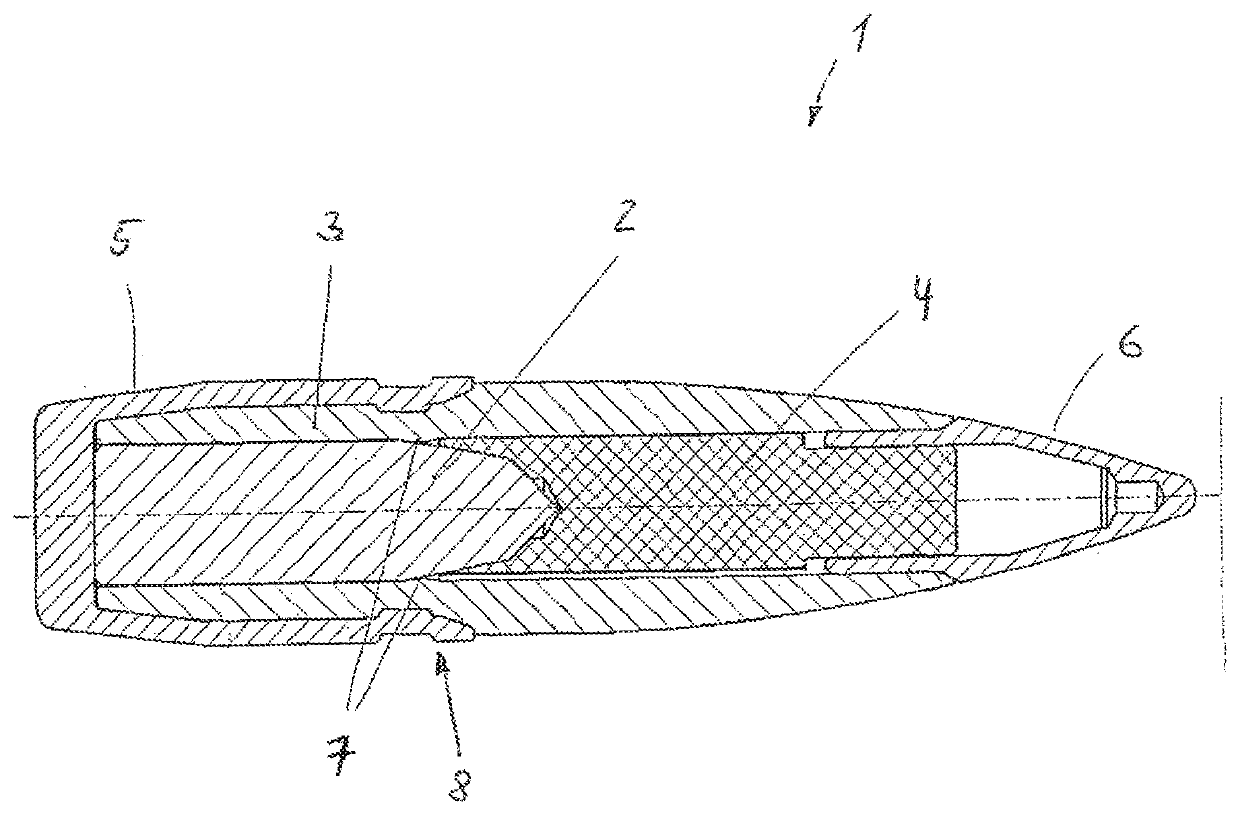

Projectile, in particular in the medium caliber range

ActiveUS20200166317A1Improve hit accuracyReduce effortAmmunition projectilesProjectilesArmor-piercing shellClassical mechanics

A projectile having a projectile body for holding a penetrator, a projectile rear, and a projectile ogive. The projectile body has a narrowed point, on which the penetrator can be supported. The narrowed point results in reliable breaking open of the projectile body when the projectile hits a target.

Owner:RHEINMETALL WAFFE MUNITION GMBH

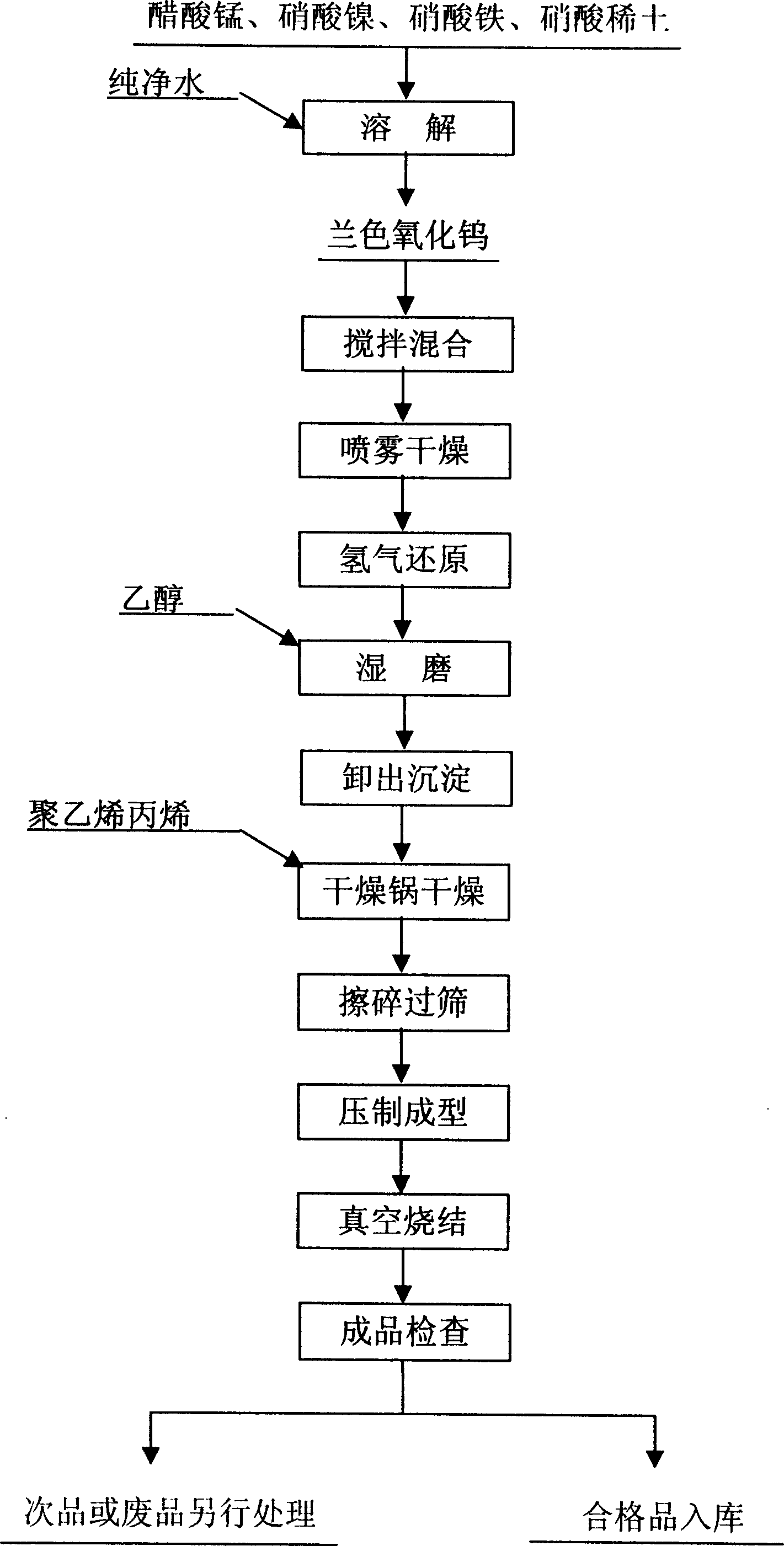

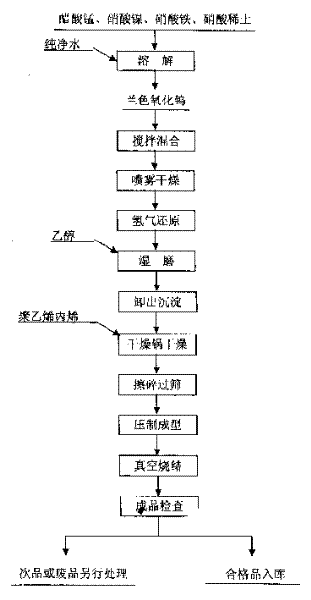

Tungsten heavy alloy for armour-piercing projectile core and preparing method thereof

InactiveCN1455013ASolve densityAddress organizational structureAmmunition projectilesProjectilesMANGANESE ACETATENitrate

Owner:戴汉臣

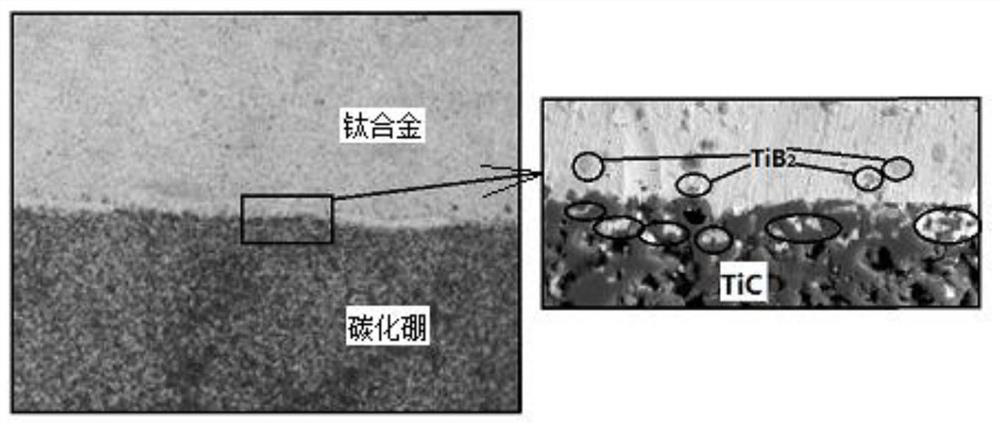

Boron carbide ceramic and preparation method and application thereof

ActiveCN112759408AEasy reunionOvercome the problem of uneven distributionArmour platesArmor-piercing shellCarbon nanotube

The invention discloses boron carbide ceramic and a preparation method and application thereof, and belongs to the technical field of weaponry. The preparation method of the boron carbide ceramic comprises the following steps: fully mixing boron carbide powder and carbon nanotubes in proportion, compacting and forming, then carrying out flash sintering-plasma sintering, and in the sintering process, generating nano-diamonds in situ from at least part of the carbon nanotubes, so as to obtain the boron carbide ceramic in which the carbon nanotubes and the nano-diamonds are uniformly distributed. The boron carbide ceramic prepared by the invention has the characteristics of high toughness, high hardness and high strength, can be used for bulletproof decks, and can resist multiple strikes of armor-piercing bullets and armor-piercing incendiary bombs.

