An ultra-high-speed turbo pump and overflow valve matching test device

A test device, turbo pump technology, applied in the field of hydraulic system, can solve the problems of violent vibration and whistling, affecting hydraulic pump, poor pressure stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

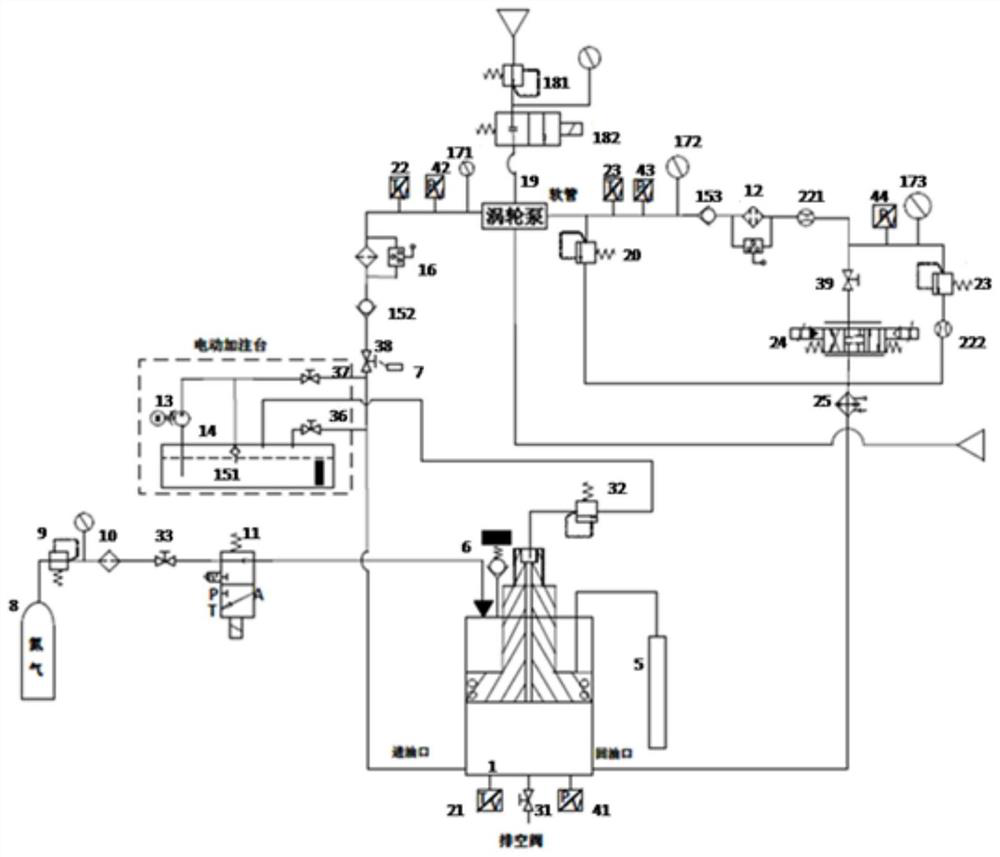

[0037] The invention provides a matching test device for an ultra-high-speed turbine pump and an overflow valve. The system mainly includes a turbine drive device, a hydraulic system, a computer acquisition and control system, and a real-time spectrum analyzer. The speed of the ultra-high speed turbo pump is greater than the first critical speed of the rotor.

[0038] Turbine drive device: used to drive the turbo pump during the test.

[0039] Hydraulic System: Provides equivalent simulated loads for ultra-high speed turbo pumps.

[0040] Computer acquisition and control system: adjust the flow rate of the equivalent simulated load according to performance requirements; collect and process the speed of the ultra-high-speed turbo pump, the vibration of the small shaft end of the rotor, and the opening pressure, flow rate, rated pressure, and closing pressure of the overflow valve The pressure and natural frequency are processed to obtain the dynamic characteristics of the reli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com