Patents

Literature

111results about How to "Protection strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

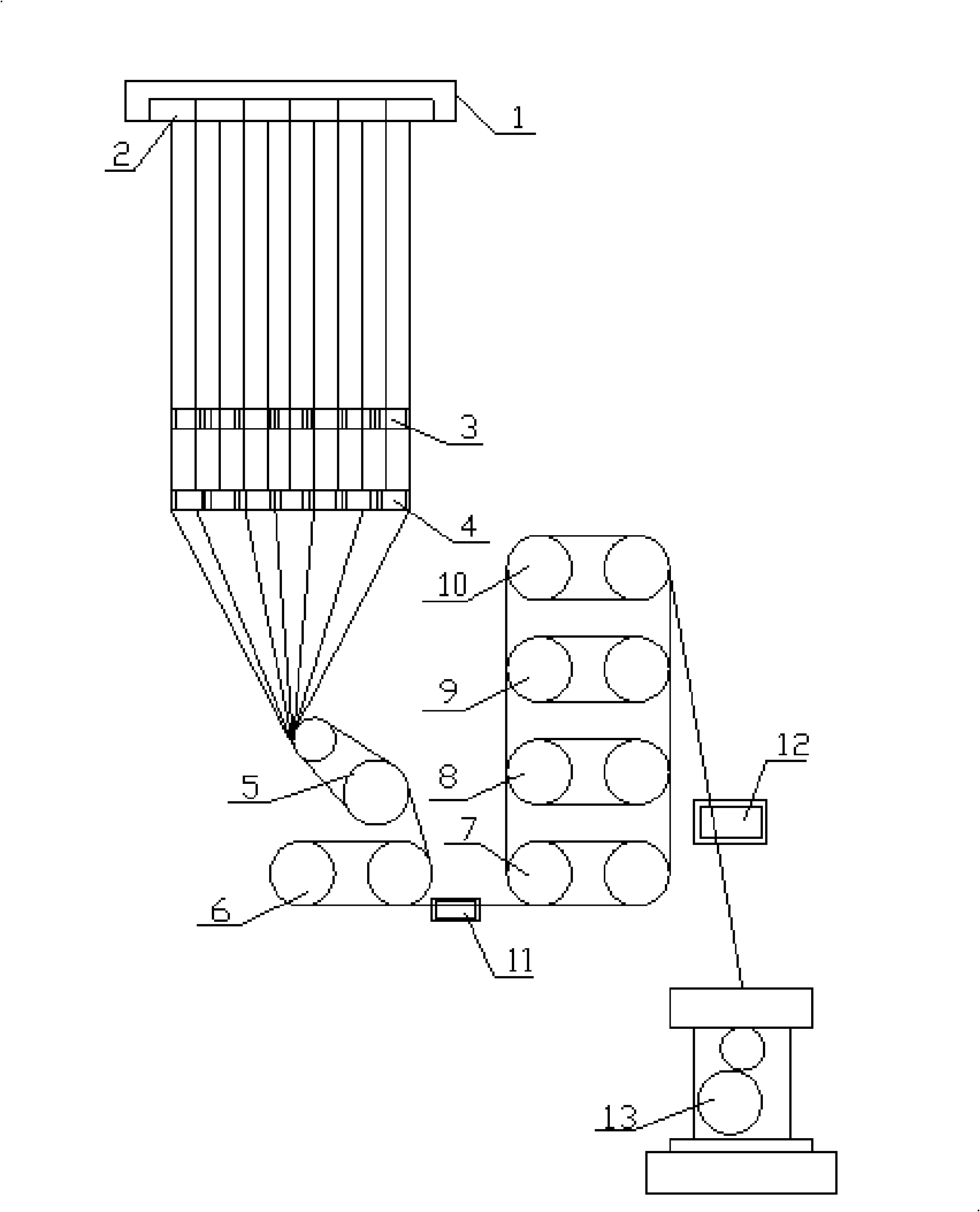

One-step method production process of ultra-low contract terylene industry fiber

ActiveCN101407942AGuaranteed uniformityLow Dry Heat ShrinkageMelt spinning methodsFilament-forming treatmentSolid phasesMelt spinning

The invention discloses a one-step production technology of ultra-low shrinkage terylene industrial fibers, which comprises the steps as follows: A. the preparation of high-viscosity chips: the high-viscosity chips with the viscosity of 0.99 plus or minus 0.015 are obtained by the solid phase polymerization of low-viscosity chips; B. melt spinning: the high-viscosity chips are extruded by melting by a screw extruder in a spinning manifold, spun by a spinning component, and shaped by lateral blowing cooling, and pump oiling is carried out by adopting an ester leveling agent with the kinematic viscosity of 20 to 60mm<2> / s at the temperature of 30 DEG C, and the oiling rate is 0.6 plus or minus 0.15 percent; C. heat setting by drawing: heat setting by drawing is carried out firstly by a pre-tension roller, and sequentially by two groups of drawing rollers and three groups of hot rollers for shaping; and D. shaping by winding: products can be obtained by winding by a winding head after the obtained fibers pass through a main network device. In the invention, not only the technology has high production efficiency, but also the dry heat shrinkage value of the obtained ultra-low shrinkage terylene industrial fibers is low and has high strength and excellent combination property.

Owner:ZHEJIANG UNIFULL IND FIBER

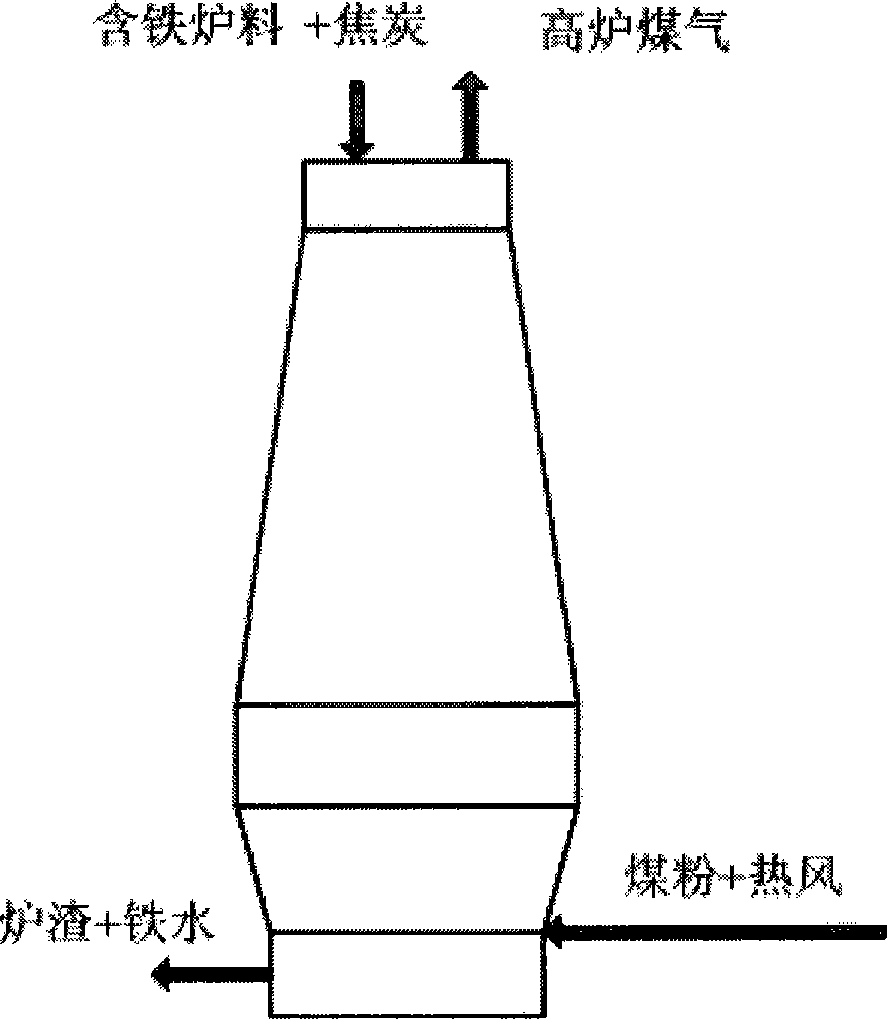

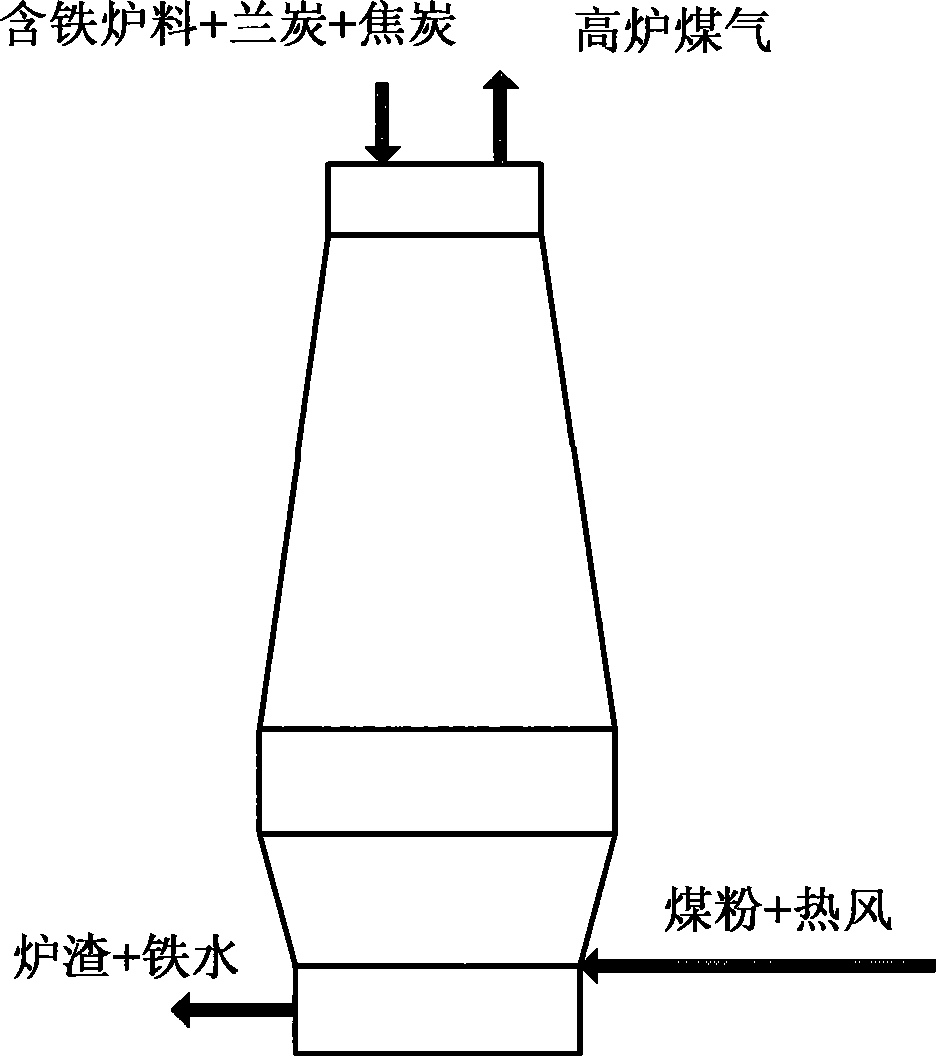

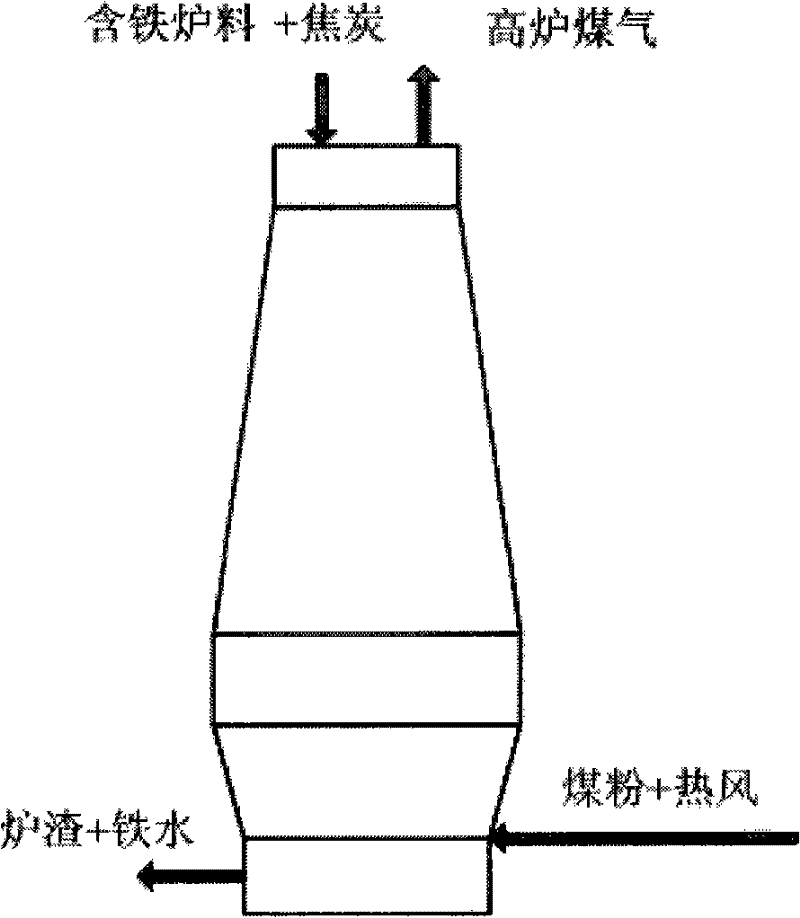

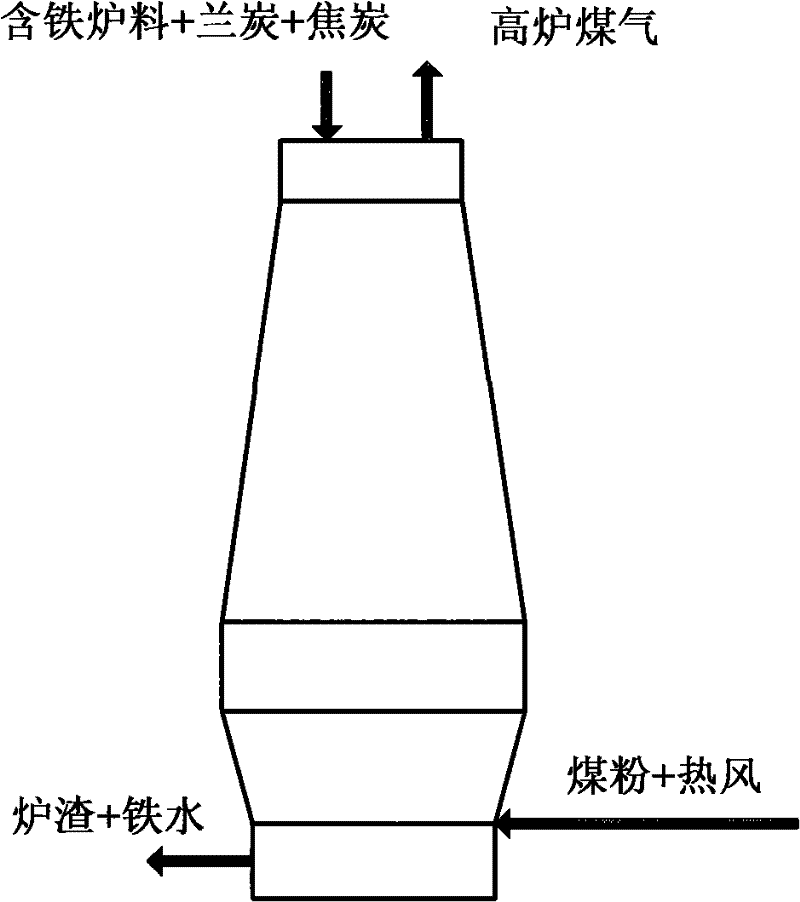

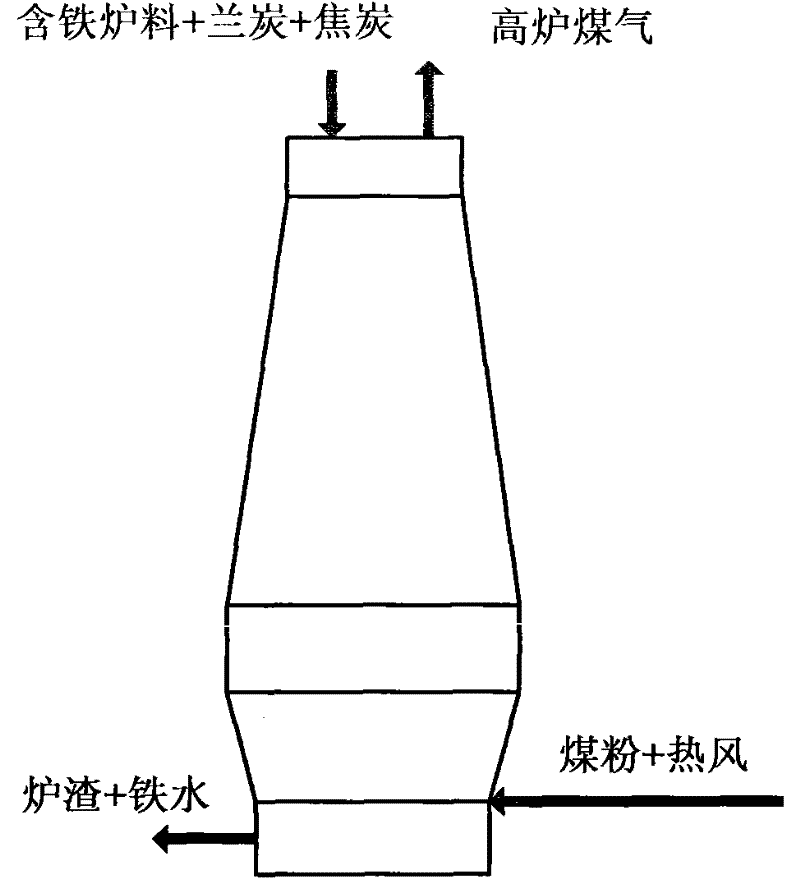

Blast furnace iron manufacturing process

InactiveCN101476002APromote reductionImprove economyBlast furnace detailsSmelting processBlast furnace

The present invention provides a blast furnace iron-smelting method, including: a first step, loading coke, semi-coke and other iron-contained charging stock into the blast furnace, wherein, the semi-coke has a scheduled weight ratio in the coke and semi-coke; and a second step, performing conventional iron-smelting operations after the loading. The method can use semi-coke to replace part of coke, thus can reduce the amount of coke in the blast furnace iron-smelting process.

Owner:BEIJING ZHONGDIAN HUAFANG TECH +1

Grass type un-bleaching pulp, preparation method and use thereof

ActiveCN101451322AProtection strengthLow priceCellulosic pulp after-treatmentDigestersCelluloseKappa number

The invention discloses grass unbleached pulp and a preparation method thereof. The fracture length of the unbleached pulp is between 3.48 and 7.2km, the folding resistance is between 15 and 70 times, the tearability is between 180 and 275 mN, the whiteness is 33 to 48 percent ISO, and the beating degree is between 33 and 38 DEG SR. The unbleached pulp can be taken as pulp of corrugated paper, napkin paper and packing paper. The preparation method comprises the steps of cooking, oxygen delignification and so on, and the unbleached pulp is obtained by obtaining high-hardness pulp the hardness of which has a potassium permanganate value of between 16 and 28 and is equivalent to a Kappa number of between 24 and 50 through the cooking, and then performing oxygen delignification treatment by introducing oxygen and adding sodium hydroxide, or being matched with a pulp squeezing step and / or a disintegration step before the oxygen delignification. The use of the method can not cause the unbleached pulp to be polluted by a bleaching agent, and the strength of the pulp is protected at the same time, thereby preventing cellulose in the pulp from being degraded due to the influence of bleaching.

Owner:SHANDONG TRALIN PAPER

Method for preparing environment-friendly paper pulp by utilizing biological enzyme and production technique thereof

InactiveCN101139804AReduce manufacturing costReduce energy consumptionCellulose material pulpingFiberLacquer

The invention discloses a method and relevant production techniques to produce environmental protection type paper pulp with biologicall zyme. The invention is characterized in that, after pulp-prepration raw materials are cut into pieces or processed through rough cutting, paint zyme and lignin zyme is put into raw material soaking tank to degradate lignin. The purposes are to lower molecule quality lignin, increase resolving and fractionated capacity of lignin, fulfill separation of lignin cellulose from semi-cellulose. Meanwhile, adopt such methods aas mechanical twisting, grinding and pulp-beating, pulp grinding, screw pressing, fiber loosening, fine pulp regulation, fine screening and etc., so as to reach the following technical targets: Low production cost of paper pulp, high perfect pulp concentrate, no polluted drainage, simple technique and advanced method. Therefore, the invention can be widely utilized in paper pulp preparation technologies in paper-making industry.

