Production method of desulfurization and denitrification active coke catalyst

A production method, a technology of nitrating activated coke, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as not being able to meet the requirements of sintering flue gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

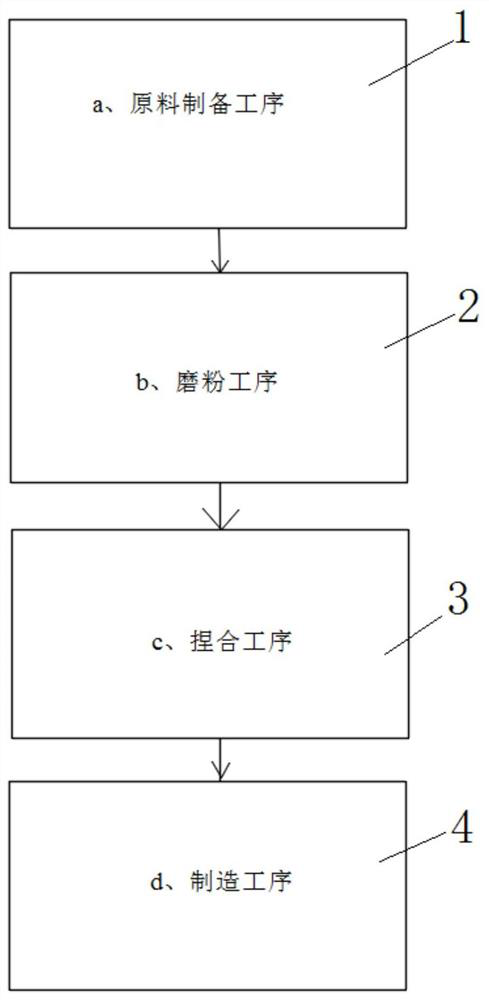

[0039] A method for producing a desulfurization and denitrification active coke catalyst, which comprises the following steps,

[0040] a. Raw material preparation process 1: According to parts by weight, mix 3 parts of semi-coke, 2 parts of Shenmu coal, 3 parts of coking coal, 1 part of anthracite and 1 part of catalyst evenly. The catalyst is sodium calcium salt of phthalocyanine cobalt tetrasulfonate, hydroxide Potassium, carbonamide, sodium carbonate, chromium nitrate, vanadium pentoxide and copper nitrate;

[0041] b. Milling process 2: The mixed raw materials are stored in the closed raw material warehouse, and the raw materials are poured into the raw material buffer warehouse through the loader, and then sent to the Raymond mill through the conveyor belt, and the Raymond mill grinds the mixed raw materials Powder, so that the raw materials can pass through the 200-mesh sieve, and the raw materials with qualified particle size are airtightly transported to the raw mater...

Embodiment 2

[0056] A method for producing a desulfurization and denitrification active coke catalyst, which comprises the following steps,

[0057] a. Raw material preparation process 1: According to parts by weight, mix 2 parts of semi-coke, 1 part of Shenmu coal, 2 parts of coking coal, 0.5 part of anthracite and 0.5 part of catalyst evenly. The catalyst is sodium calcium salt of cobalt phthalocyanine tetrasulfonate, hydroxide Potassium, carbonamide, sodium carbonate, chromium nitrate, vanadium pentoxide and copper nitrate;

[0058] b. Milling process 2: The mixed raw materials are stored in the closed raw material warehouse, and the raw materials are poured into the raw material buffer warehouse through the loader, and then sent to the Raymond mill through the conveyor belt, and the Raymond mill grinds the mixed raw materials Powder, so that the raw materials can pass through the 200-mesh sieve, and the raw materials with qualified particle size are airtightly transported to the raw ma...

Embodiment 3

[0073] A method for producing a desulfurization and denitrification active coke catalyst, which comprises the following steps,

[0074] a. Raw material preparation process 1: According to parts by weight, mix 4 parts of semi-coke, 3 parts of Shenmu coal, 4 parts of coking coal, 1.5 parts of anthracite and 1.5 parts of catalyst evenly. The catalyst is sodium calcium salt of cobalt phthalocyanine tetrasulfonate, hydroxide Potassium, carbonamide, sodium carbonate, chromium nitrate, vanadium pentoxide and copper nitrate;

[0075] b. Milling process 2: The mixed raw materials are stored in the closed raw material warehouse, and the raw materials are poured into the raw material buffer warehouse through the loader, and then sent to the Raymond mill through the conveyor belt, and the Raymond mill grinds the mixed raw materials Powder, so that the raw materials can pass through the 200-mesh sieve, and the raw materials with qualified particle size are airtightly transported to the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com