Method for reducing uncombined explosive welding detonator zone through energy polymerizing cover detonation

A technology of explosive welding and energy-gathering cover, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of inconspicuous detonator area effect, reduced strength, scrapped composite board, etc., to reduce the defects of detonator area, detonator The effect of the reduction of area defects and the simple establishment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 06Cr18Ni11Ti stainless steel and Q345R carbon steel plate are explosively welded, and the base plate and double plate are ground and polished with grinding wheels and cloth wheels. The base and doubler plates are installed in parallel, and the detonation point is located in the center of the plate surface.

[0021] The double board material is 06Cr18Ni1lTi stainless steel, and the board size: 4×1500×1500mm;

[0022] Substrate material is Q345R carbon steel plate, board size: 25×1480×1480mm;

[0023] The explosive is made of powdered emulsified ammonium oil explosive, and the detonation velocity is 2800-2500m / s after adding inert materials.

[0024] The drug distribution process adopts the uniform drug distribution method, and the drug distribution height is 35mm.

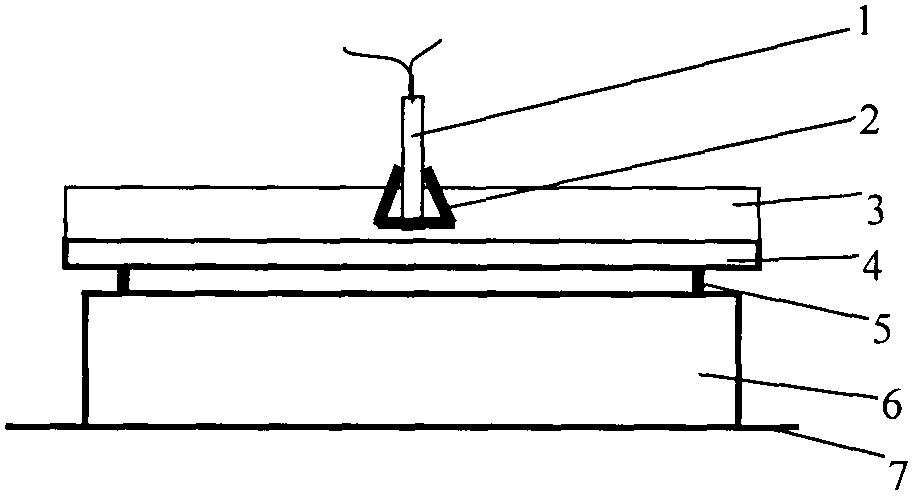

[0025] The energy gathering cover adopts such as figure 1 The cone shown is made of PVC plastic, and the diameter of the upper cone is (equivalent to the outer diameter of the detonator used), the diamet...

Embodiment 2

[0029] TA1 titanium plate and Q235 carbon steel plate are explosively welded, and the base plate and double plate are ground and polished with grinding wheels and cloth wheels. The base and doubler plates are installed in parallel, and the detonation point is located in the center of the plate surface.

[0030] The composite plate material is TA1 titanium plate, and the size of the plate surface is 5×1200×1500mm;

[0031] Substrate material is Q235 carbon steel plate, board size: 20×1160×1460mm;

[0032] The explosive is powdery expanded ammonium oil explosive, and the detonation velocity is 1800-2000m / s after adding inert materials.

[0033] The drug distribution process adopts the uniform drug distribution method, and the drug distribution height is 45mm.

[0034] The energy gathering cover adopts such as figure 1 The cone shown is made of wood and the diameter of the upper cone is (equivalent to the outer diameter of the detonator used), the diameter of the lower cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com