Armor-piercing projectile and its preparation method

A technology for armor-piercing projectile cores and bullets, which is applied to warheads, ammunition, weapon accessories, etc., and can solve problems such as not considering the impact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

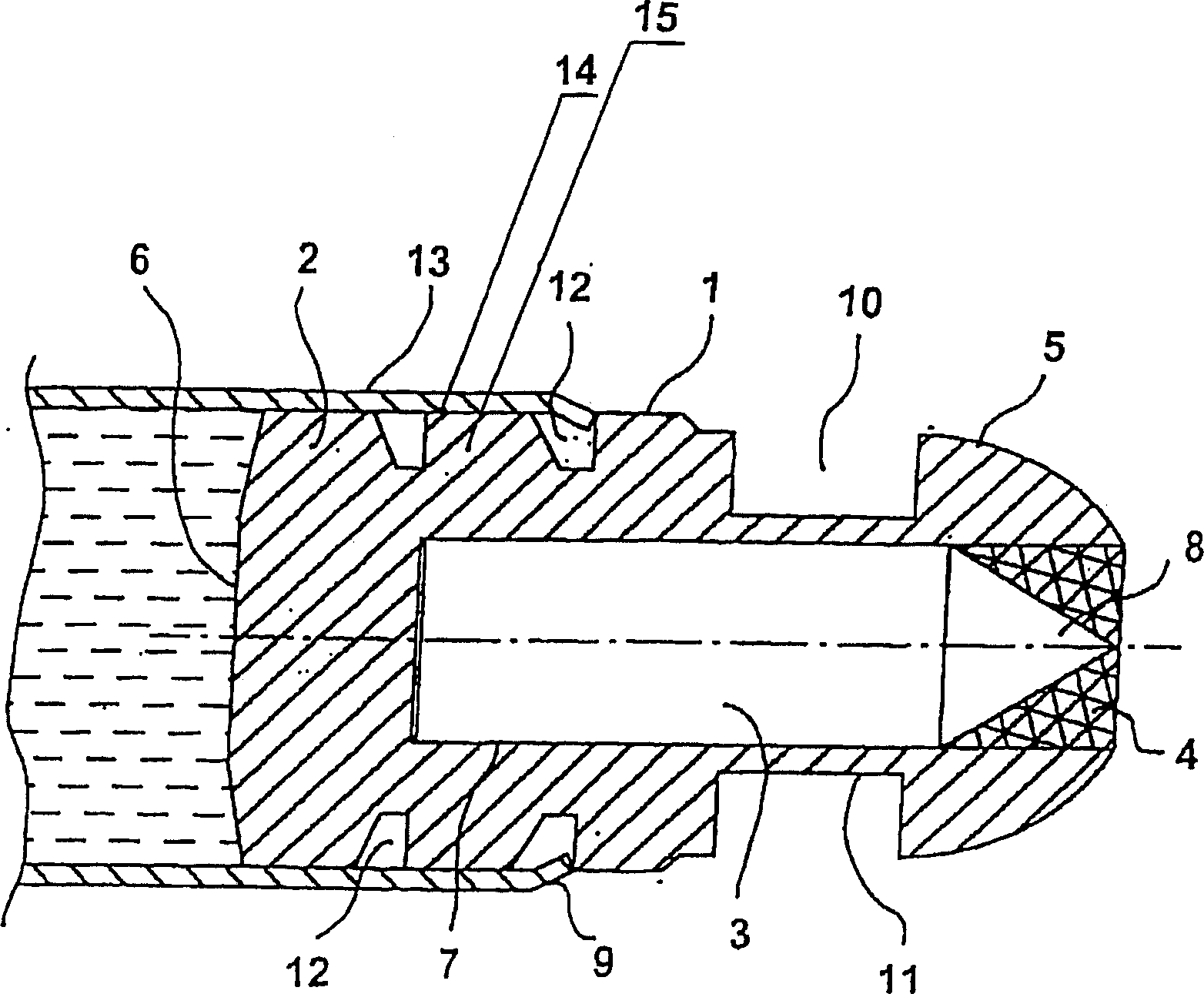

[0017]The armor-piercing projectile 1 comprises a cylindrical body 2 usually made of brass, light metal elements, plastics, etc., which is placed with clearance and in a predetermined position inside a case 13 having a corresponding size. The body 2 is inseparably attached to the casing 13 in a conventional manner, usually rolled or coated. During the production of body 2 its initial outer reference diameter is larger than when completed. At its rear (relative to the direction of movement of the cartridge 1 after being fired from the gun), preferably inside the cartridge case 13, the outer surface of the body 12 is provided with radial or helical cuts (usually one to three cuts). ). The cutouts 12 are spaced apart from each other by the guide surfaces of the cylindrical part of the body 2 of the cartridge 1 for guiding the cartridge 1 in the bore of the barrel for its rotation in the barrel. The cutouts 12 can be produced by various methods, such as cutting, rolling, extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com