Tungsten heavy alloy for armour-piercing projectile core and preparing method thereof

A heavy alloy, armor-piercing projectile technology, applied in the direction of ammunition, warheads, offensive equipment, etc., can solve the problems of impurity segregation, unstable performance, incomplete reduction of solubility oxides, etc., to achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

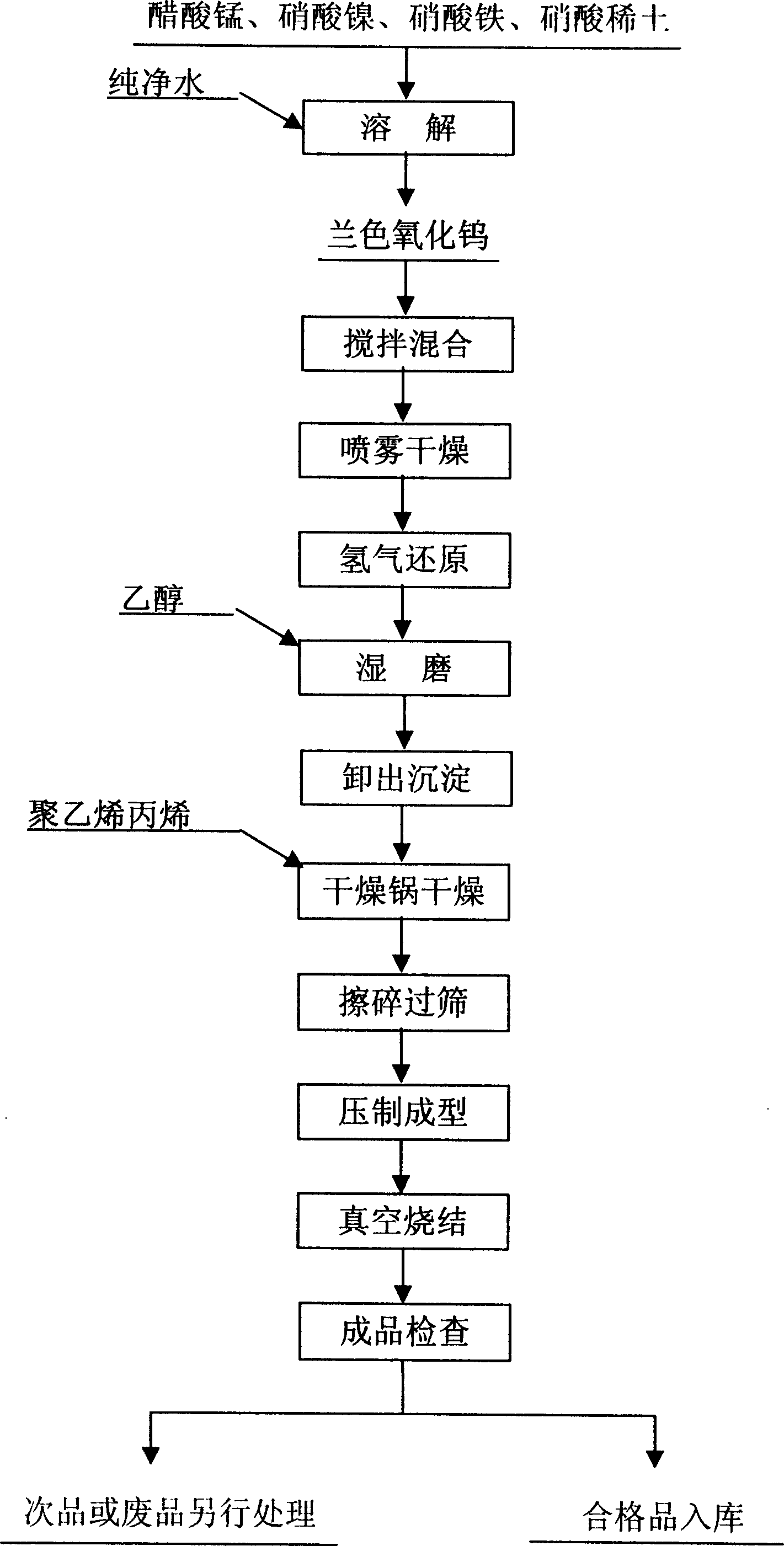

Method used

Image

Examples

example 1

[0019] Put the following raw materials in the following weight ratio: 0.6 parts of manganese acetate, 6.75 parts of nickel nitrate, 2.25 parts of iron nitrate, 0.67 parts of rare earth nitrate, put them in a stainless steel container, dissolve them with pure water, pour the aqueous solution into a container containing blue tungsten oxide Stir and mix in 90 parts of stainless steel barrels, inject the mixture into the spray drying tower for spray drying at 200°C, the dried powder is reduced in a hydrogen furnace at 700°C, and the composite powder obtained after reduction is placed in a tiltable Add ethanol and grind for 6 hours to unload, then dry and sieve in a drying pot at a temperature of 100°C, add polyethylene propylene with a concentration of 20% as a molding agent, and the solid content of the composite powder and the molding agent The liquid ratio (weight ratio) is 1:0.08, and the pressure is 0.8 tons / cm 2 under the conditions of vacuum pressure of 10Pa, temperature of...

example 2

[0021] The raw materials with the following weight proportions: 0.5 parts of manganese acetate, 4.73 parts of nickel nitrate, 1.58 parts of iron nitrate, 0.57 parts of rare earth nitrate, and 93 parts of blue tungsten oxide were placed in a spray drying tower and dried at 250 °C. 1.0 tons / cm 2 Next, mold it with a hydraulic press; then place the briquette in a boat of zirconia or alumina, sinter at a vacuum of 40Pa, at a sintering temperature of 1470°C, for a holding time of 50 minutes, and the rest are the same as in Example 1.

example 3

[0023] The weight ratio of raw materials is: 0.5 parts of manganese acetate, 4 parts of nickel nitrate, 1 part of iron nitrate, 0.55 parts of rare earth nitrate, 97 parts of blue tungsten oxide, the drying temperature in the spray drying tower is 300 ℃, and the pressure is 1.2 tons / cm 2 , sintering temperature 1480 ℃, holding time 60 minutes, all the other with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com