Gas self-pressurization hybrid rocket engine

A rocket engine, self-pressurization technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of complex charge structure, difference in fuel retreat rate, low fuel density, etc., to simplify the structure quality and Complexity, reduce negative mass, achieve the effect of gas self-pressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

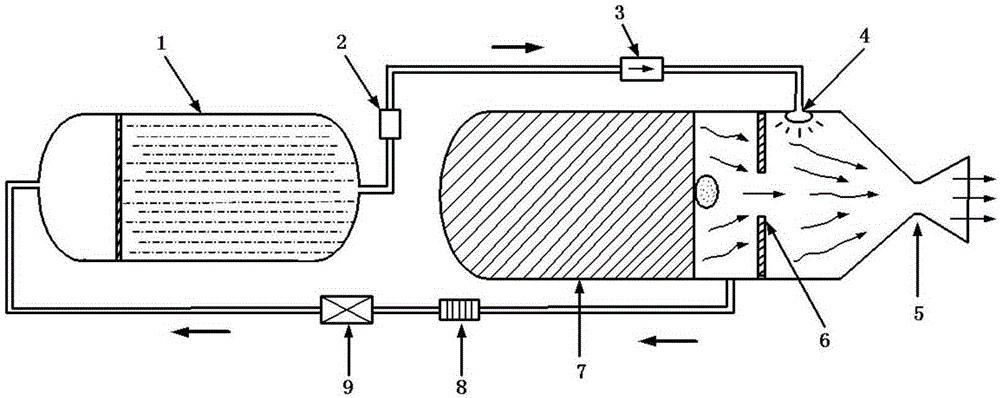

[0013] The structure of the test device of the present invention is as follows: figure 1 As shown, it includes: oxidant storage tank 1, oxidant control valve 2, one-way valve 3, oxidant injector 4, nozzle 5, flow regulating valve 6, oxygen-lean gas generator 7, filter 8, pressure reducer 9 .

[0014] The oxidant storage tank 1 is provided with a sealed piston, which divides the oxidant storage tank 1 into a first storage tank and a second storage tank; the second storage tank is filled with an oxidant; one end of the oxygen-poor gas generator 7 is poured with a powder column, and the other A cavity is left at one end, and a flow regulating valve 6 is arranged in the cavity, and the flow regulating valve 6 divides the cavity into a first cavity and a secondary combustion chamber;

[0015] The second storage tank of the oxidant storage tank 1 is connected with the oxidant injector 4 through the first pipeline, and the oxidant control valve 2 and the one-way valve 3 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com