Longitudinal element, in particular for traction or suspension means

A technology of longitudinal elements, traction devices, applied in the direction of handling parts, applications, textiles and paper making, which can solve the problems of insufficient protection of combined ropes, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

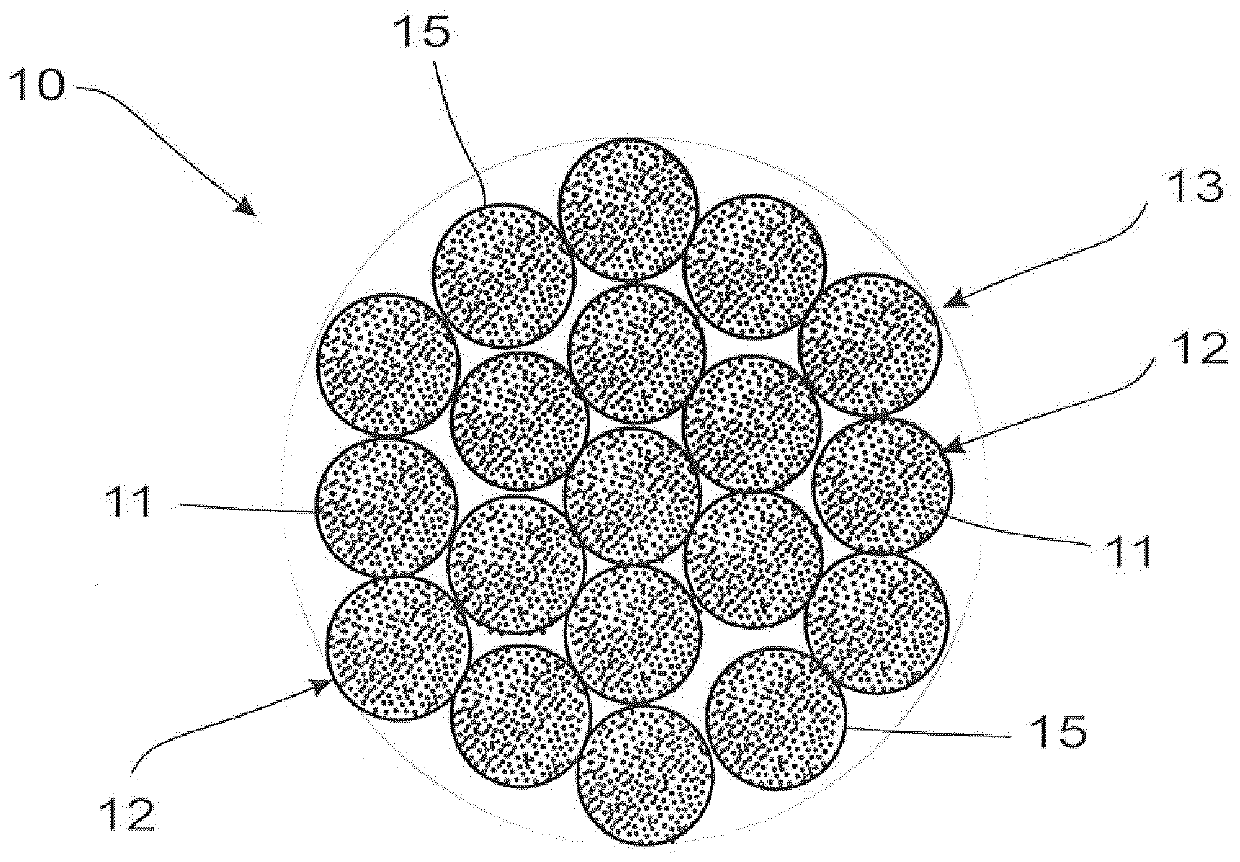

[0029] figure 1 A longitudinal element 13 is shown, by means of which traction and / or load-bearing forces can be absorbed, in particular even at very high forces. The longitudinal element can be used in various fields, as explained below according to different embodiments.

