Sliding plate rotor engine

A rotary engine and skateboard technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of low efficiency, unreasonable structure, large weight, etc., and achieve high efficiency, low mechanical vibration and wear, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

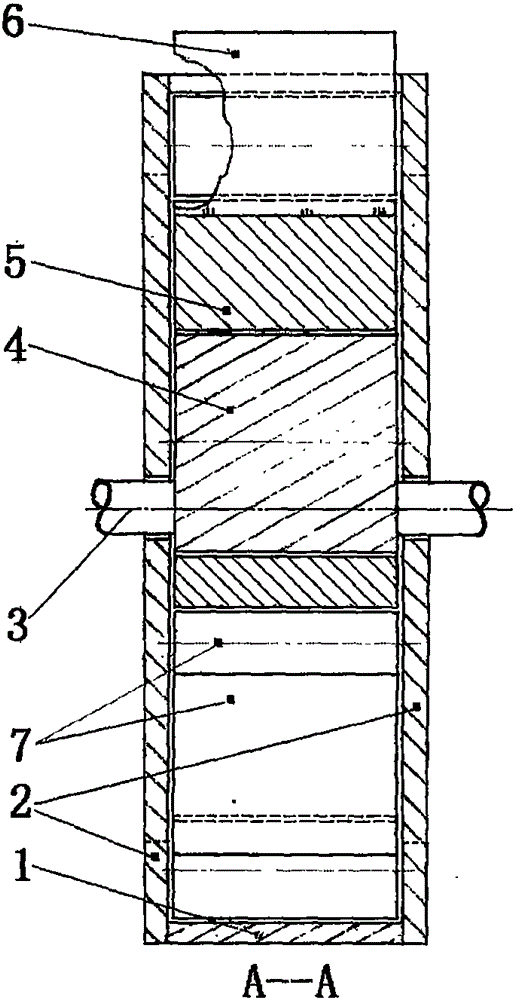

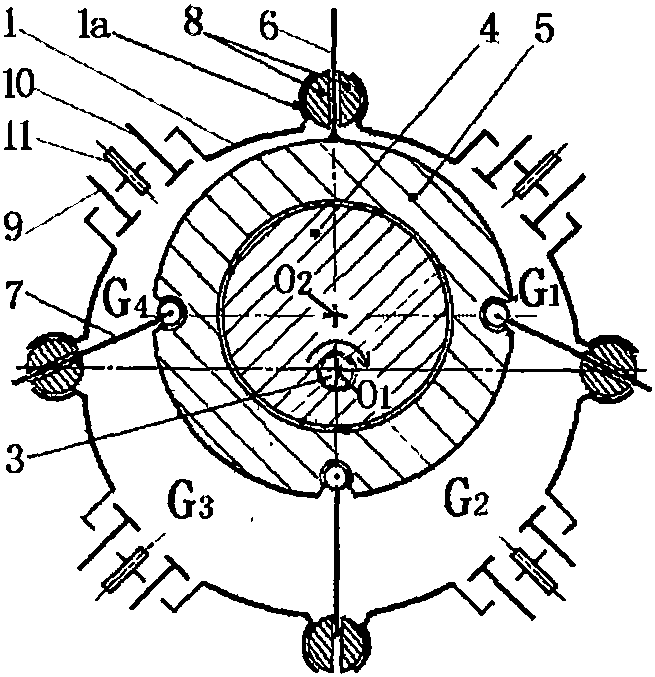

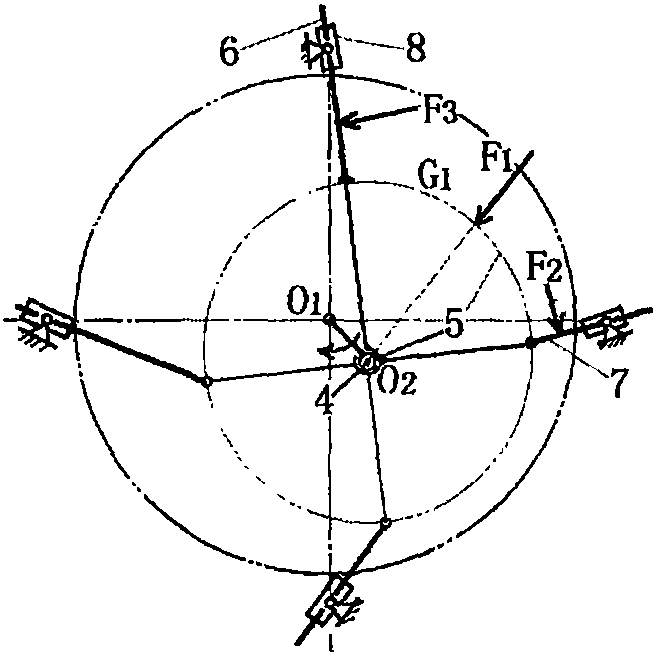

[0017] Such as figure 1 , 2 As shown, in the skateboard rotor engine of the present invention, the two ends of the cylindrical stator 1 are closed by the end cover 2, and the built-in engine main shaft 3 is supported in the center of the end cover, and the eccentric wheel 4 connected thereon is covered with a skateboard ring for rotation fit. 5. The surface of the skateboard ring is fixed with a radial fixed skateboard. 6. Three outward hinged skateboards are hinged. 7. Each skateboard is evenly distributed on the skateboard ring. The inner wall of the cover is used for sliding and sealing fit. On the outer wall of the stator facing each slide plate, a longitudinal shaft seat 1a is respectively provided. The connection between each shaft seat and the stator wall and the opposite side are provided with a full length wider than the thickness of the slide plate. Notch, each shaft seat is equipped with a circular shaft body 8 for rotating and sealing fit, each slide plate penetra...

Embodiment 2

[0031] On the basis of the skateboard rotor engine described in Embodiment 1, a fixed slide plate 6 is still retained, and the hinged slide plate 7 that is hinged to the slide plate ring 5 is changed from the original three to two, and each slide plate is on the slide plate. Evenly distributed on the ring, on the outer wall of the stator facing each slide plate, a longitudinal shaft seat 1a is respectively arranged, and the connection between each shaft seat and the stator wall and the opposite side are provided with a full-length gap wider than the thickness of the slide plate. Each shaft seat is equipped with a circular shaft body 8 for rotating and sealing fit, each slide plate penetrates radially along the round shaft body and performs sliding and sealing fit, and an air inlet is provided on the stator wall between two adjacent shaft seats. Valve 9, exhaust valve 10, spark plug 11 (as Figure 15 Shown), other structures and operating principles of the engine are as in Embo...

Embodiment 3

[0033] On the basis of the skateboard rotor engine described in Embodiment 1, a fixed slide plate 6 is still retained, and the hinged slide plate 7 that is hinged to the slide plate ring 5 is changed from the original three to four, and each slide plate is on the slide plate. Evenly distributed on the ring, on the outer wall of the stator facing each slide plate, a longitudinal shaft seat 1a is respectively arranged, and the connection between each shaft seat and the stator wall and the opposite side are provided with a full-length gap wider than the thickness of the slide plate. Each shaft seat is equipped with a circular shaft body 8 for rotating and sealing fit, each slide plate penetrates radially along the round shaft body and performs sliding and sealing fit, and an air inlet is provided on the stator wall between two adjacent shaft seats. Valve 9, exhaust valve 10, spark plug 11 (as Figure 16 Shown), other structures and operating principles of the engine are as in Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com