Owner:李增鹏

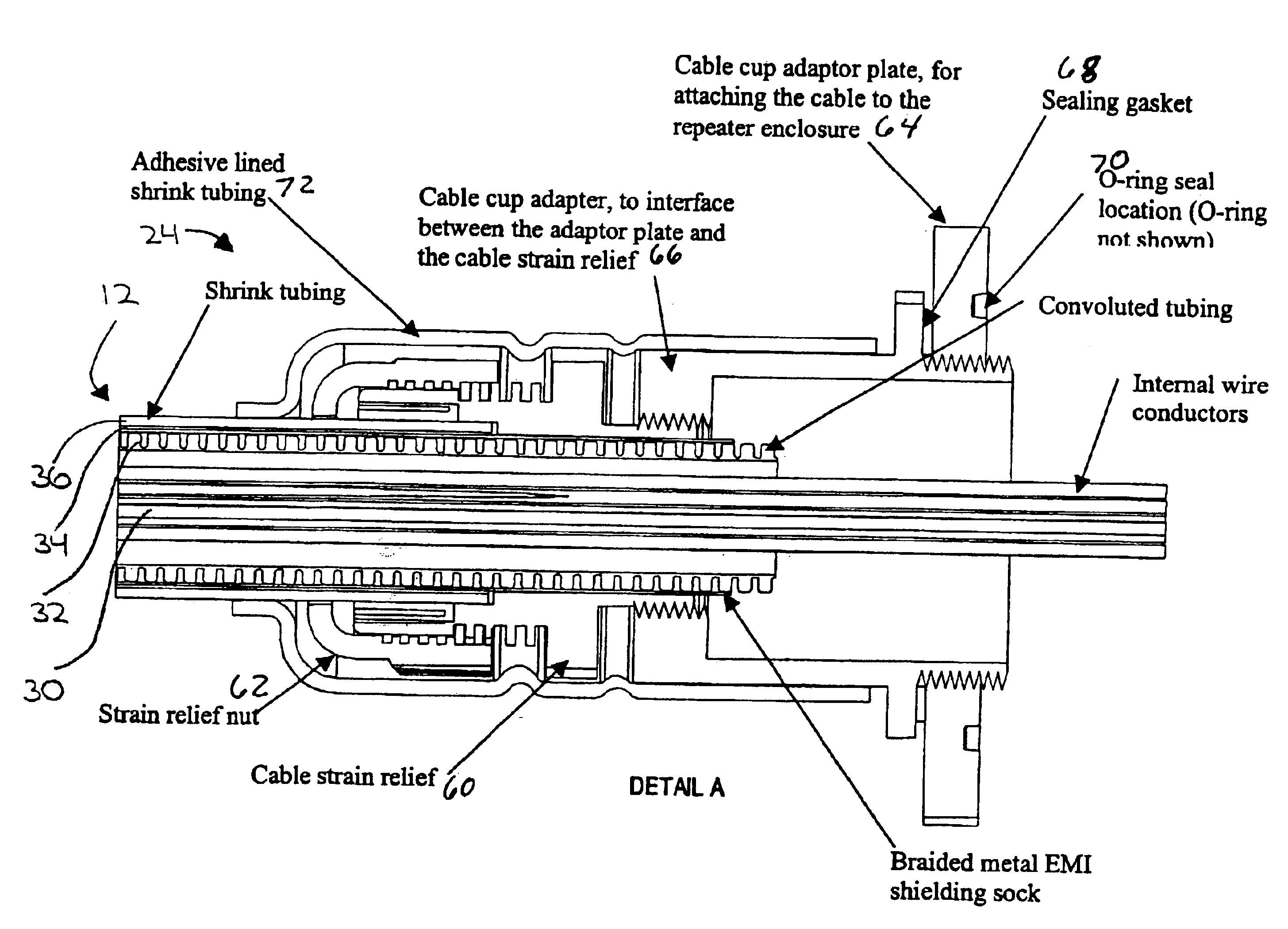

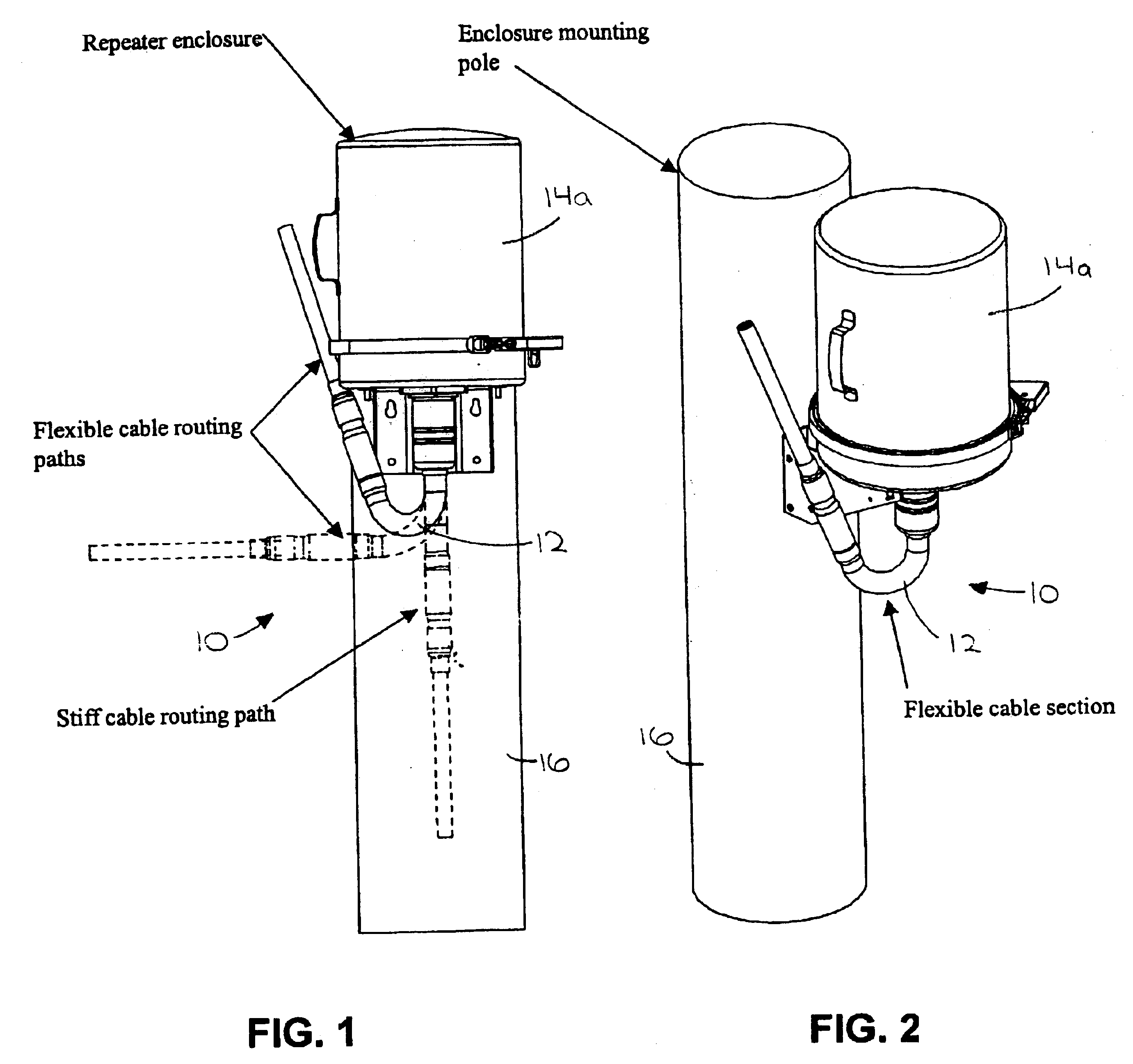

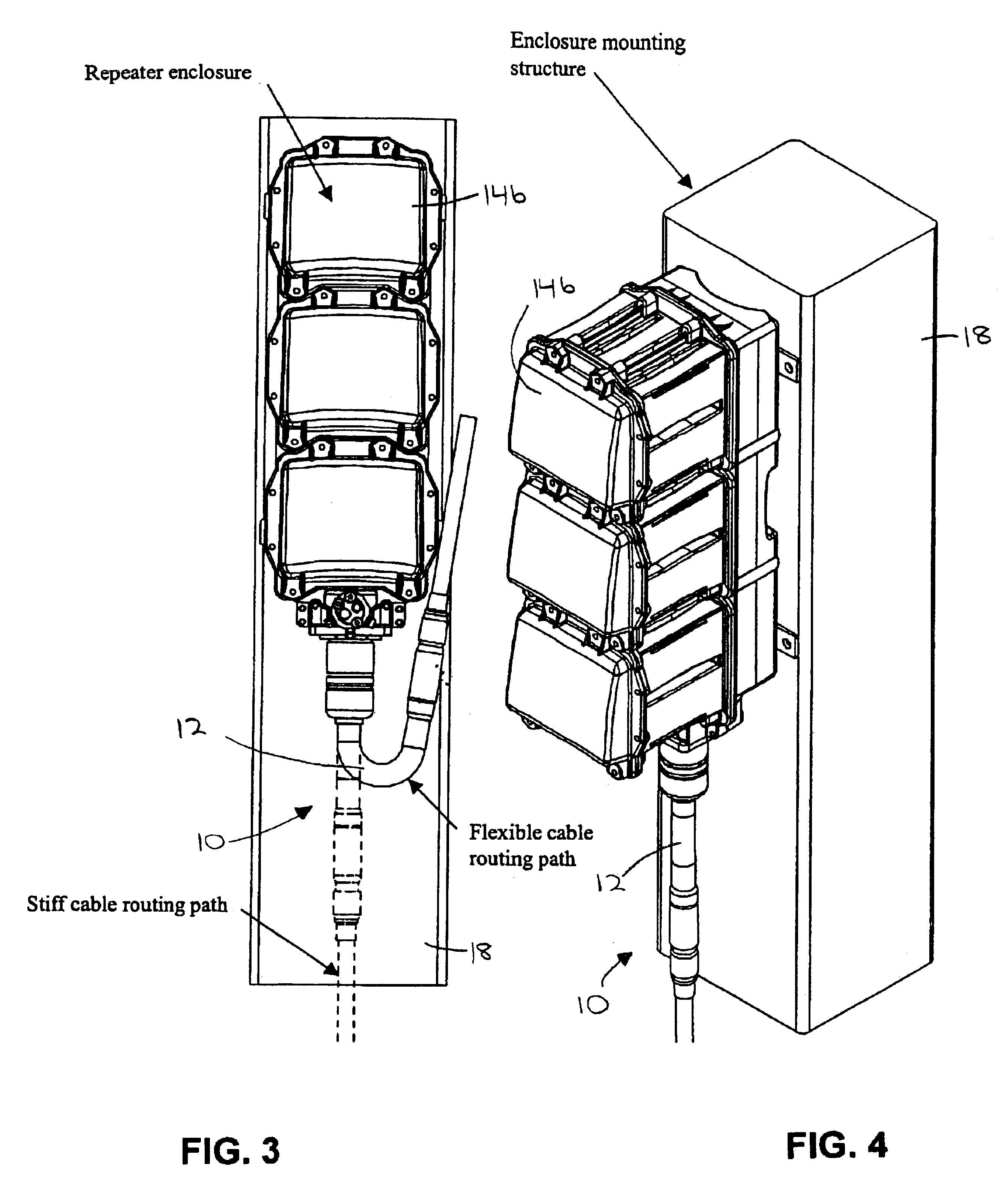

Flexible telecommunications cable for outside plant equipment

InactiveUS6870106B1Increase flexibilityFacilitates accommodating alignmentElectrically conductive connectionsCable junctionsElectrical conductorTelecommunications cable

A telecommunications cable section (12) for connection with telecommunications or signaling equipment or other outside plant equipment, wherein the cable section (12) comprises a plurality of conductors (30) surrounded by an intermediate layer of corrugated material (32). A flexible braided or mesh protective sheathing (34) substantially surrounds the intermediate layer (32). The braided sheathing (34) is preferably a braided or mesh sock or tubular sleeve or sleeve of copper or other metal or material. An exterior layer of substantially moisture-proof shrinkable tubing (36) substantially surrounds the braided sheathing (34).

Owner:SPECIAL PRODS

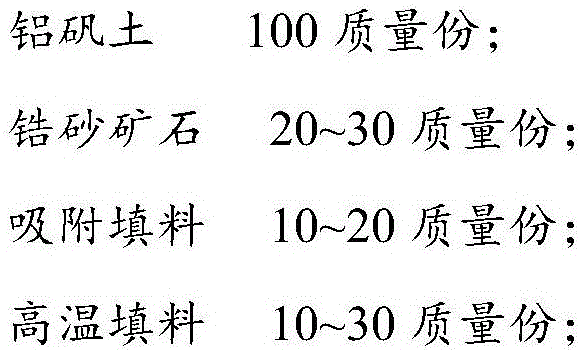

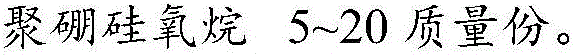

High-temperature resisting foundry sand and preparation method thereof

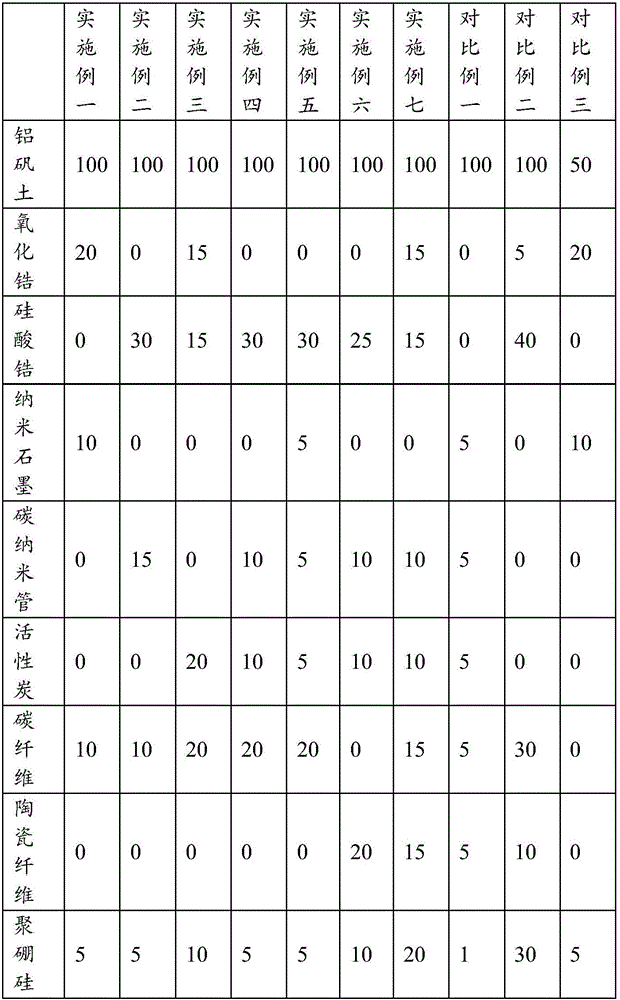

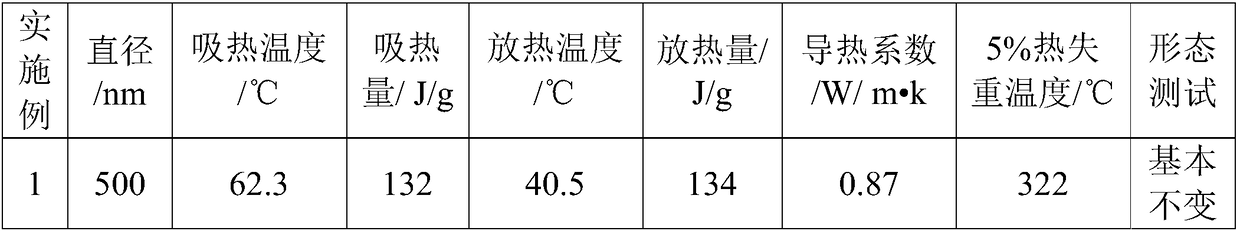

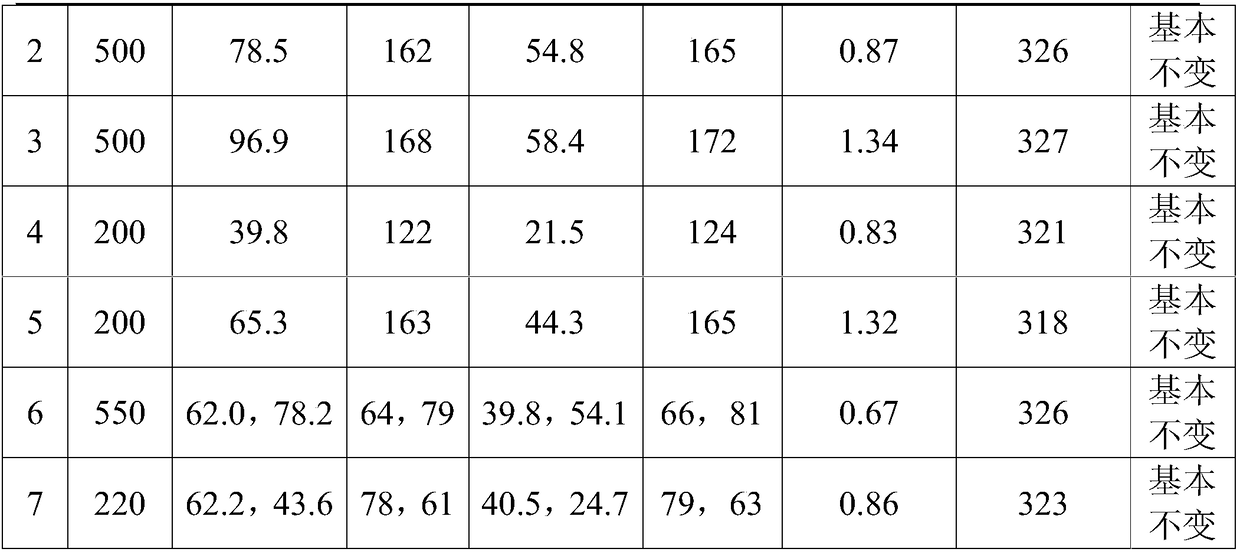

The invention aims to provide high-temperature resisting foundry sand. The high-temperature resisting foundry sand comprises the following components in parts by weight: 100 parts of bauxite by mass, 20-30 parts of zircon sand ores by mass, 10-20 parts of absorption fillers by mass, 10-30 parts of high-temperature fillers by mass, and 5-20 parts of polyborosiloxane by mass; and the prepared high-temperature resisting foundry sand is excellent in high-temperature resistance, is used for casting an alloy at a temperature of 2000-2500 DEG C, and obtains an excellent effect. The invention also aims to provide a preparation method of the high-temperature resisting foundry sand; and the preparation method comprises the following steps: (1) the fillers are pretreated; (2) a mixture after treatment in the step (1) and bauxite are put in a ball mill for mixing; (3) the mixture in the step (2) is put in a ball former; and a proper amount of water is added in the ball former to pelletize to obtain a ball-shaped blank; and (4) the ball-shaped blank in the step (3) is put in a graphite crucible for high-temperature sintering and cooling to obtain the high-temperature resisting foundry sand.

Owner:WENLING NEWIMPETUS CASTINGANDMACHINING CO LTD

Method for producing sugar charcoal particle sugar charcoal by physical method

InactiveCN101503190ACaramel decolorization is goodImprove wear resistanceMonosodium glutamateInorganic compound

The invention discloses a method for producing sugar charcoal particles by using physical method. Ammonium polyphosphate and petroleum hard bitumen are added into coal property and proper exciple carbonized material and then crushed; the crushed material is kneaded after being added with coal tar and water solution containing inorganic compound to be extruded into strip material, and then the obtained material is dried, carbonized at 500-550 DEG C and activated at 850-950 DEG C. The obtained sugar charcoal particles have the technical performance of physical carbon and chemical carbon, and caramel has good decolourization and high abrasive resistance, so that the sugar charcoal particles can be widely applied for decolourization, water treatment and recovery of organic macromolecular solution, for example, the decolourization of citric acid, monosodium glutamate, lactic acid and starch sugar, the recovery of high boiling macromolecular organic solvents such as gasoline, dimethyl diamide, etc.

Owner:HUAIBEI DAHUA ACTIVE CARBON +1

Preparation method of wood pulp for long viscose fibers

InactiveCN102174753AFully refined and purifiedEasy to refine and purifyArtificial filaments from viscosePulping with inorganic basesChemical oxygen demandHemicellulose

The invention relates to a preparation method of wood pulp for long viscose fibers. The method comprises the preparation steps of material preparation, alkali liquor preparation, screw pressing, stewing, washing, impurity removing and pulp preparation, wherein alkali liquor preparation comprises the following steps of: controlling the temperature at 30-40 DEG C and then separately adding 1-2% of sodium hydroxide, 0.2-0.25% of a scouring agent, 1.5-2% of hydrogen peroxide, 0.1-0.2% of anthraquinone and 0.1-0.2% of bioactive complex hemicellulase relative to the quantity of oven dry pulp to prepare alkali liquor. The prepared wood pulp has high alpha cellulose content, high yield, good reaction property and low content of non-fiber impurities and conforms to the quality requirement of the preparation of long viscose fibers. The COD (chemical oxygen demand) content in the discharged wastewater is 1000-1200mg / l, therefore the method belongs to low pollution, thus reducing the environmental pollution.

Owner:山东银鹰股份有限公司

Preparation method of wood pulp for fibranne

InactiveCN102174752AFast degradationLye penetrationPulping with inorganic basesMaterials preparationChemical oxygen demand

The invention relates to a preparation method of wood pulp for fibranne. The method comprises a material preparation process, an alkali liquor preparation process, a spiral squeezing process, a stewing process, a washing process, an impurity removal process and a pulp copying process. The alkali liquor preparation process comprises the following steps of: controlling the temperature to be between 30 and 40 DEG C; and adding 3 to 4 percent of sodium hydroxide, 0.2 to 0.25 percent of boiling agent, 2.5 to 4 percent of hydrogen peroxide, 0.1 to 0.2 percent of anthraquinone and 0.1 to 0.2 percent of bioactivity complex enzyme according to oven dry stock amount respectively to obtain alkali liquor. The prepared wood pulp has high alpha cellulose content, high yield, high reactivity and low non-fibrous impurity content and meets the quality requirements of preparing fibranne; and by the method, the chemical oxygen demand (COD) content of discharged wastewater is 1,100 to 1,300 mg / l which belongs to low pollution, and pollution to the environment is reduced.