Owner:SUZHOU FIRST ELEMENT NANO TECH

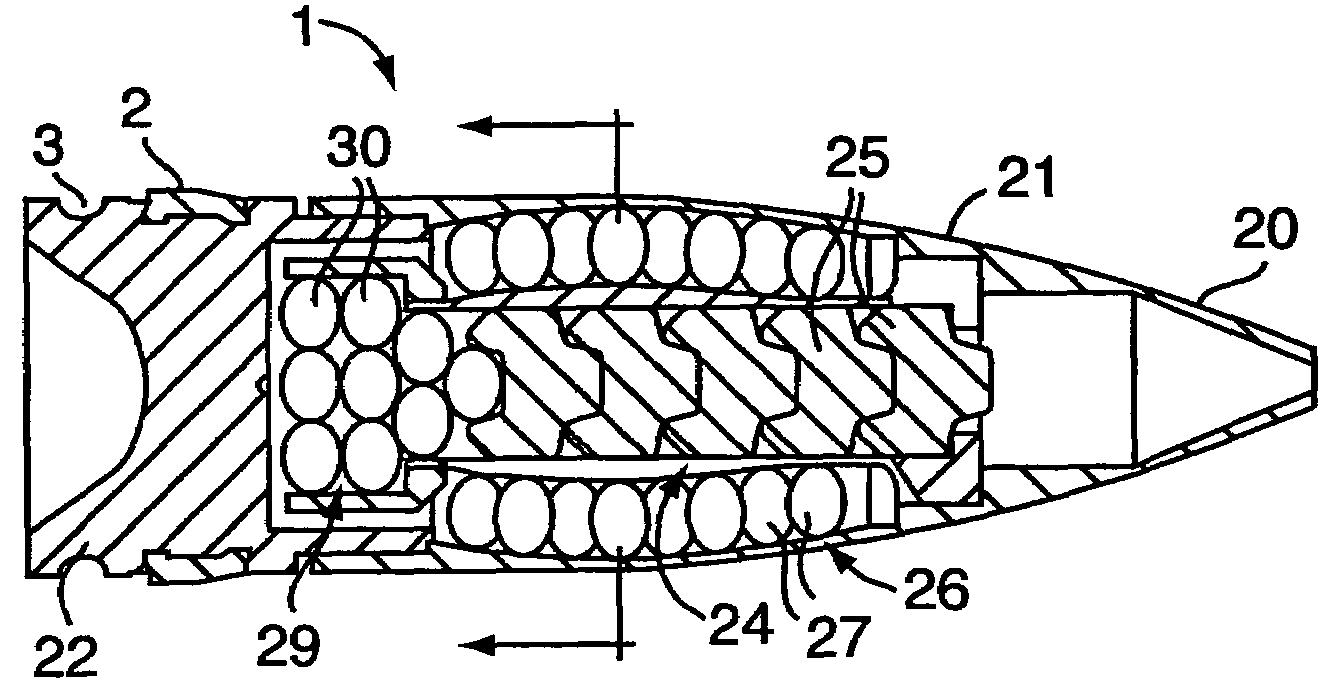

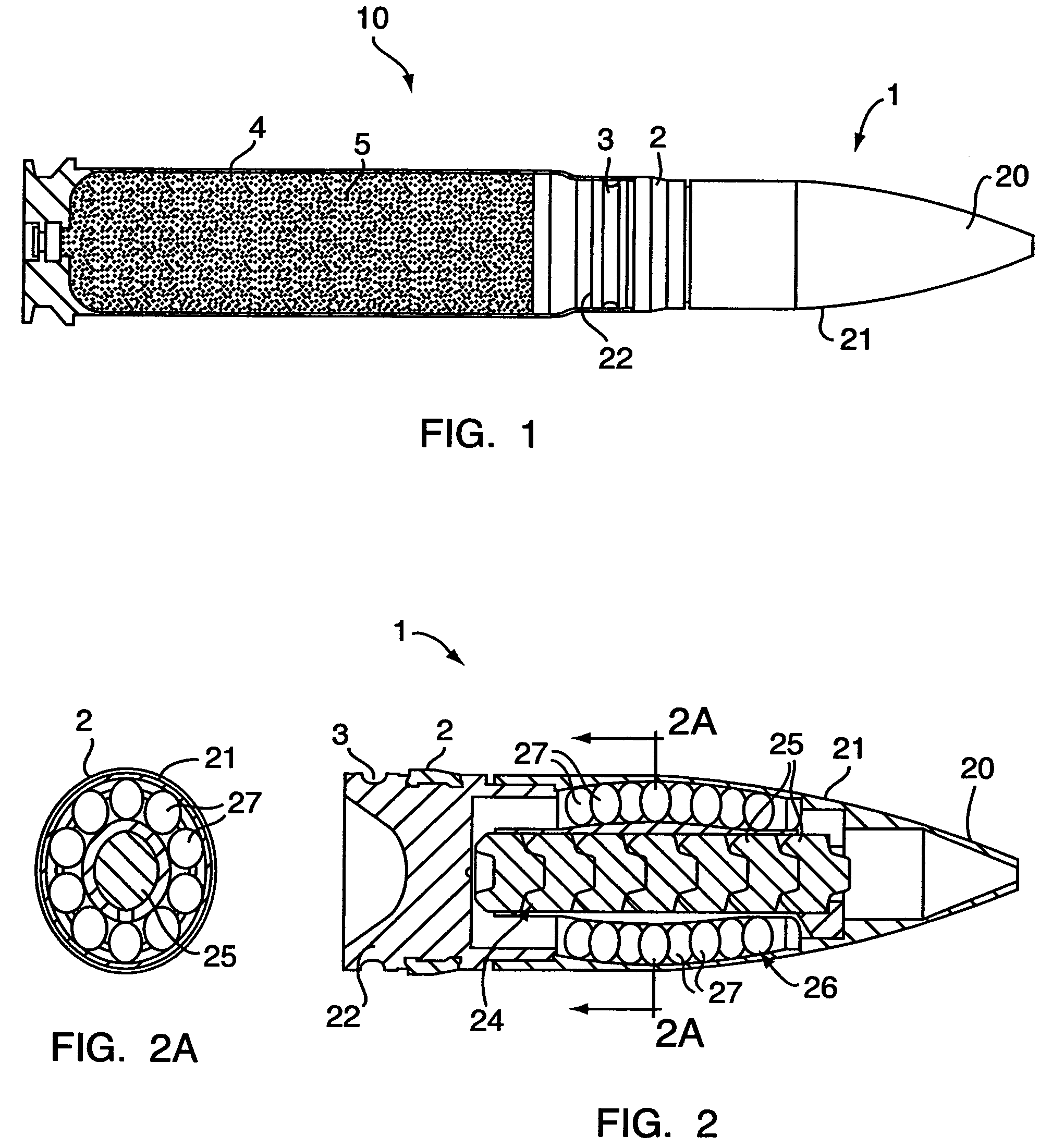

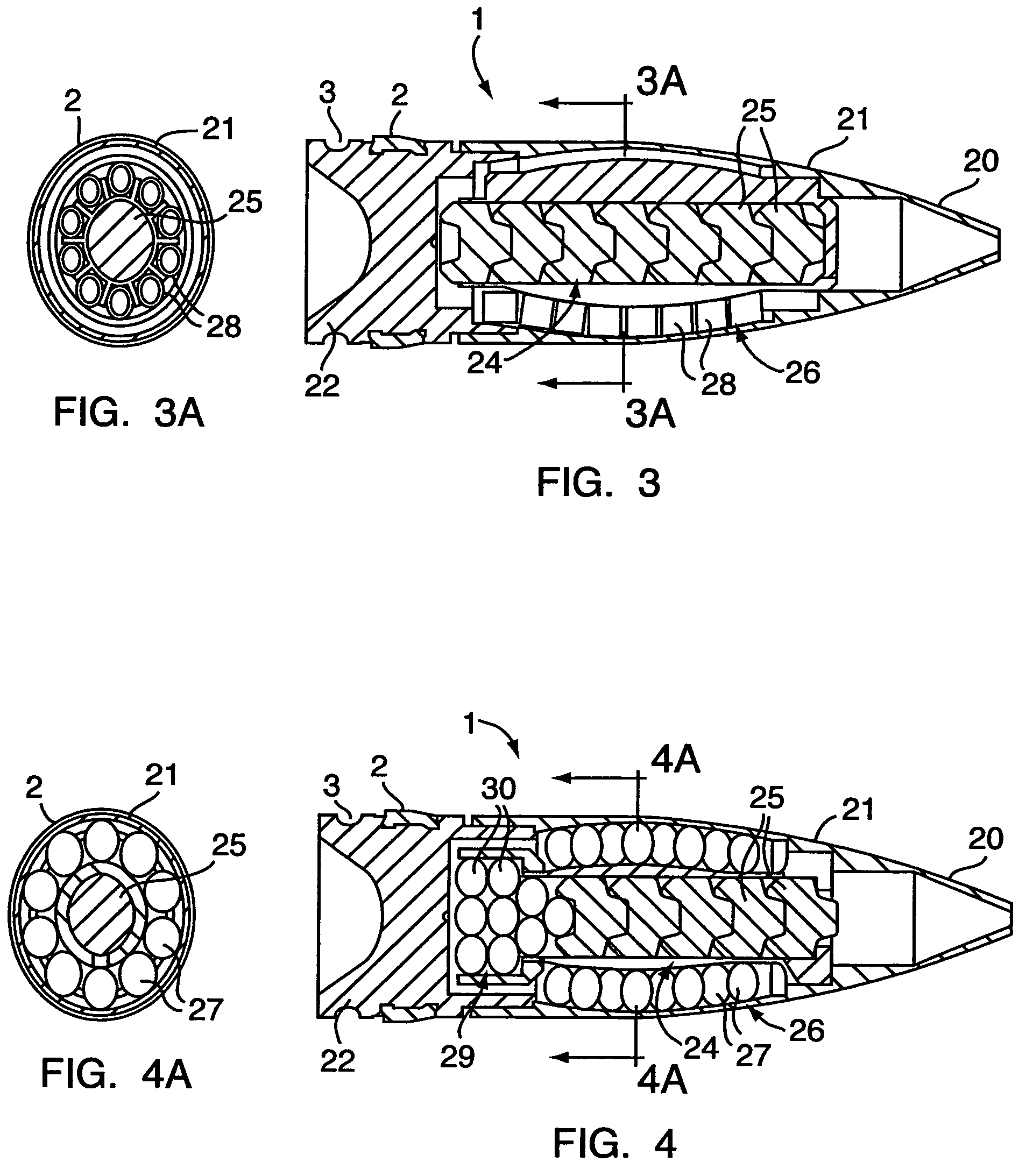

Universal KE projectile, in particular for medium caliber munitions

It is proposed to combine the cascade effect of frangible pellets with sub-projectiles made of ductile heavy metal, that is, to produce a munition in which the advantages of for example frangible pellets of a central penetrator are combined with the advantages of the ductile heavy metal in an external penetrator\whereby an improved performance on various targets is achieved along with deeper impact speeds.

