Multi-Functional Armor System

a multi-functional, armor technology, applied in the field of ballistic armor, can solve the problems of exposing the vehicle to piercing, unable to protect at all from a certain type of projectile, and generally not providing protection against a plurality of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

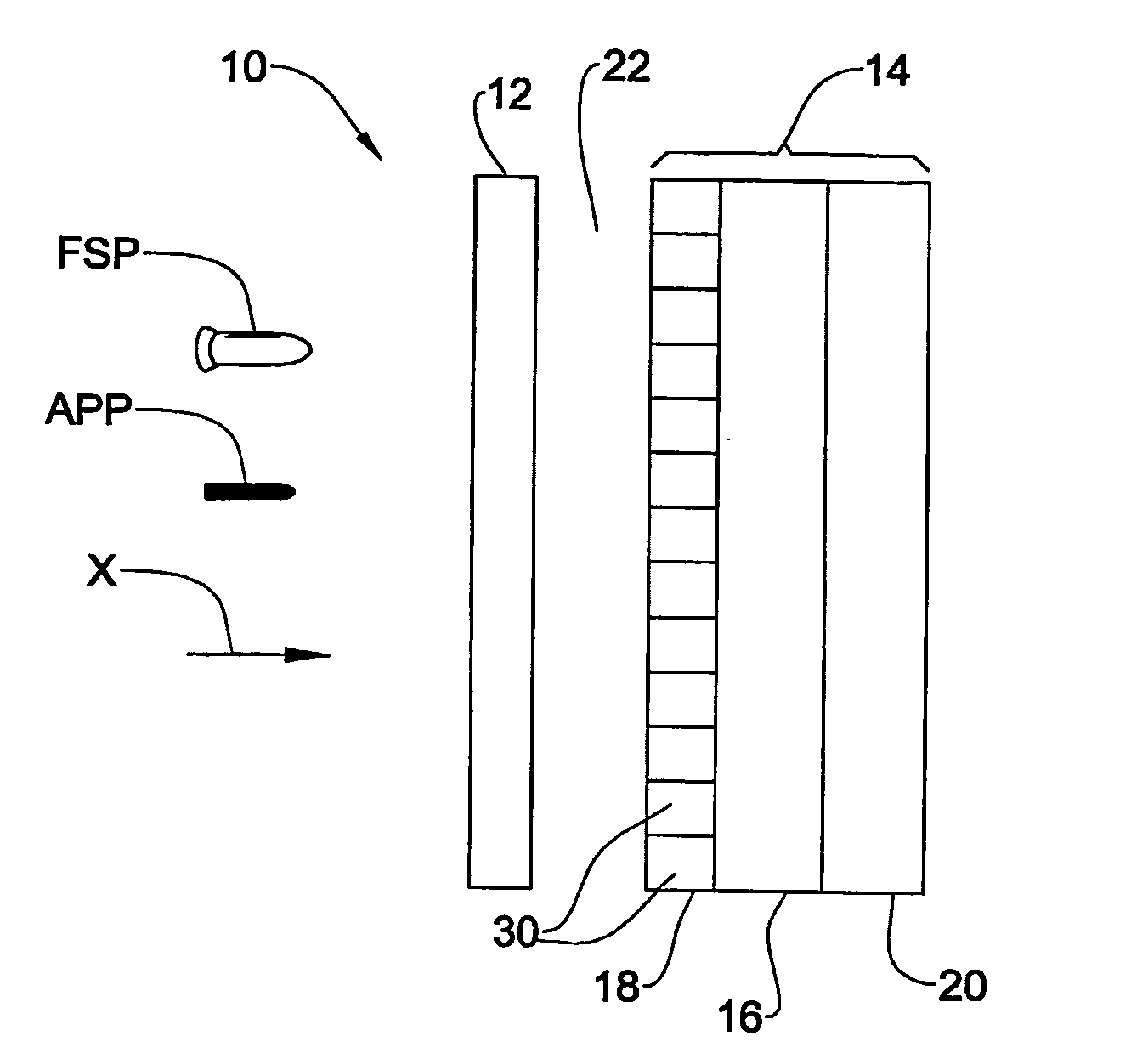

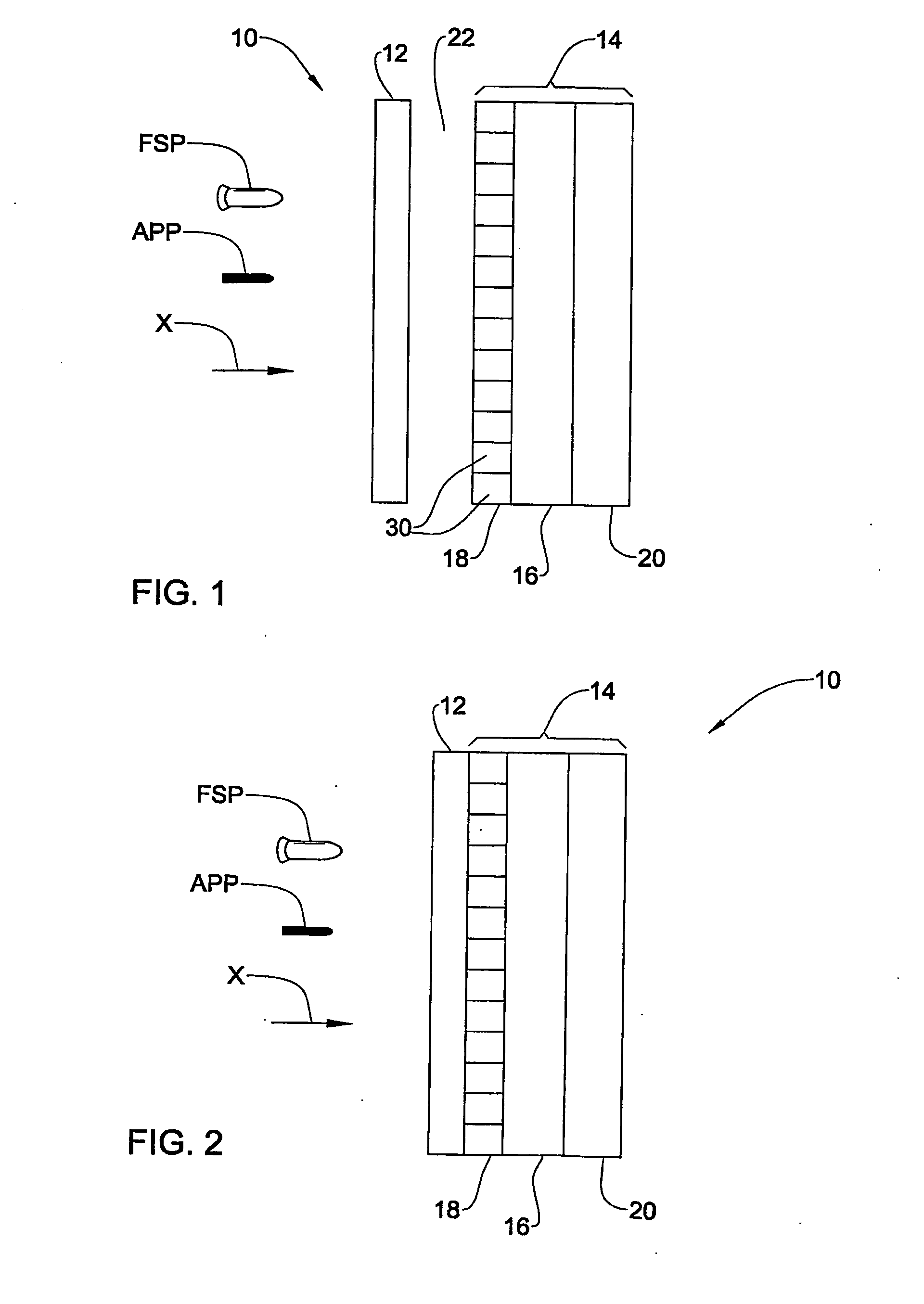

[0016]FIG. 1 is a schematic representation of ballistic armor 10 according to one embodiment of the present invention, adapted to protect a vehicle (not shown) against both a fragment-simulating projectile (FSP) and an armor piercing projectile (APP) traveling in the direction indicated by arrow X.

[0017]The armor 10 comprises an auxiliary layer 12 and a main armor layer, which may or may not be separated by a gap 22, as shown in FIGS. 1 and 2.

[0018]The main armor layer 14 comprises a base layer 16, an add-on layer 18 and, optionally, an inner liner 20.

[0019]The base layer 16 is typically made from a hard metallic material such as RHA or high hardness steel which may have a thickness between 4 mm and 20 mm. In the present embodiment, this layer is constituted by the sidewall of the vehicle protected by the armor 10.

[0020]Alternatively, the base layer may comprise dual hardness armor (DHA). For example, such DHA may comprise a layer of UHH steel facing the projectile, and a layer of H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com