Owner:山东银鹰股份有限公司

Thermo-regulated nanofiber with rapid heat absorption and release functions and preparation method of thermo-regulated nanofiber

ActiveCN108360083AImprove structural stabilityImprove thermal stabilityMonocomponent synthetic polymer artificial filamentHeat-exchange elementsPolymer sciencePolyethylene glycol

The invention discloses a thermo-regulated nanofiber with rapid heat absorption and release functions and a preparation method of the thermo-regulated nanofiber. The fiber comprises a comblike polymerphase-change material and heat conductive particles, wherein the heat conductive particles are graphene, nano-silver, nano-titania, nano-silicon or a mixture of the substances; the comblike polymer phase-change material is selected from the following three groups: 1, polyacrylonitrile acrylic acid grafted with n-alkanol or polyethylene glycol; 2, polyacrylonitrile acrylic acid grafted with n-alkanol with two different molecular weights, polyacrylonitrile acrylic acid grafted with polyethylene glycol with two different molecular weights, or polyacrylonitrile acrylic acid grafted with n-alkanoland polyethylene glycol simultaneously; 3, two polyacrylonitrile acrylic acid-g-n-alkanols with different molecular weights, a mixture of two polyacrylonitrile acrylic acid-g-polyethylene glycols, ora mixture of polyacrylonitrile acrylic acid-g-n-alkanols and polyacrylonitrile acrylic acid-g-polyethylene glycols. According to the preparation method of the thermo-regulated nanofiber, the raw materials are mixed with a solvent, and then electrospinning is performed. The fiber has the characteristics of good setting performance, high thermal stability and faster heat absorption and release.

Owner:江苏普泰克新材料科技有限公司

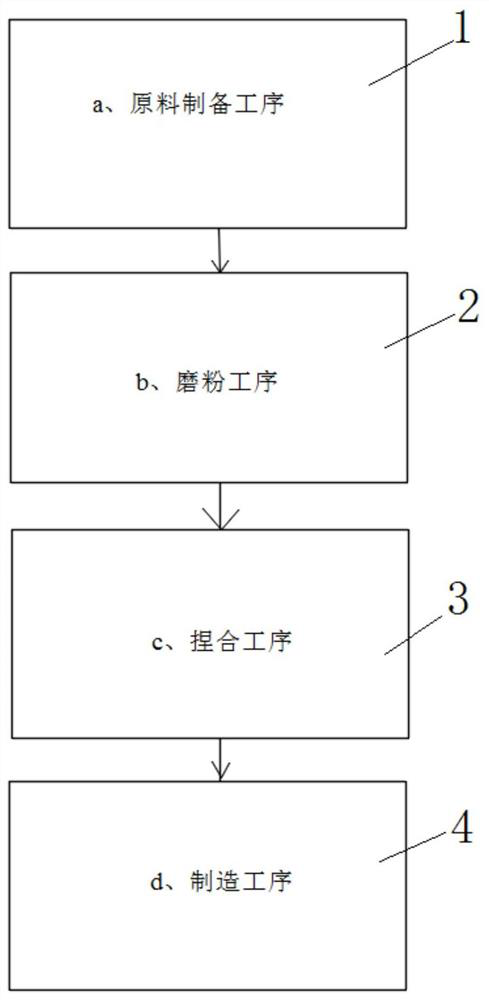

Production method of desulfurization and denitrification active coke catalyst

PendingCN111804339AWell mixedUniform particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCokeCarbonization

The invention discloses a production method of a desulfurization and denitrification active coke catalyst. The production method comprises the following steps: a, preparing raw materials: uniformly mixing 2-4 parts by weight of semi-coke, 1-3 parts by weight of Shenmu coal, 2-4 parts by weight of coking coal, 0.5-1.5 parts by weight of anthracite, and 10.5-1.5 parts by weight of a catalyst; b, grinding: grinding the uniformly mixed raw materials to enable 85% or above of the raw materials to pass through a 200-mesh sieve; c, kneading: adding 25-30 parts by weight of a binder and 8-12 parts byweight of water into the ground raw materials, and kneading at 65-90 DEG C; d, manufacturing: sequentially carrying out granulation, first screening, carbonization, second screening, activation, thirdscreening and packaging on the kneaded raw material which is coal paste. According to the prepared sulfur denitration active coke catalyst, the desulfurization value is increased to 25-30 mg / g, and the denitration rate is increased to 50-55%.

