Air-cooled screw unit condenser structure and assembly method thereof

An air-cooled screw and condenser technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of poor heat exchange effect of condensers, and the length of heat exchange tubes is easily limited by expansion tube technology. The effect of small flow resistance, reduced length, and improved energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the purpose, technical solution and advantages of the air-cooled screw unit condenser structure and assembly method of the present invention clearer, the present invention will be further described in detail below in conjunction with specific drawings and specific embodiments.

[0051] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

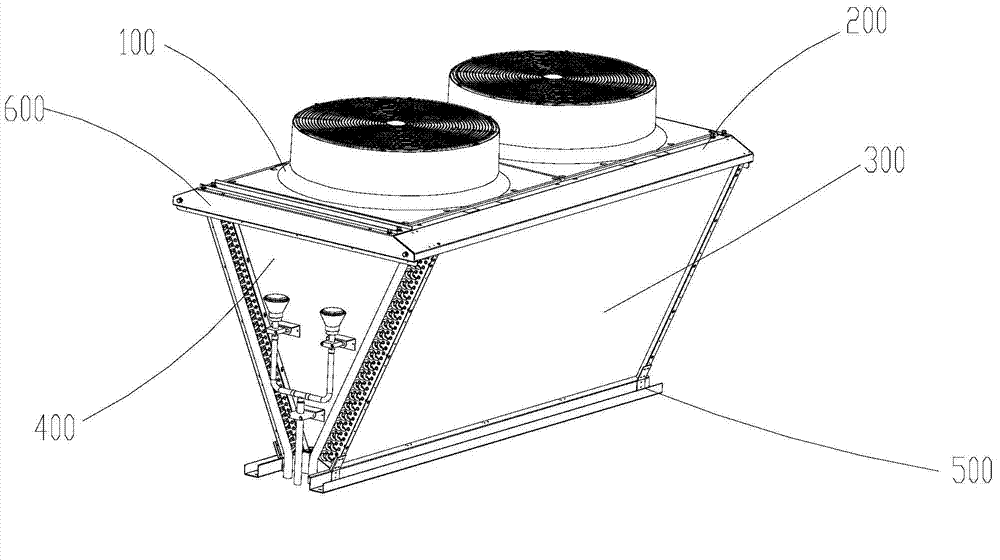

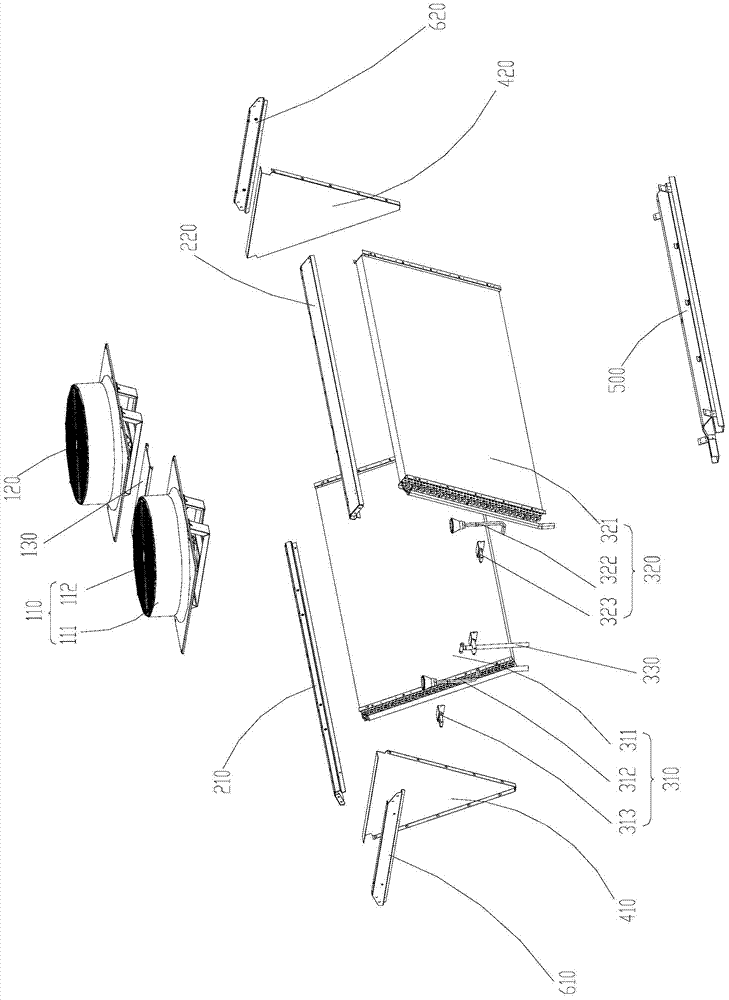

[0052] see figure 1, the present invention provides a condenser structure for an air-cooled screw unit, which includes a fan part 100, a fan mounting beam part 200, a condenser part 300, a windshield part 400, a water tray part 500 and a reinforcement plate assembly 600, wherein The fan part 100 is installed on the fan installation beam part 200, the condenser part is installed on the fan installation beam part 200, the windshield part 400 is installed on the condenser part 300 and the fan installation beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com