Blasting method for reducing ore loss and dilution

A depletion and ore technology, applied in the field of blasting to reduce ore loss and depletion, can solve the problems of difficulty in realizing the reservation of a regular thin ore protective layer, failure to meet the strength requirements of the supporting roof, blasting and shock of the protective layer, etc. The effect of reducing ore dilution rate, preventing ore loss, and protecting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

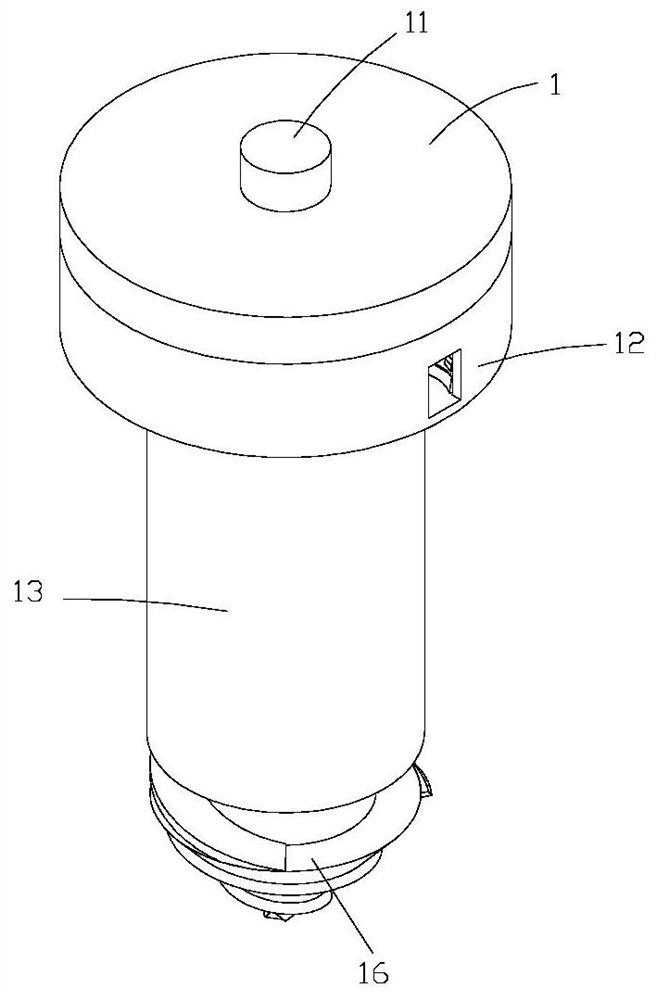

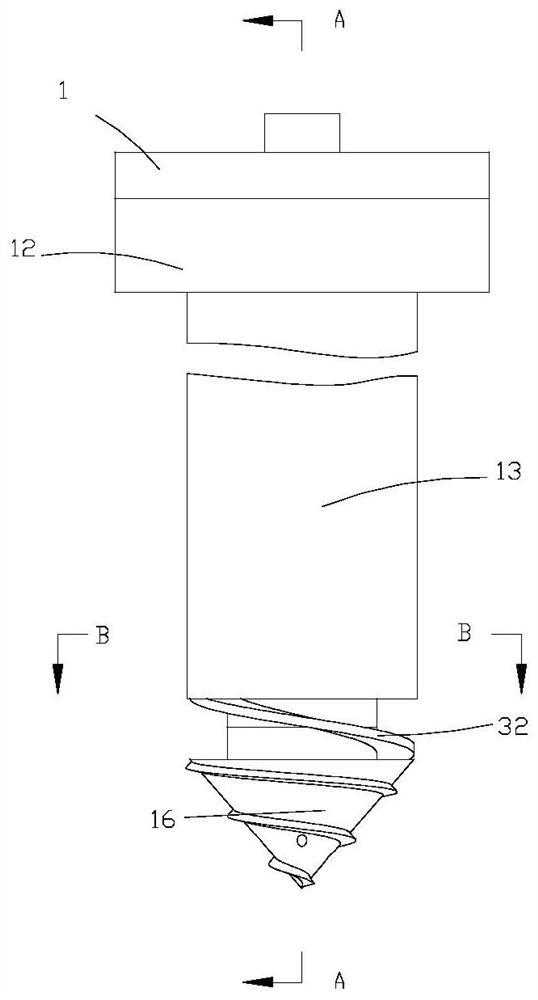

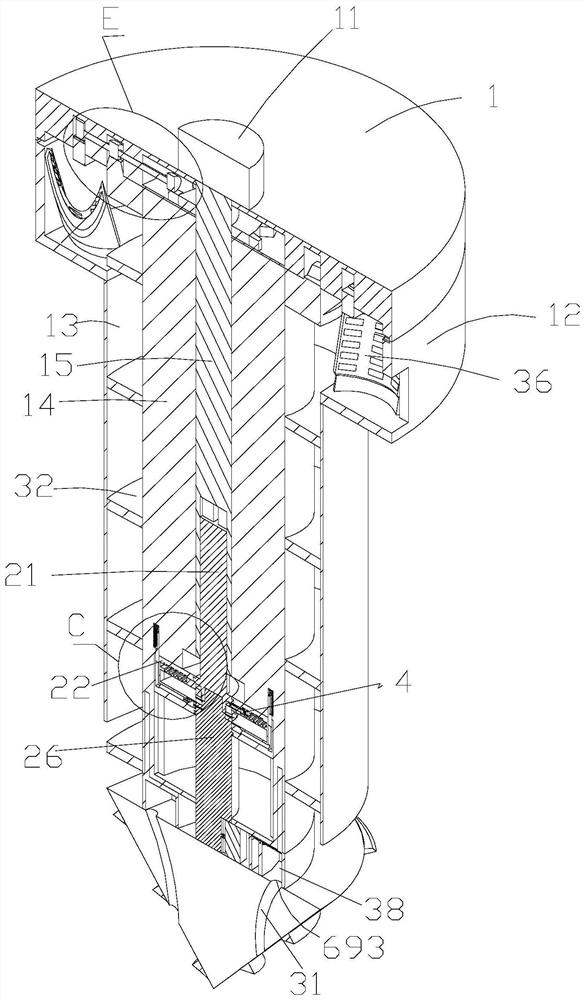

[0033] Such as Figure 1-12 As shown, a blasting method for reducing ore loss and dilution includes the following steps: a. Hole row: after determining the blasting section, arrange a row of control blasting holes horizontally near the boundary line between the direct roof and the ore body. Several rows of main gun holes are longitudinally arranged below the holes;

[0034] b. Drilling: Use a punching machine to drill holes so that the directions of the blast holes are parallel to each other, and the depth of the main blast hole is greater than the depth of the control blast hole;

[0035] c. Charging: charge the main gun hole according to the designed charging density according to the continuous charging structure, and charge the control blast hole according to the interval charging structure; And the differential detonator is detonated and connected in series;

[0036] d. Blasting: starting from the main blast holes near the free surface, detonate the main blast holes one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com