Empennage stable shelling armor-piercing projectile support and preparation method thereof

A stabilizing technology for armor-piercing projectiles, applied in warheads, ammunition, offensive equipment, etc., can solve the problems of heavy mass of the bullet holder and insufficient tooth bud strength, and achieve the effect of high initial velocity, good consistency and low inertia mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also proposes a method for preparing the empennage-stabilized shell-piercing projectile carrier as described above, comprising:

[0033] S1: According to the force analysis results of the spring holder, divide the spring holder into tooth buds and outer casings, and design the layer angle and layer thickness of the tooth buds;

[0034] According to the limitations of the process conditions, the tooth bud is divided into several sections along its axial direction and prepared separately;

[0035] S2: Choose carbon fiber prepreg as the layering material of the tooth bud, prepare the carbon fiber prepreg according to the layer thickness of the tooth bud, and prepare the carbon fiber prepreg (resin mass content is 25-35%) according to the layering angle of the tooth bud Lay layers on a flat mold according to the thickness of the layer, heat and pressurize, solidify, demould, and process to obtain a tooth bud shape block;

[0036] S3: Repeat step S2 to...

Embodiment 1

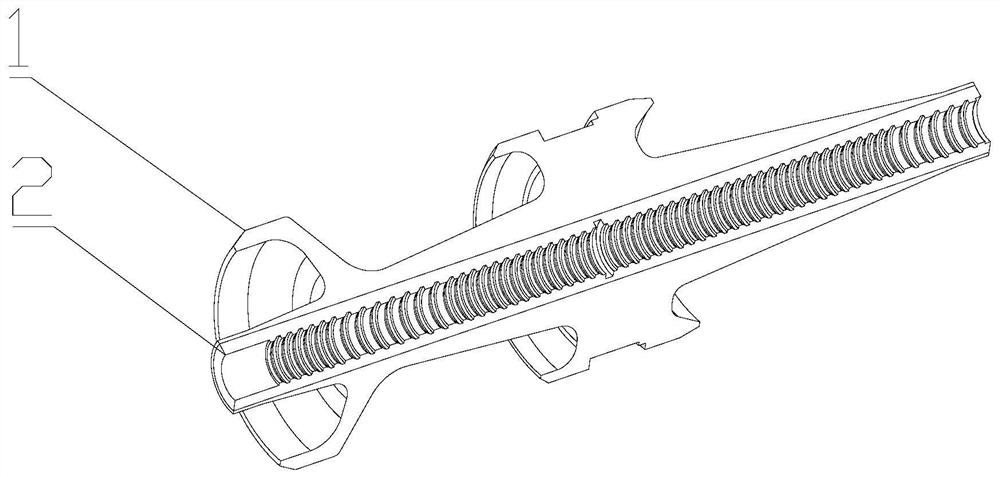

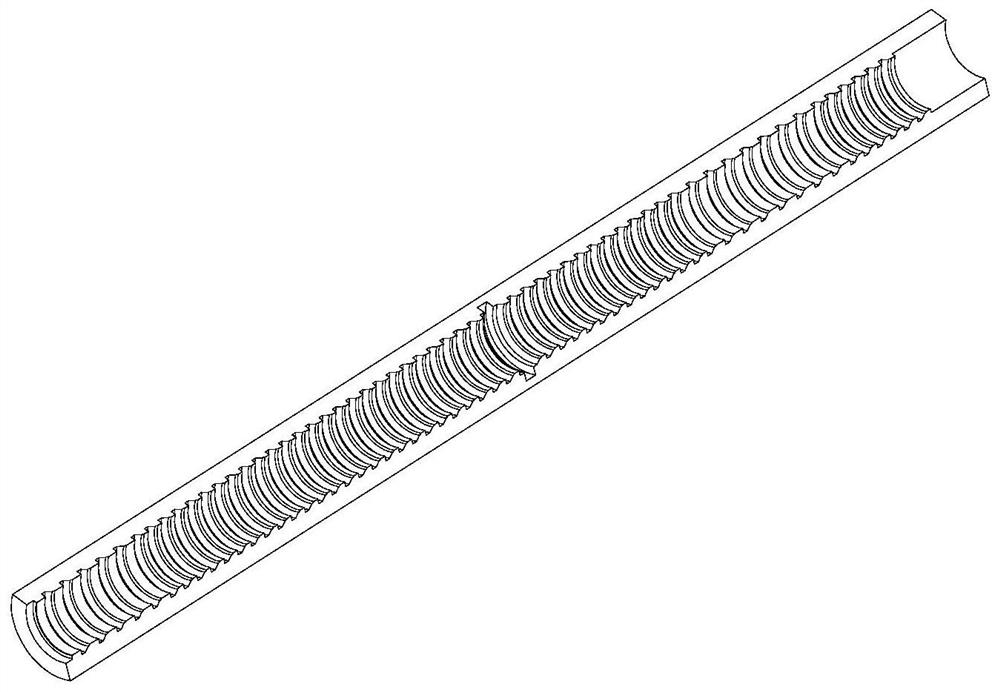

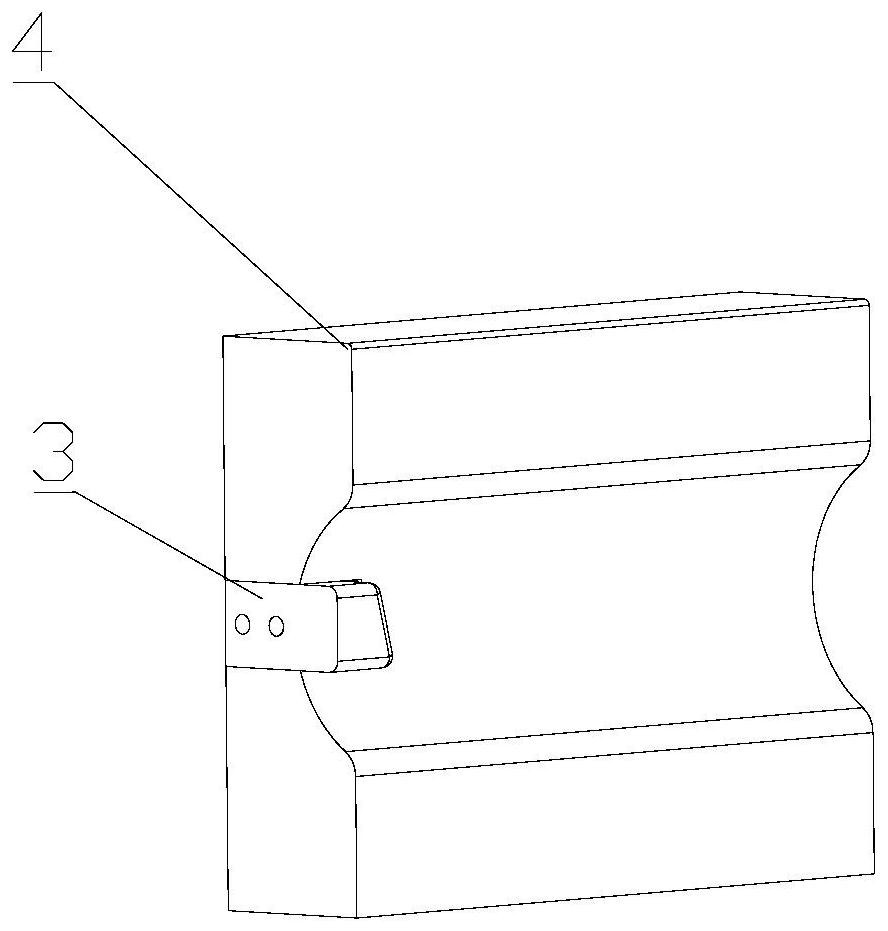

[0062] The present invention provides a kind of empennage stabilizing armor-piercing projectile receptacle, and described receptacle is made up of 3 pieces of 120 ° carbon fiber composite clasp by hoop combination, and described clasp comprises tooth bud 2 and outer casing 1 (such as figure 1 and 2 As shown), the outer shell 1 is covered on the outer surface of the tooth bud 2, and the tooth bud 2 is processed and combined by several carbon fiber molded plates with different layup angles and layup thicknesses; the outer shell 1 is made of chopped carbon fiber prepreg yarn Molded.

[0063] The present invention also provides a method for preparing the above-mentioned tail-stabilized shell-piercing armor-piercing projectile carrier, comprising:

[0064] S1: According to the force analysis results of the spring holder, divide the spring holder into tooth buds and outer casings, and design the layer angle and layer thickness of the tooth buds;

[0065] According to the limitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com