Owner:RWM SCHWEIZ

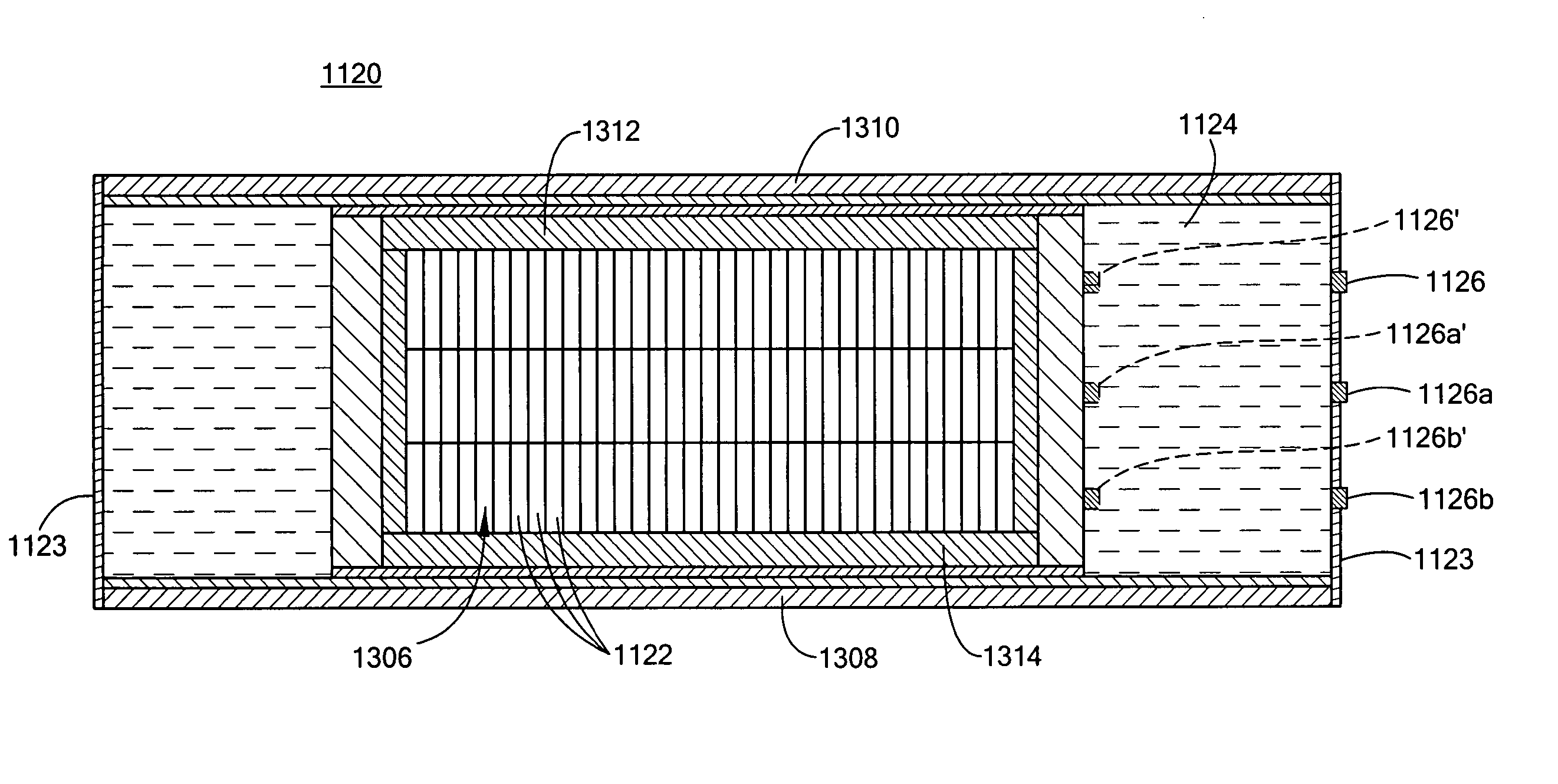

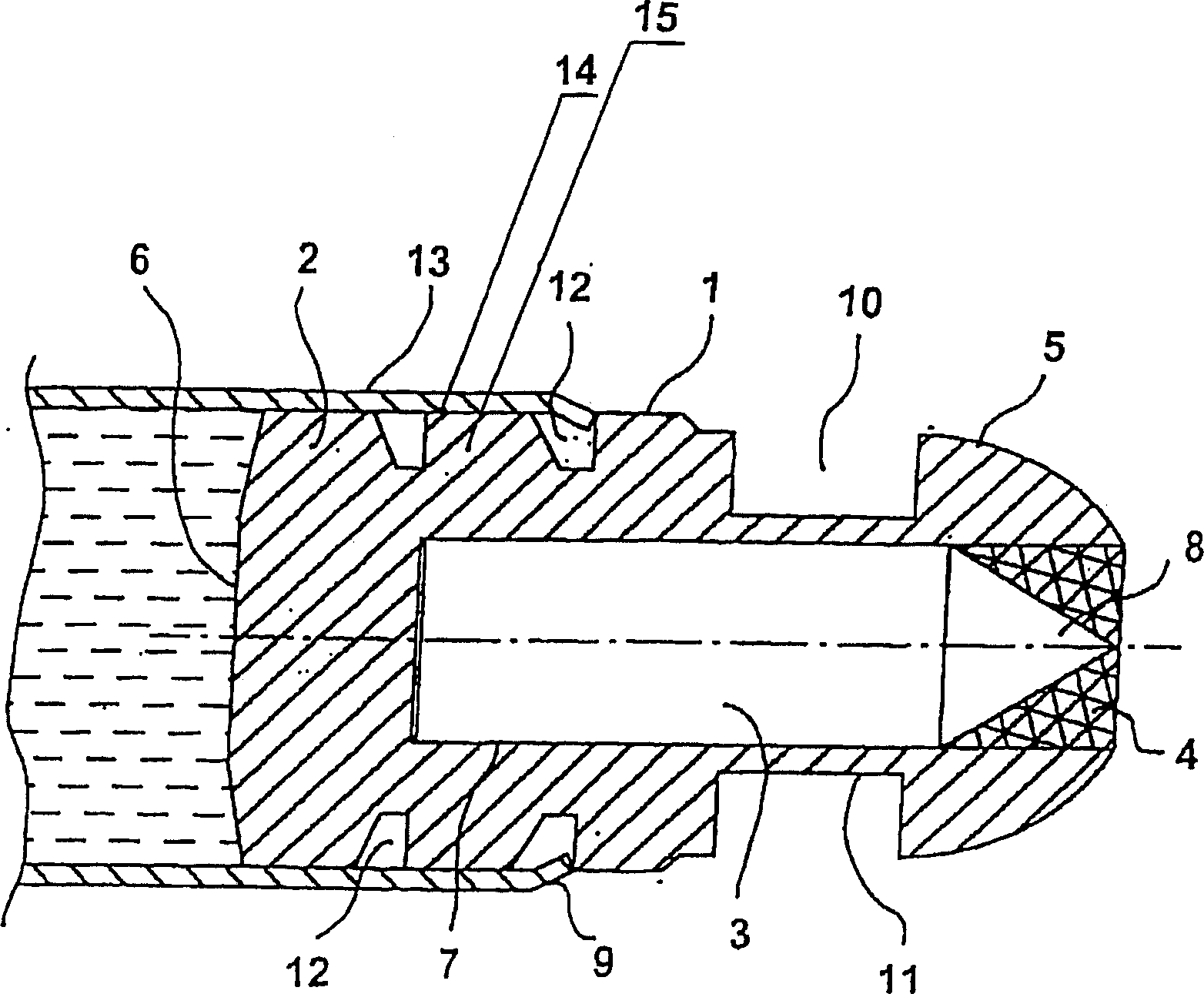

Armor-piercing projectile and its preparation method

InactiveCN1551972AGreat penetration depthIncrease the initial velocityAmmunition projectilesProjectilesArmor-piercing shellEngineering

The cartridge consists of a shell (13) with powder filling (16) and a bullet (1), where the bullet (1) comprises a body (2) having a rear base (6) and peripheral walls, in the axis of which is fixed a piercing core (3). The body (2) of the bullet (1) is adapted for controlled detachment, in the area of weakening of its peripheral wall, of at least one of its forward portion (5) and a rear portion (17) of greater diameter, corresponding to the calibre of the gun, for stabilising and guiding the bullet (1) in the gun barrel. The piercing core (3) is lodged with radial allowance in the body (2), in the opening (19) on the fron side. Between the forward portion (5) and the rear portion (17) of the bullet (1), the body (2) has a deforming wall (10) with reduced thickness, so that the area where it meets the shouldered rear portion (17) forms the ripper zone of the front portion of the body (2), while the piercing core (3) comes to point at its front end (8) and the hollow between this front end of the core (3) and the adjacent part of the inner wall of the opening (19) of the body (2) is filled with a malleable plug (4) whose outer surface forms at least the greater part of the impacting surface (20) of the bullet (1). The subject of the invention also involves a method of preparing at least one radial incision in the body (2) of the bullet (1) of the cartridge, during which the rear portion (17) of the body (2) is formed with a greater outer diameter with at least one radial incision (12) of trapezoidal section with symmetrical sides.