Owner:宁夏乐天碳素有限公司

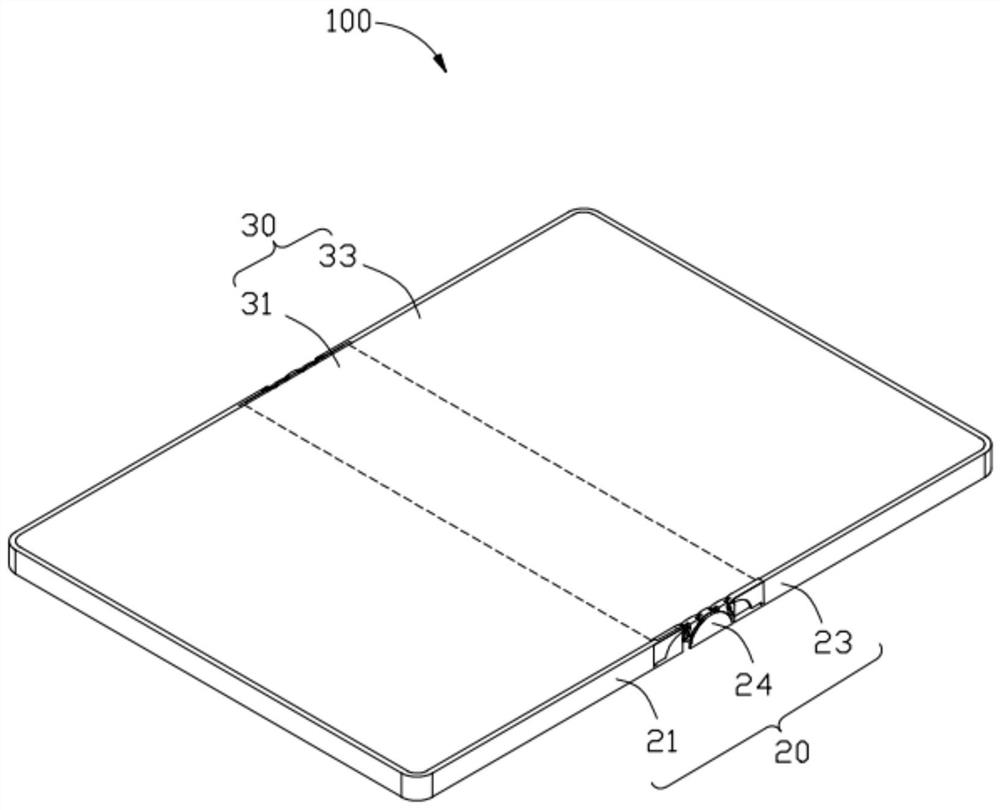

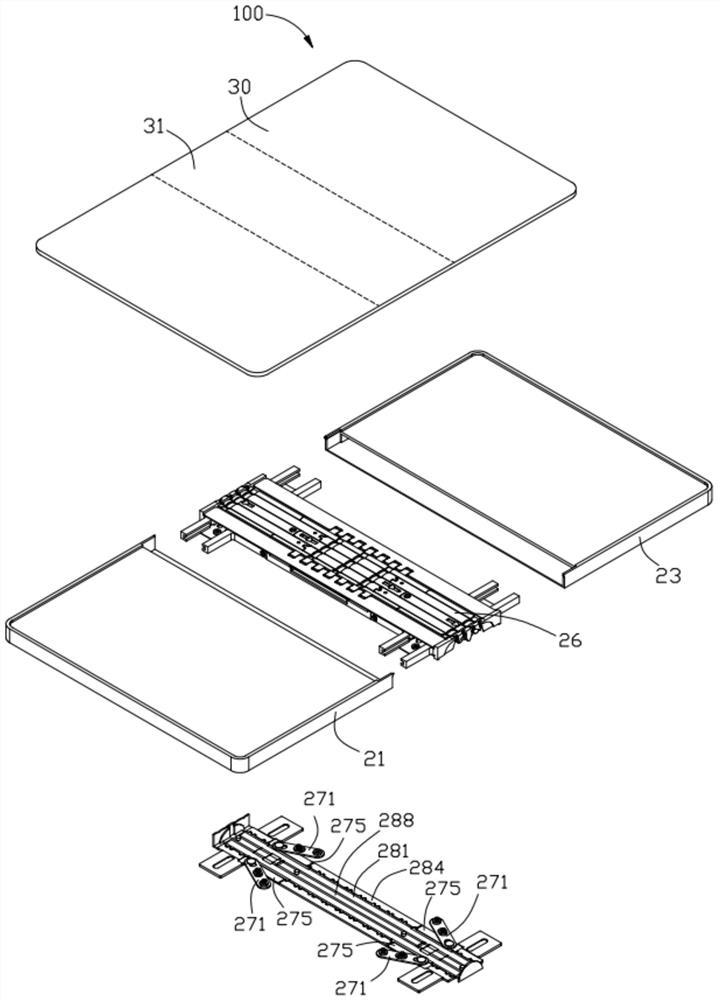

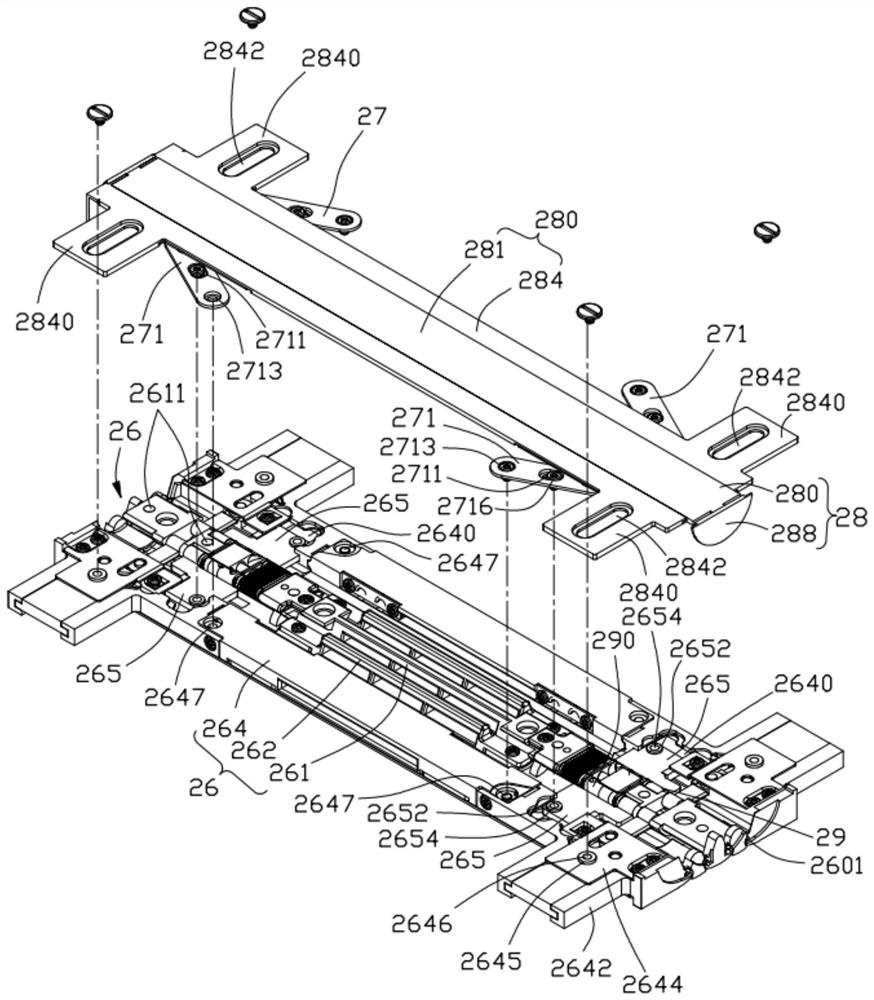

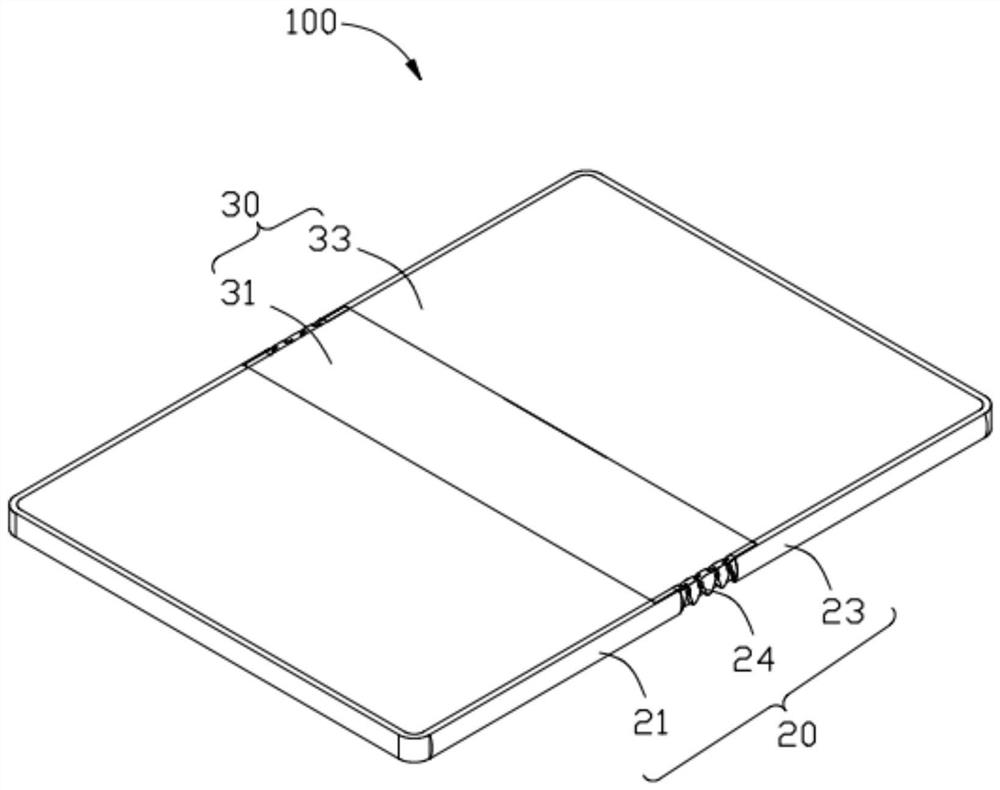

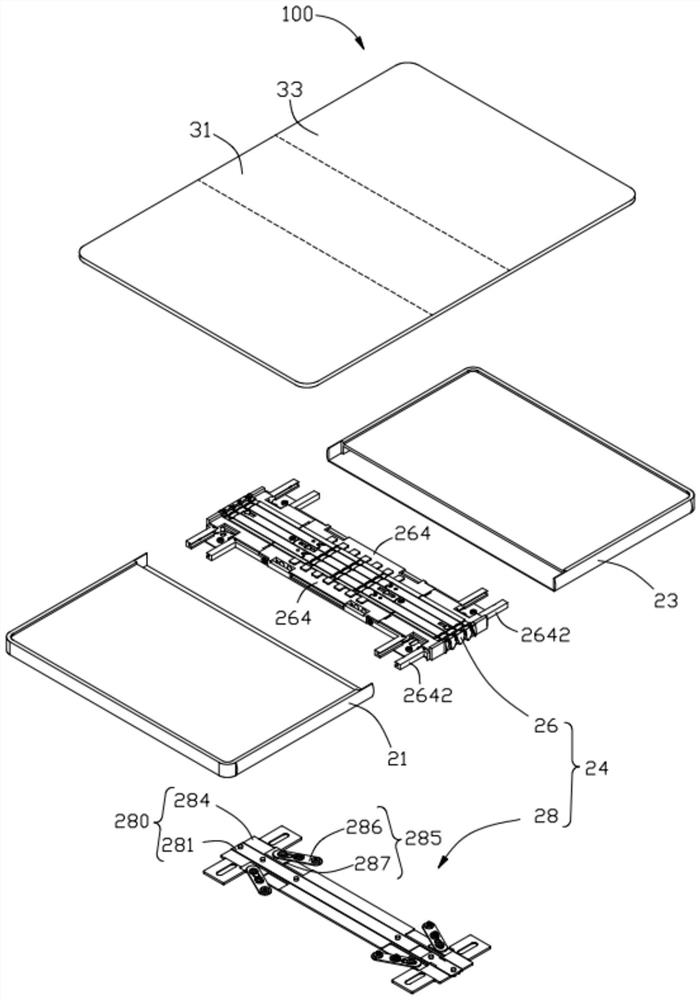

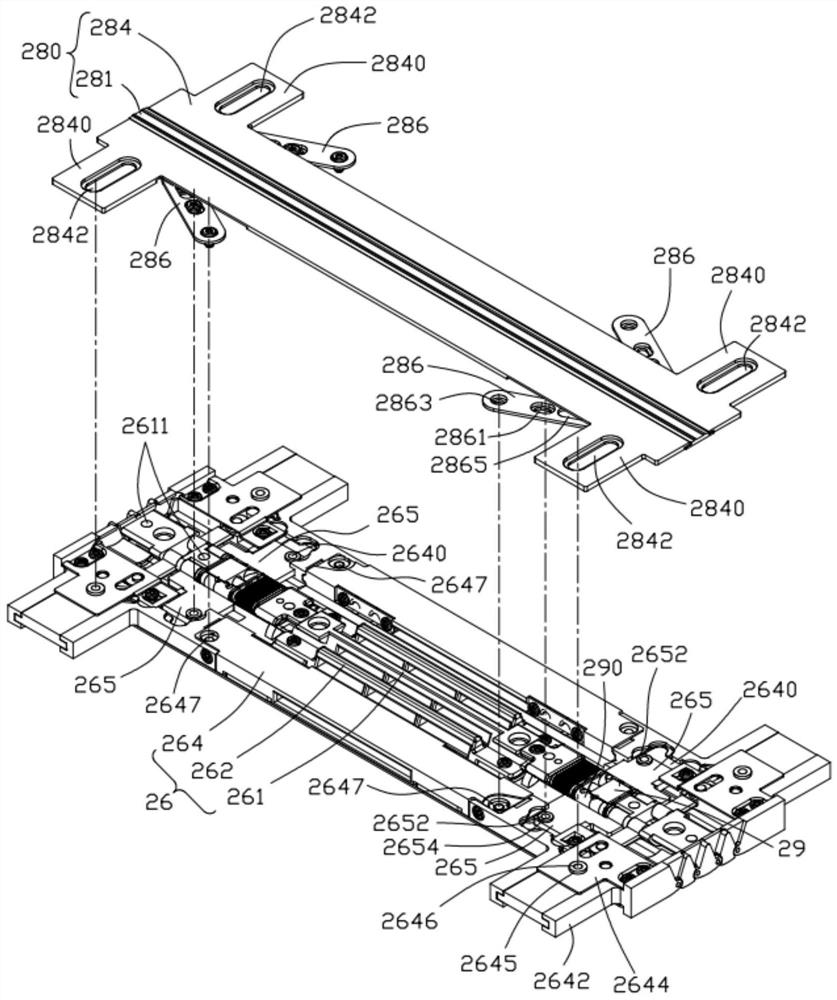

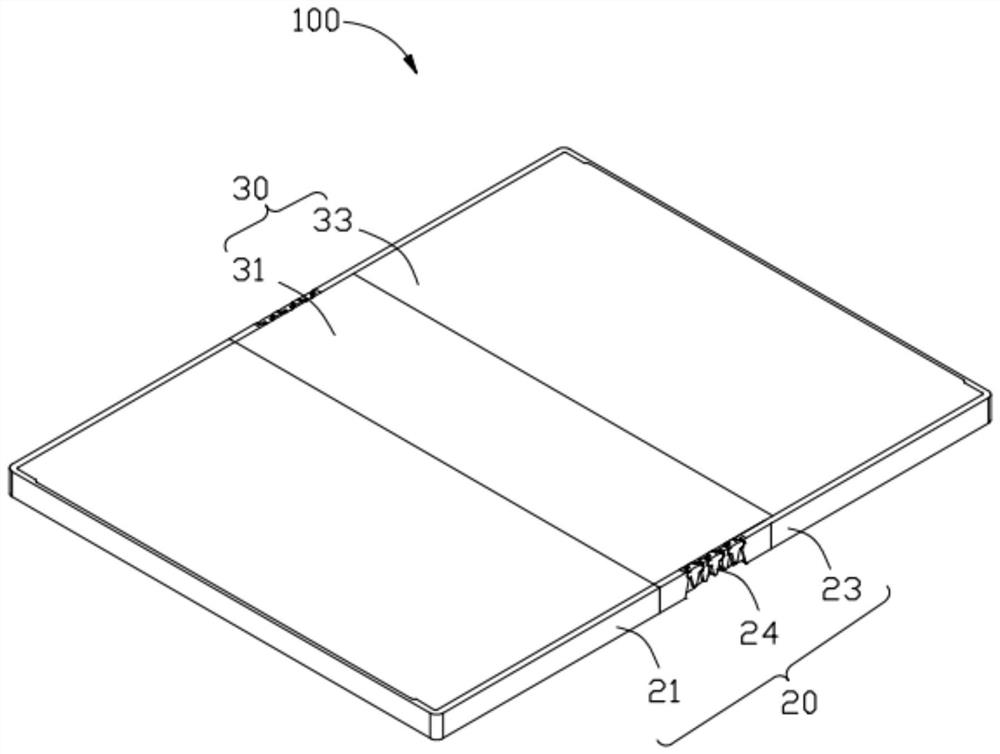

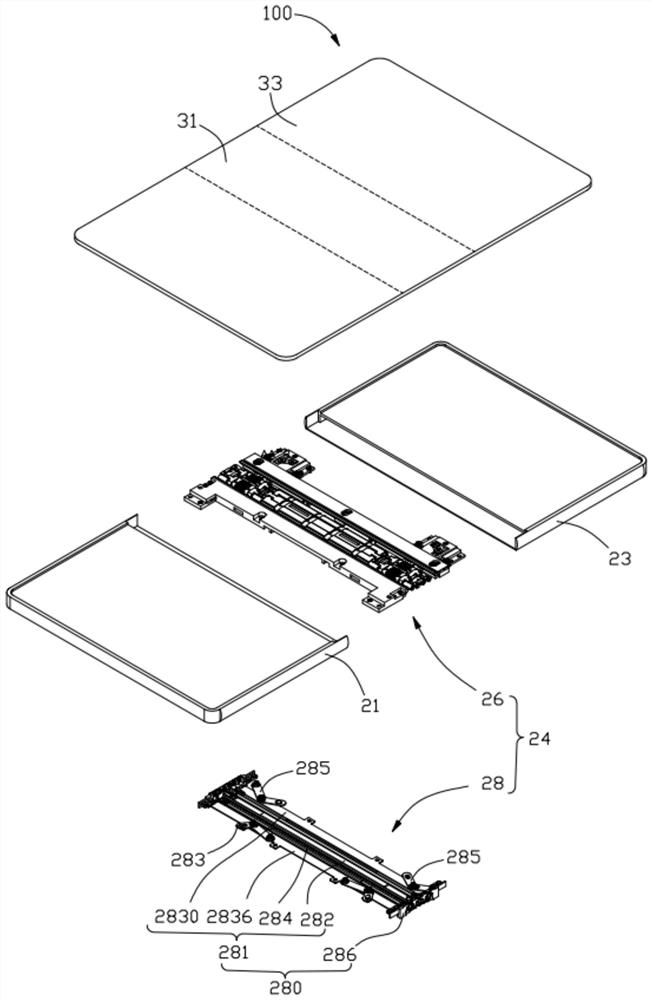

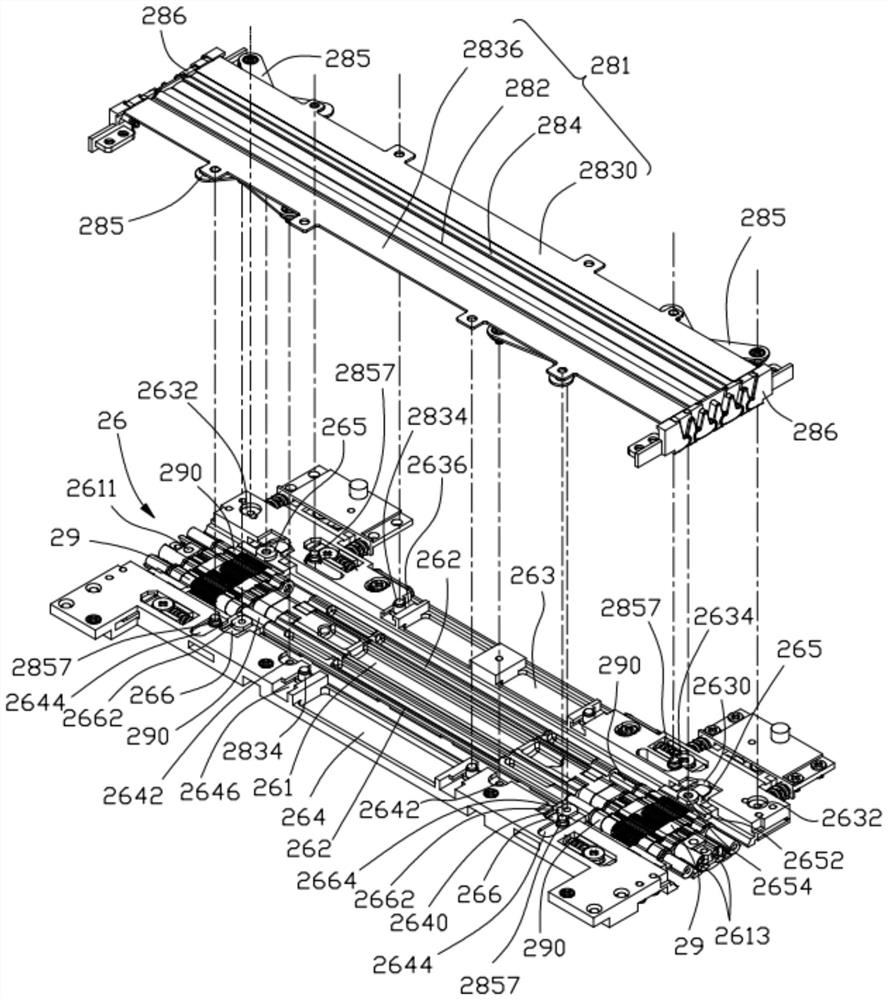

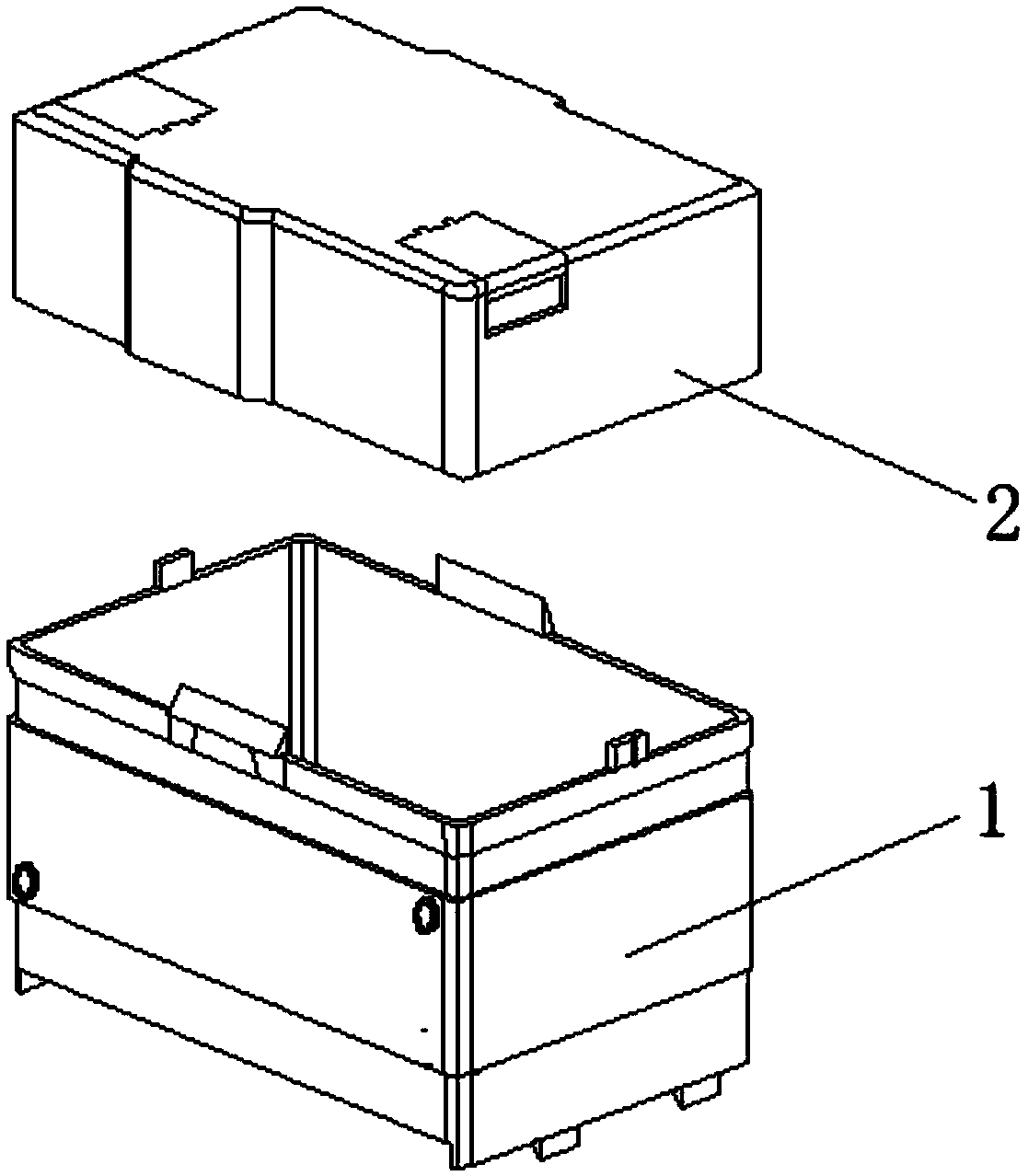

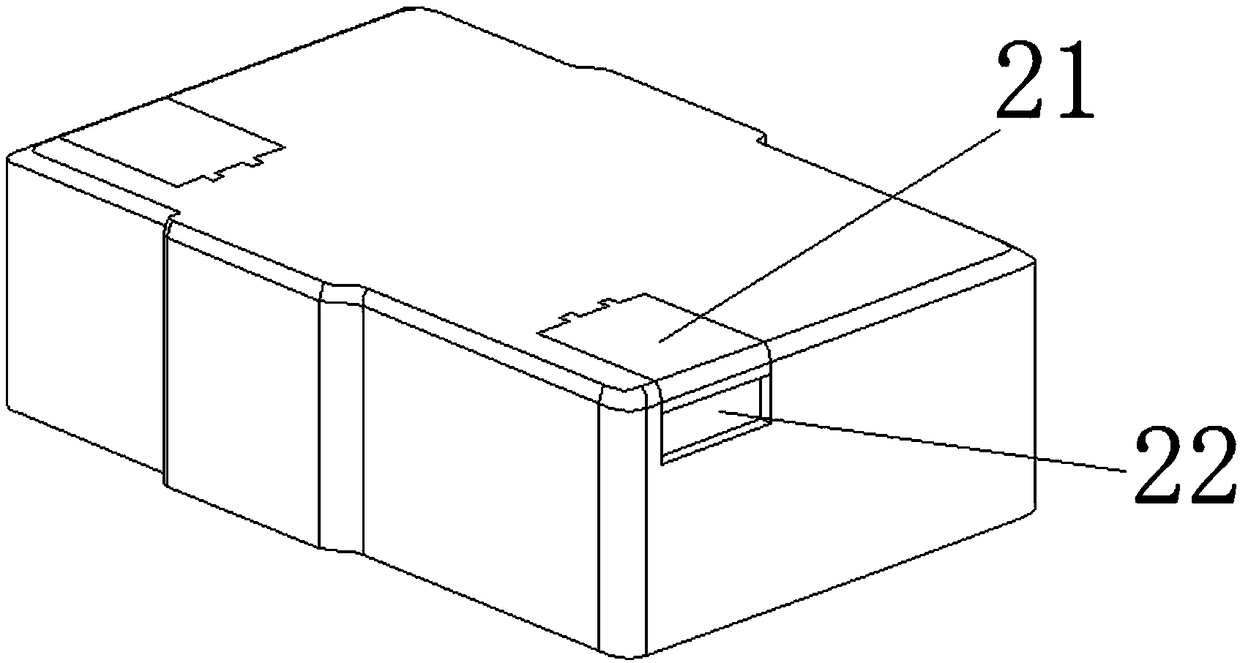

Folding device and electronic equipment

InactiveCN111833725AProtection strengthAvoid enteringIdentification meansStructural engineeringMechanical engineering

The invention provides electronic equipment. The electronic equipment comprises a flexible part, a shell and a folding device, wherein the shell comprises a first frame body and a second frame body; the folding device comprises a bendable component and a covering mechanism arranged on the bendable component, and a transmission assembly connected between the bendable part and the covering mechanism; the covering mechanism comprises a covering part covering one side of the bendable component and connecting parts covering the two opposite ends of the bendable component, the bendable component drives the covering part to be bent or flattened through the transmission assembly when being bent or flattened, and the flexible part is bent or flattened along with the folding device. The invention further provides the folding device of the electronic equipment.

Owner:SHENZHEN ROYOLE TECH CO LTD

Preparation method of fir nano fiber

ActiveCN106480765AIncrease the effective surface areaHigh catalytic activityWashing/displacing pulp-treating liquorsDigestersFiberFreeze-drying

The invention provides a preparation method of a fir nano fiber. The preparation method comprises the following steps: 1, boiling fir fibers in a boiling liquid to prepare paper pulp; 2, extracting the fir fibers, 3, preparing sodium chlorite solution, adding polyethylene friction blocks into the sodium chlorite solution, treating the fir fibers by the sodium chlorite solution; 4, treating the fir fibers with alkali solution to obtain purified cellulose; 5, preparing iron-ruthenium composite nano-particles; 6, preparing the iron-ruthenium composite nano-particles; 6, subjecting the purified cellulose to catalytic oxidation in the catalytic system comprising TEMPO, the composite nano-particles, sodium bromide and sodium hypochlorite; 7, carrying out a microwave heating reaction on the obtained cellulose suspension liquid under the condition of alternating magnetic field, subjecting the reaction product to washing and drying in vacuum to obtain the absolute dry oxidized cellulose fiber; 8 freeze-drying the suspension liquid to obtain a final product. The method disclosed by the invention is specially used for preparing the fir nano fibers, and the prepared fir nano fibers are very uniformly dispersed, and the nano fibers are low in mutual aggregation degree, high in production efficiency and good in product performance.

Owner:TIANJIN ZHONGZHI TECH DEV CO LTD

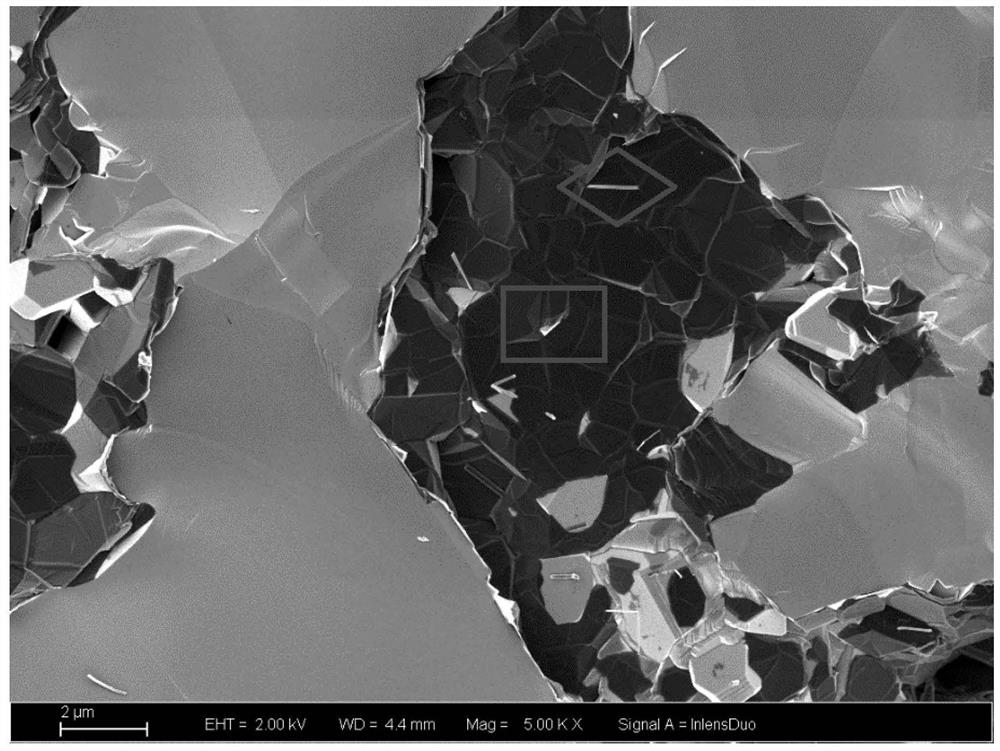

Boron carbide ceramic and preparation method and application thereof

ActiveCN112759408AEasy reunionOvercome the problem of uneven distributionArmour platesArmor-piercing shellCarbon nanotube

The invention discloses boron carbide ceramic and a preparation method and application thereof, and belongs to the technical field of weaponry. The preparation method of the boron carbide ceramic comprises the following steps: fully mixing boron carbide powder and carbon nanotubes in proportion, compacting and forming, then carrying out flash sintering-plasma sintering, and in the sintering process, generating nano-diamonds in situ from at least part of the carbon nanotubes, so as to obtain the boron carbide ceramic in which the carbon nanotubes and the nano-diamonds are uniformly distributed. The boron carbide ceramic prepared by the invention has the characteristics of high toughness, high hardness and high strength, can be used for bulletproof decks, and can resist multiple strikes of armor-piercing bullets and armor-piercing incendiary bombs.

Owner:SUZHOU FIRST ELEMENT NANO TECH

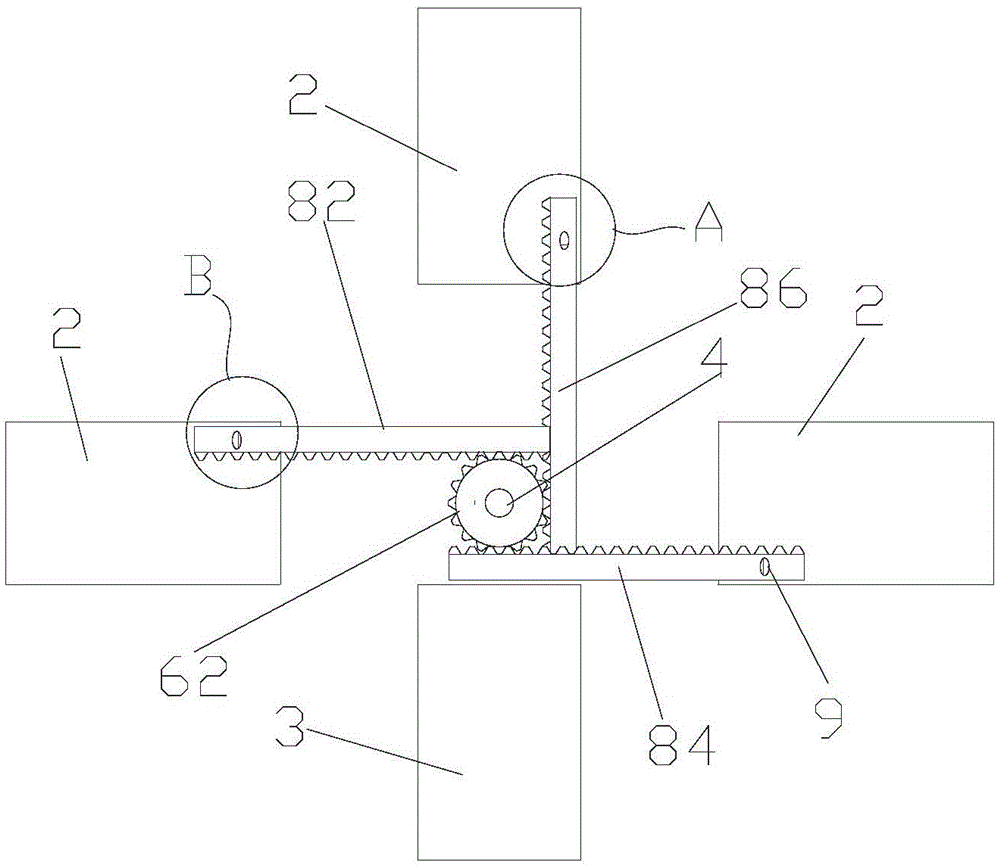

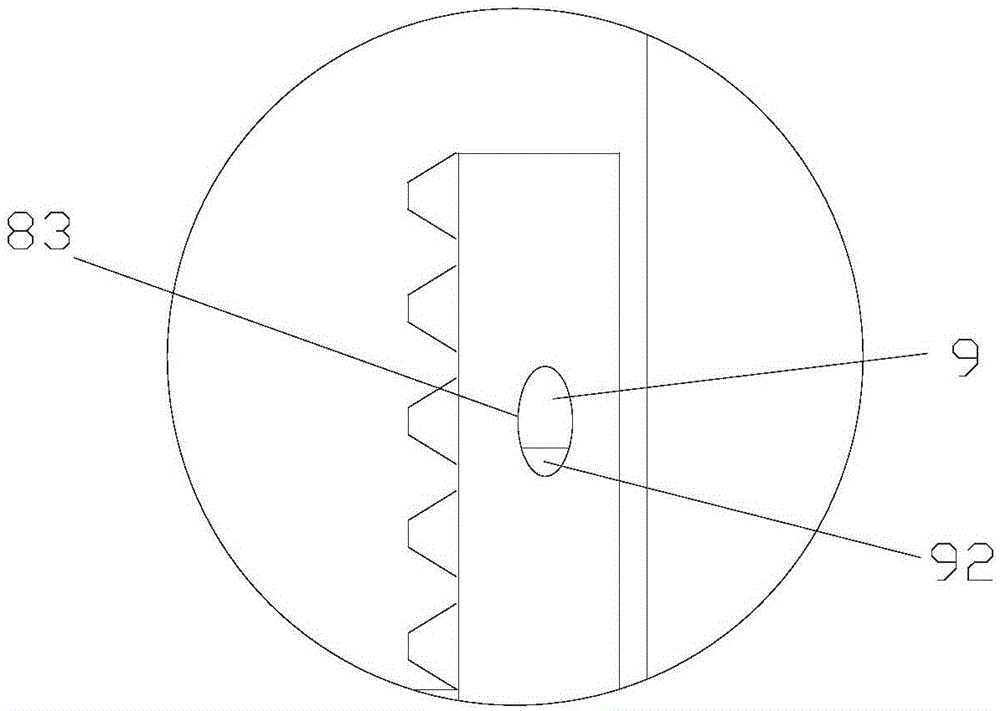

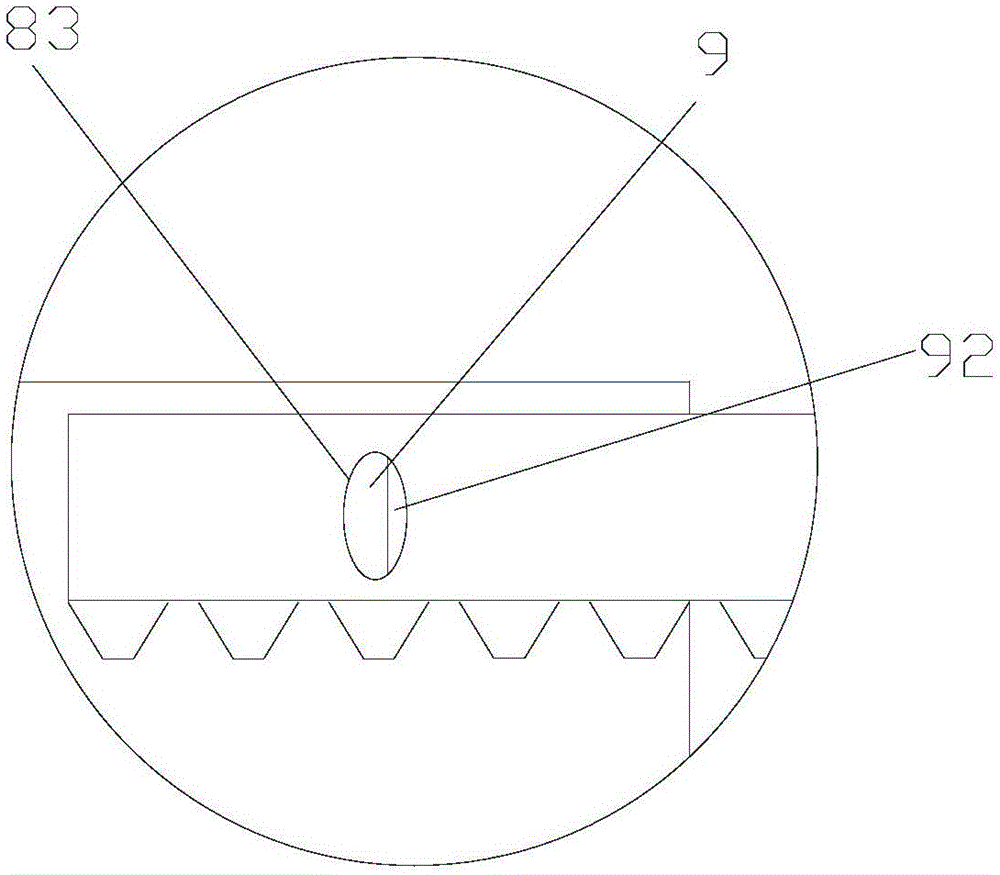

High-synchronicity forging equipment

The invention relates to high-synchronicity forging equipment. The equipment comprises three hammer units which are distributed in a T shape and arranged in a manner that the heads of the hammer units face the center and a driving device which drives the hammer units to move towards the center or the outer portion. The equipment is characterized by further comprising a transmission device for connecting the driving device with the hammer units; the transmission device comprises two gears which are coaxially integrated; and one of the two gears is at least in transmission fit with a rack, and the other one of the two gears is at least in transmission fit with two racks; and the racks are correspondingly connected with the hammer units. According to the forging equipment, the three hammer units which are distributed in the T shape can be matched with a fixed hammer unit for beating forging, and the gears and the racks are transmitted in a matched manner; and due to the fact that the two gears are coaxially integrated, the racks can be driven to synchronously move, and it is guaranteed that the hammer units synchronously carry out hammering and retreating; and the equipment is simple in structure and high in synchronicity.

