Boron carbide ceramic and preparation method and application thereof

A technology of boron carbide ceramics and boron carbide powder, which is used in offensive equipment, protective equipment, and the structure of armor plates, etc., can solve the decline in the hardness and bending strength of ceramics, weaken the ability of boron carbide bulletproof ceramics to strike multiple times, and is difficult to achieve. Problems such as uniform dispersion and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

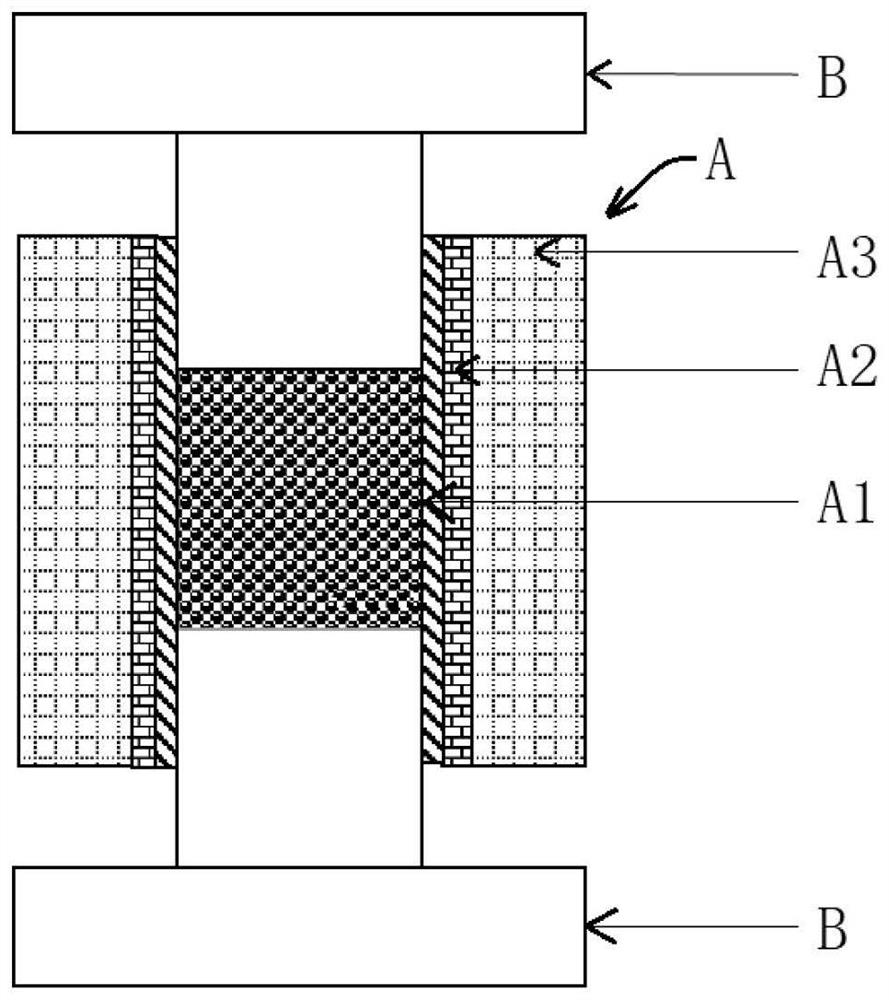

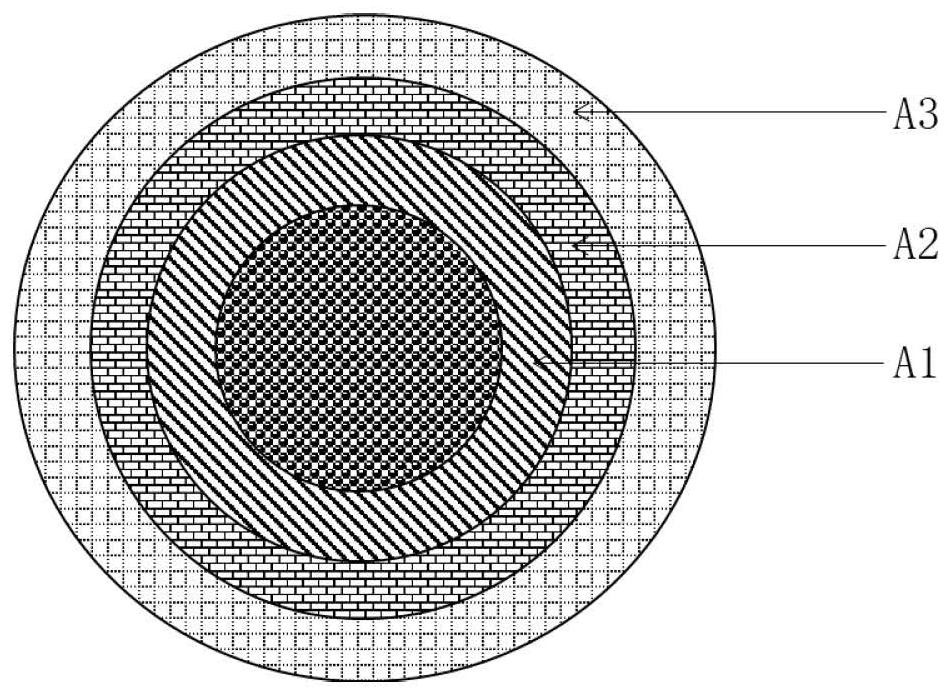

[0029] use Figure 1a and Figure 1b The device shown sinters boron carbide ceramics. The mixture of boron carbide powder and carbon nanotubes is placed in a sintering mold A, and the electrode pressure heads B at both ends are pressed tightly, and then sintered. The sintering container A is provided with graphite foil A1, boron nitride layer A2 and carbon fiber composite layer A3 sequentially from inside to outside in the radial direction.

[0030] The present embodiment relates to a process of flash firing-plasma sintering boron carbide ceramics, comprising the following steps:

[0031] Step 1, take 1.75 kg of boron carbide powder with a particle size of 0.5-25 μm, and 0.25 kg of carbon nanotubes (Suzhou First Element) with a length of 5-20 μm and a diameter of 10-200 nm, and mix them thoroughly to make a mixed material. The volume ratio of boron carbide powder to carbon nanotubes reaches 85:15;

[0032] Step 2, flash firing-plasma sintering mixed materials to obtain boron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com