Ceramic-titanium alloy-PE composite bulletproof deck and preparation method thereof

A technology of bulletproof deck and composite deck, which is applied in the direction of protective equipment, protective equipment, armor plate structure, etc., and can solve problems such as poor bonding, large contact area, and easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

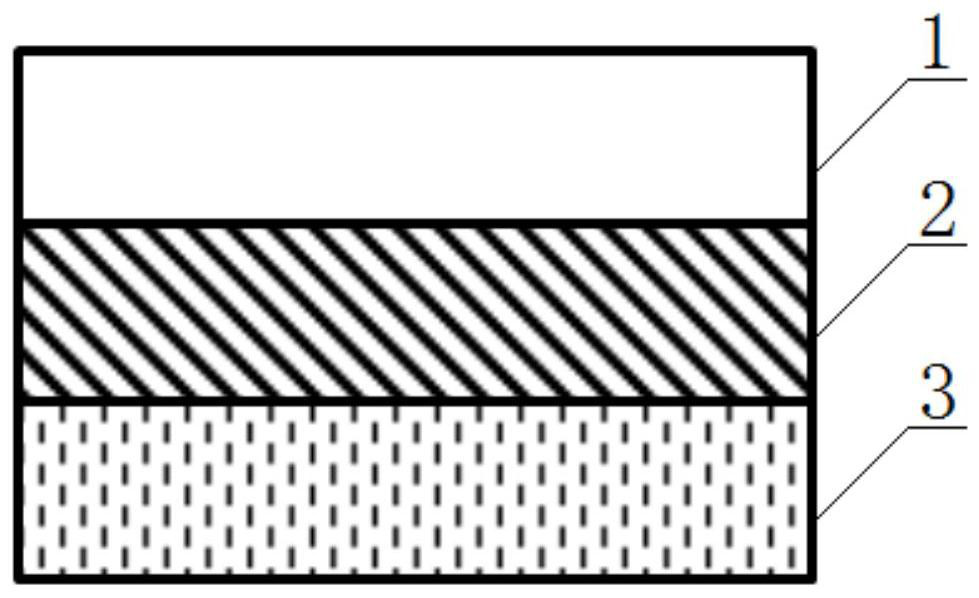

[0028] This embodiment relates to a method for preparing a veneer integral ceramic-titanium alloy-PE composite bulletproof deck, comprising the following steps:

[0029] S1, 250g of Ti-6Al-4V alloy powder with particle size distribution of 5-50μm and 25g of aluminum-coated nano-carbon fiber (Suzhou First Element CNTa, fiber length 5-20μm, diameter 50-200nm, fiber thermal conductivity greater than 1200W / ( m·k), the thickness of the aluminum coating layer on the fiber surface is 5-20nm), and stir and mix evenly to obtain titanium alloy composite powder;

