Thermo-regulated nanofiber with rapid heat absorption and release functions and preparation method of thermo-regulated nanofiber

A heat storage and temperature adjustment, heat absorption and release technology, applied in the direction of fiber chemical characteristics, heat exchange materials, chemical instruments and methods, etc., can solve the problems that limit the development and application of organic phase change materials, and achieve excellent structural stability, The effect of fast adjustment ability and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

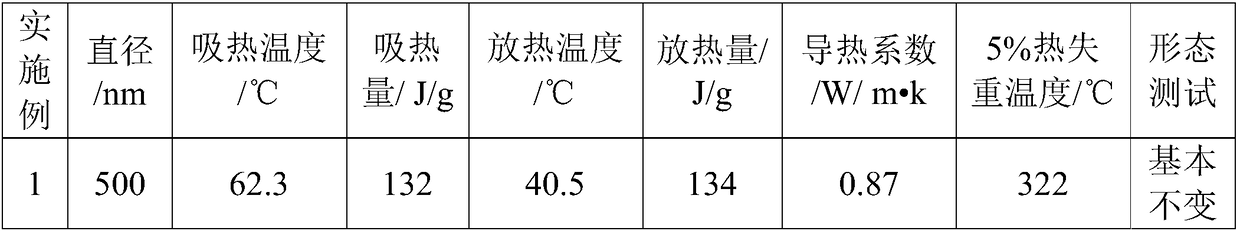

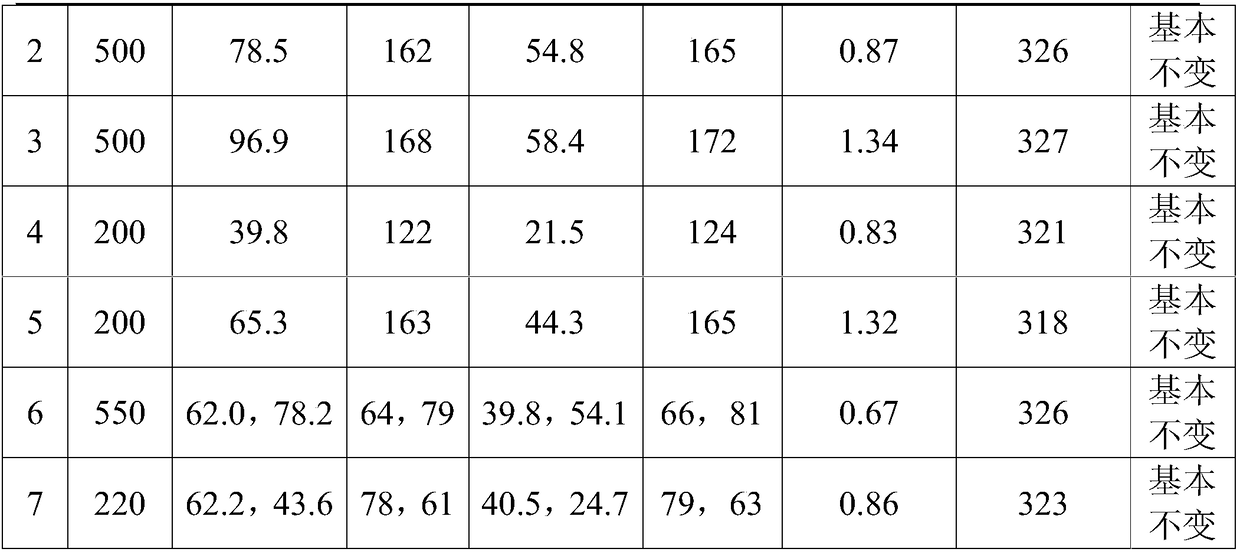

Embodiment 1

[0037] Mix polyacrylonitrile acrylic acid-g-n-octadecyl alcohol and graphene with a mass ratio of 95:5 into DMF to prepare a spinning solution with a mass concentration of 20%, and perform electrospinning under the following conditions to obtain nano-scale heat storage Warm fiber;

[0038] The electrospinning conditions are as follows: spinning voltage is 15kV, receiving distance is 20cm, propulsion rate is 10ml / min, nanofibers are collected by drum, and the drum speed is 800r / min; the ambient temperature is 25°C, and the humidity is 65%.

Embodiment 2

[0040] Mix polyacrylonitrile acrylic acid-g-n-hexacosanol and graphene with a mass ratio of 95:5 into DMF to prepare a spinning solution with a mass concentration of 20%, and electrospin under the following conditions to obtain nano heat storage temperature regulating fiber;

[0041] The electrospinning conditions are as follows: spinning voltage is 15kV, receiving distance is 20cm, propulsion rate is 10ml / min, nanofibers are collected by drum, and the drum speed is 800r / min; the ambient temperature is 25°C, and the humidity is 65%.

Embodiment 3

[0043] Mix polyacrylonitrile acrylic acid-g-tetracontanol and graphene with a mass ratio of 90:10 into DMF to prepare a spinning solution with a mass concentration of 20%, and perform electrospinning under the following conditions to obtain nano-scale heat storage Warm fiber;

[0044] The electrospinning conditions are as follows: spinning voltage is 15kV, receiving distance is 20cm, propulsion rate is 10ml / min, nanofibers are collected by drum, and the drum speed is 800r / min; the ambient temperature is 25°C, and the humidity is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Endothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com