Owner:弗拉斯蒂米尔·利布拉

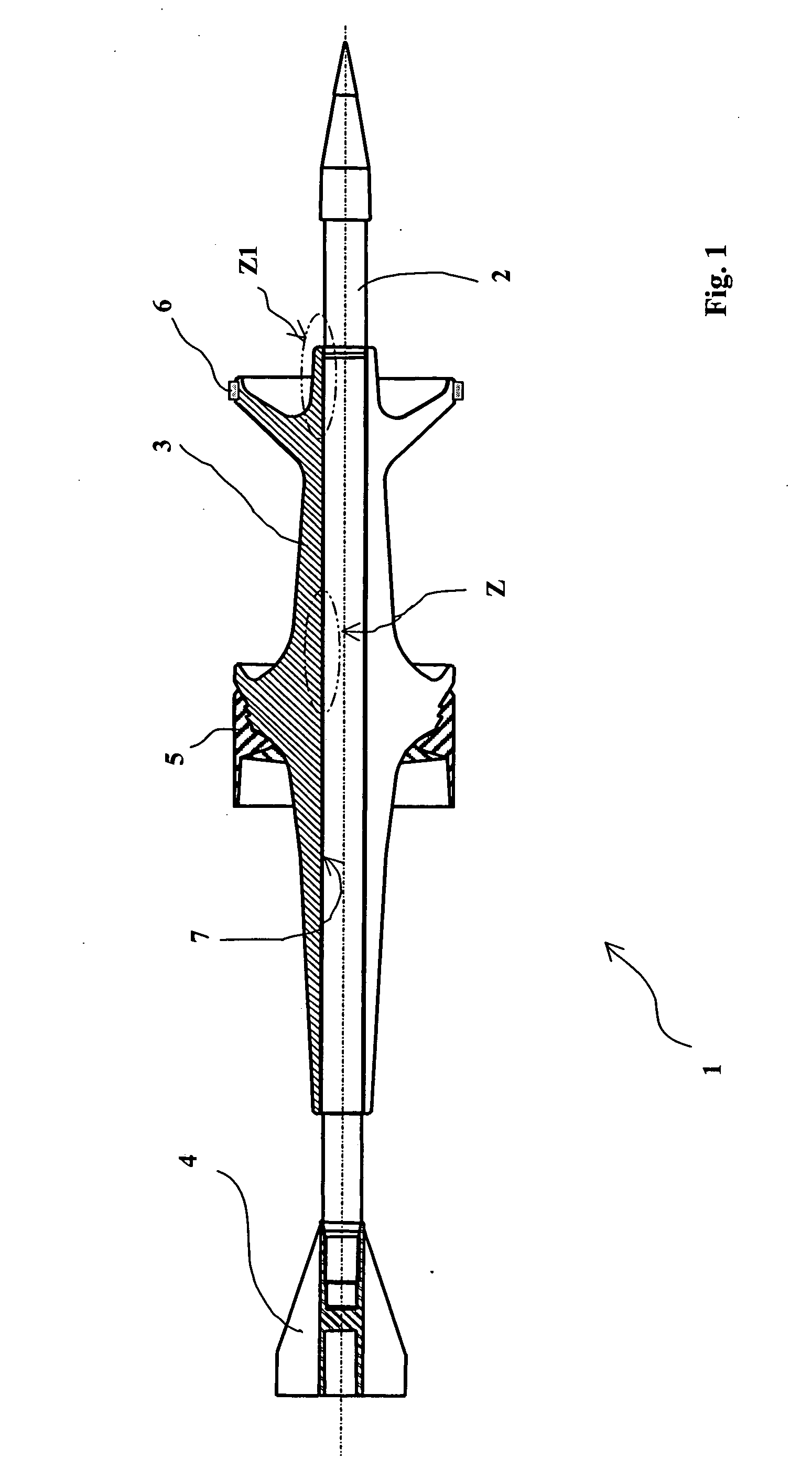

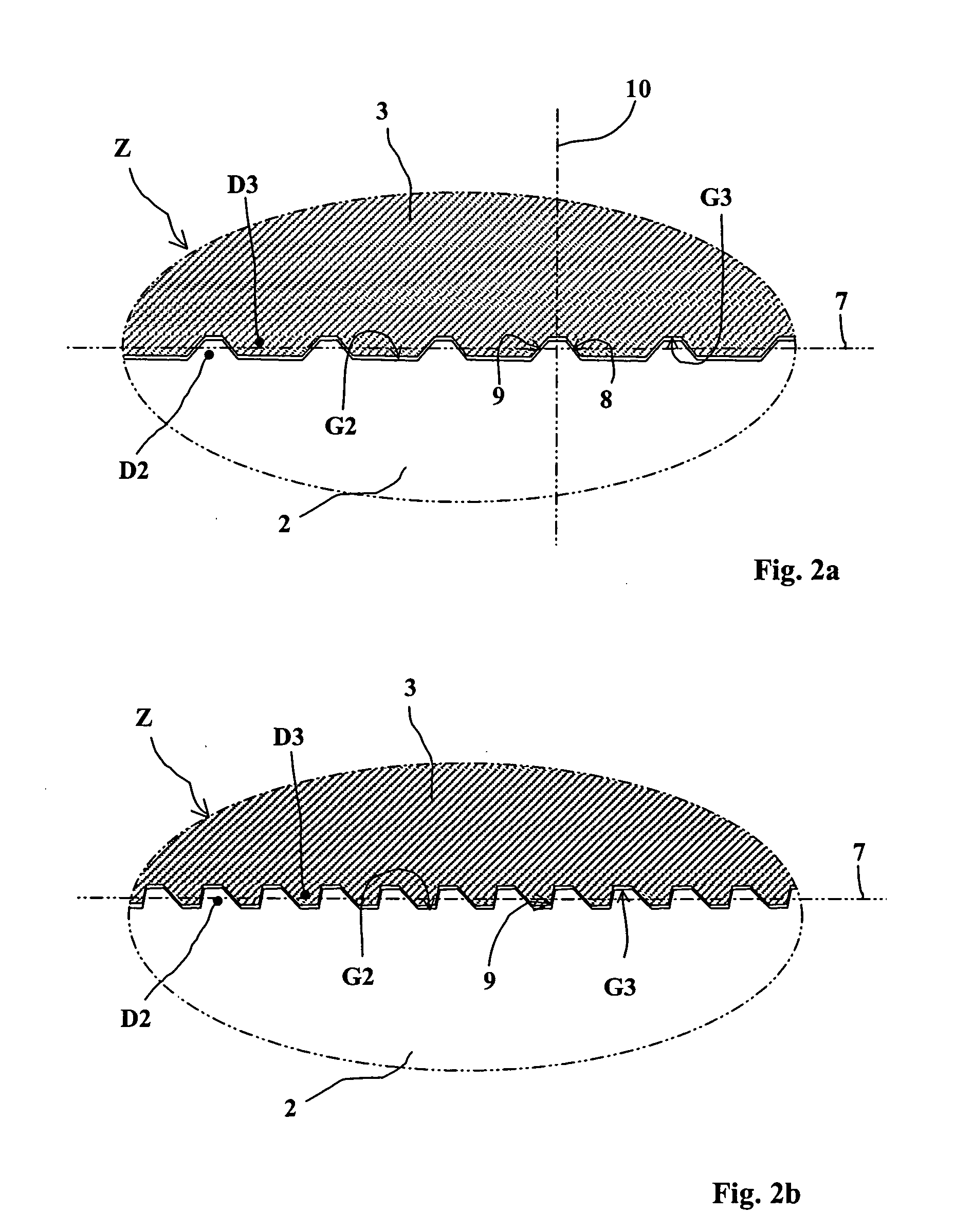

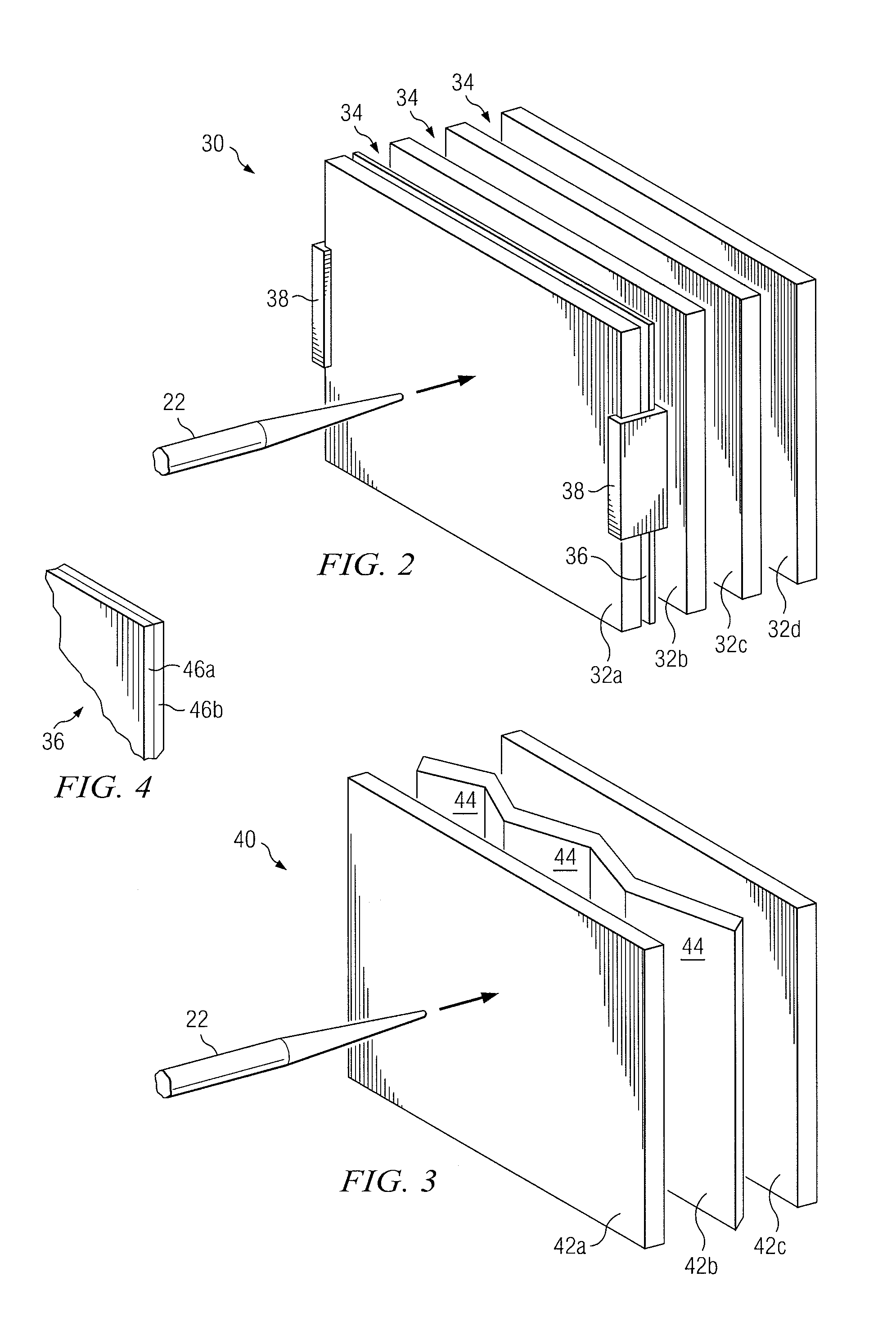

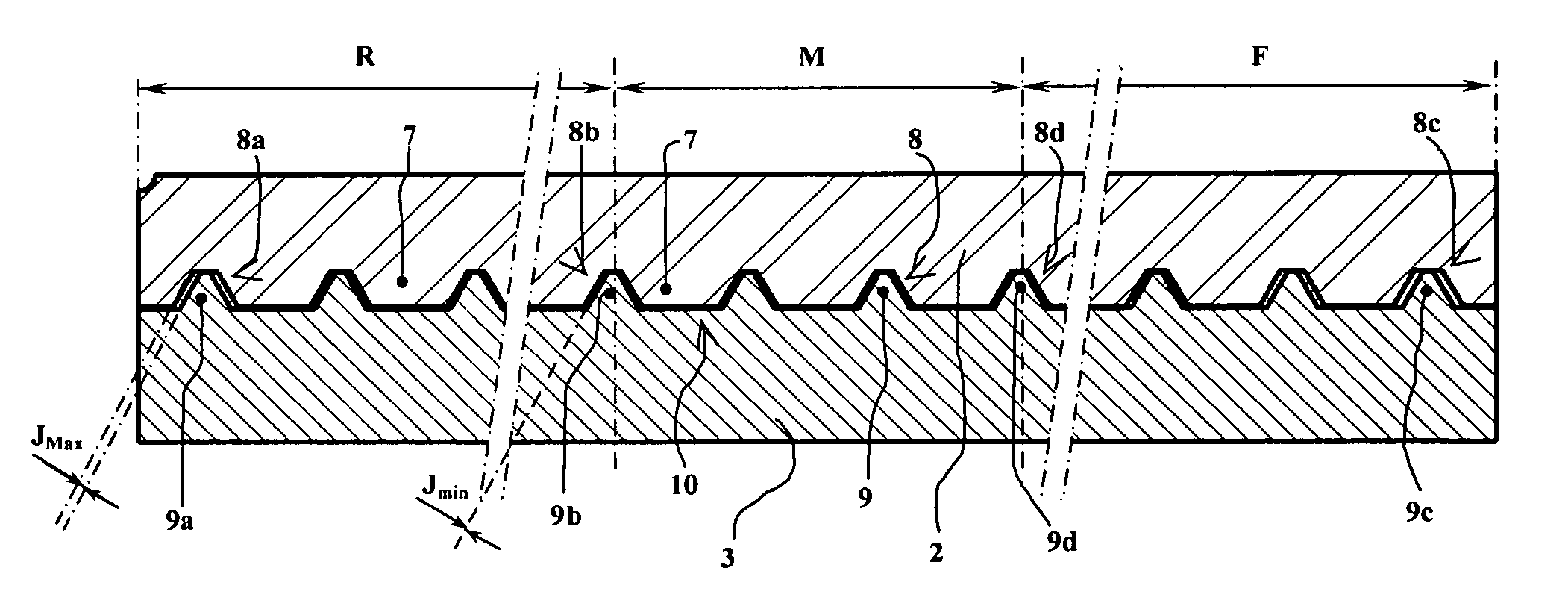

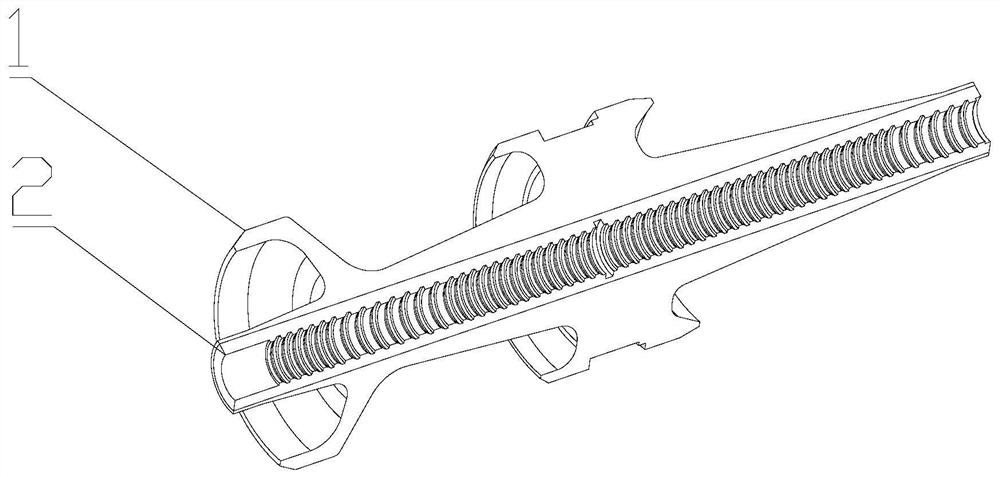

Sub-calibre projectile of the fin-stabilised type incorporating a sabot and a penetrator

ActiveUS20110011297A1Reduce interfaceSimple interfaceAmmunition projectilesProjectilesArmor-piercing shellEngineering

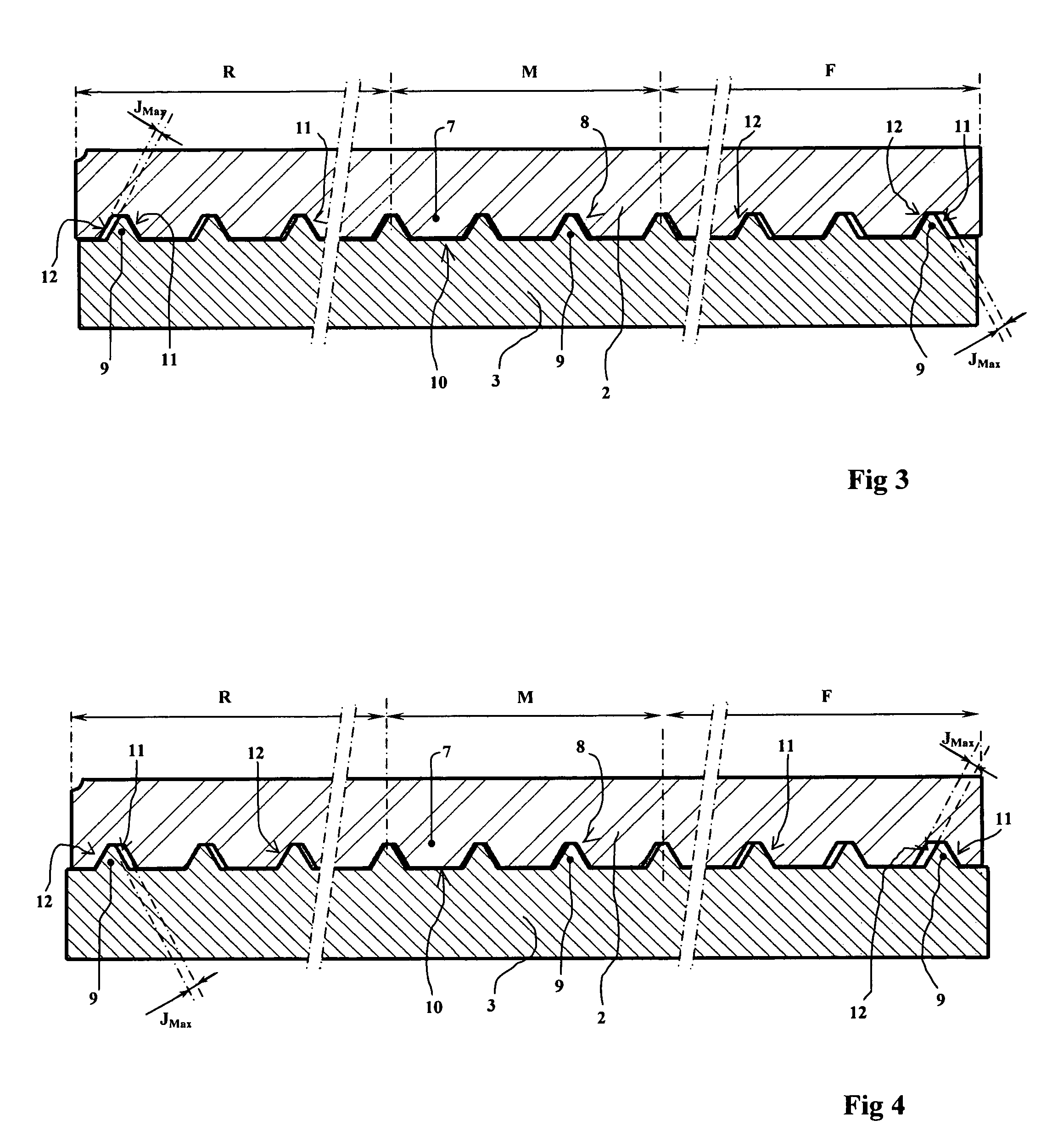

A sub-caliber projectile of the fin-stabilized type incorporating a sabot and a penetrator linked together by shape matching linking means, said linking means incorporating a first profile machined at a bore of said sabot and cooperating with a second profile on said penetrator, each of said first and second profiles having a shape according to a section in an axial plane that alternates teeth and grooves, the axial play between one of said teeth of said penetrator and one of said grooves forming the housing of said one of said teeth in said sabot being variable along the axis of said projectile, wherein said linking means incorporate a front part (F) and a rear part (R) in which the play, at a mean temperature, between said penetrator teeth and the housings of said teeth in said sabot is variable, the play, firstly, increasing between said median zone (M) of said sabot and a front end of said sabot and, secondly, increasing between said median zone (M) of said sabot and a rear end of said sabot.

Owner:NEXTER MUNITIONS

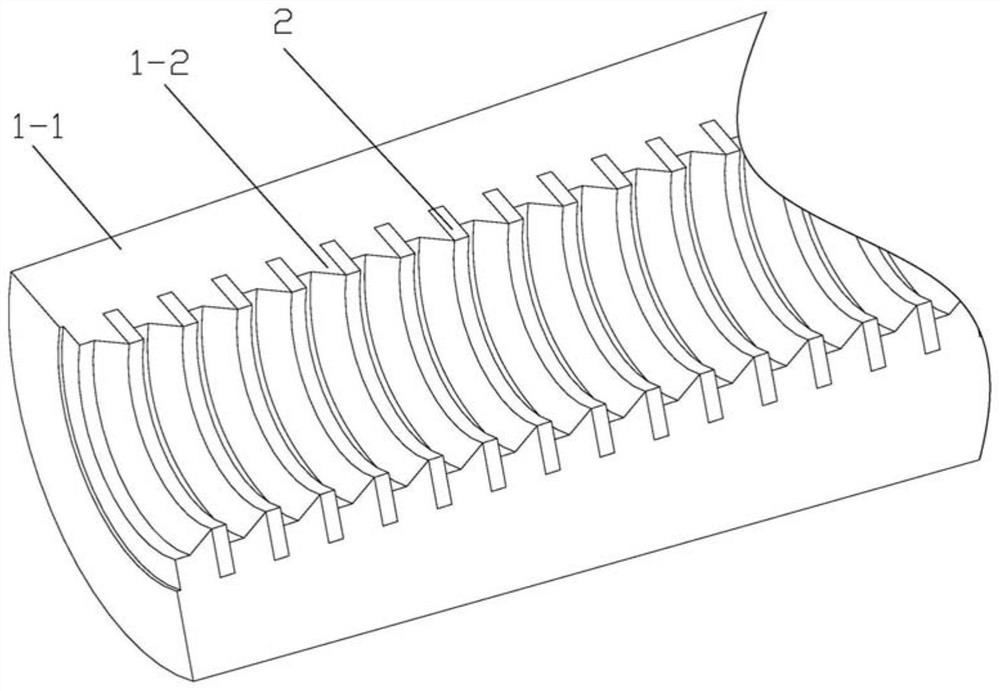

Cartridge holder clamping petal of carbon fiber composite armor-piercing bullet and forming method and forming die thereof