Owner:忻州市质量技术监督检验测试所

Light-weight high-strength fabric for fencing protective clothing and preparation process thereof

ActiveUS20180163329A1High strengthProtection strengthWeft knittingLayered productsFiberAfter treatment

A light-weight high-strength fabric for fencing protective clothing uses UHMWPE fibers with fiber number of 360-420D and high-strength terylene silks with fiber number of 460-540D as raw materials. The fabric is prepared through the steps of batching, twisting, weaving, and after-treatment. The resulting fabric has less defects due to improvements in fabric formula and weaving techniques, etc. The puncture strength of the fabric can reach 3300N, and the mass per unit area can be reduced to 600 g / m2.

Owner:YUAN MINGFU +1

Covering mechanism, folding device and electronic equipment

PendingCN111828461AProtection strengthAvoid enteringPivotal connectionsIdentification meansStructural engineeringMechanical engineering

The invention provides electronic equipment. The electronic equipment comprises a flexible part, a housing and a folding device, wherein the housing comprises a first frame body and a second frame body; the folding device is arranged between the first frame body and the second frame body; the flexible part is arranged on the housing and the folding device; the folding device comprises a bendable part and a covering mechanism which is arranged on the bendable part; the covering mechanism comprises a covering part which covers the bendable part and a transmission assembly which is connected between the covering part and the bendable part; the covering part comprises a middle covering plate connected to the bendable part and slide plates which are arranged at opposite two sides of the middlecovering plate; and the bendable part is bent or stretched to drive the two slide plates to movably abut against the middle covering plate through the transmission assembly, so that the covering partis bent or stretched. The invention further provides a folding device of the electronic equipment and a covering mechanism.

Owner:SHENZHEN ROYOLE TECH CO LTD

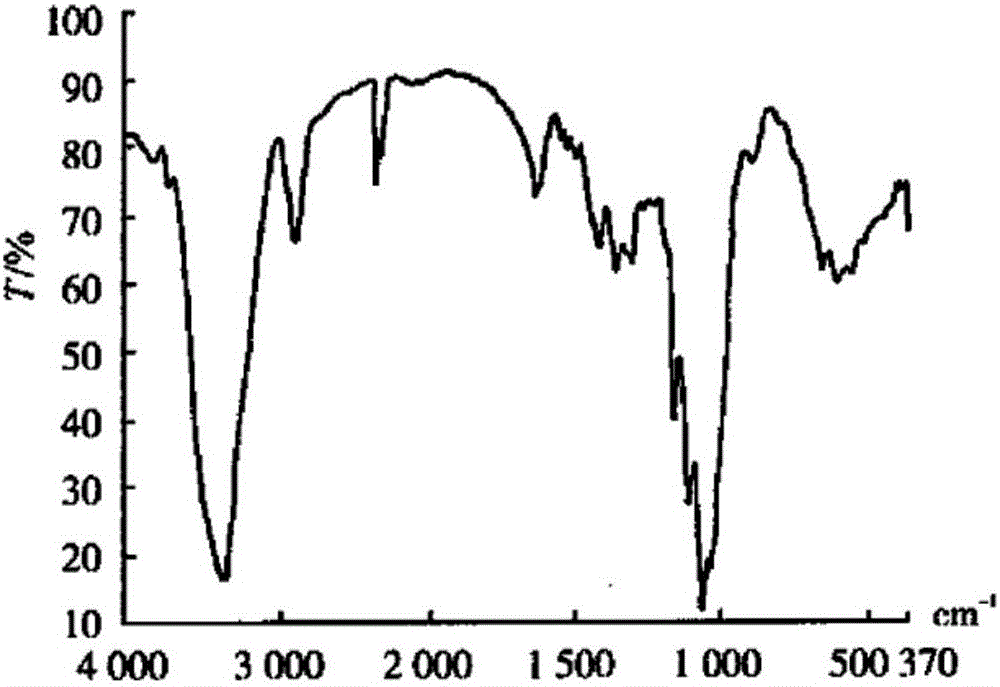

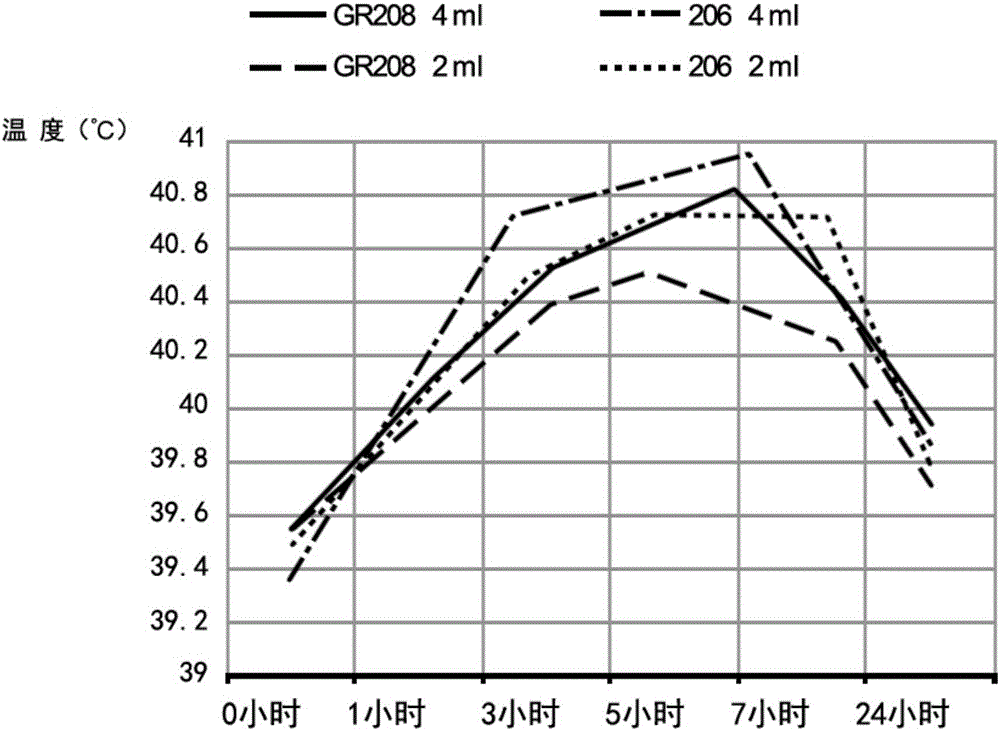

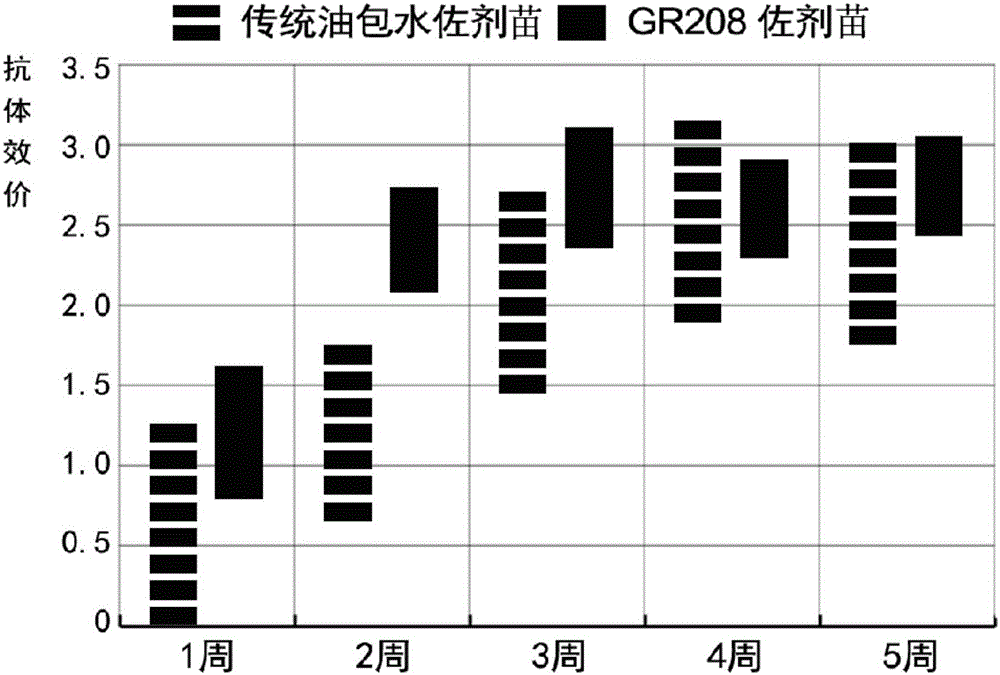

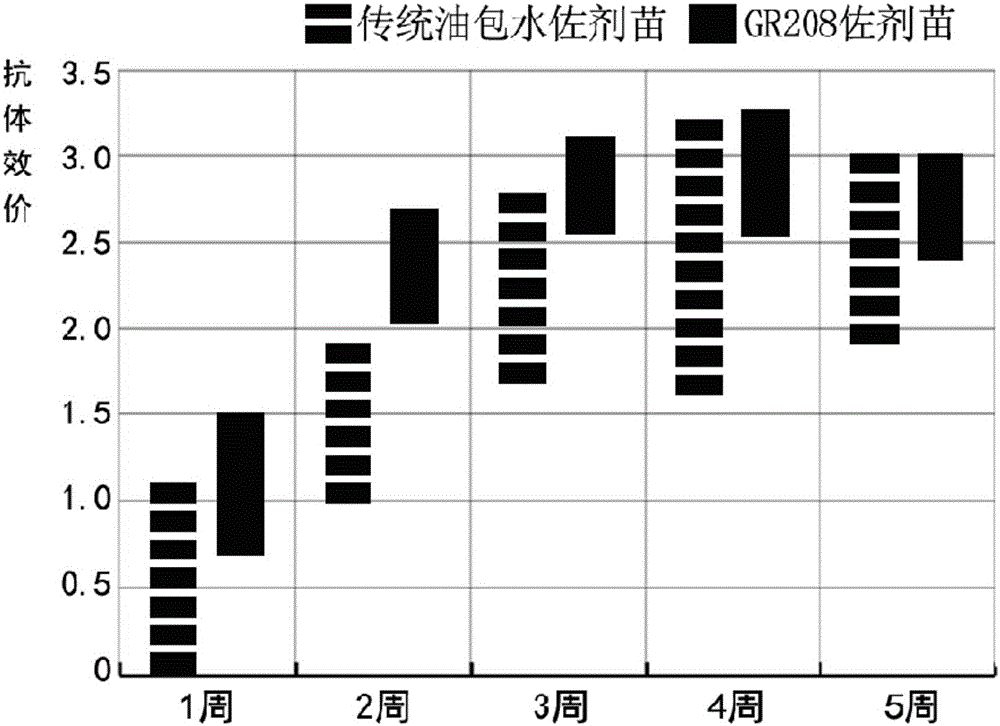

Adjuvant for animal vaccines, and preparation method and application thereof

ActiveCN106692966AReduce allergic reactionsRapid immune responseEmulsion deliveryAntibody medical ingredientsAdjuvantAnimals vaccines

The invention discloses an adjuvant for animal vaccines, and a preparation method and application thereof. The adjuvant for animal vaccines comprises the following raw materials by volume: 75 to 90% of low-density mineral oil, 1 to 10% of octyl and decyl glycerate and Span-80, 0.5 to 5% of glycerin and polyglycerol isostearate and 1 to 10% of polyethylene glycol-12-hydroxystearate-15, Tween-80 and propylene glycol, wherein the amount of Tween-80 is in a range of 0 to 5%. The preparation method comprises the following steps: weighing the low-density mineral oil; then adding octyl and decyl glycerate, Span-80, glycerin, polyglycerol isostearate, 1 to 10% of polyethylene glycol-12-hydroxystearate-15, Tween-80 and propylene glycol; and carrying out mixing and standing. The adjuvant provided by the invention has safety, stability and self-emulsifying performance, has low sensitivity to temperature in the process of emulsification, can form a water-in-oil-in-water spatial structure, and is extensively applicable to preparation of animal vaccines.

Owner:长沙国瑞生物科技有限公司

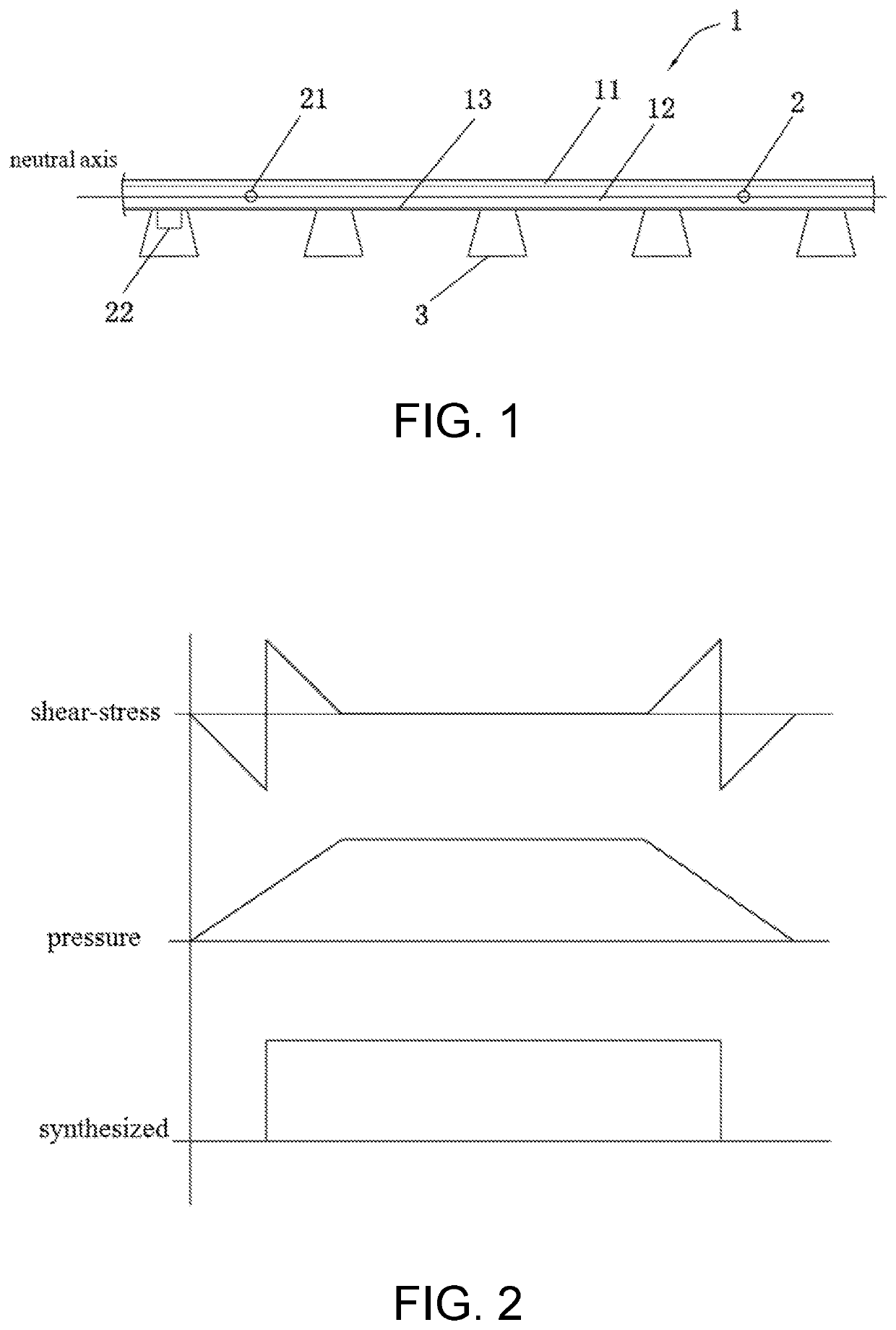

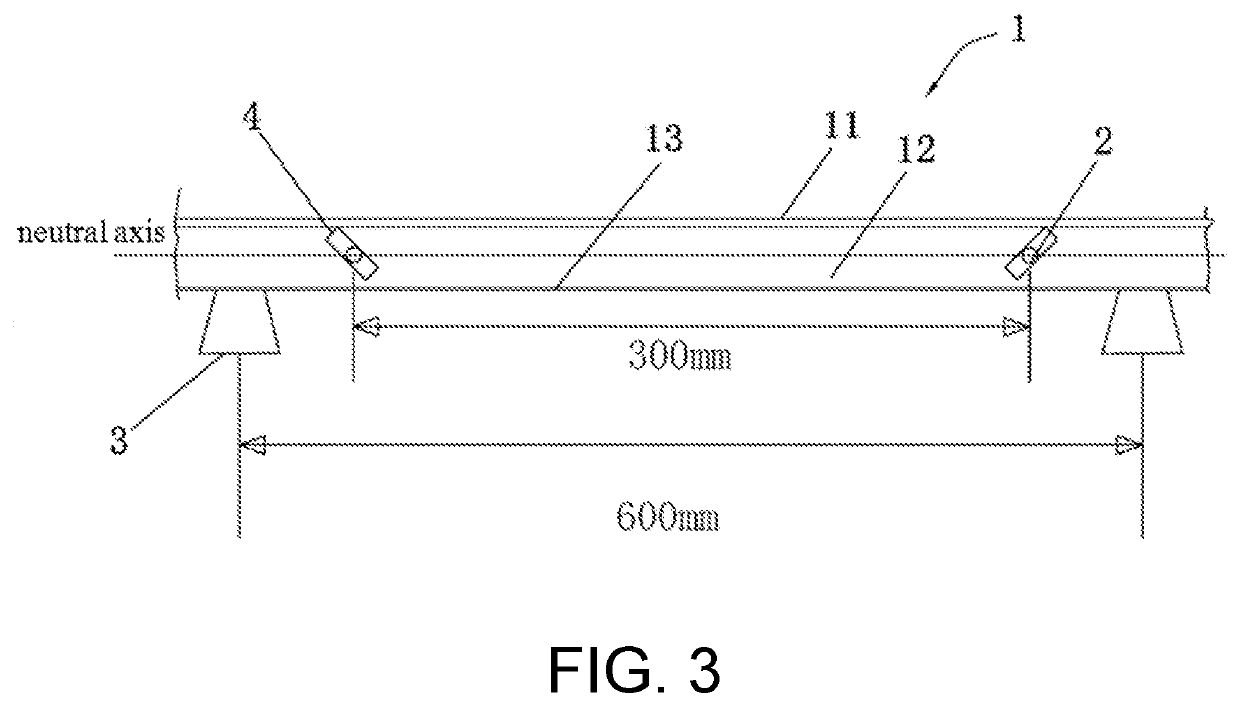

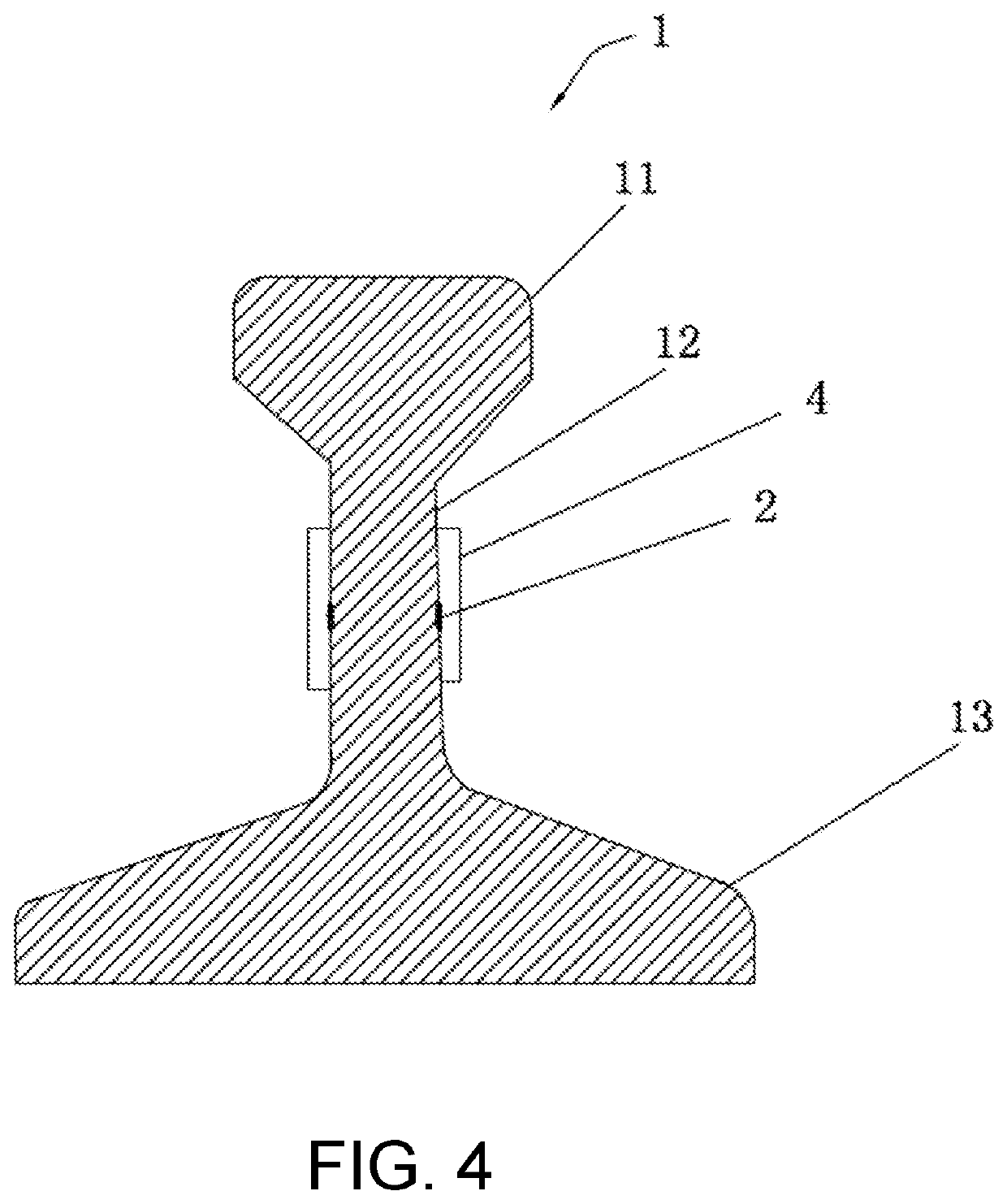

Overload and unbalanced load detecting system for railway and detecting method

PendingUS20200339167A1Improve safety performanceProtection strengthWheel-rims surveying/measuringTrack side maintainanceStructural engineeringControl theory

