Protection method for resisting penetration of high velocity armour piercer

An armor-piercing projectile and armor protection technology, applied in protective equipment, armor plate structure, armor and other directions, can solve problems such as slow performance of protective materials, limitations on the thickness of protective materials and the setting size of armor, and the difficulty of effective survival of armored platforms. Damage and damage-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

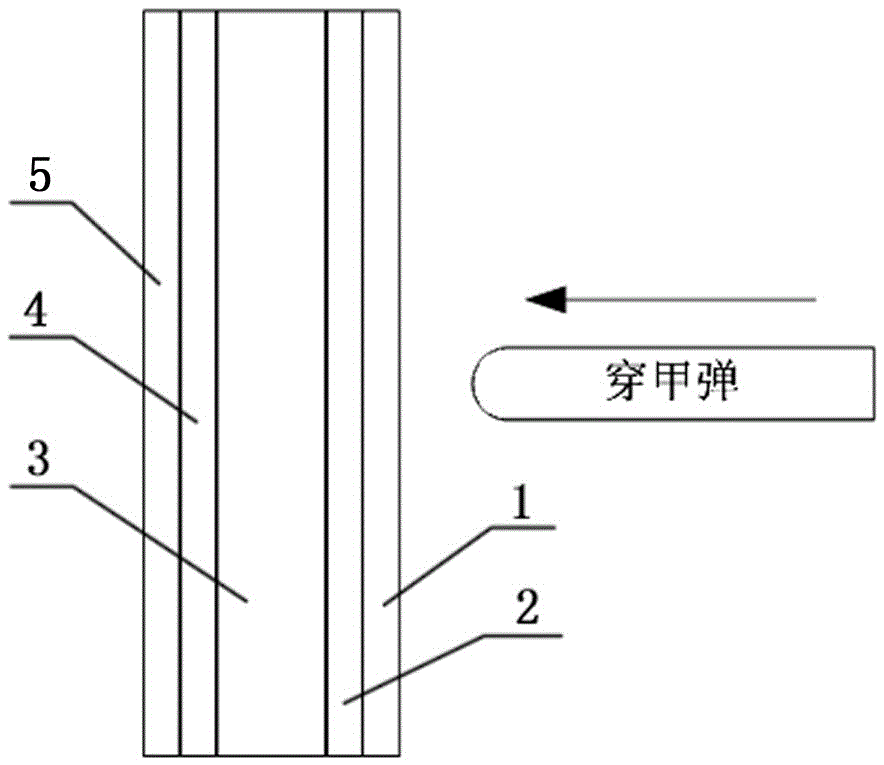

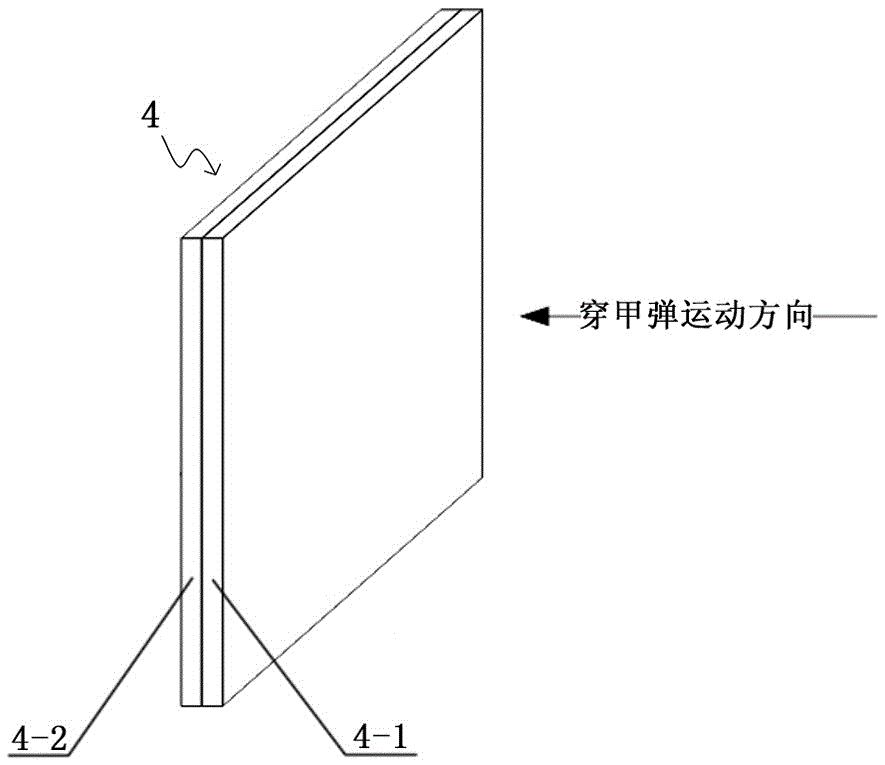

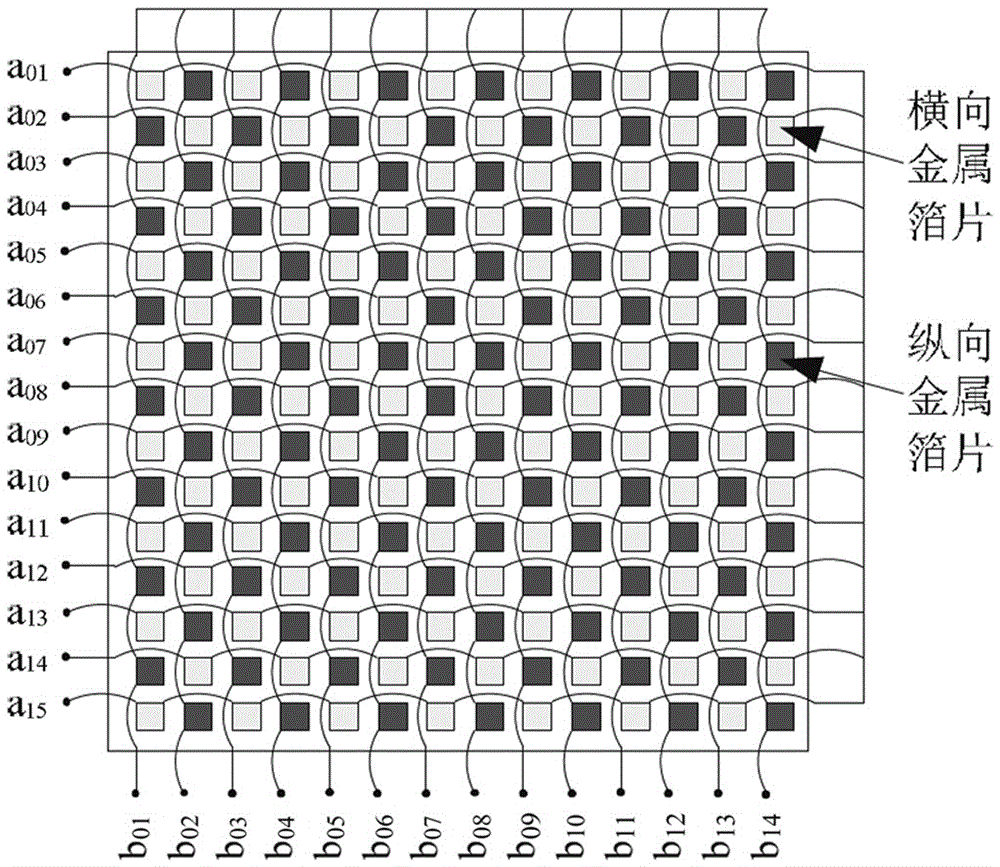

[0029] The anti-high-speed armor-piercing projectile penetration protection method provided by the present invention first needs to set an armor protection device outside the protected target, such as figure 1 As shown, the armor protection device includes a deformation expansion layer 1, a high-density and high-extensibility layer 2, an explosive layer 3, an induction detonation array layer 4, and an explosion protection layer 5, which are stacked together from outside to inside (or from front to back). ; When the armor-piercing projectile (its movement direction is shown by the arrow in the figure) penetrates, the first contact is the deformation expansion layer 1.

[0030] The deformation expansion layer 1 is formed by immersing the fiber fabric in a shear thickening fluid (Shear Thickening Fluid, STF). The fiber fabric can be Kevlar, PBO or UHMWPE fiber fabric. STF means that the fluid is in the state of concentrated colloidal suspension, and its viscosity increases with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com