Preparation method of fir nano fiber

A technology of nanofiber and Chinese fir, which is applied in fiber raw materials, fiber raw material treatment, cellulose pulp post-treatment, etc. It can solve the problems of low catalytic activity of Chinese fir pulp, difficulty in obtaining and meeting requirements, low production efficiency, etc., and achieve excellent catalytic performance. Activity, high production efficiency, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 of the present invention provides a kind of preparation method of Chinese fir nanofiber, comprises the following steps carried out in sequence:

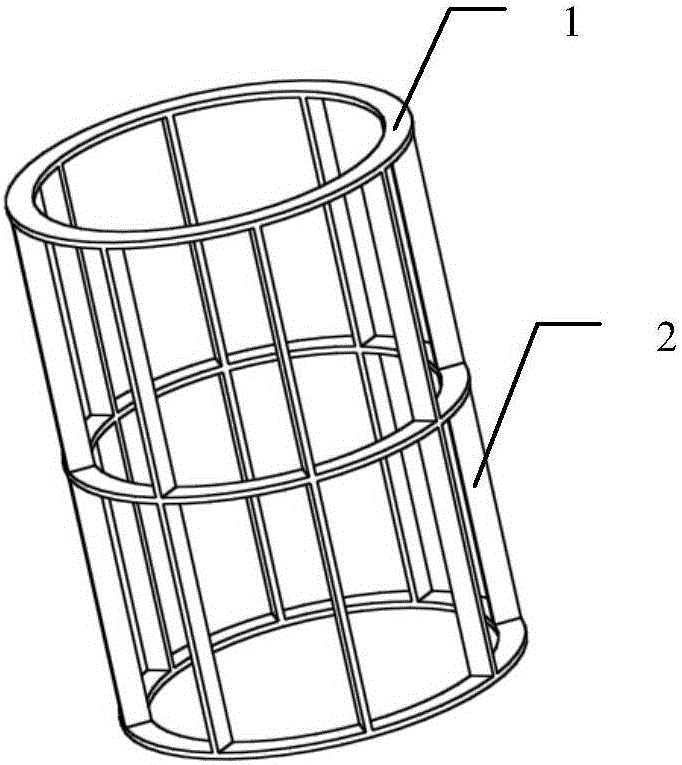

[0031] S1. Add the Chinese fir fiber raw material to the cooking equipment, add 12-18% of the cooking liquid by weight of the Chinese fir fiber raw material, first pre-cook at 80-95°C for 30-45min, then heat up to 130-160°C for 2-2.5 hours , then lower the temperature to 60°C, spray 1,2-dibromoethane ethanol solution into the cooking equipment, stir for 1 hour, remove the residual liquid, and finally obtain the cooking slurry; wherein, the cooking liquid contains the following components in weight percentage : Emodin 2-3%, NaOH 1-1.5%, tetrabutylammonium bromide 0.3-0.6%, hydroxymethyl cellulose 1-2%, o-benzoylsulfonimide 0.05-0.2%, potassium citrate 1 to 3%, 1.5 to 2% methacrylic acid; the volume ratio of 1,2-dibromoethane to ethanol in the 1,2-dibromoethane ethanol solution is 1:10, and the spraying amount is th...

Embodiment 2

[0044] Embodiment 2 of the present invention provides a kind of preparation method of Chinese fir nanofiber, comprises the following steps carried out in sequence:

[0045] S1. Add the Chinese fir fiber raw material to the cooking equipment, add 12-18% of the cooking liquid by weight of the Chinese fir fiber raw material, first pre-cook at 80-95°C for 30-45min, then heat up to 130-160°C for 2-2.5 hours , then lower the temperature to 60°C, spray 1,2-dibromoethane ethanol solution into the cooking equipment, stir for 1 hour, remove the residual liquid, and finally obtain the cooking slurry; wherein, the cooking liquid contains the following components in weight percentage : Emodin 2-3%, NaOH 1-1.5%, tetrabutylammonium bromide 0.3-0.6%, hydroxymethyl cellulose 1-2%, o-benzoylsulfonimide 0.05-0.2%, potassium citrate 1 to 3%, 1.5 to 2% methacrylic acid; the volume ratio of 1,2-dibromoethane to ethanol in the 1,2-dibromoethane ethanol solution is 1:10, and the spraying amount is th...

Embodiment 3

[0060] Embodiment 3 of the present invention provides a kind of preparation method of Chinese fir nanofiber, comprises the following steps carried out in sequence:

[0061] S1. Add the Chinese fir fiber raw material to the cooking equipment, add 12-18% of the cooking liquid by weight of the Chinese fir fiber raw material, first pre-cook at 80-95°C for 30-45min, then heat up to 130-160°C for 2-2.5 hours , then lower the temperature to 60°C, spray 1,2-dibromoethane ethanol solution into the cooking equipment, stir for 1 hour, remove the residual liquid, and finally obtain the cooking slurry; wherein, the cooking liquid contains the following components in weight percentage : Emodin 2-3%, NaOH 1-1.5%, tetrabutylammonium bromide 0.3-0.6%, hydroxymethyl cellulose 1-2%, o-benzoylsulfonimide 0.05-0.2%, potassium citrate 1 to 3%, 1.5 to 2% methacrylic acid; the volume ratio of 1,2-dibromoethane to ethanol in the 1,2-dibromoethane ethanol solution is 1:10, and the spraying amount is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com