This application relates to an overload and unbalanced load detecting system for a railway and a detecting method. This system includes at least one steel rail. A rail web of each steel rail is provided with two sampling points at two sides between every two adjacent rail sleepers, respectively, and the two sampling points on one side are symmetrically disposed about the steel rail with respect to the two sampling points on the other side. A fiber-optic sensitive element used for continuously measuring a load when a train passes through the two sampling points is obliquely fixed at each sampling point, and two fiber-optic sensitive elements on the same side of each steel rail are disposed at an angle of 90° with each other.

Owner:BEIJING ORIENTAL RAILWAY TECH DEV CO LTD

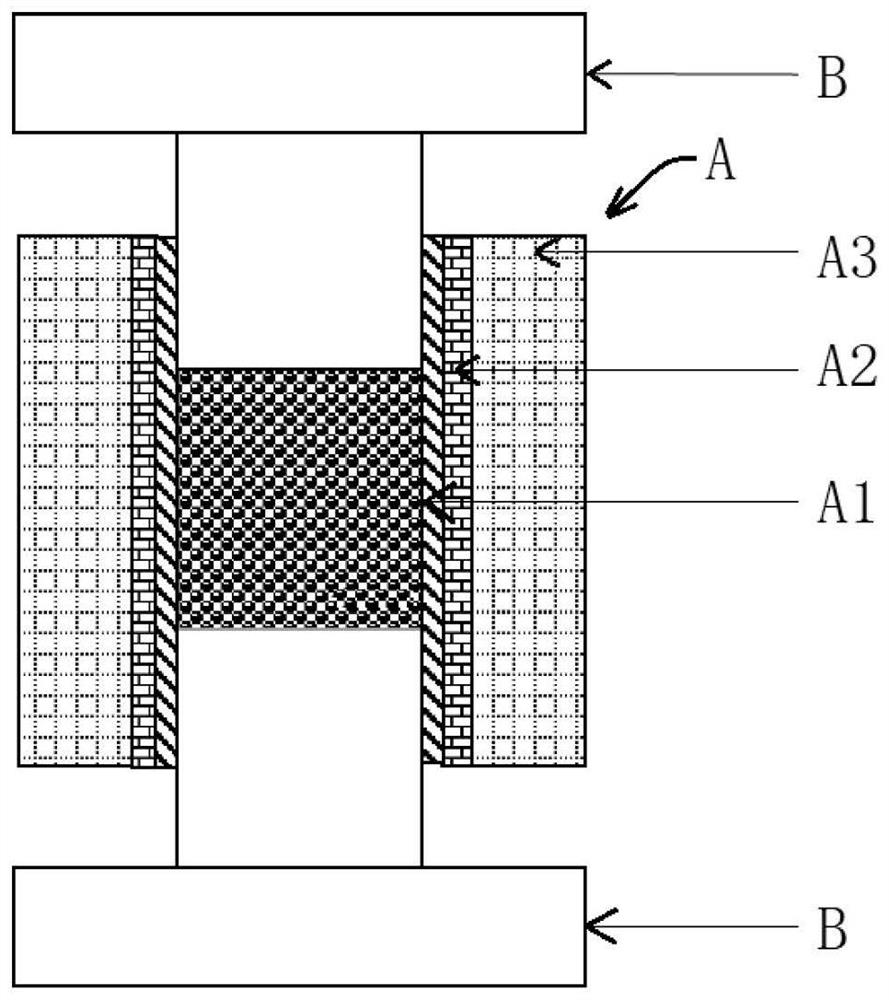

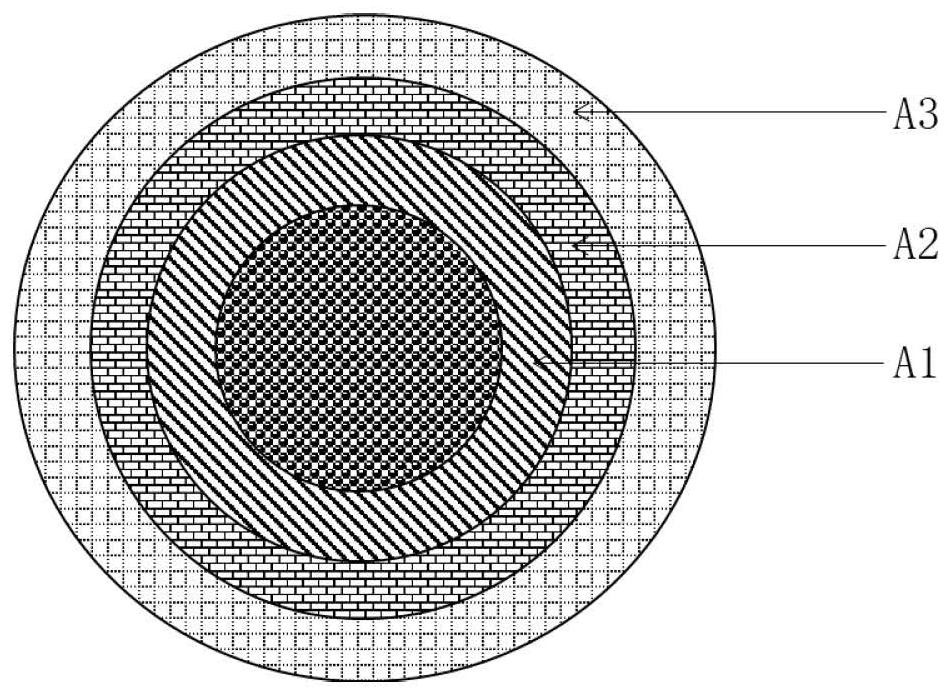

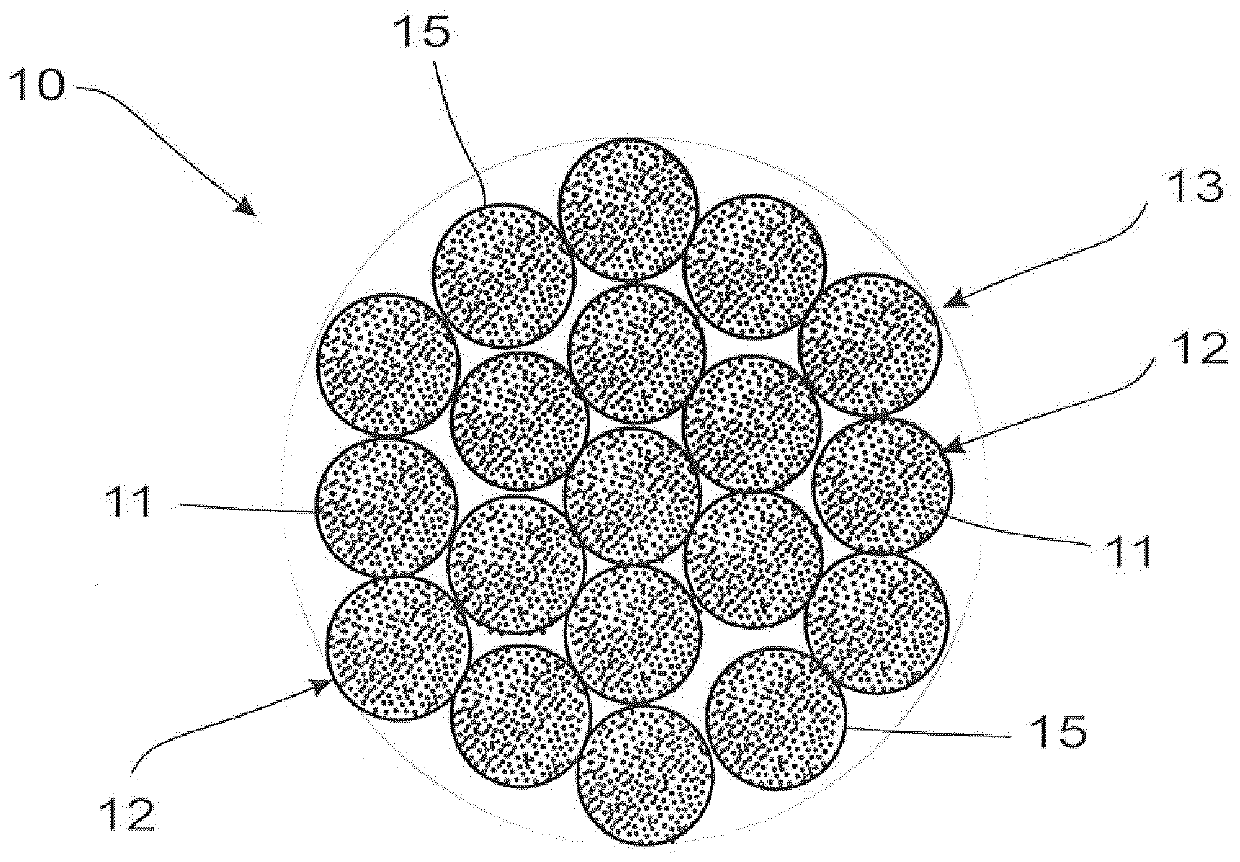

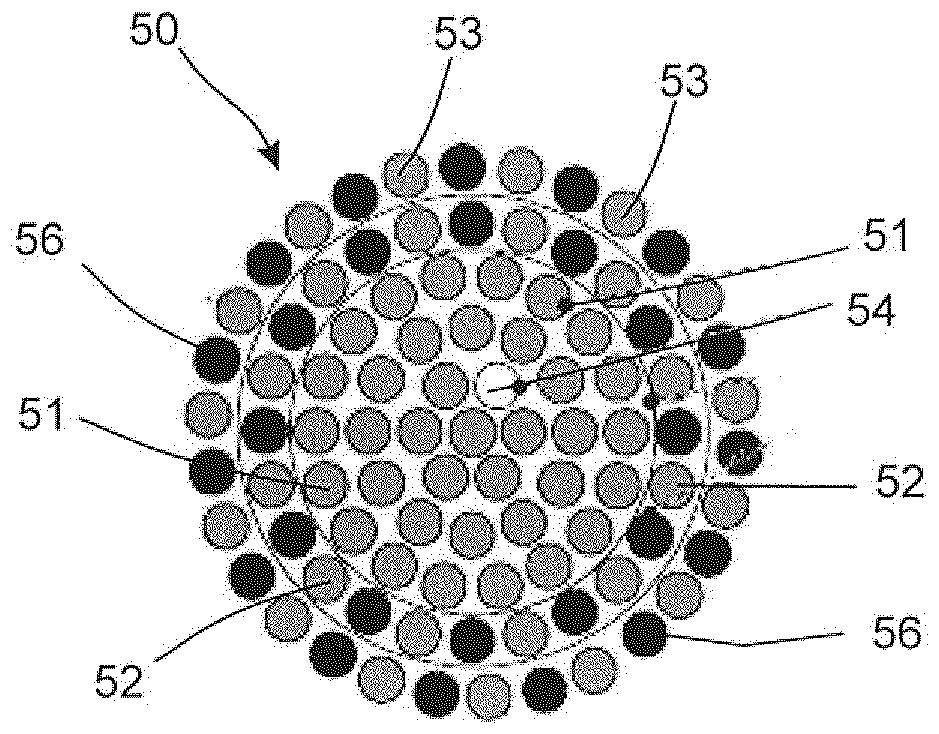

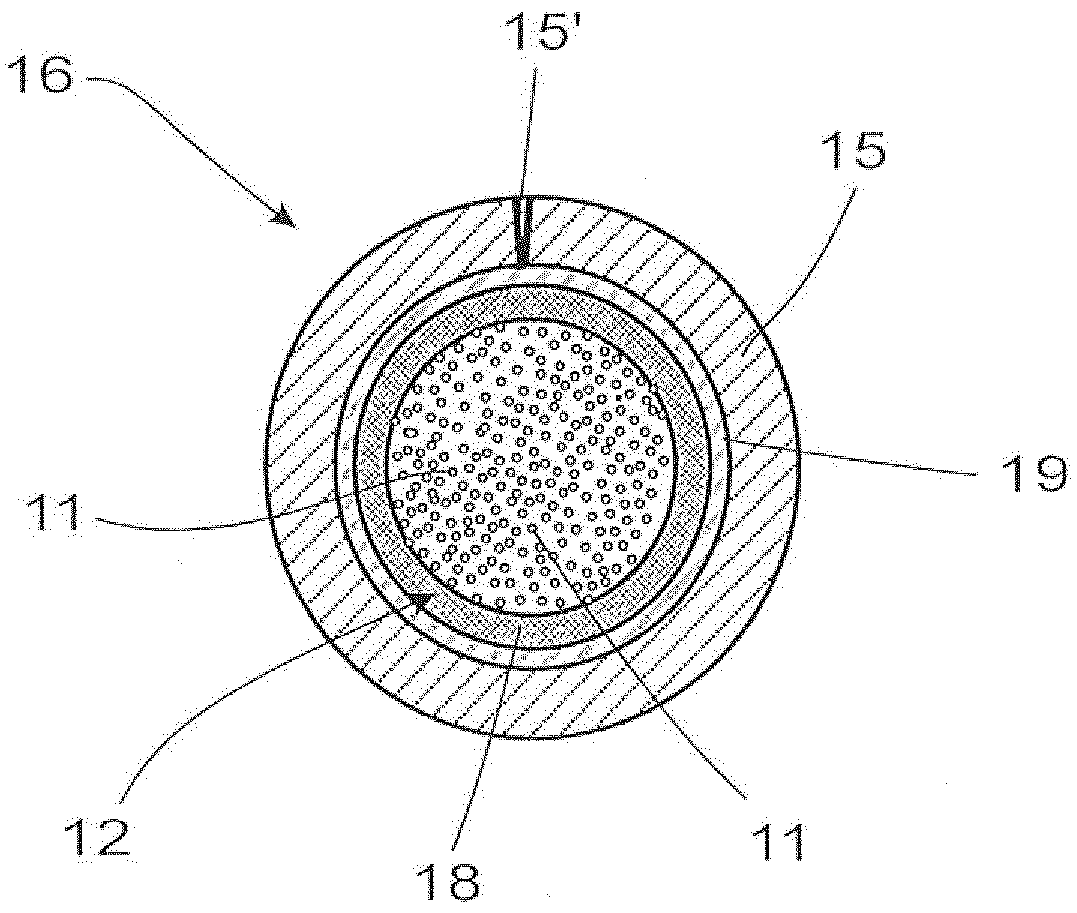

Longitudinal element, in particular for traction or suspension means

PendingCN110678602AProtection strengthRetention strengthAgriculture tools and machinesControlFiberThermodynamics

The invention relates to a longitudinal element (13) produced with a core (12) made of high-strength fibres (11) and at least one metal casing (15), preferably steel, surrounding the core (12). In this way, there is the significant advantage that these high-strength fibres, which are very lightweight in relation to their strength, are protected in a number of ways, namely against humidity, moisture, UV light and other environmental influences. In addition, the metal casing provides the fibres with protection against transverse loads. In this way, all the high-strength properties of the traction or suspension means are maintained over a sustained period.

Owner:法策股份公司钢丝绳厂

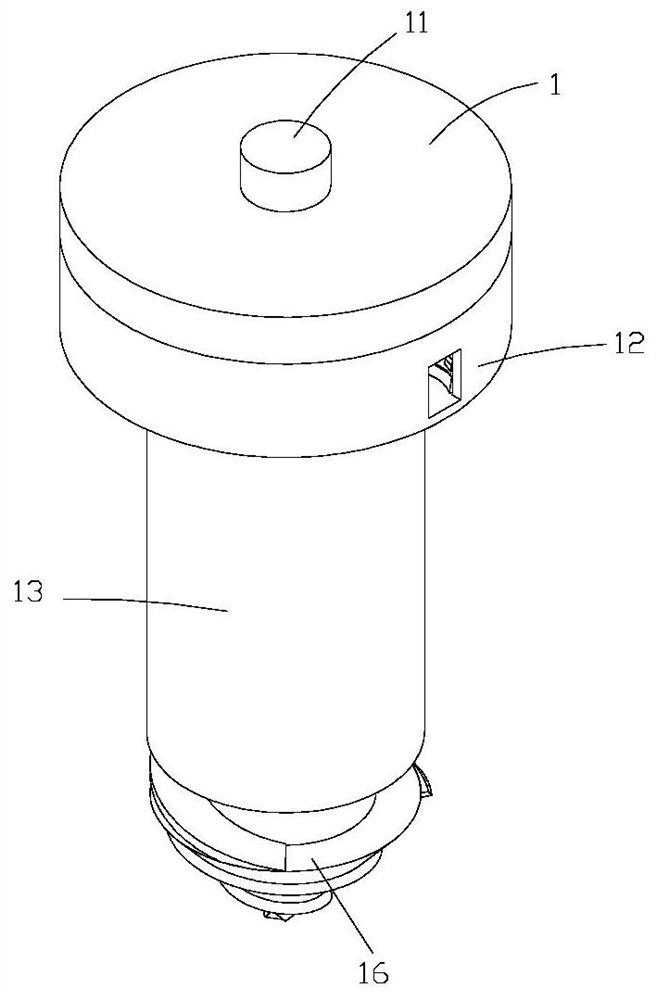

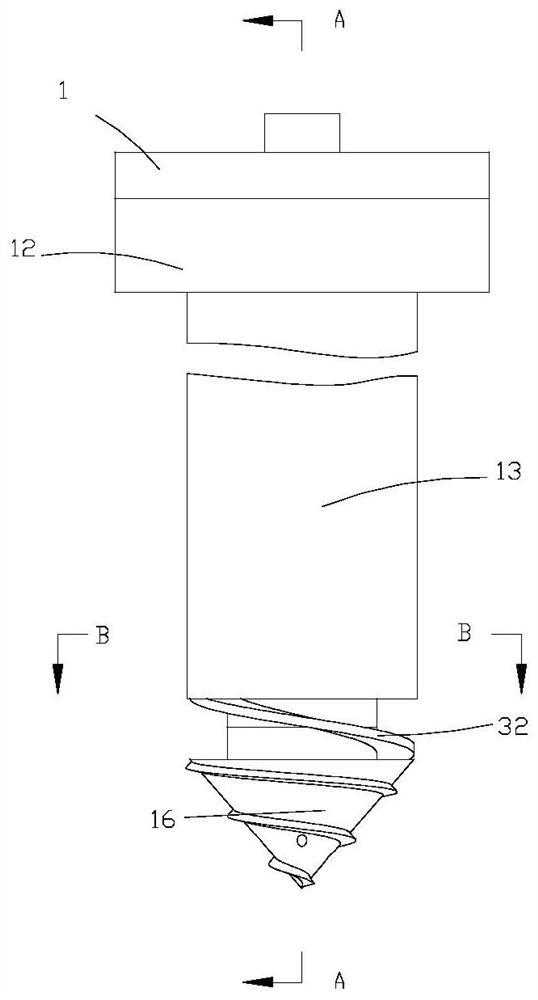

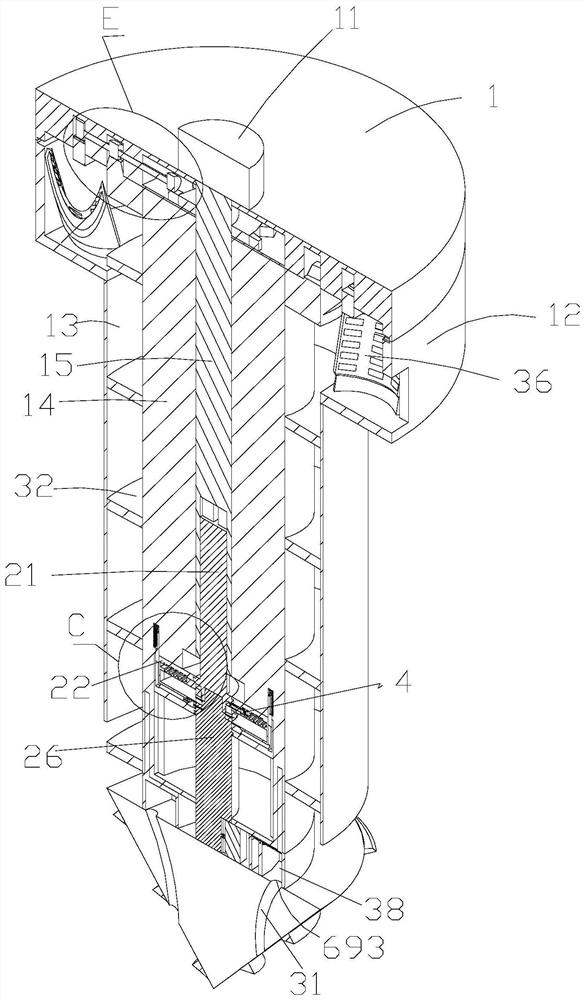

Blasting method for reducing ore loss and dilution

InactiveCN113607018ATimely exclusionImprove stone removal abilityConstructionsUnderground miningPunchingMining engineering

The invention discloses a blasting method for reducing ore loss and dilution. The blasting method comprises the following steps that a, hole arrangement is achieved: a plurality of rows of main blast holes are arranged after determining a blasting section; b, punching is conducted, specifically, punching is conducted through a punching machine; c, charging is achieved: a main blast hole is charged with powder, and then the blast hole is plugged; and d, blasting is achieved: blasting is achieved from a main blast hole close to a free surface; the punching machine in the step b comprises a base, a motor, a storage bin, a fixing sleeve, a fixing barrel, a rotating roller, a linkage device, a drill bit and a stone discharging device. According to the blasting method for reducing ore loss and dilution, by means of blasting in the mode, stope ore loss caused by roof collapse is effectively prevented, and the recovery rate is increased; roof barren rock mixing is reduced, and the ore dilution rate is reduced; through the linkage device, intermittent progressing can be achieved during blast hole drilling, and the strength of the drill bit can be protected; and stone powder can be removed in time during punching through the stone discharging device, and the punching effect is improved.

