Non-expanding modular bullet

a modular bullet and bullet platform technology, applied in the field of bullets, can solve the problems of high cost and damage to the target, and achieve the effect of reducing the necessary tooling requirements and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] While this invention may be embodied in many different forms, there are described herein various embodiments of the invention. This description is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiments illustrated.

[0031] The term “non-expanding” as used herein is intended to describe a bullet capable of impacting soft tissue without experiencing a substantial deformation or an appreciable increase in the diameter of the bullet.

[0032] For the purposes of this disclosure, like reference numerals in the Figures shall refer to like features unless otherwise indicated.

[0033] In some embodiments, the invention may comprise a modular bullet platform from which a plurality of non-expanding bullet types may be manufactured. In some embodiments, the invention may comprise a method of manufacturing non-expanding bullets using a modular bullet platform.

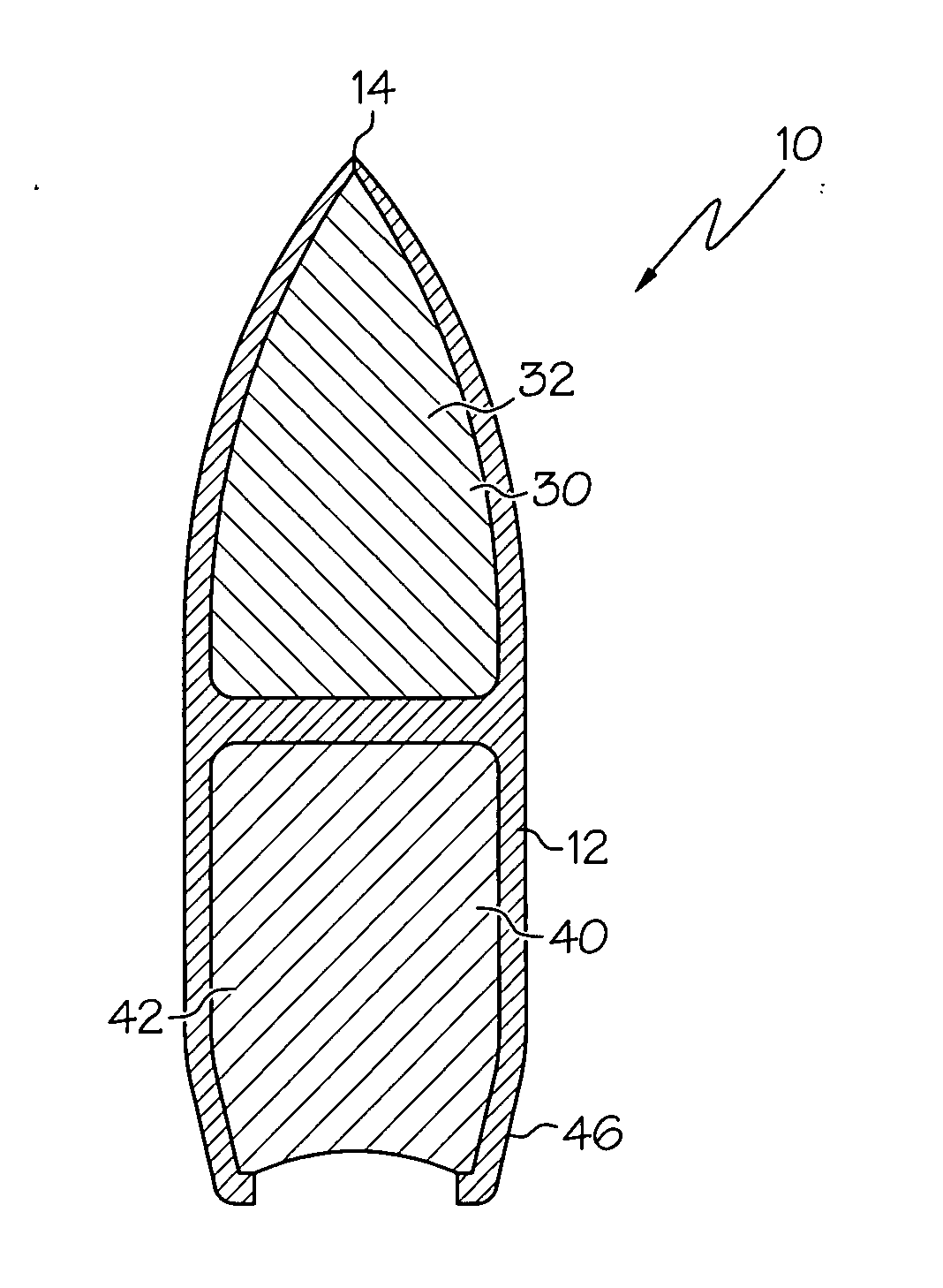

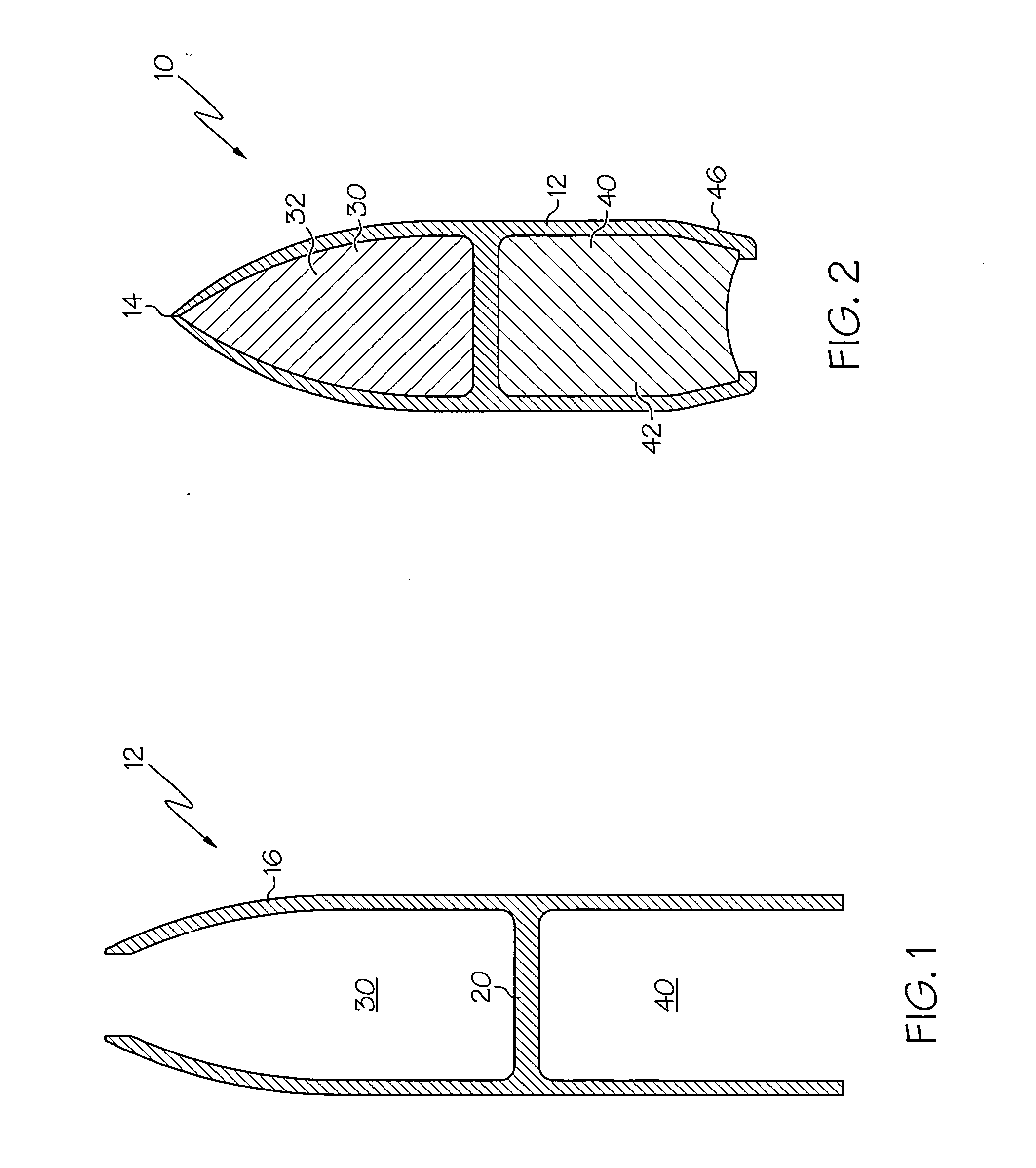

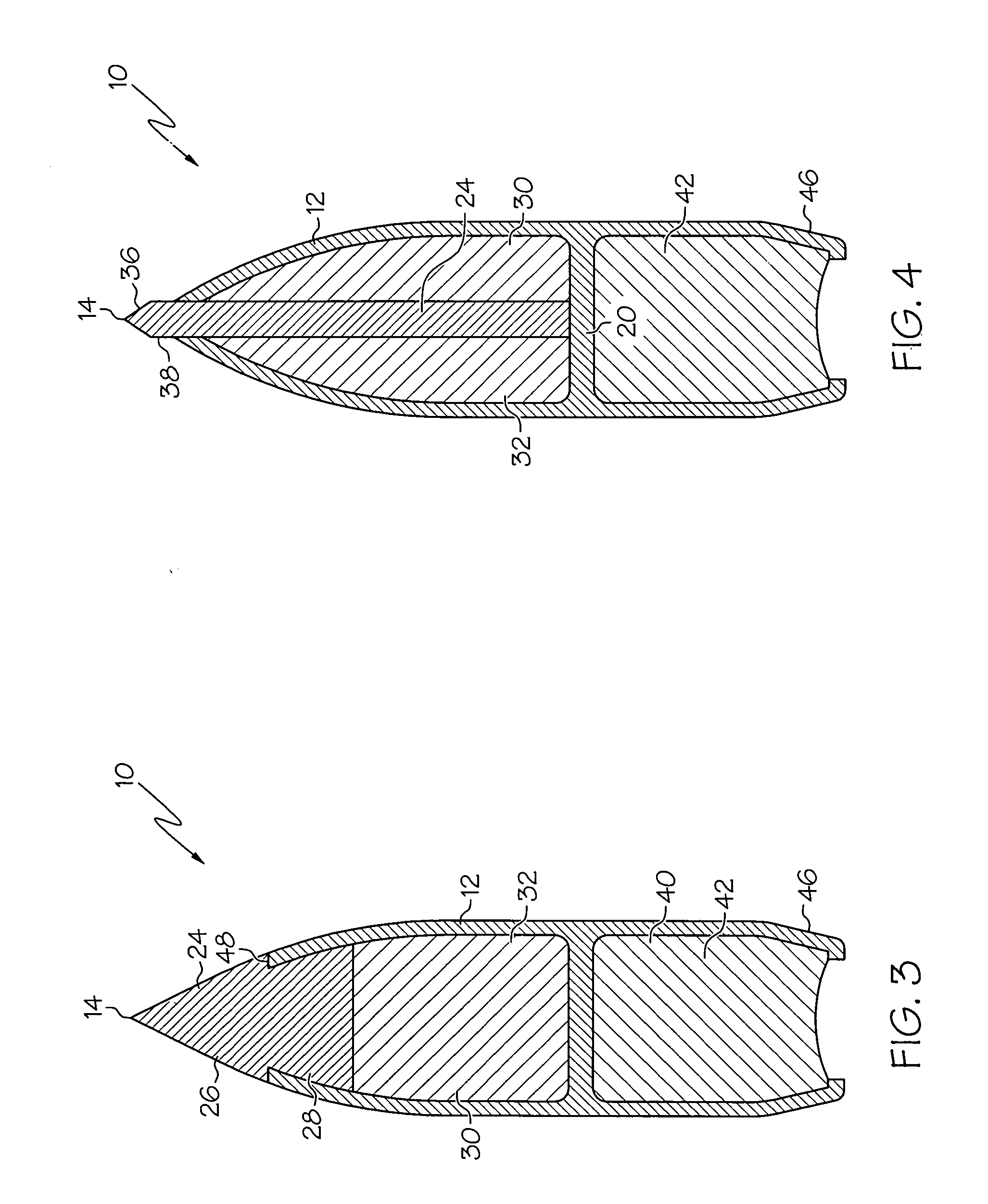

[0034]FIG. 1 shows an embodiment of a modular bullet jacket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com