PendingCN114311746AHigh strengthAvoid breakingAmmunition projectilesProjectilesFiberArmor-piercing shell

The invention belongs to the technical field of armor-piercing projectile supports, and particularly relates to a carbon fiber composite armor-piercing projectile support clamping petal, a forming method of the carbon fiber composite armor-piercing projectile support clamping petal and a forming mold. The advantages of the short cut carbon fiber prepreg in complex shape forming and the high strength of continuous fibers are integrated, the structure of the bullet support clamping petal is divided into the tooth reinforcing plate and the shell, the tooth reinforcing plate is embedded in the annular groove of the shell, the tooth strength is enhanced, the tooth reinforcing plate is formed by fabric carbon fiber prepreg in a mold pressing and machining mode, and the service life of the bullet support clamping petal is prolonged. The shell is formed by mould pressing of the short carbon fiber prepreg, compared with a continuous carbon fiber mould pressing process, the laying time in the manufacturing process is greatly shortened, and the manufacturing efficiency is improved; compared with a chopped carbon fiber prepreg mold pressing process, the strength of the teeth is improved through the tooth reinforcing plate, and the teeth are prevented from being broken when the armor-piercing bullet is launched; compared with a metal sabot, the density of the product can be reduced to about 1.4 g / cm < 3 >, and the negative mass in the launching process is greatly reduced.

