Manufacturing method of composite sabot of armor-piercing bullet and sabot

A manufacturing method and technology of armor-piercing projectiles, which are applied in the directions of warheads, ammunition, weapon accessories, etc., can solve the problems of fully exerting fiber ability and high negative quality in the way of laying, and achieve light weight, high export speed, and high performance utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

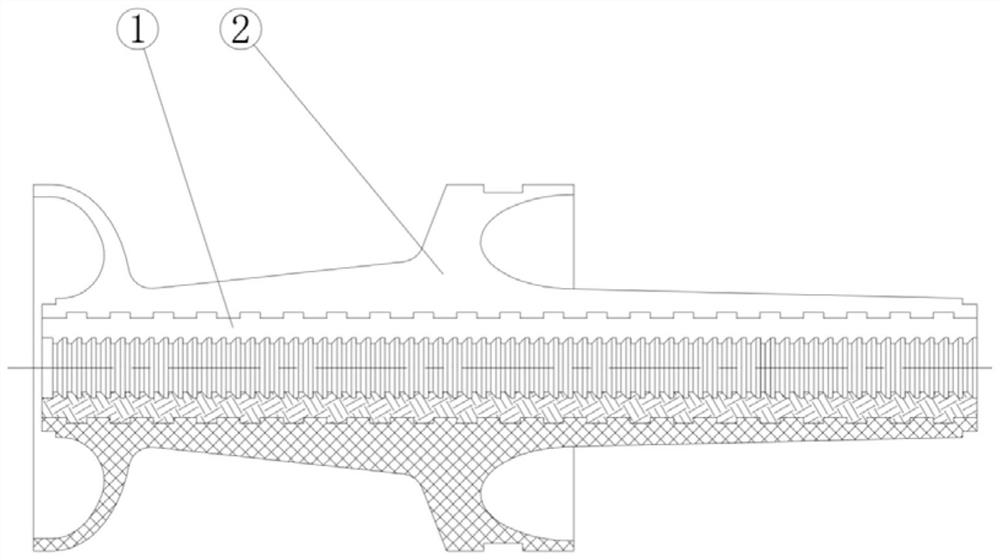

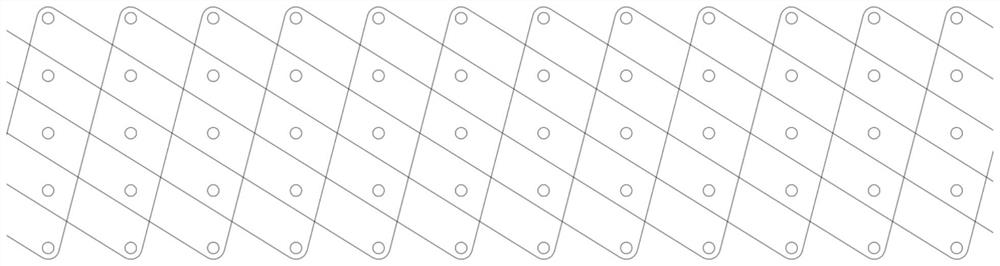

[0034] A method for manufacturing a composite armor-piercing projectile support flap, which mainly includes four parts: support core production, external side saddle injection molding, cutting and mechanical processing. The production of the support core uses a carbon fiber prefabricated body as the reinforcing material at the joint with the penetrating rod, and the high-strength support core 1 with internal teeth is produced through the RTM process. The specific method is: first, according to the outer contour of the penetrating body and the supporting surface The braided mandrel is made of graphite, and then a three-dimensional circular weaving preform of high-strength carbon fiber filaments is used on the graphite mandrel. During circular weaving, the inner warp yarn is pressed into the tooth groove of the graphite mandrel under the action of the tension of the weft yarn in the circular direction. Form a tight incarceration; before dipping, put support rings outside the pref...

Embodiment 2

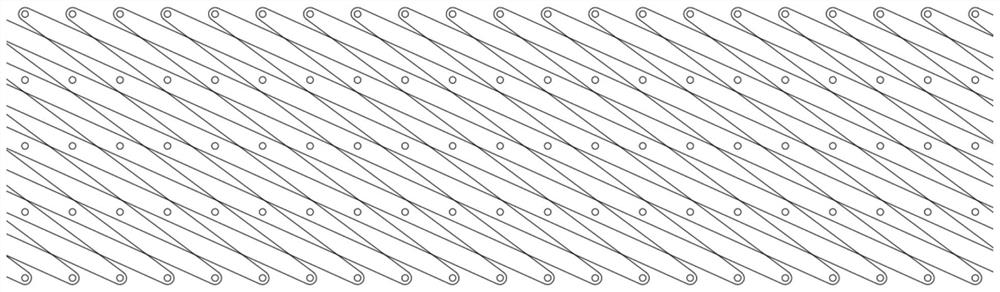

[0036] A method for manufacturing a composite armor-piercing projectile support flap, which mainly includes four parts: support core production, outer saddle molding, cutting and mechanical processing. The production of the support core uses the PBO fiber prefabricated body as the reinforcing material at the joint with the penetrating rod, and the high-strength support core with internal teeth is produced through the RTM process. The specific method is: first, according to the outer contour of the penetrating body and the supporting surface Use graphite to make the braiding mandrel, and then use PBO fiber filament three-dimensional circular weaving prefabricated body on the graphite mandrel. Specifically, it adopts a heavy backward structure with axial yarns. The warp yarn is pressed into the tooth groove of the graphite core shaft to form a tight incarceration, and the heavy back structure can significantly improve the single-directional effect of the warp yarn, making the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com