Owner:浙江交投矿业有限公司

Folding device and electronic equipment

InactiveCN111828460AProtection strengthAvoid enteringPivotal connectionsIdentification meansStructural engineeringMechanical engineering

The invention provides electronic equipment. The electronic equipment comprises a flexible part, a housing and a folding device, wherein the housing comprises a first frame body and a second frame body; the folding device is arranged between the first frame body and the second frame body; the flexible part is arranged on the housing and the folding device; the folding device comprises a bendable part and a covering mechanism which is arranged on the bendable part; the covering mechanism comprises a covering assembly which covers the bendable part and a transmission part which is connected between the covering assembly and the bendable part; the covering assembly comprises a first covering part which covers the bending inner side of the bendable part; and bending or stretching of the bendable part drives the first covering part to bend or stretch through the transmission part. The invention further provides a folding device of the electronic equipment.

Owner:SHENZHEN ROYOLE TECH CO LTD

Method for enhancing flexibility of pure cotton fabrics

InactiveCN108978202AGood flexibilityStable soft statePhysical treatmentGrip property fibresEngineeringVapor pressure

The invention discloses a method for enhancing flexibility of pure cotton fabrics and relates to the technical field of pure cotton fabrics. The method for enhancing flexibility of pure cotton fabricscomprises the following steps: (1) adding the pure cotton fabrics into water for heat treatment, and drying; (2) soaking the pure cotton fabrics with water to form a dripless state, tiling the fabrics on a flat worktable, flattening the pure cotton fabrics by a flat plate, and hanging up; (3) adding a soft preparation into water to be uniformly mixed, atomizing by an atomizer, and spraying onto the erected pure cotton fabrics; (4) baking the pure cotton fabrics sprayed with the soft preparation by a baker; and (5) seaming the baked pure cotton fabrics under saturated vapor pressure, cooling,tiling on the flat table-top, and heating and drying by using high infrared radiation. The flexibility of the prepared pure cotton fabrics is greatly increased, the fabrics can also maintain excellentflexibility after washing, and the breathability and strength of the pure cotton fabrics are not damaged, so that the wearing comfort is increased.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Vehicle-mounted noise reduction battery heat shield and processing method thereof

ActiveCN108933208AReduce the temperatureExtended service lifeBattery isolationSecondary cellsNoise reductionWater cooling

The invention discloses a vehicle-mounted noise reduction battery heat shield and a processing method thereof. The vehicle-mounted noise reduction battery heat shield comprises a shield cover and a shield body, the bottom of the shield body is open and is connected with the tray of a vehicle-mounted battery by a buckle, the shield cover is connected with the top opening of the shield boy by a buckle, the top of the shield cover is provided with electrode holes, an electrode lid is hinged to every electrode hole, each of the shield body and the shield cover has a heat insulating shell obtainedthrough injection molding of a heat insulating resin material, every heat insulating shell has a columnar shape, a metal shell is arranged outside every heat insulating shell, a plurality of heat-dissipating water channels are arranged around every metal shell, and the water inlets and the water outlets of the heat-dissipating water channels are communicated with the cooling water way of the vehicle. The external metal shells adopt the heat-dissipating water channels to greatly reduce the surrounding temperature of the vehicle-mounted battery in a water-cooling manner, so the service life of the vehicle-mounted battery is effectively prolonged, and the failure probability of the vehicle-mounted battery is reduced.

Owner:宁波尚唯汽车饰件有限公司

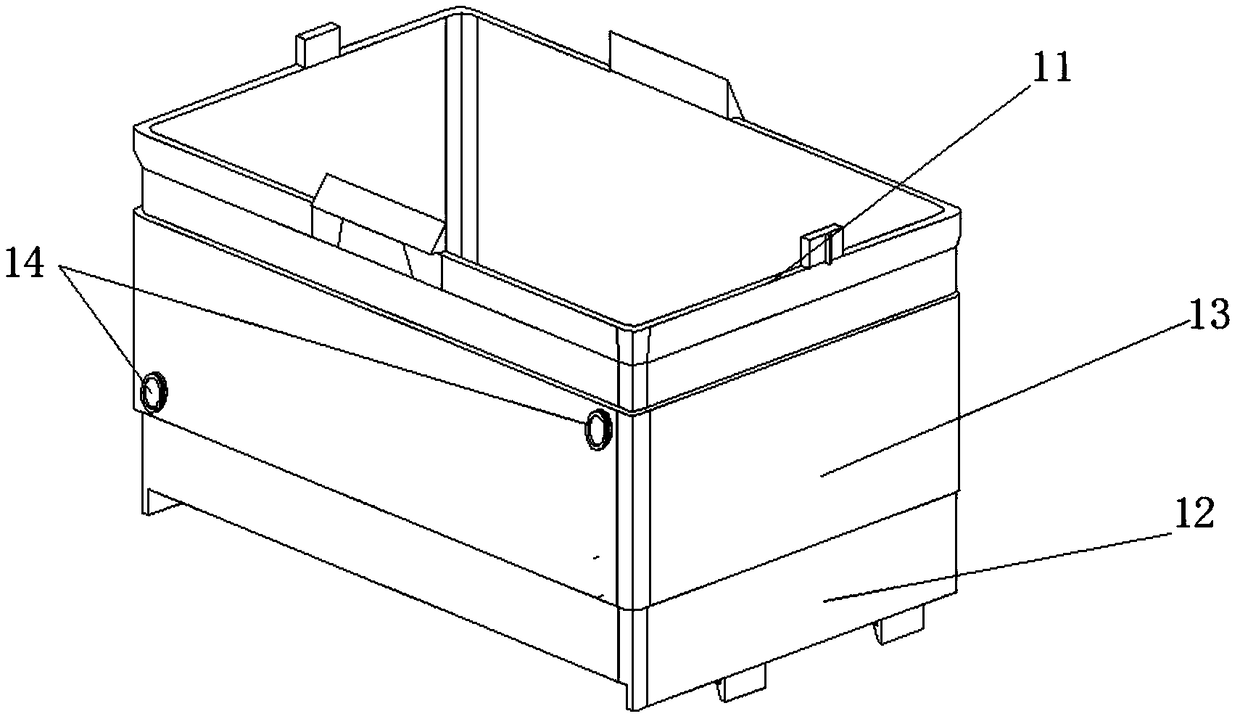

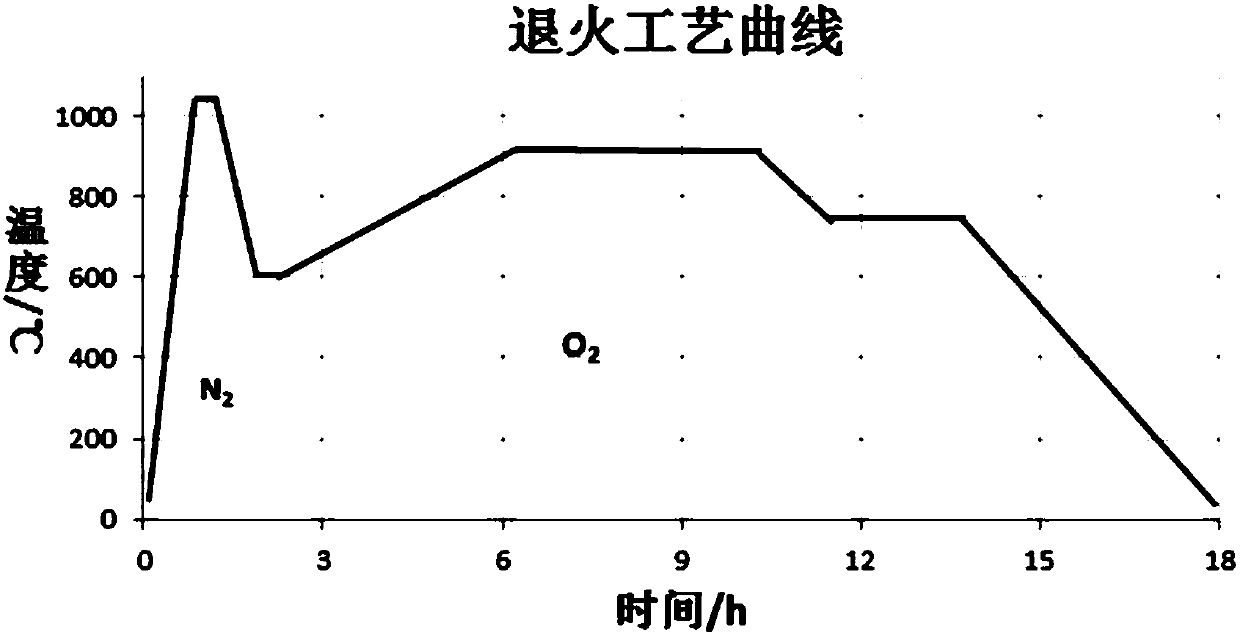

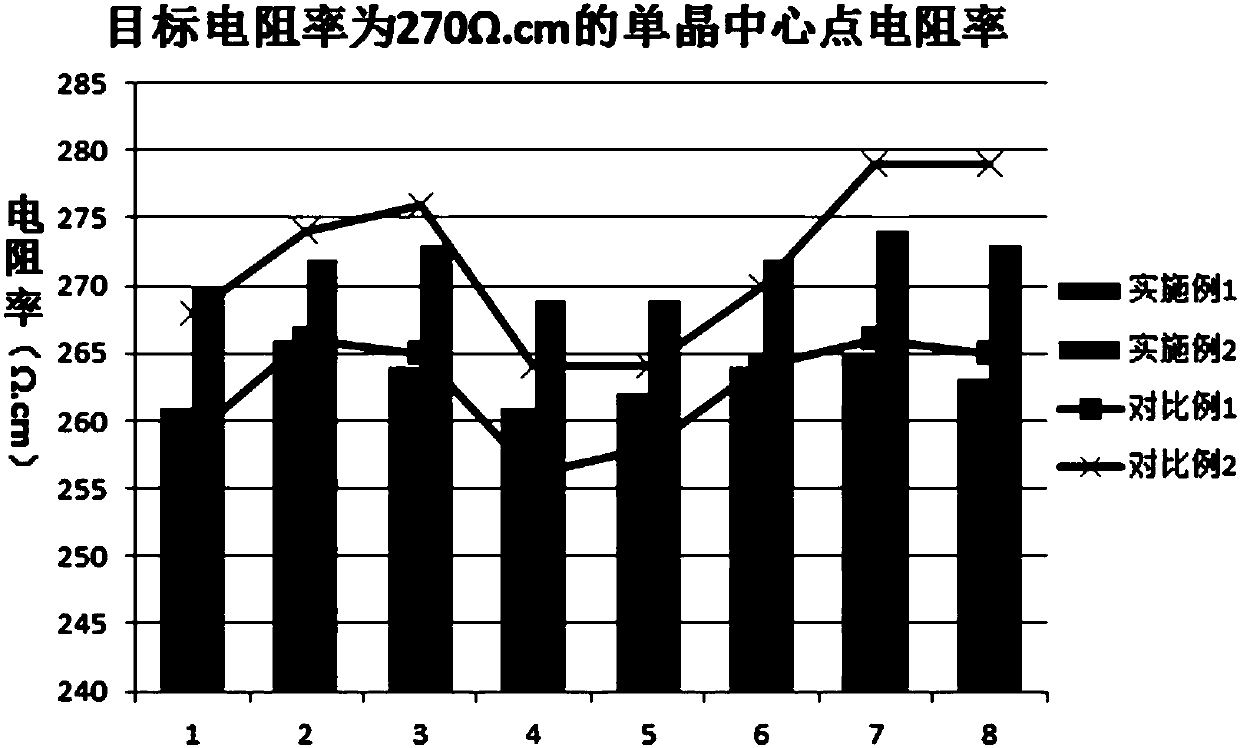

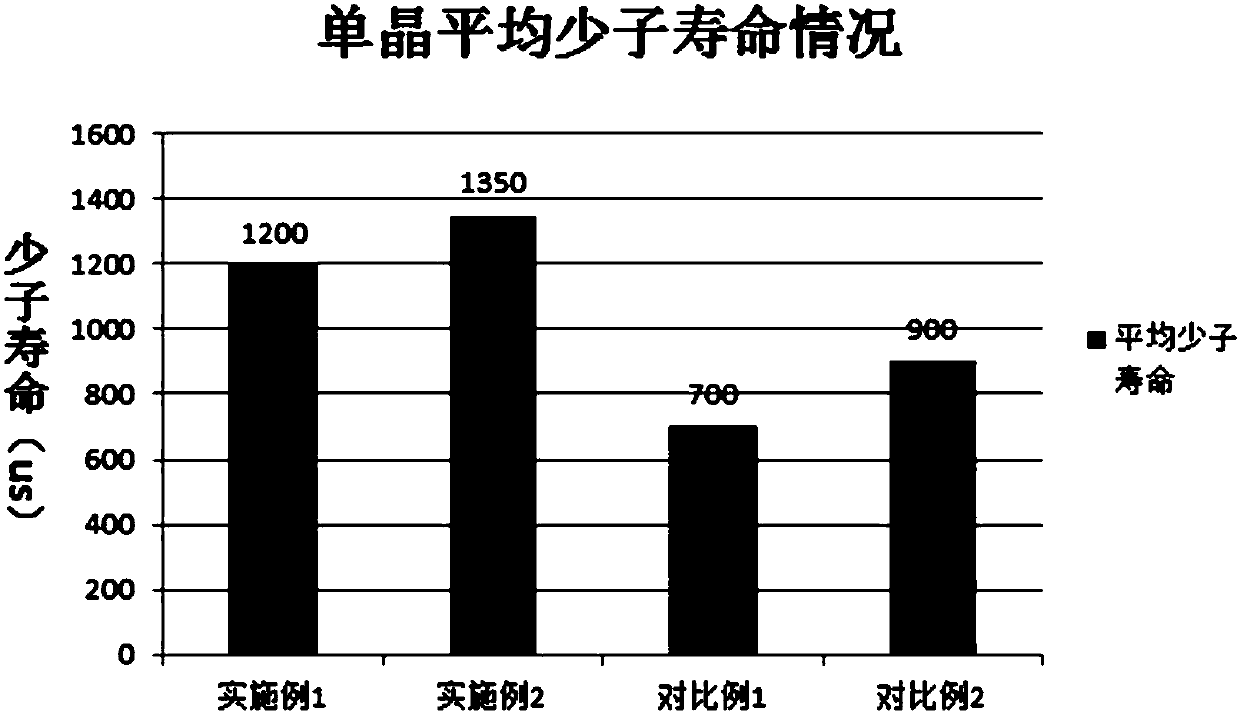

Annealing method capable of recovering real resistivity of NTD (neutron transmutation doping) zone-melting monocrystalline silicon

ActiveCN107641837ARecover damageLow impurity contentAfter-treatment detailsNeutron irradiationSurface cleaning

The invention discloses an annealing method capable of recovering the real resistivity of NTD (neutron transmutation doping) zone-melting monocrystalline silicon. The method includes the steps A, performing corrosion and surface cleaning on the zone-melting silicon single crystals after neutron transmutation doping; B, performing surface passivation on the cleaned zone-melting silicon single crystals; C, loading the passivated zone-melting silicon single crystals into an annealing furnace quartz tube under nitrogen atmosphere, and performing fast annealing; D, closing a nitrogen flow valve, opening an oxygen flow valve, and performing annealing on the single crystals; E, closing the oxygen flow valve, taking out the silicon single crystals from the quartz tube, pickling to remove an oxidelayer, performing sand blasting to test single crystal resistivity and minority carrier lifetime. The annealing method has the advantages that the real resistivity of the NTD zone-melting silicon single crystals annealed by the method can be reflected effectively, the resistivity of the single crystals does not change evidently through multiple times of annealing, and the minority carrier lifetimeof the single crystals is prolonged evidently.

