Vehicle-mounted noise reduction battery heat shield and processing method thereof

A processing method and heat shield technology are applied in the vehicle-mounted noise-reducing battery heat shield and its processing field, which can solve the problems of high noise in the air-cooling process and limited heat insulation effect of ordinary heat shields, so as to ensure safety and good performance. Protection, little vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

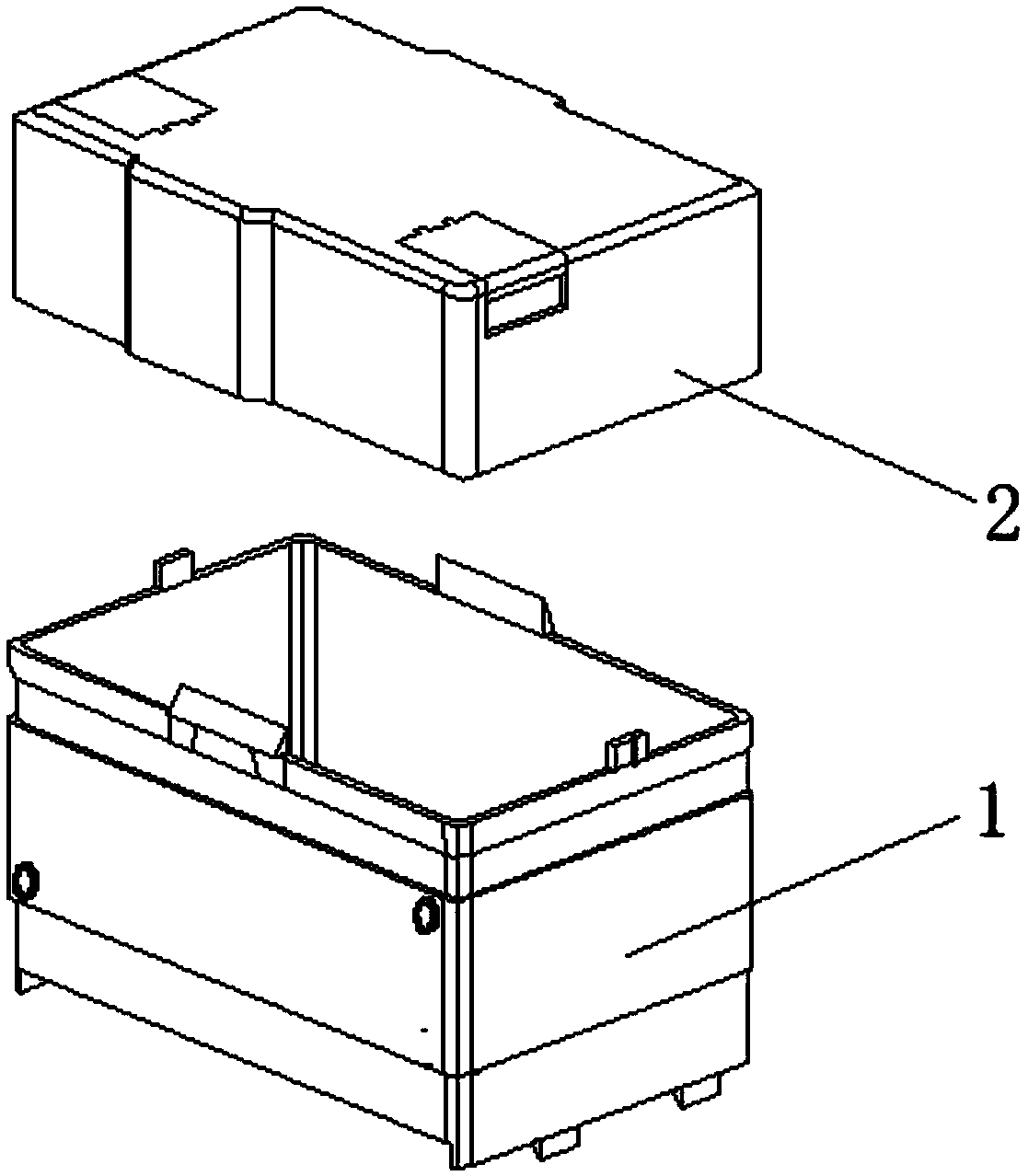

[0032] like Figure 1-Figure 5 As shown, the present invention provides a vehicle-mounted noise reduction battery heat shield. Specific embodiments are as follows:

Embodiment

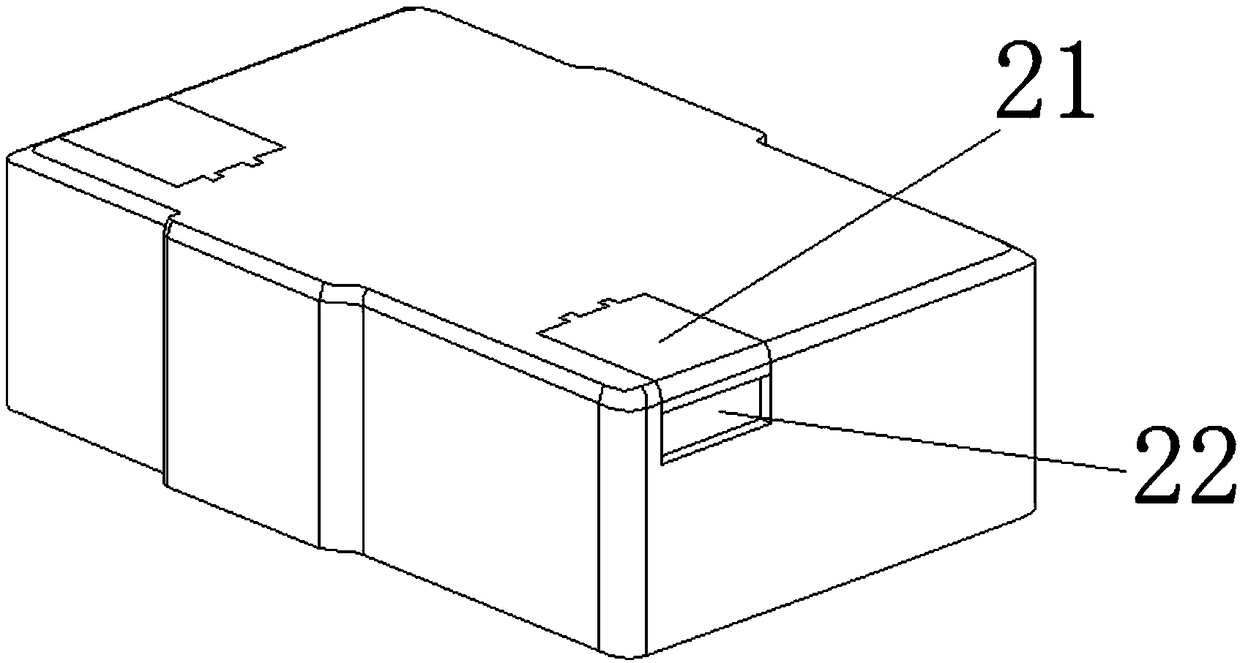

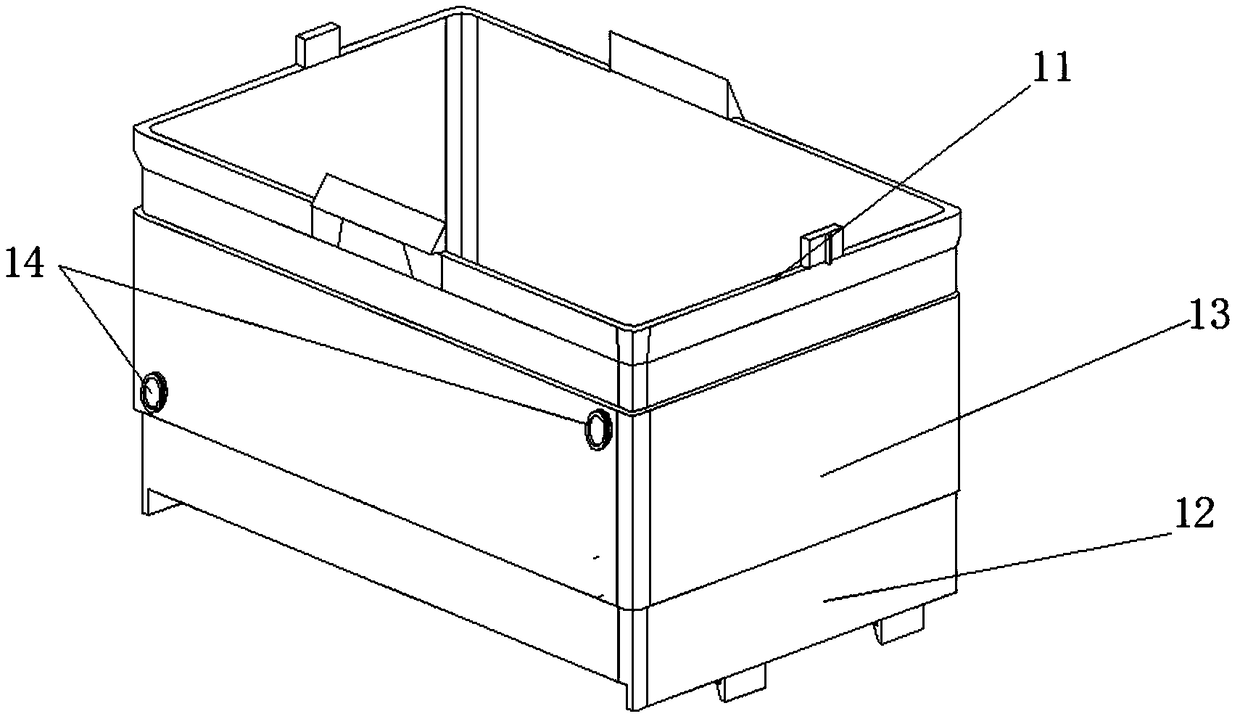

[0034] The vehicle-mounted noise reduction battery heat shield includes a cover body 1 and a cover cover 2. The cover cover 2 has only one layer of shell that is a heat-insulating shell 11. The cover body 1 has two layers of shells, and the inner shell is also a heat-insulating shell 11. On the outside is the metal casing. The heat insulation shell 11 of the cover body 1 is columnar and a metal shell is riveted outside.

[0035] The metal shell is also divided into two layers, which are an inner shell 12 and an outer shell 13 respectively. The surface of the inner casing 12 is provided with a groove 151 extending from top to bottom in an orderly manner along the outer side of the inner casing 12 , and a sealing plate 152 is welded on the outer side of the inner casing 12 and extends along the groove 151 . In this way, the groove 151 sealed by the sealing plate 152 forms the cooling channel 15 . The outer casing 13 is welded on the outer side of the inner casing 12 to cover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com