High density perforating gun system producing reduced debris

a perforating gun and high density technology, applied in the direction of fluid removal, explosive charges, borehole/well accessories, etc., can solve the problems the interstitial space is unavoidably left between the neighboring charges, and the placement of the perforation charge used, etc., to achieve the effect of reducing the amount of debris resulting from the detonation or eliminating i

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention relates to devices and methods for perforating wellbores. The present invention is susceptible to embodiments of different forms. There are shown in the drawings, and herein will be described in detail, specific embodiments of the present invention with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that illustrated and described herein.

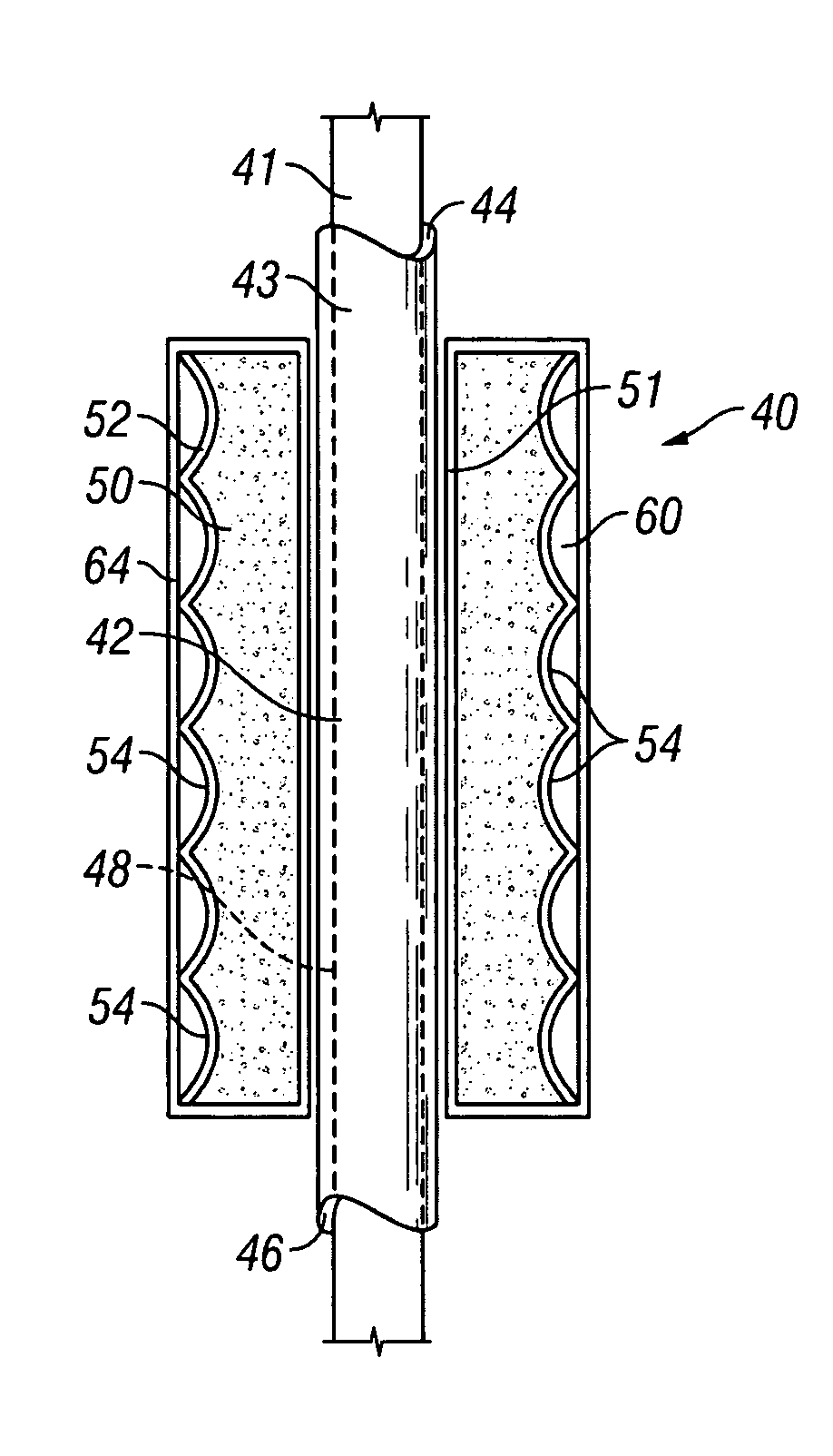

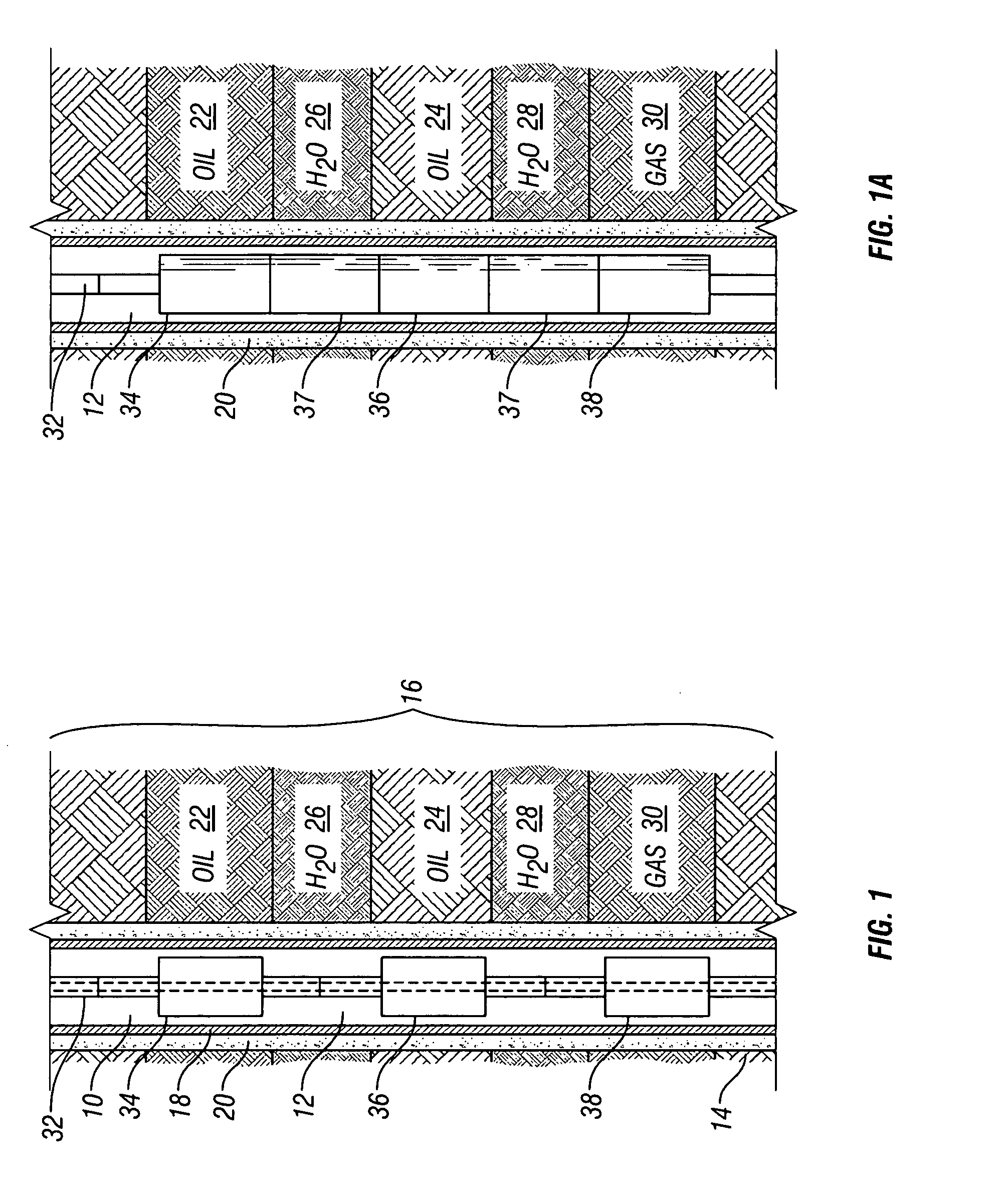

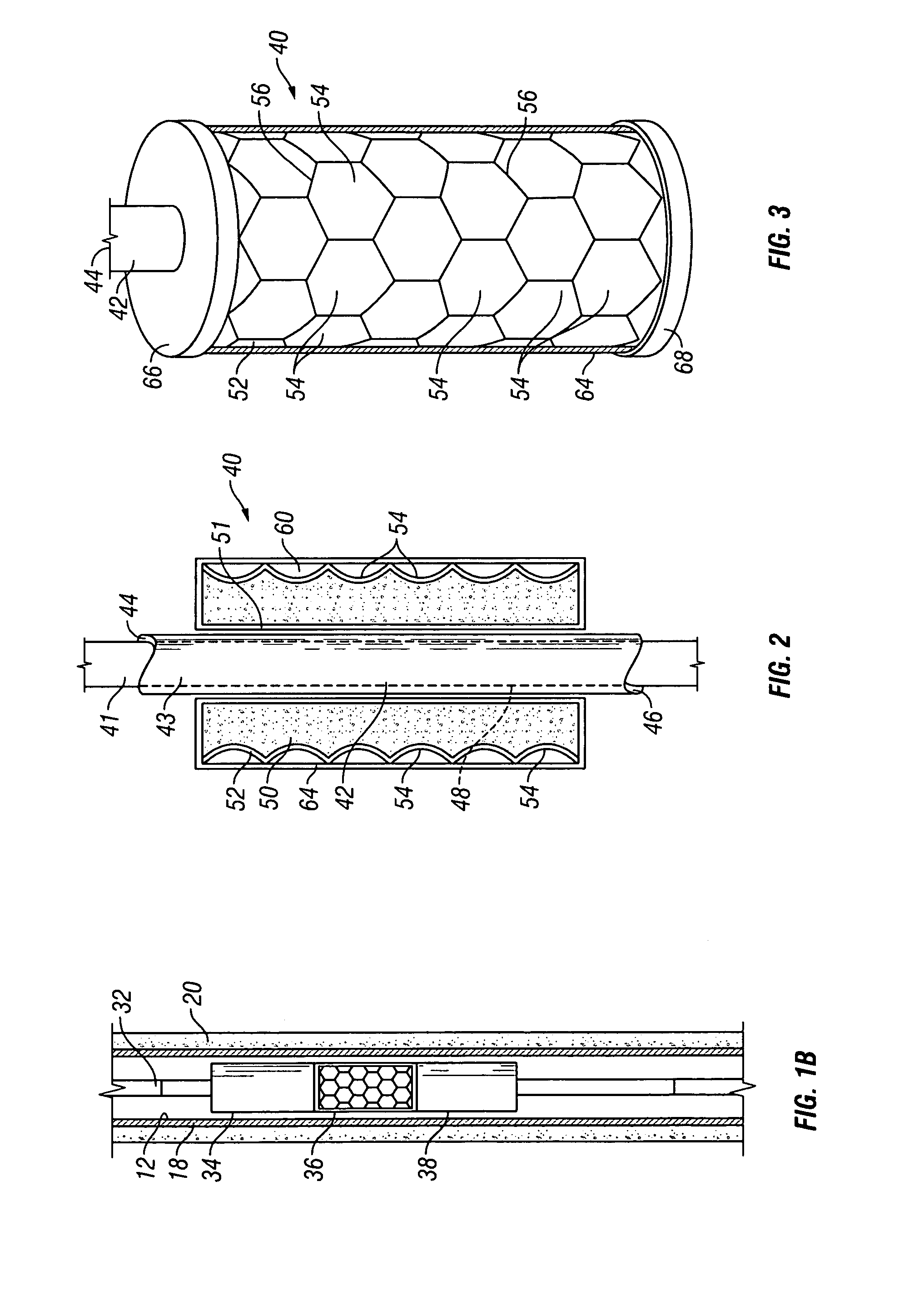

[0025]FIG. 1 illustrates an exemplary perforation system 10 that is configured in accordance with one embodiment of the present invention. The perforation system 10 is disposed within a wellbore 12 that has been drilled through the earth 14 and a hydrocarbon-bearing formation 16. Portions of the wellbore 12 are cased by a steel casing 18 that is secured within the open wellbore hole by cement 20.

[0026] The hydrocarbon-bearing formation 16 contains two oil-bearing strata 22, 24, which are separated by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com