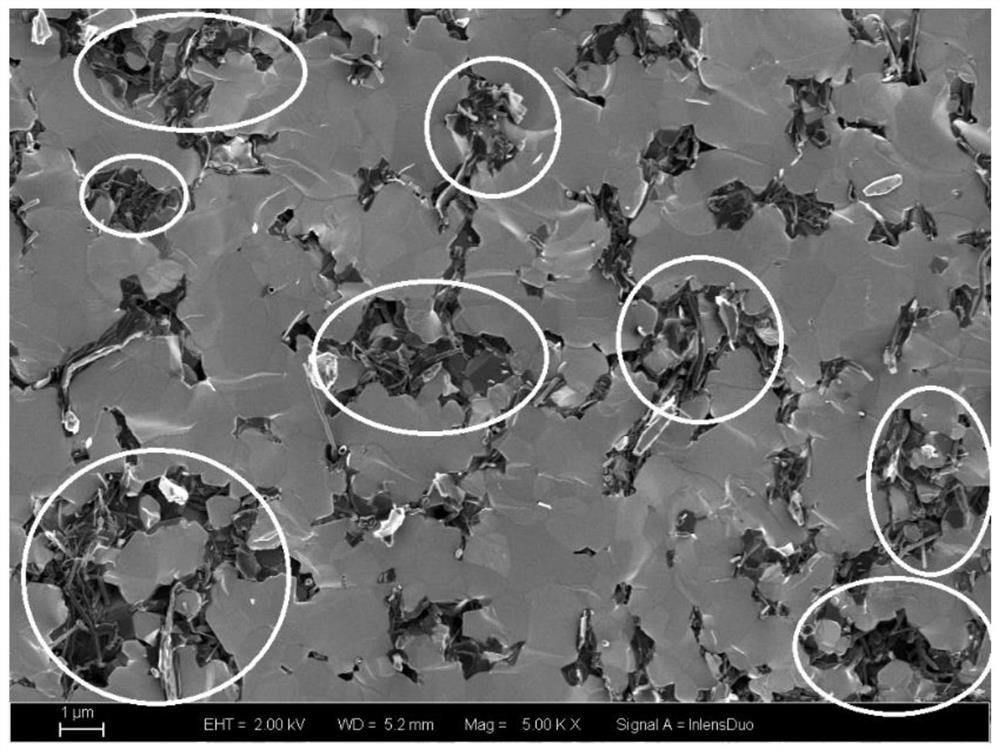

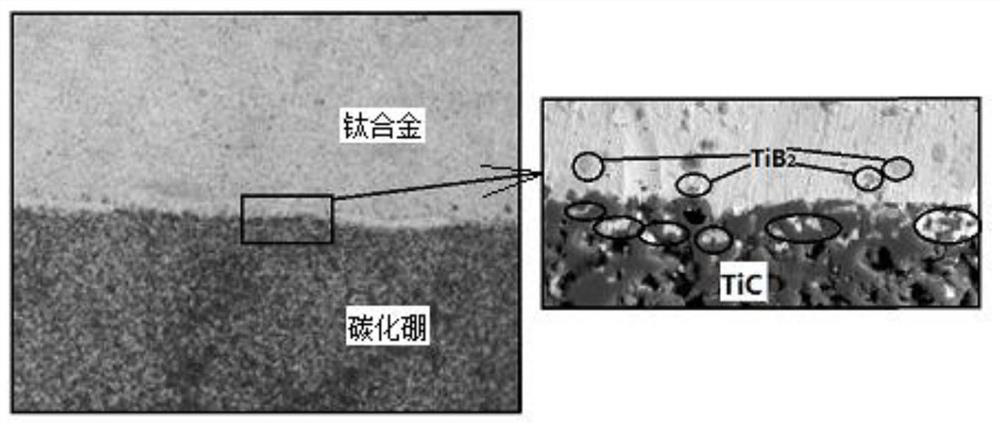

[0030] S2, spread the above-mentioned titanium alloy composite powder on the graphite mould, and then add a layer of nano-carbon fiber toughened boron carbide ceramic sheet (Suzhou First Element, density 2.47g / cm2) with a thickness of 10mm. 3 ), under the pressure of 1000℃ and 50MPa, keep it in a vacuum environment for 10 minutes, so that the titanium alloy composite powder can fully react with the nano-carbon fiber toughened b...

Embodiment 2

[0034] This embodiment relates to a method for preparing a honeycomb composite ceramic-titanium alloy-PE composite bulletproof deck, including:

[0035] Step 1, 250g of Ti-6Al-4V alloy powder with a particle size distribution of 0.5-50μm and 25g of aluminum-coated nano-carbon fiber (Suzhou First Element CNTa, fiber length 5-20μm, diameter 50-200nm, fiber thermal conductivity greater than 1200W / (m·k), the thickness of the aluminized layer on the surface of the fiber is 5-20nm) and stir and mix evenly to obtain a titanium alloy composite powder;

[0036] Step 2, spread the above-mentioned titanium alloy composite powder in a graphite mold with a curved surface, and then add a layer of regular hexagonal nano-carbon fiber toughened nano-carbon fiber toughened boron carbide ceramic sheet with a thickness of 10mm (Suzhou First Element , density 2.47g / cm 3 ), at 980°C and 50MPa pressure, in an argon environment for 10 minutes; during this process, nano-toughened titanium alloy powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com