Owner:江苏集萃碳纤维及复合材料应用技术研究院有限公司

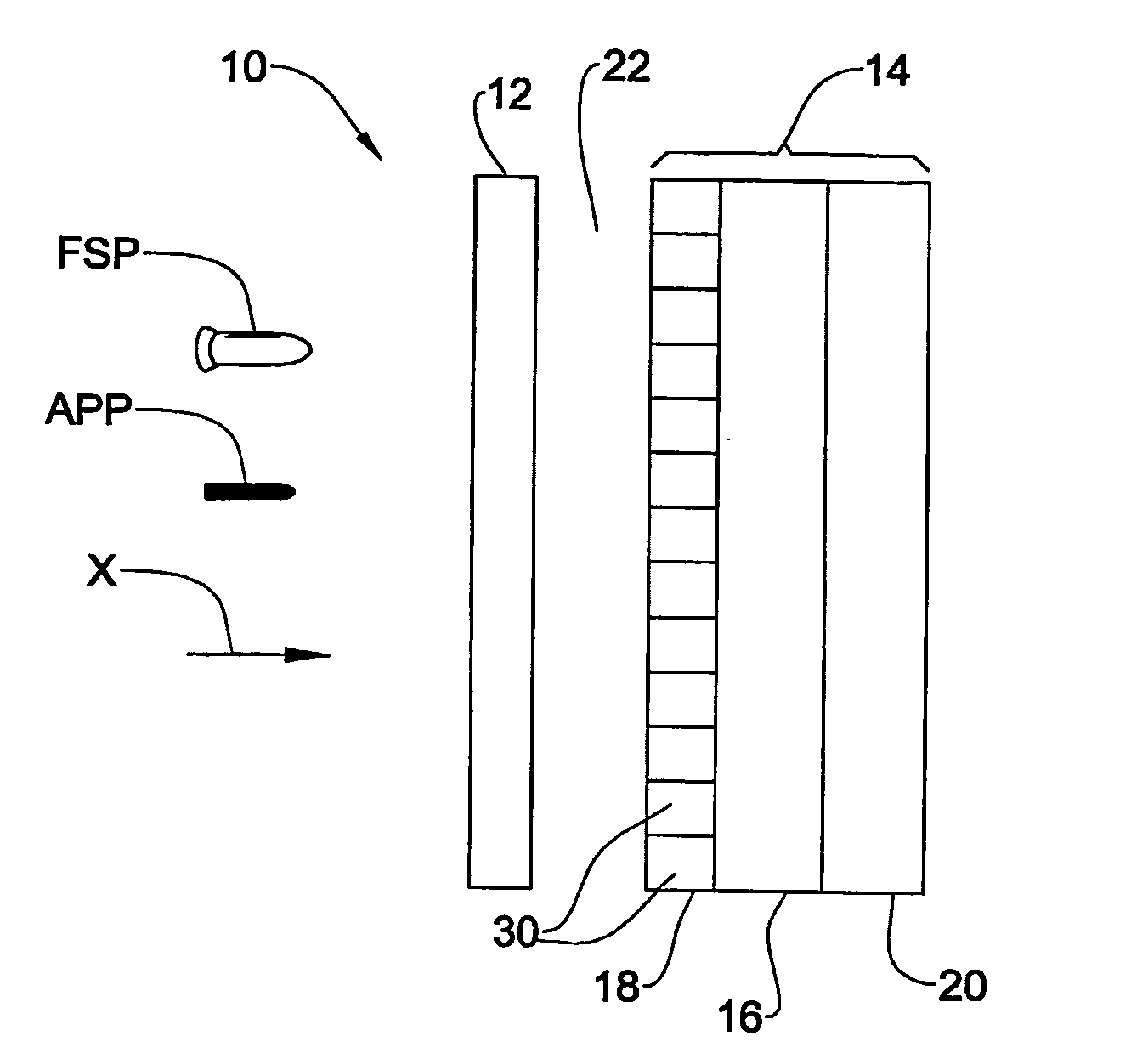

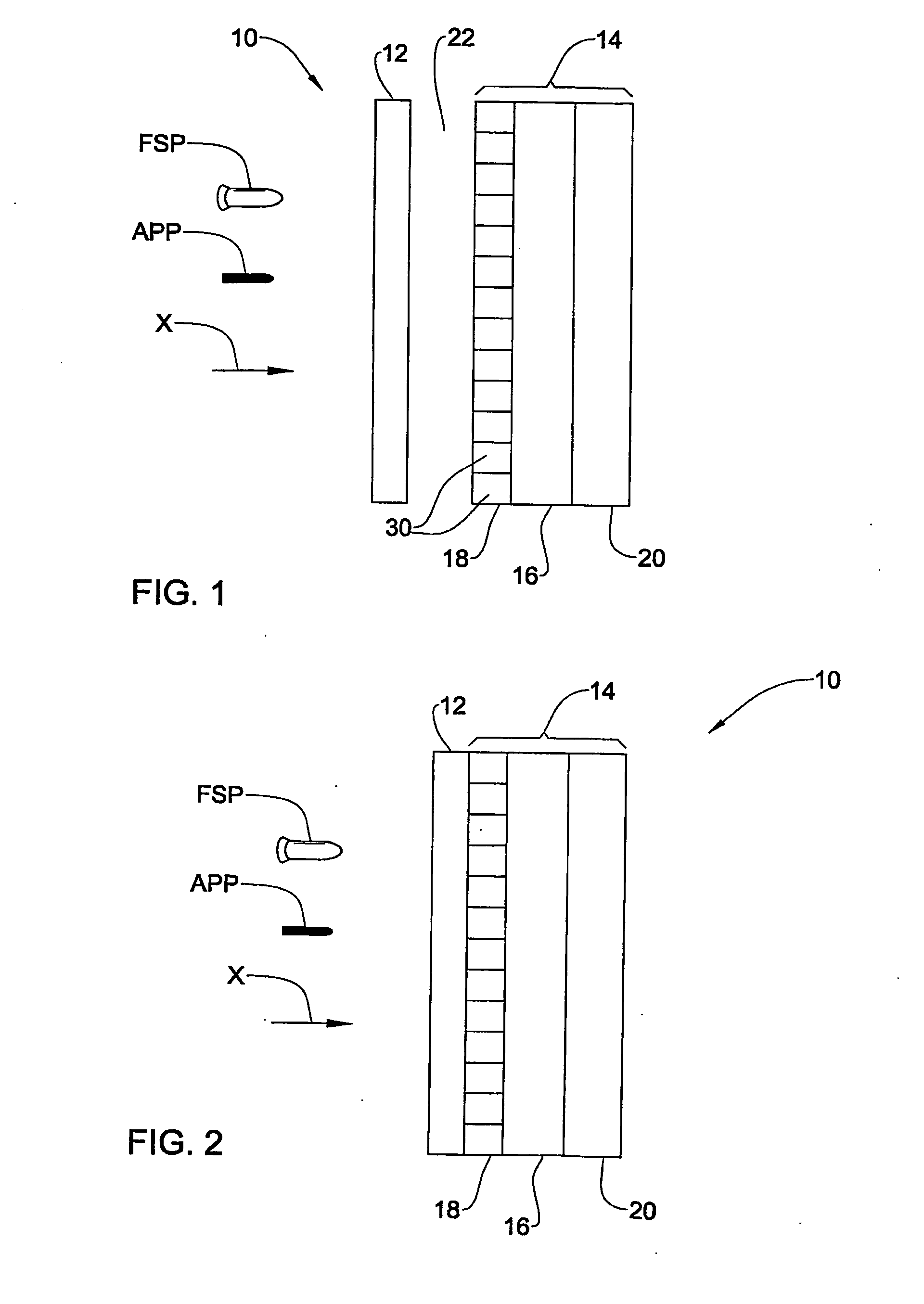

Multi-Functional Armor System

InactiveUS20110083549A1Increase speedLower capability requirementsArmoured vehiclesArmour platesArmor-piercing shellEngineering

A ballistic armor adapted to protect against armor piercing projectiles and to withstand multiple impacts of fragment simulating projectiles of a predetermined type, traveling at an initial velocity not exceeding a first velocity. The armor comprises a main armor layer and an auxiliary layer. The main armor layer is adapted to absorb most of the energy of the armor piercing projectiles and to withstand the impacts of the fragment simulating projectiles traveling at a velocity not exceeding a second velocity which is lower than said first velocity. The auxiliary layer is disposed in front of the main armor layer to face the projectiles, and is made of a material which is adapted to undergo a ductile failure mode when perforated by said fragment simulating projectiles and thereby experience localized deformation in the vicinity of each perforation, and which is adapted to cause the fragment simulating projectiles to experience such an energy loss associated with the perforation and deformation as to reduce their velocity from the initial velocity to a velocity not exceeding the second velocity.

