Tungsten alloy and preparation method thereof

A tungsten alloy and alloy technology, applied in the field of tungsten alloy materials and their preparation, can solve the problems of good elongation, poor diffusivity, and low density of materials, and achieve the effect of expanding the scope of application and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

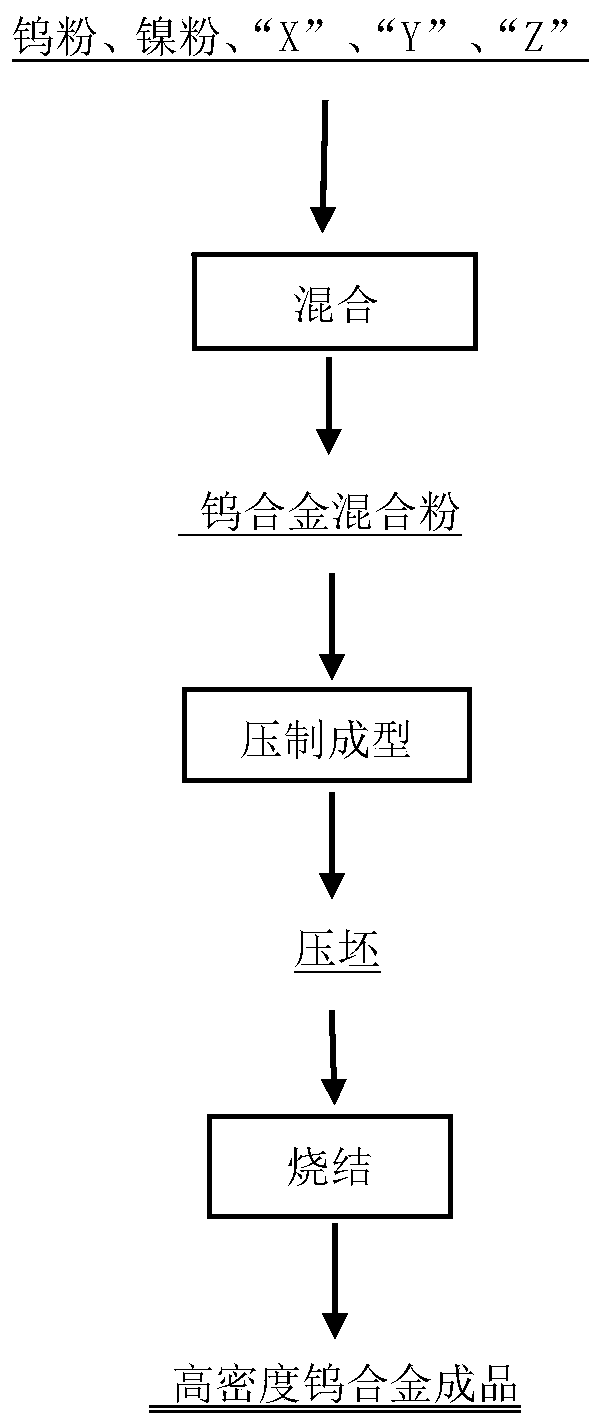

[0038] A kind of preparation method of high-density tungsten alloy for high aftereffect armor-piercing projectile core, such as figure 1 , including the following steps:

[0039] Step 1: Mixing of tungsten alloy powder

[0040] The components and their contents in terms of mass percentage are: W: 94.5%, Ni: 4.0%, Fe: 0.05%, Al 2 o 3 : 0.05%, Cr 3 C 2 : 0.3%, TiC: 0.4%, WC: 0.7%, wherein: "X" component content: 0.05%; "Y" component content: 0.05%; "Z" component content: 1.4%. Put the powders of each component into the V-shaped mixer according to the above mass percentages, and mix for 24 hours.

[0041] Step 2: Compression molding

[0042] Put the uniformly mixed tungsten alloy mixed powder into the mold, and press it into a compact by hydraulic press or cold isostatic press.

[0043] Step 3: Sintering

[0044] Put the tungsten alloy compact into a molybdenum boat or a corundum boat. The filler is alumina powder. The boat is sintered in a hydrogen-protected molybdenum w...

Embodiment 2

[0047] Step 1: Mixing of tungsten alloy powder

[0048] The components and their contents in terms of mass percentage are: W: 96.4%, Ni: 0.2%, Cu: 0.9%, Co: 2.0%, Mn: 0.1%, ZrO 2 : 0.25%, SiO 2 : 0.1%; VC: 0.05%, wherein: "X" component content: 3.0%; "Y" component content: 0.35%; "Z" component content: 0.05%. Put the powders of each component into the V-shaped mixer according to the above mass percentages, and mix for 22 hours.

[0049] Step 2: Compression molding

[0050] Put the uniformly mixed tungsten alloy mixed powder into the mold, and use a hydraulic press or a cold isostatic press at a rate of 2.0 tons / cm 2 The pressing pressure is pressed into a compact

[0051] Step 3: Sintering

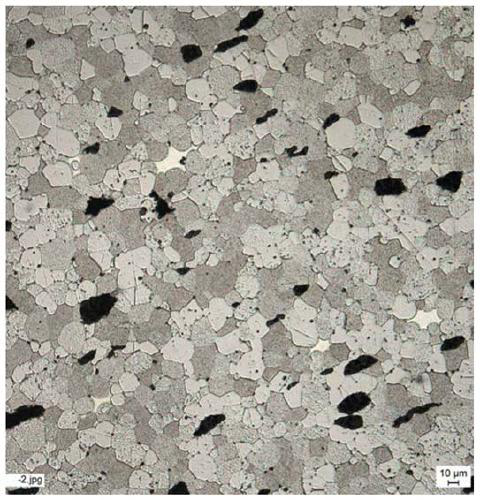

[0052] Put the tungsten alloy compact into a molybdenum boat or a corundum boat. The filler is alumina powder. The boat is sintered in a hydrogen-protected molybdenum wire heating furnace. The sintering temperature is 1500°C and the holding time is 1.0h. In the structure of the high-...

Embodiment 3

[0054] Step 1: Mixing of tungsten alloy powder

[0055] The components and their contents in terms of mass percentage are: W: 98.5%, Ni: 0.5%, Cr: 0.7%, Y 2 o 3 :0.1%;Cr 3 C 2 : 0.2%, of which: "X" component content: 0.7%; "Y" component content: 0.1%; "Z" component content: 0.2%. Put the powders of each component into the V-type mixer according to the above mass percentages, and mix for 20 hours.

[0056] Step 2: Compression molding

[0057] Put the uniformly mixed tungsten alloy mixed powder into the mold, and use a hydraulic press or a cold isostatic press at a rate of 2.5 tons / cm 2 The pressing pressure is pressed into a compact

[0058] Step 3: Sintering

[0059] Put the tungsten alloy compact into a molybdenum boat or a corundum boat. The filler is alumina powder. The boat is sintered in a hydrogen-protected molybdenum wire heating furnace. The sintering temperature is 1530°C and the holding time is 0.5h. In the structure of the high-density tungsten alloy materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com