[0030] According to the invention, this longitudinal element 13 configured as a wire is made of a core 12, which is preferably steel or Stainless steel.

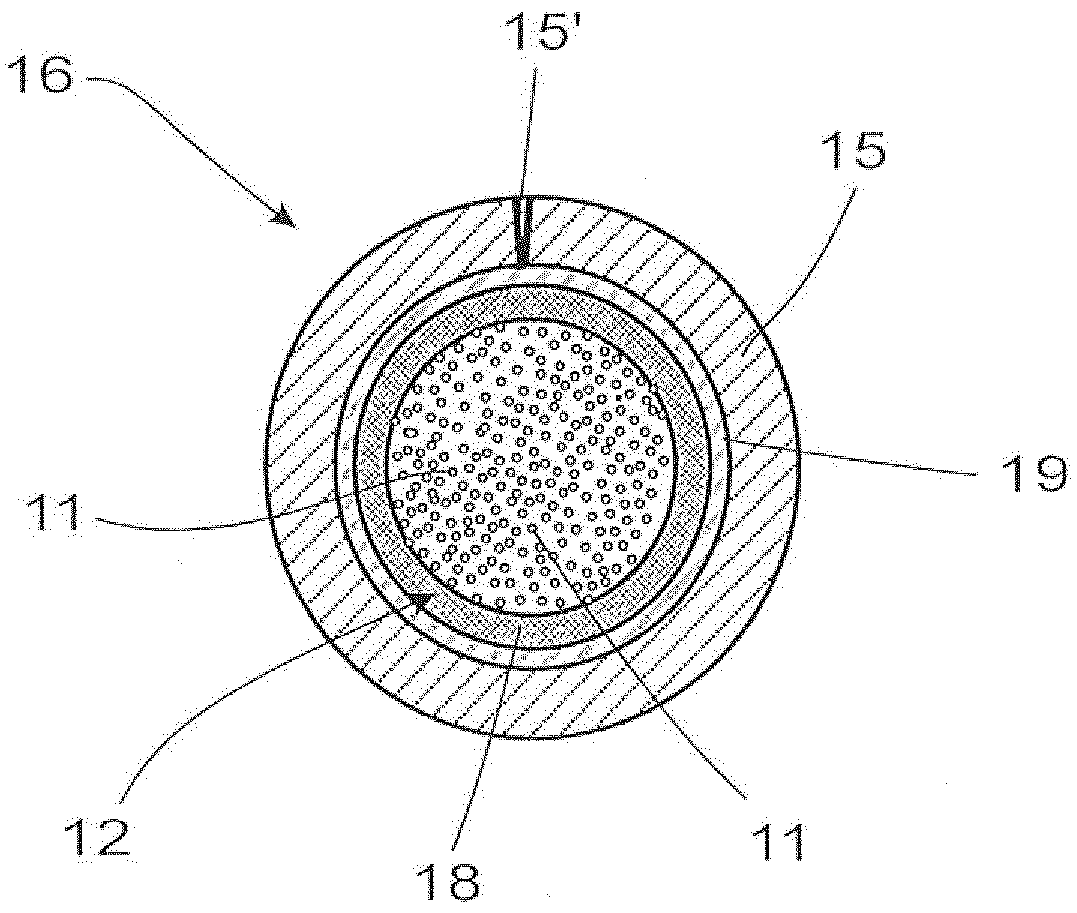

[0031] A metal sheath 15 is arranged around the core 12 formed by the fibers 11 and remains connected along the longitudinal extension of the longitudinal element 13, for example by welded seams 15' at the abutment faces of the side edges.

[0032] Such welding with the metal sheath 15 produces an air- and water-tight layer for the fibers 11 . Thus, these fibers remain permanently sealed against UV light and the atmosphere, which results in a longer service life with virtually unchanged strength, but virtually no aging. If the metal casing is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com