Owner:HEBEI UNIV OF TECH

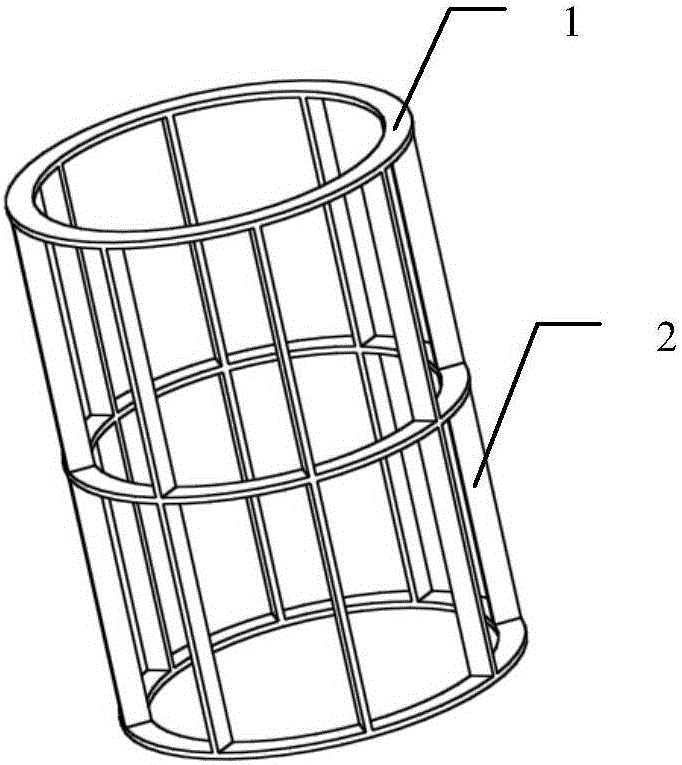

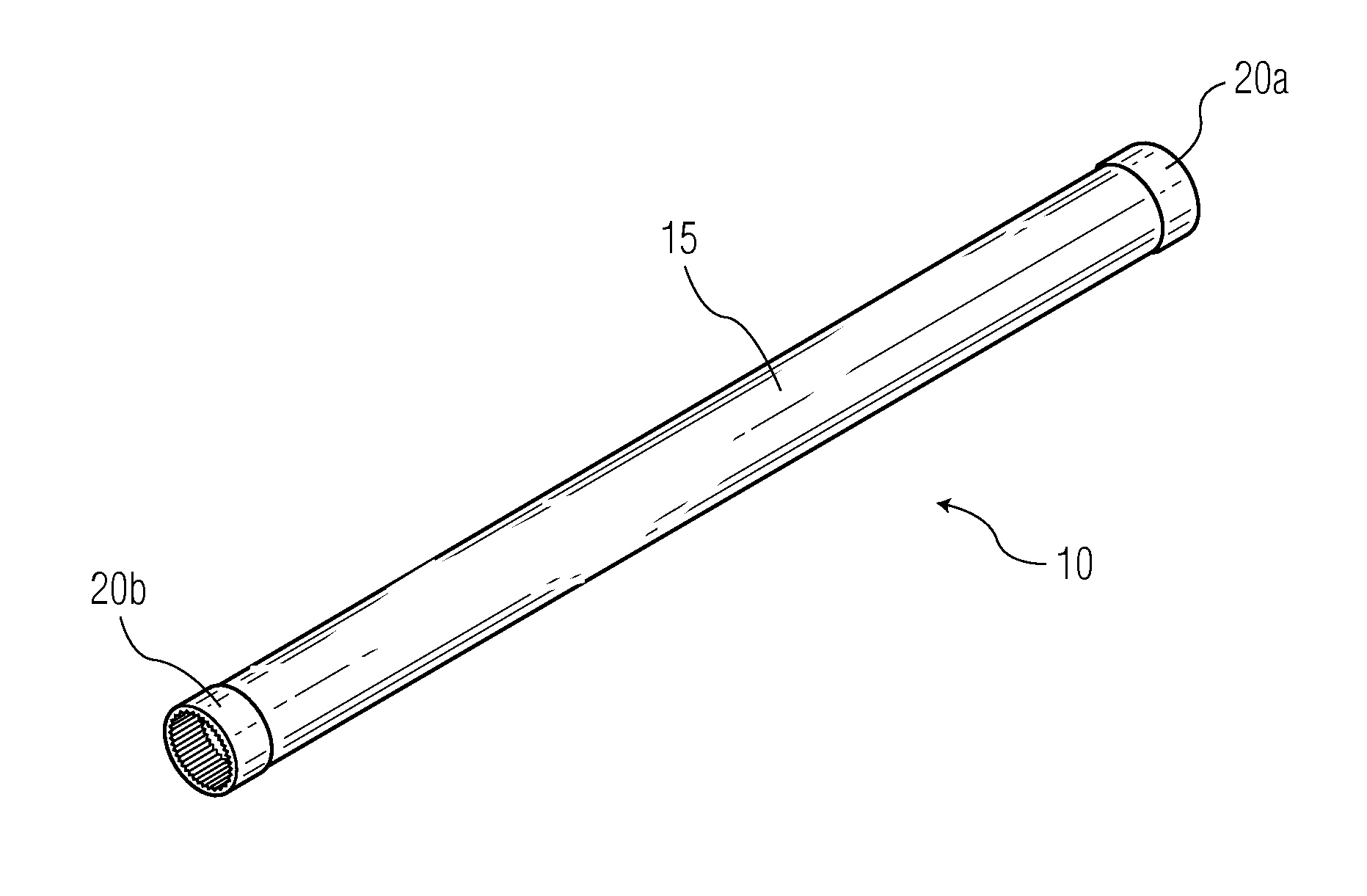

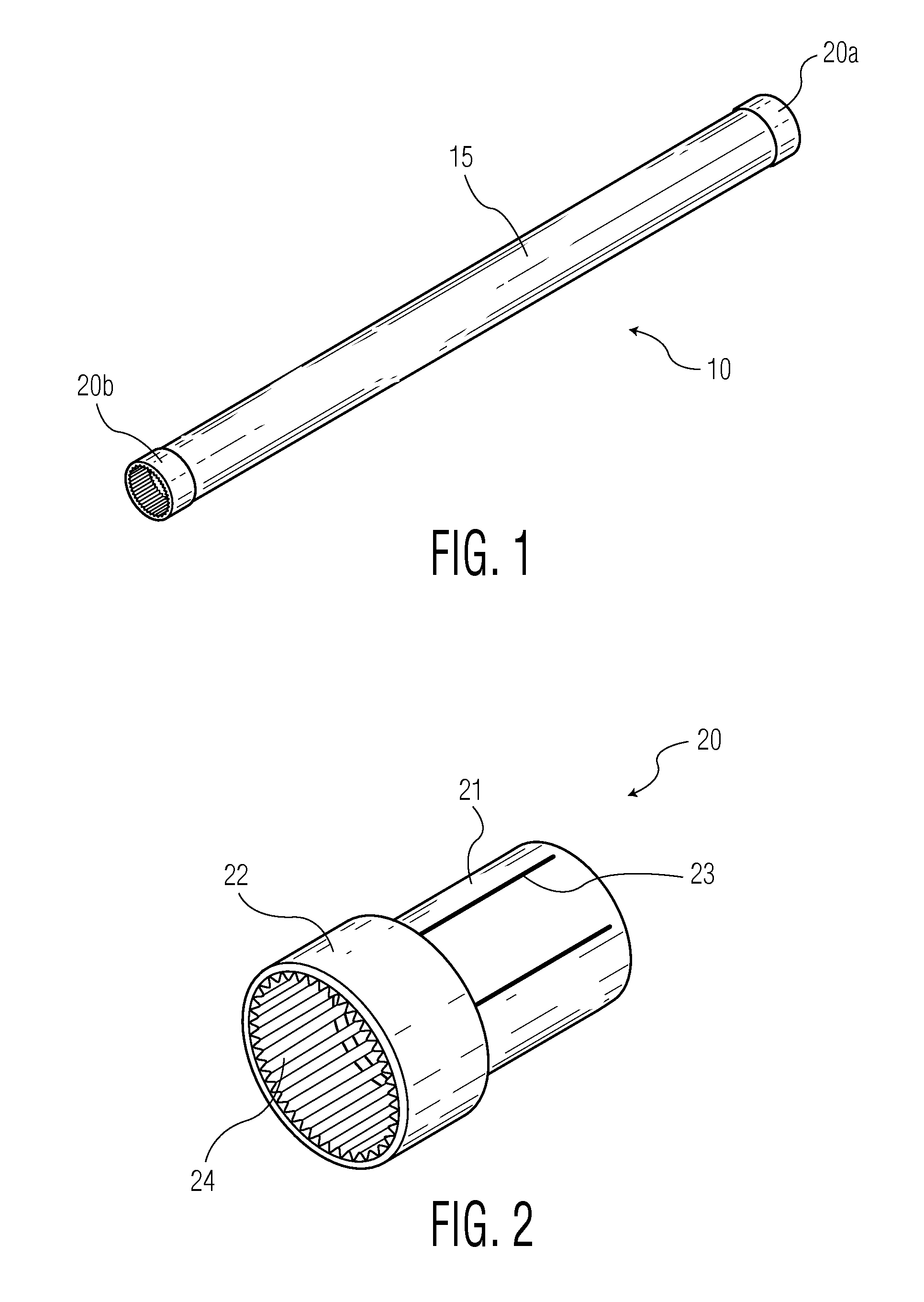

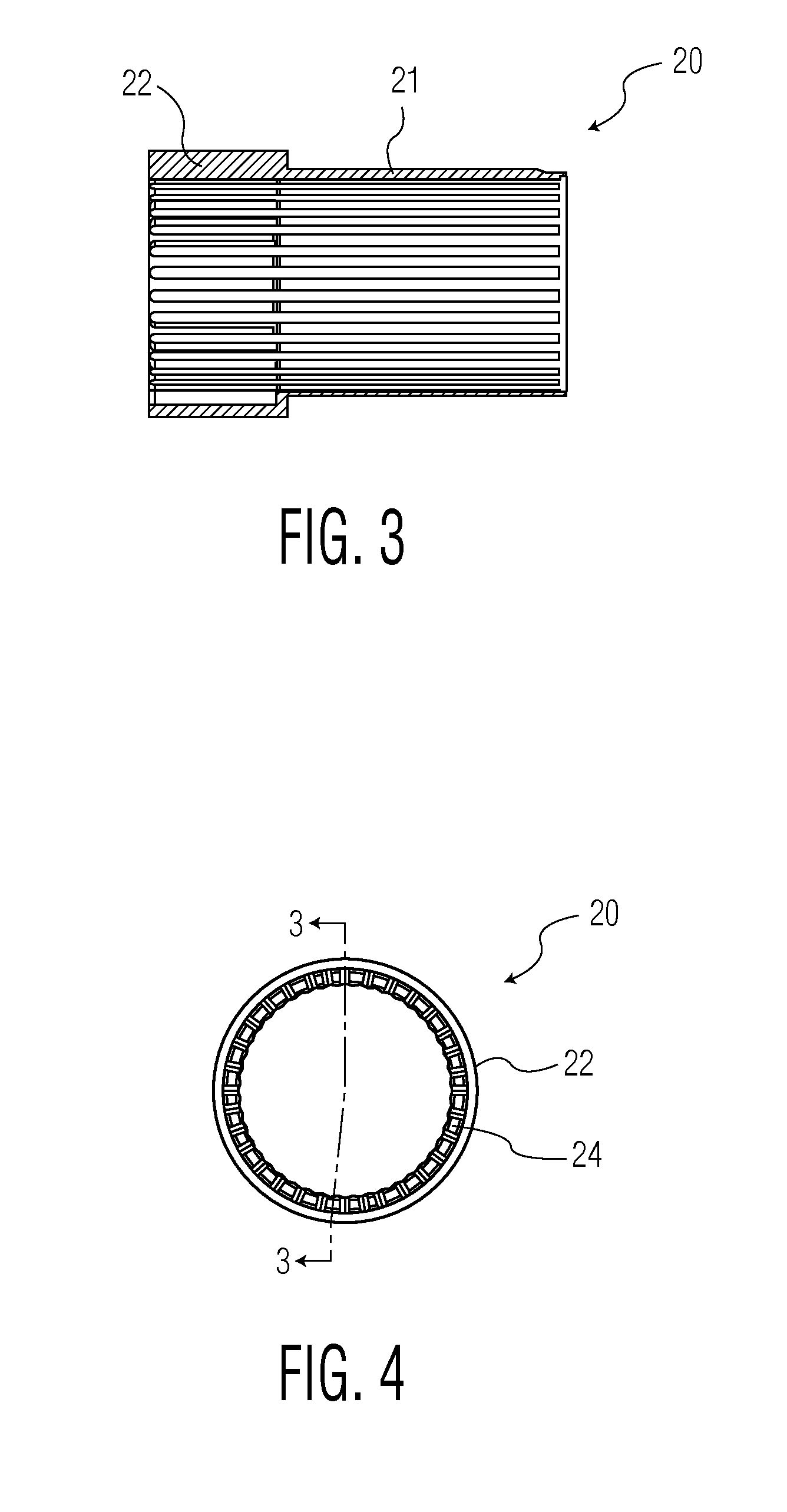

Bobbin for roll stock

In one embodiment of the present invention, a device for supporting and storing wound material thereon may include a substantially cylindrical, hollow bobbin having a thickness defined by an inner and outer diameter for supporting and storing material wound around the exterior surface thereof, and a reinforcing apparatus located at one end of the bobbin, the apparatus having generally a cylindrical shape and a length comprising two zones, the outside surface of the first zone being in contact with a portion of an inner surface of the bobbin, and the second zone of the apparatus extending beyond the end of the bobbin.

Owner:TAMA PLASTIC IND

Method for producing sugar charcoal particle sugar charcoal by physical method

InactiveCN101503190BCaramel decolorization is goodImprove wear resistanceMonosodium glutamateInorganic compound

The invention discloses a method for producing sugar charcoal particles by using physical method. Ammonium polyphosphate and petroleum hard bitumen are added into coal property and proper exciple carbonized material and then crushed; the crushed material is kneaded after being added with coal tar and water solution containing inorganic compound to be extruded into strip material, and then the obtained material is dried, carbonized at 500-550 DEG C and activated at 850-950 DEG C. The obtained sugar charcoal particles have the technical performance of physical carbon and chemical carbon, and caramel has good decolourization and high abrasive resistance, so that the sugar charcoal particles can be widely applied for decolourization, water treatment and recovery of organic macromolecular solution, for example, the decolourization of citric acid, monosodium glutamate, lactic acid and starch sugar, the recovery of high boiling macromolecular organic solvents such as gasoline, dimethyl diamide, etc.

Owner:HUAIBEI DAHUA ACTIVE CARBON +1

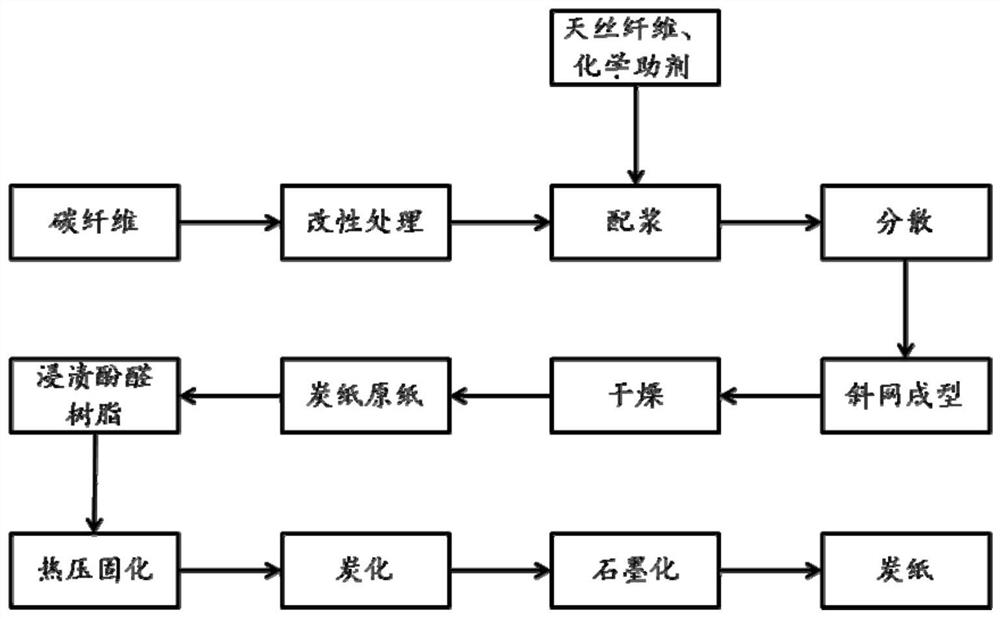

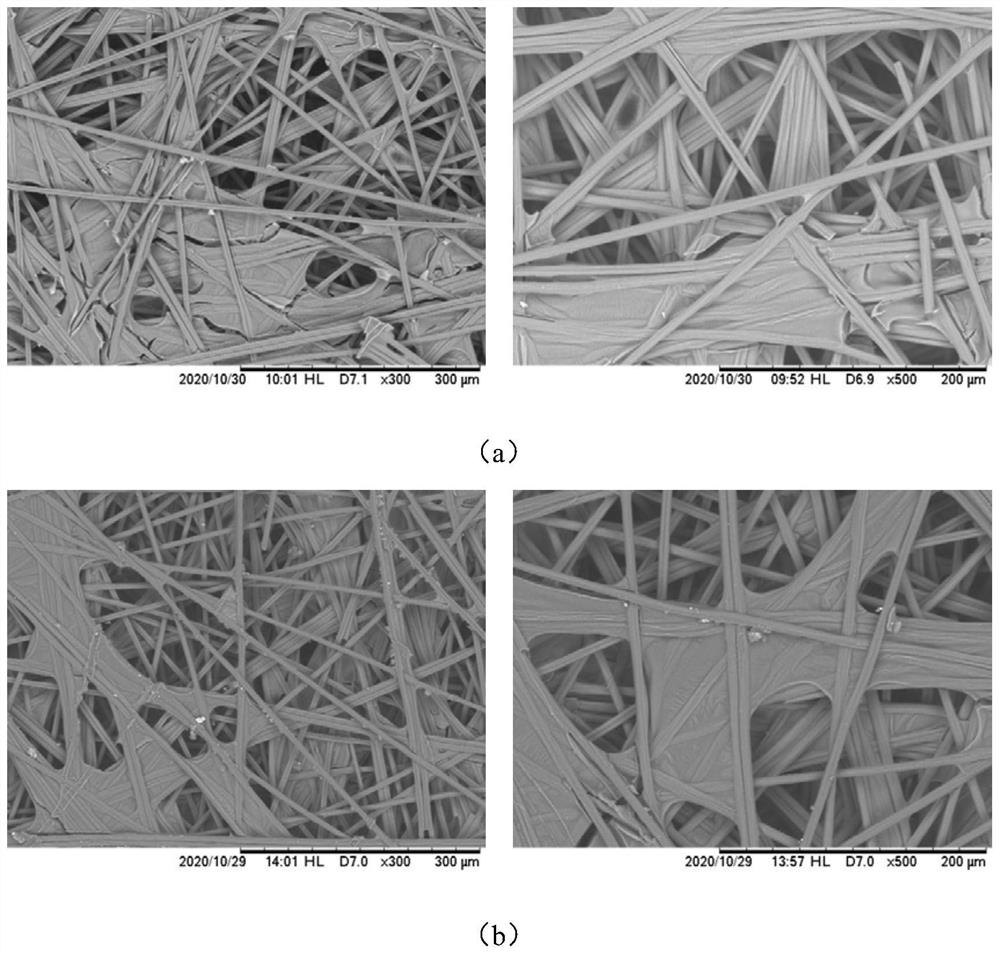

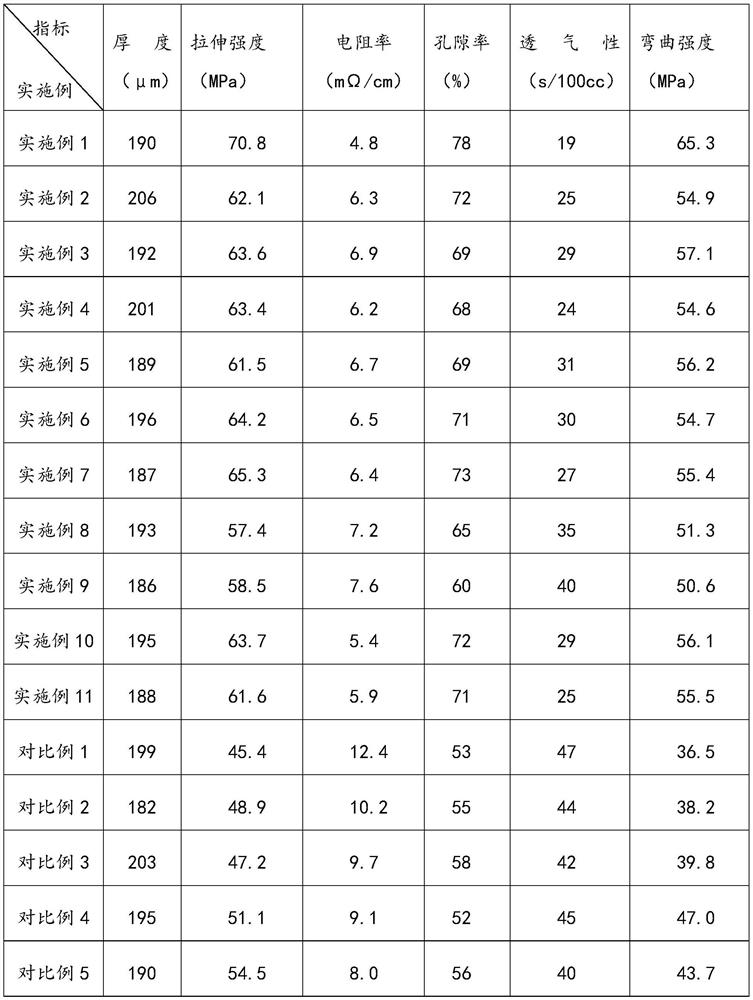

Method for modifying high-performance carbon paper based on supercritical fluid technology

ActiveCN112982027AIndestructible strengthGood dispersionSpecial paperCarbon fibresFiberCarbon fibers

The invention discloses am ethod for modifying high-performance carbon paper based on supercritical fluid technology. Under the action of the supercritical fluid, O2 and a titanate coupling agent are used for cooperatively modifying the carbon fibers, on one hand, the oxidation time can be shortened, the roughness and oxygen-containing groups of the surfaces of the carbon fibers can be improved, the surfaces of the carbon fibers are more effectively wetted, and uniform surface modification is achieved; and on the other hand, the titanate coupling agent has molecules with two groups with different properties, so that the defect that the modification effect of a single titanate coupling agent is not obvious because the number and the variety of oxygen-containing functional groups on the surface of the carbon fiber are relatively small can be overcome, and the mechanical property and the conductivity of the carbon paper are improved.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

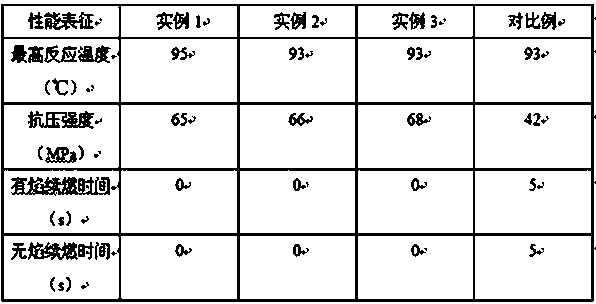

Preparation method of mining reinforcement material

InactiveCN109971159AExcellent flame retardantIncrease surface areaIn situ polymerizationLayered structure

The invention relates to a preparation method of a mining reinforcement material, and belongs to the technical field of mining materials. The preparation method of the mining reinforcement material ischaracterized in that based on the flame retardance characteristic of ammonium polyphosphate, with diatomite as a carrier, a double-component ammonium polyphosphate-diatomite inorganic composite flame-retardant filler is prepared by an in-situ polymerization method, and an ammonium polyphosphate-diatomite / synergist composite flame-retardant filler is designed on the basis of the double-componentcomposite flame-retardant filler with magnesium hydroxide the synergist; with good smoke absorbing effect of the diatomite with high specific surface area and based on the special layered structure and composition and also flame retarding, smoke suppressing and acid resisting functions of magnesium hydroxide, the prepared mining reinforcement material is allowed to have good flame retarding and smoke suppressing properties; cellular glass cloth is used as a reinforcing agent for the mining reinforcement material, so that the strength of the mining reinforcement material is effectively improved; and according to the invention, a synergistic effect between two flame-retardant elements silicon and phosphorus causes a decrease in the number of brittle amorphous carbon layers generated and an improvement in the flame retardance of the mining reinforcement material.

Owner:张文中

Blast furnace iron manufacturing process

InactiveCN101476002BPromote reductionImprove economyBlast furnace detailsSmelting processMaterials science

The present invention provides a blast furnace iron-smelting method, including: a first step, loading coke, semi-coke and other iron-contained charging stock into the blast furnace, wherein, the semi-coke has a scheduled weight ratio in the coke and semi-coke; and a second step, performing conventional iron-smelting operations after the loading. The method can use semi-coke to replace part of coke, thus can reduce the amount of coke in the blast furnace iron-smelting process.

Owner:BEIJING ZHONGDIAN HUAFANG TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com