Bulletproof composite armor and preparation method thereof

An armor and bulletproof technology, which is applied in the direction of protective equipment, armor, protective equipment, etc., can solve the problems of overweight bulletproof plates and cannot meet the surface density limit of lightweight protective decks, so as to reduce weight and improve the ability to resist multiple bullets Ability to enhance the effect of adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment relates to a preparation method of bulletproof composite armor, comprising:

[0031] Step 1, put 5200g of B 4 C powder (Safe Nanotechnology), 520g of nano-carbon fiber (Suzhou First Element CNTcr), 152g of water-soluble phenolic resin and 6000g of high-purity water are evenly mixed to obtain a ceramic slurry, which is then spray-dried. The temperature of the spray-dried air inlet is 200°C, the temperature of the air outlet is 100°C, and the composite raw material is obtained; then cold-pressed under the pressure of 350MPa to form a regular hexagonal green body with a height of 50mm and a thickness of 6.6mm;

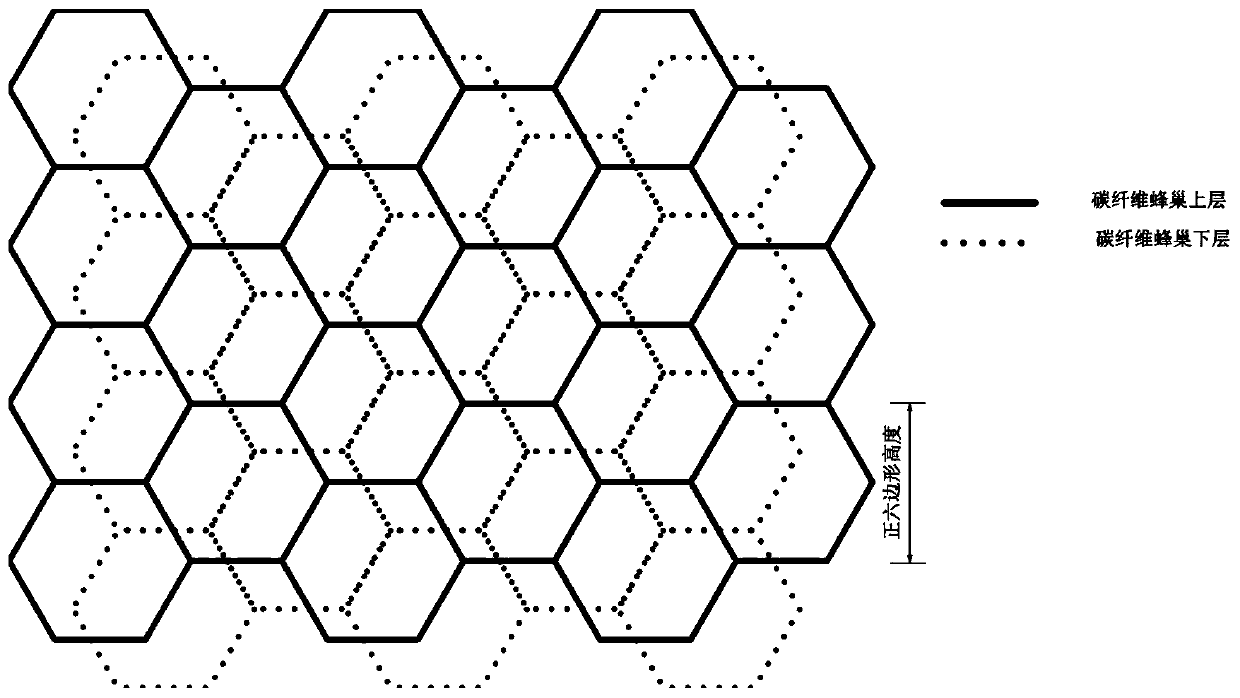

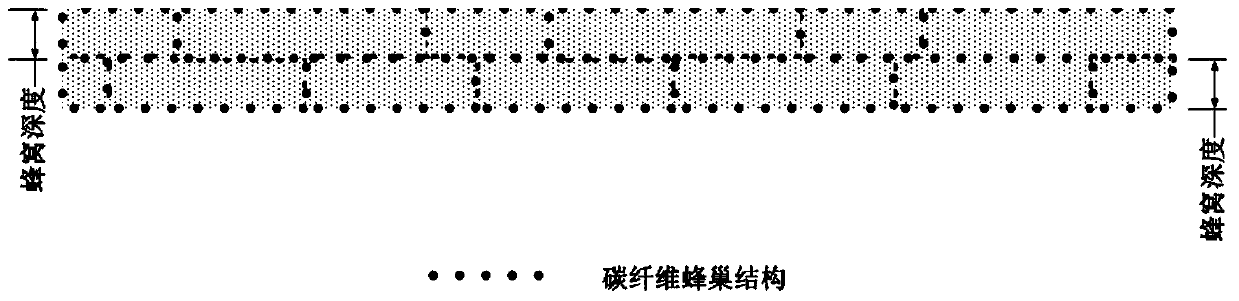

[0032] Step 2, put 192 regular hexagonal green bodies into figure 1 and figure 2 In the two-layer structure honeycomb carbon fiber mesh bag with staggered arrangement as shown, cover the honeycomb with carbon fiber cloth of the same material, and then place it in a hot pressing mold with the same shape and size as the above honeycomb mesh bag; un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com