Gradient aluminum-based composite material for resisting 30 mm armor-piercing bullet and preparation method of gradient aluminum-based composite material

An aluminum-based composite material and composite material technology are applied in the field of anti-30mm armor-piercing projectile gradient aluminum-based composite materials and their preparation, which can solve the problems of poor resistance to multiple elastics and large thickness, and achieve reduced strength, low areal density, and target reduction. Effects of plate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

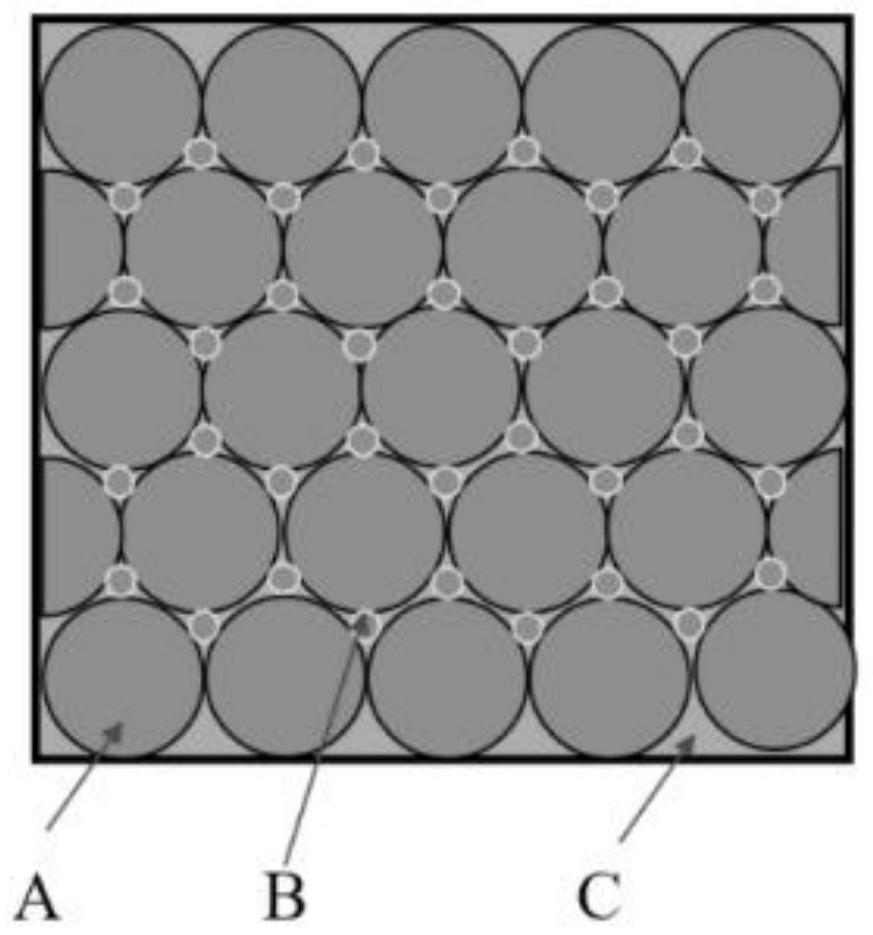

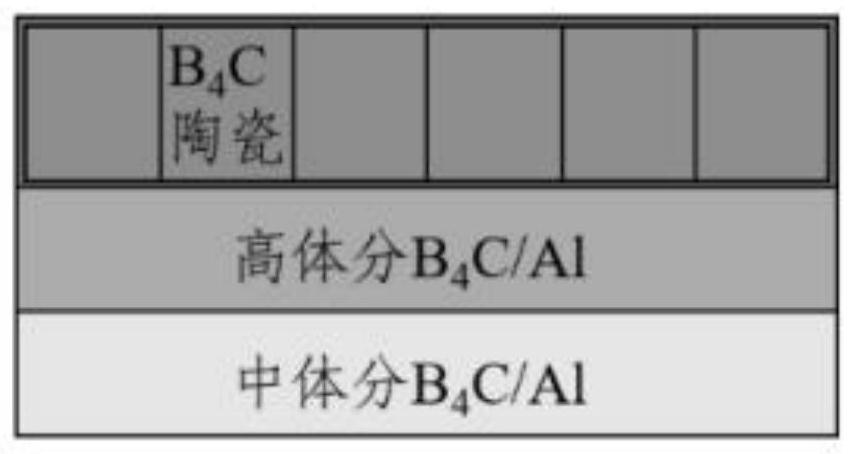

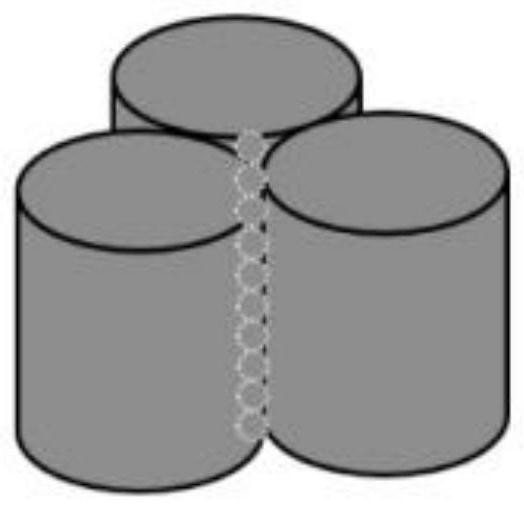

[0018] Specific implementation mode 1: In this implementation mode, a kind of anti-30mm armor-piercing projectile gradient aluminum matrix composite material has a three-layer gradient structure; the outer layer is densely packed ceramic cylinders, ceramic spheres and B 4 C is an aluminum-based composite material reinforced by ceramic powders, the ceramic spheres are filled in the column gaps of closely packed ceramic cylinders, and the overall volume fraction of ceramic phases in the outer layer is greater than 90%; the middle layer is a high volume fraction B 4 C / Al composite material, in which the volume fraction of the ceramic phase is 60-75%; the inner layer is a medium volume fraction of B 4 The C / Al composite material, wherein the volume fraction of the ceramic phase is 25-55%; the gradient aluminum-based composite material resistant to 30mm armor-piercing projectile is prepared by pressure infiltration and integrated, and has a metallurgical bonding interface.

[0019...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the material of the ceramic cylinder and the ceramic sphere is B 4 C or SiC, and the ceramic cylinder and ceramic sphere are made of the same material. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: the ceramic cylinder is a regular cylinder or a cylinder with a curved end; the height is 15-20mm, and the length-to-diameter ratio is 0.5- 1.5. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com