Owner:PLASAN SASA

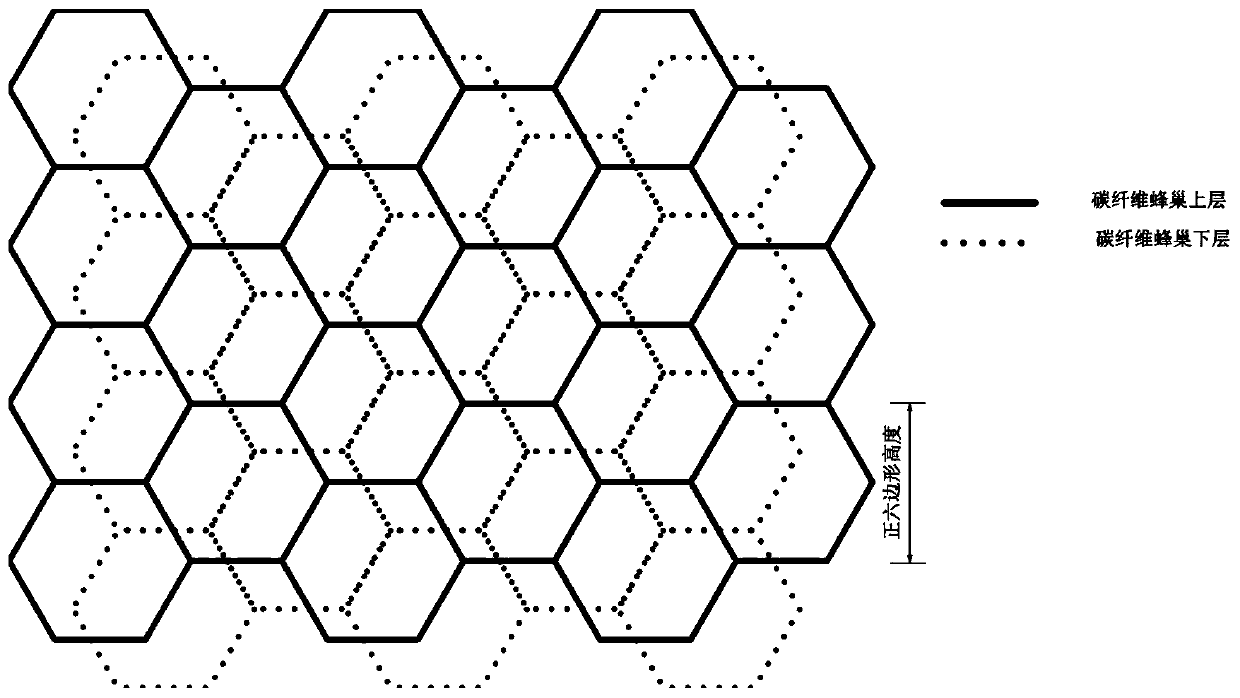

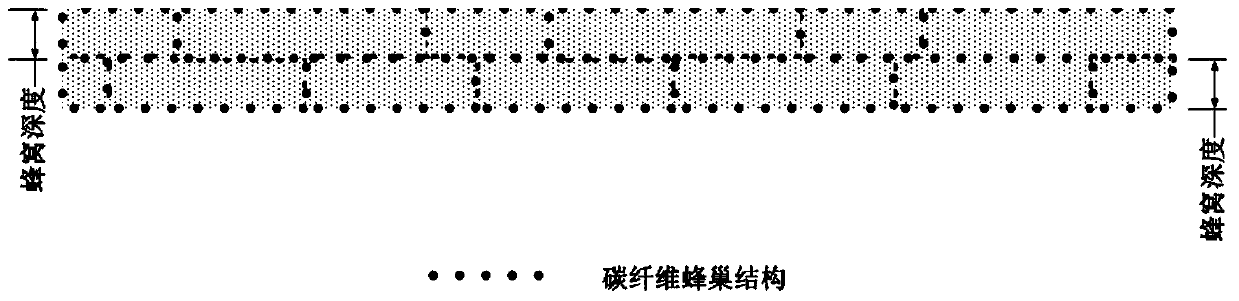

Bulletproof composite armor and preparation method thereof

ActiveCN111238309AImprove toughnessImprove thermal conductivityAnodisationProtective equipmentAl powderFiber

The invention discloses a bulletproof composite armor and a preparation method thereof, and belongs to the preparation technology of ceramic and metal-based composite materials. The preparation methodof the bulletproof composite armor comprises the following steps that 1, B4C powder, carbon nanofibers, water-soluble phenolic resin and water are evenly mixed to obtain ceramic slurry, then spray drying is carried out to obtain a raw material, then cold pressing is carried out to obtain a regular hexagon green body; 2, the regular hexagon green body is put into a honeycomb of a faveolate carbonfiber mesh bag, the honeycomb is covered with carbon fiber cloth made of the same material, then vacuum hot-pressing sintering is carried out, an integral composite ceramic plate is formed; 3, the carbon nanofibers and aluminum powder are evenly mixed, an aluminum alloy bulletproof back plate is formed through powder metallurgy, forging forming and micro-arc oxidation treatment; and 4, the composite ceramic plate and the aluminum alloy bulletproof back plate are subjected to hot isostatic pressing compounding, and the bulletproof composite armor is obtained. According to the bulletproof composite armor and a preparation method thereof, the mode that a high-toughness composite ceramic is combined with the aluminum alloy back plate is adopted, so that the capacity of the composite armor forresisting multiple strikes of armor-piercing bullets and armor-piercing incendiary bullets is greatly improved.

Owner:SUZHOU FIRST ELEMENT NANO TECH

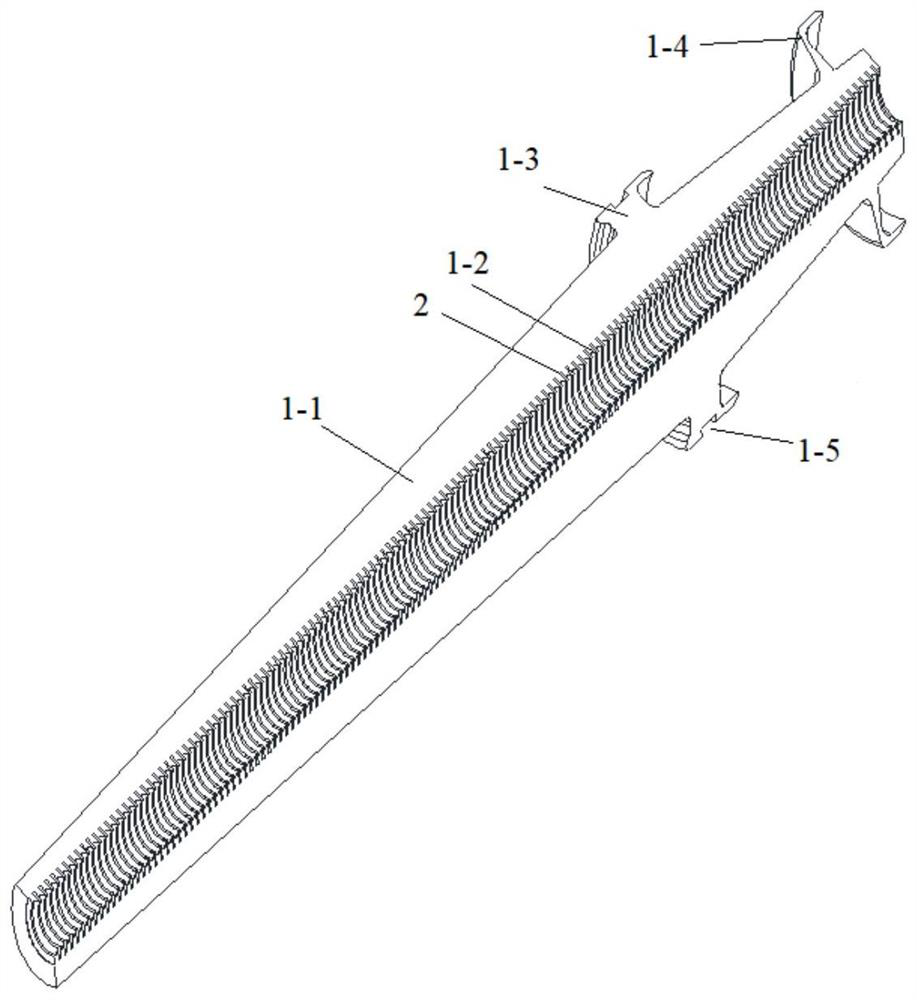

Empennage stable shelling armor-piercing projectile support and preparation method thereof

The invention discloses an empennage stable shelling armor-piercing projectile support and a preparation method thereof. The projectile support is formed by combining three 120-degree carbon fiber composite clamping petals through hoops, a thread of the projectile support is formed by machining and combining a plurality of carbon fiber mold pressing plates with different laying layer angles and laying layer thicknesses, and an outer shell is formed by short carbon fiber prepreg yarns through mold pressing. The preparation method comprises the steps of projectile support design, thread preforming, clamping petal forming and the like. The preparation method provided by the invention is simple in process, the prepared projectile support is light in mass and small in inert mass, and compared with a projectile support made of a metal material, the initial velocity of ammunition is higher and the firing range is farther under the same working condition. In addition, the thread of the projectile support is formed by the continuous carbon fibers in advance, the thread is high in strength and good in consistency, a bullet core can be better supported during launching in a chamber, and the projectile support has the advantage of being higher in reliability.

