Basket type igniter of rotary solid rocket engine

A solid rocket and igniter technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., to achieve the effects of compact structure, good sealing performance and reliable ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

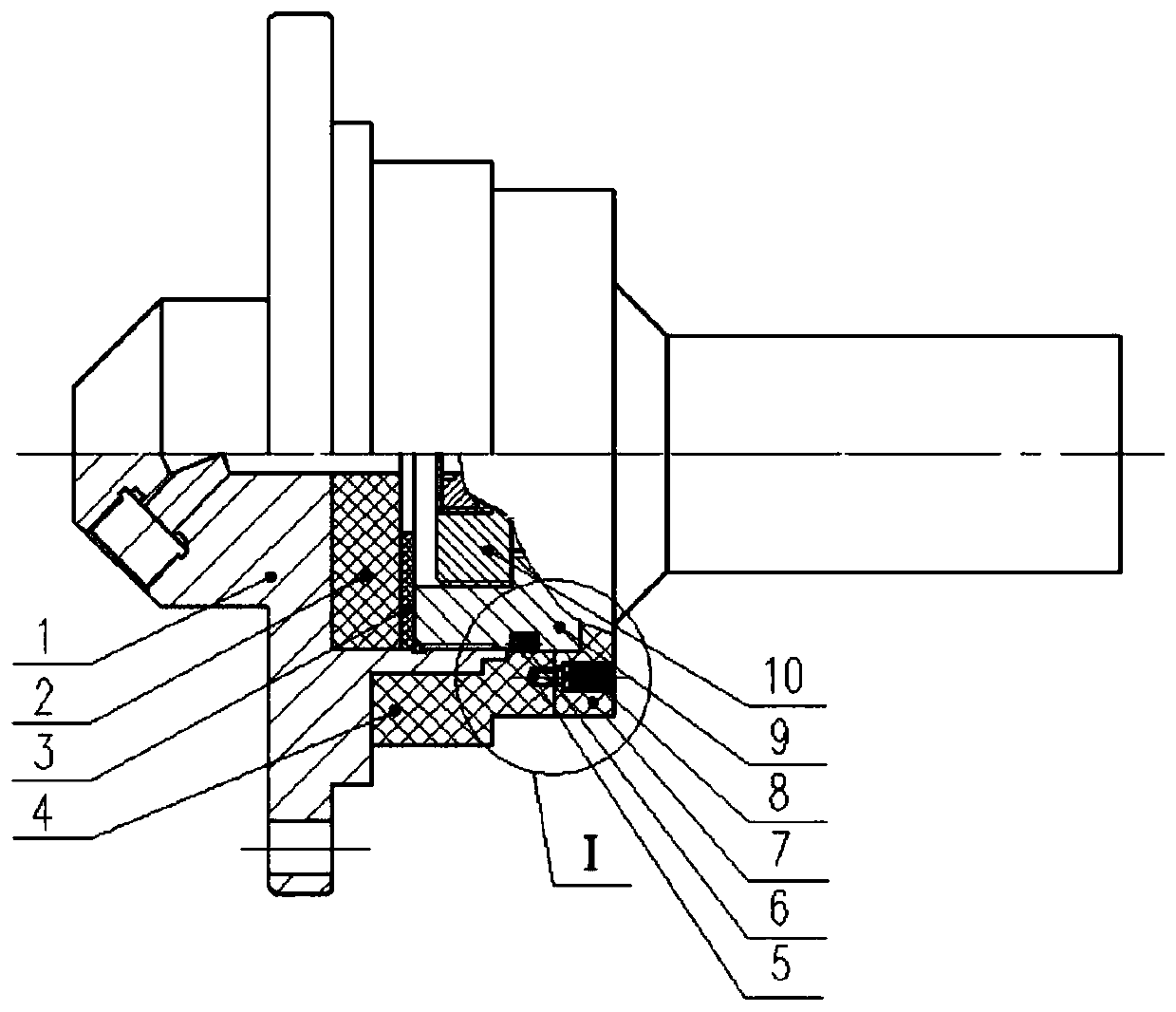

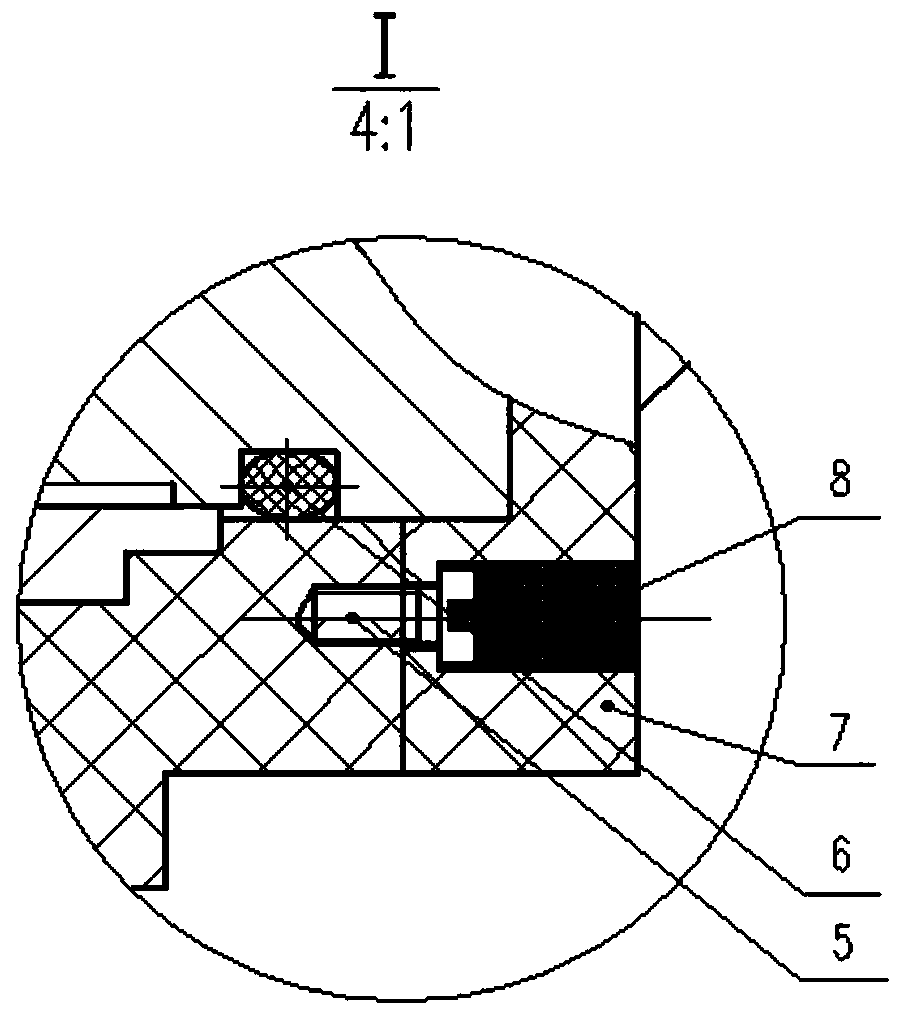

[0021] Present embodiment proposes a kind of rotating solid rocket motor basket type igniter, and its structure is as follows figure 1 and 2 shown. The igniter mainly includes ignition top cover 1, top cover hard insulation layer 2, top cover soft insulation layer 3, front insulation sleeve 4, slotted screw 5, O-ring 6, rear insulation sleeve 7, putty 8, Igniter housing 9 and pilot cartridge 10 .

[0022] When assembling, first put the top cover hard heat insulation layer 2 into the ignition top cover 1, and then paste the top cover soft heat insulation layer 3 on the surface of the top cover hard heat insulation layer 2, so as to perform heat insulation and anti-burning on the ignition top cover 1 corrosion protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com