Owner:NINGBO SHUXIANG NEW MATERIAL

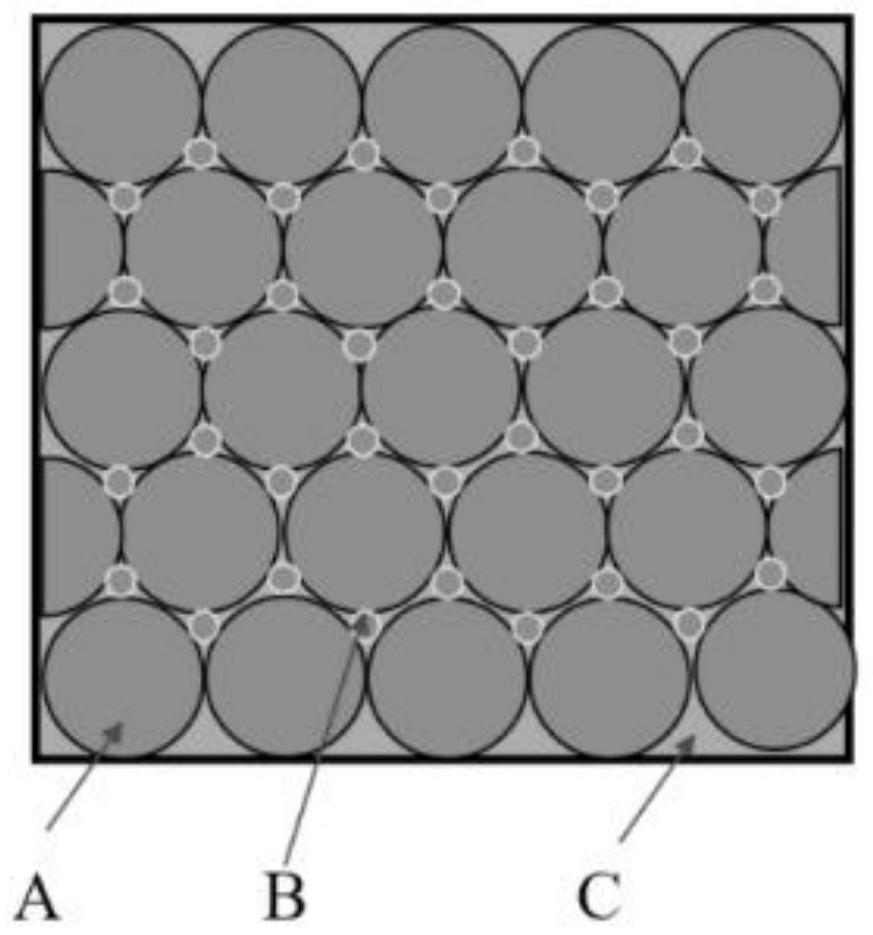

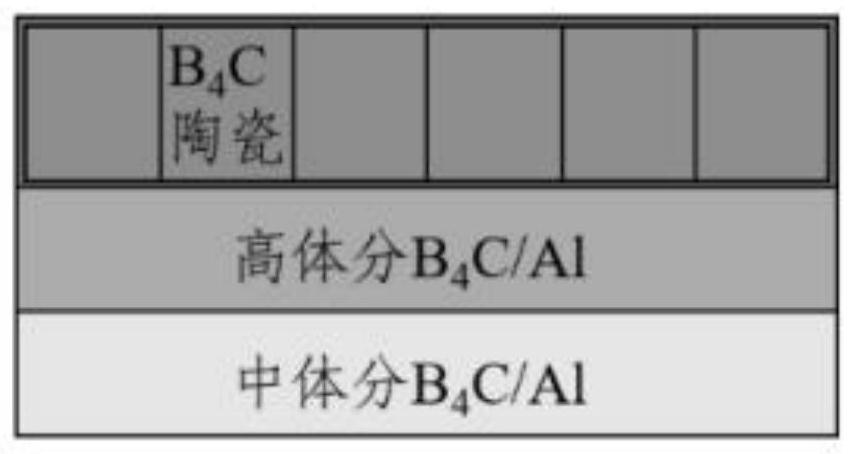

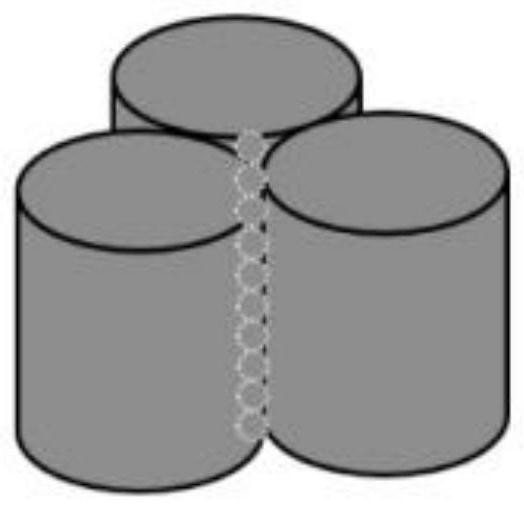

Gradient aluminum-based composite material for resisting 30 mm armor-piercing bullet and preparation method of gradient aluminum-based composite material

ActiveCN113234967AExtended failure timeReduce gapArmoured vehiclesArmour platesArmor-piercing shellCeramic composite

The invention relates to a gradient aluminum-based composite material for resisting a 30 mm armor-piercing bullet and a preparation method of the gradient aluminum-based composite material, and aims to solve the problems that a traditional ceramic composite armor structure is large in surface density and thickness and poor in frequent elasticity resistance are solved. The gradient aluminum-based composite material is of a three-layer gradient structure; the outer layer is made of an aluminum-based composite material which is reinforced by ceramic columns, ceramic balls and B4C ceramic powder which are densely arranged together; the middle layer is a high-volume-fraction B4C / Al composite material; and the inner layer is a medium-volume-fraction B4C / Al composite material. The method comprises the following steps: 1, densely arranging the ceramic columns; 2, filling gaps of the columns with the ceramic balls; 3, filling gaps with the B4C powder; 4, paving preform powder layer by layer; 5, carrying out compacting and cold-pressing to prepare a preform; and 6, melting molten aluminum, pressing the molten aluminum into the remaining gaps of the preform through pressure infiltration, and conducting pressure maintaining and demolding. Thea gradient aluminum-based composite material is used for the armor structure for resisting the 30 mm armor-piercing bullet.

Owner:HARBIN INST OF TECH

Economical anti-ship missile

The invention provides an economical anti-ship missile. The economical anti-ship missile is characterized in that the anti-ship missile is launched by a supersonic aircraft flying at the height of more than 15km and at 1.5Mach speed, then is propelled by a ramjet, carries excessive propane serving as fuel, flies at 3-5 Mach speed after rising to the 30-50km height, automatically locks a target when reaching to the approximate 50-80km height and dives at an inclination angle of 30-60 degrees, a missile head is a tungsten carbide armor-piercing missile housing, and an internal missile head only needs high explosive 20-50kg and a little amount of phosphorus powder. After the housing explodes, the explosive enables the redundant propane fuel to be bounced into air in a cabin to form aerogel, and then the phosphorus powder performs spontaneous ignition and detonation to perform secondary explosion, so that the weight of the whole anti-ship missile does not exceed 1ton, the propane fuel accounts for 500-700kg, the explosion damage capacity equivalent to TNT 3-5tons can be produced, and the economical anti-ship missile is used for attacking a large-tonnage naval vessel or an aircraft carrier.

Owner:SUZHOU NIUWU ERGUAN ELECTRICAL APPLIANCE TECH

Preparation method of bulletproof composite ceramic

The invention relates to a preparation method of bulletproof composite ceramic, and belongs to the technical field of ceramic matrix composite materials. The bulletproof composite ceramic is obtainedthrough preparation of a pure ceramic green body, preparation of a composite ceramic green body and vacuum hot-pressing sintering. The high-toughness carbon fiber and the ceramic body are subjected tohot pressed sintering, so that the hardness and the toughness of the bulletproof ceramic are greatly improved, and the capability of resisting multiple strikes of armor-piercing bombs and armor-piercing incendiary bombs is achieved.

Owner:LIAONING YIFEI TECH +1

Method for reducing uncombined explosive welding detonator zone through energy polymerizing cover detonation

InactiveCN102699517AReduce defectsHigh yieldNon-electric welding apparatusArmor-piercing shellDetonator

The invention discloses a method for reducing an uncombined explosive welding detonator zone through energy polymerizing cover detonation. The method adopts the shaped charge theory of an armor-piercing bullet, detonates explosives with an energy polymerizing cover, improves detonation energy of the explosive, and reduces unstable detonation zone of the explosive, so as to achieve the purpose of reducing the defects in the detonator zone. The energy polymerizing cover is a conical body; the diameter at the top of the conical body equals to the outer diameter of a detonator; the diameter at the bottom of the conical body changes with the thickness of a doubling plate; and generally, the height of the conical body ranges from 25 to 50 mm, and the thickness of the conical body ranges from 2 to 5 mm. Preferentially, the energy polymerizing cover is made of wood or plastic; and when low detonation velocity explosives are detonated to weld the doubling plate which is made of precious metal and large in size and thickness, the energy polymerizing cover is filled with high velocity detonation explosives, so that the energy polymerizing effect is much better, the distance of the unstable detonation zone of the explosives is much shorter, and the defects of the detonator zone are much smaller. Compared with the traditional explosive welding detonation method, the method provided by the invention has the advantage that during the detonation of the explosives, the defects of the detonator zone can be reduced by more than 90% to the most extent.

Owner:史和庆

Manufacturing method of composite sabot of armor-piercing bullet and sabot

PendingCN114248391AImprove performance utilizationThe stock is lightAmmunition projectilesProjectilesArmor-piercing shellFiber

The manufacturing method comprises the following steps that a high-strength fiber prefabricated body is adopted as a reinforcing material at the joint of the high-strength fiber prefabricated body and a penetration rod, and a support core with inner teeth is manufactured through an RTM technology; performing external molding on the support core by adopting injection molding or mold pressing to form a preparation part; cutting the prepared part to form a plurality of supporting petals; the supporting petals are placed on the steel mandrel which is the same as the matching surface of an actual penetration body and fastened through the rope, then the supporting petals are turned to the specified size, the fastening rope on the supporting petals is unfastened, and manufacturing is completed. The performance utilization rate of the reinforced fibers in the composite material is high, the weight of the sabot is lighter, and the outlet speed of a penetration body is higher under the condition of the same explosive loading amount.

Owner:XIAN YINGLIKE ELECTRIC TECH CO LTD

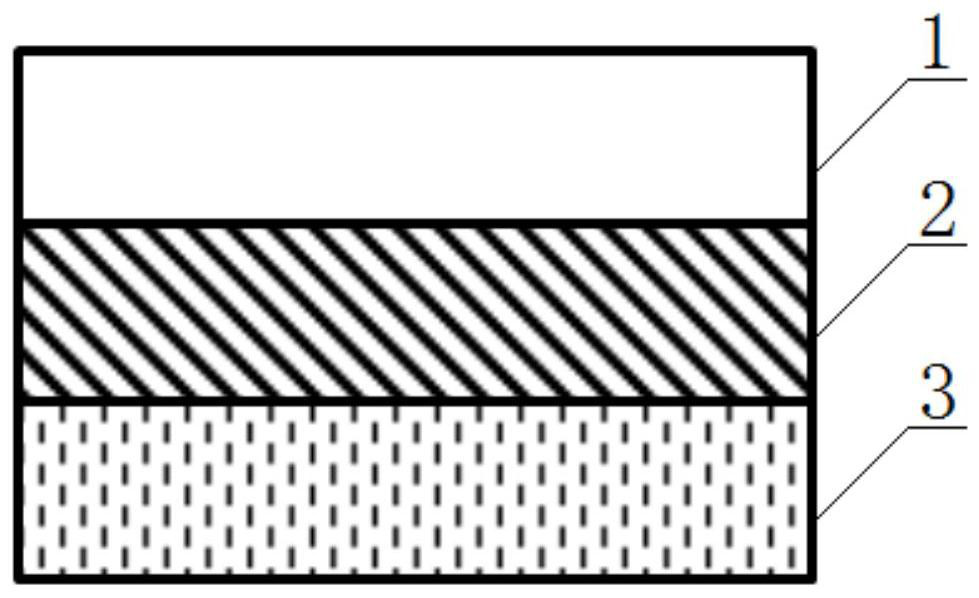

Ceramic-titanium alloy-PE composite bulletproof deck and preparation method thereof

InactiveCN111811322AImprove bindingImprove toughnessProtective equipmentSynthetic resin layered productsArmor-piercing shellCarbon nanofiber

The invention discloses a ceramic-titanium alloy-PE composite bulletproof deck and a preparation method thereof, and belongs to the technical field of weapon equipment. The preparation method of the ceramic-titanium alloy-PE composite bulletproof deck comprises the following steps: S1, mixing titanium alloy and surface-aluminized carbon nanofibers evenly, obtaining titanium alloy composite powder;S2, laying the titanium alloy composite powder on a graphite die, then, covering with a carbon nanofiber toughened boron carbide ceramic chip, and performing hot pressing and sintering to obtain a ceramic-titanium alloy composite deck; S3, adhering a PE board having ultra-high molecular weight with the ceramic-titanium alloy composite deck prepared in the step S2, and obtaining the ceramic-titanium alloy-PE composite bulletproof deck. The composite bulletproof deck prepared by the method of the invention has good overall associativity, and has high capability of resisting an armor-piercing bullet and an armor-piercing incendiary.

Owner:赛福纳米科技(徐州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com