Inner heat insulation layer of front seal head of solid rocket engine and forming method of inner heat insulation layer

A solid rocket and molding method technology, applied in rocket engine devices, machines/engines, coatings, etc., can solve problems such as difficult to achieve thermal insulation layer production, achieve good product quality consistency, reduce negative mass, and high dimensional control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

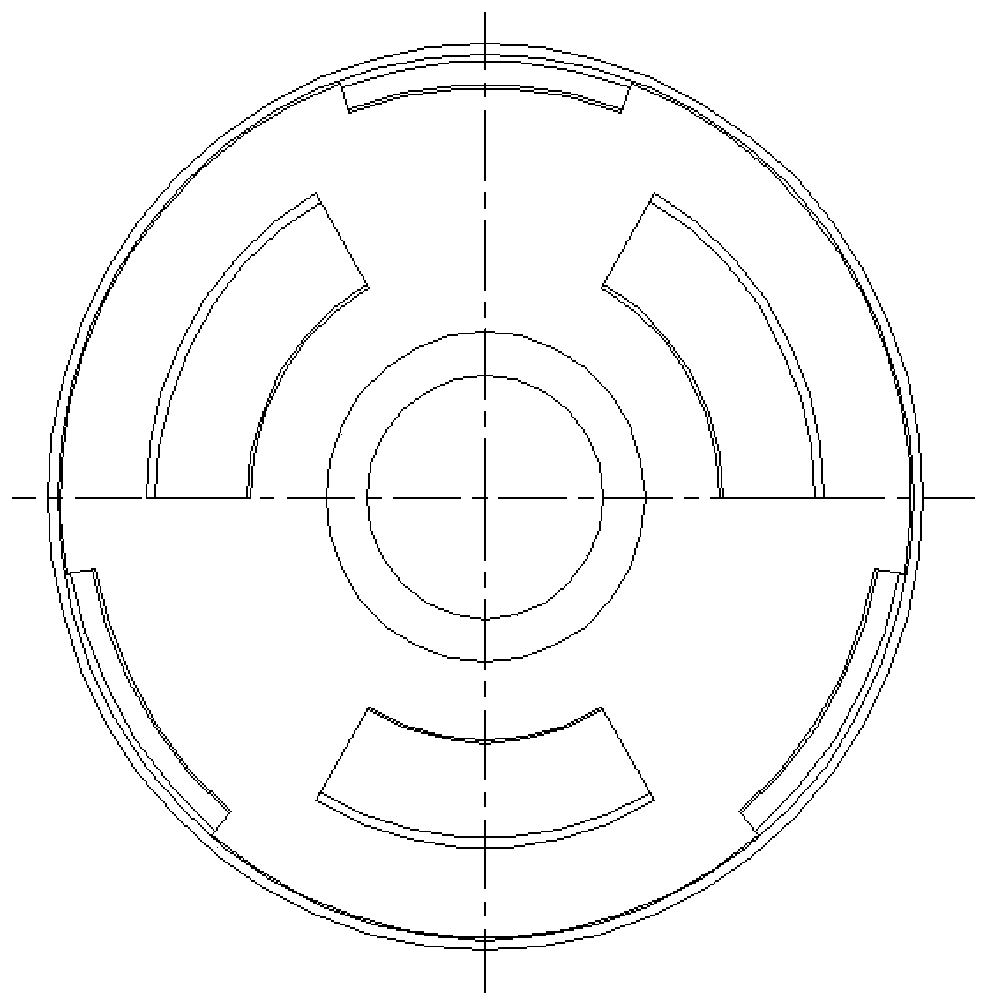

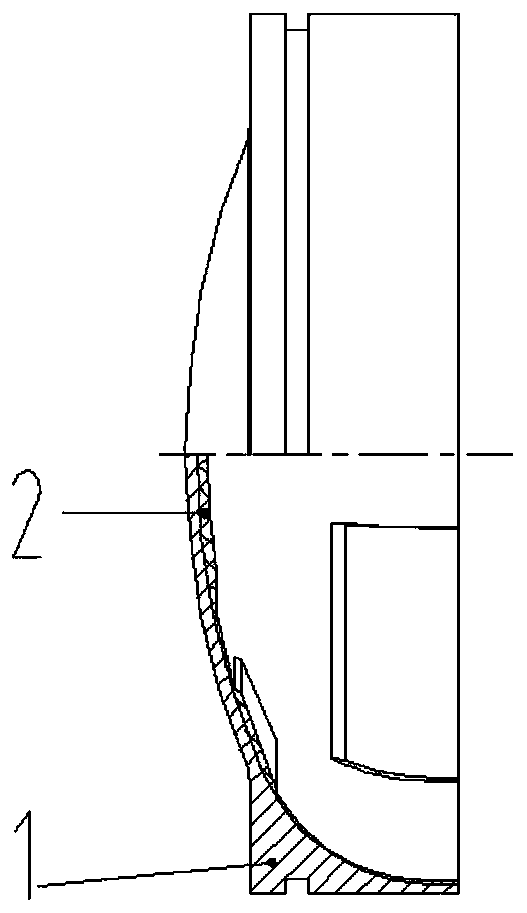

Image

Examples

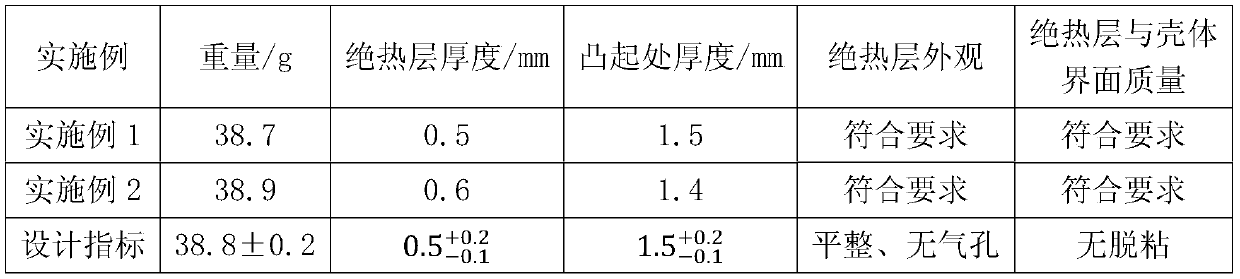

Embodiment 1

[0046] The front head 1 is made of high-strength steel 30CrMnSiA material, which is machined according to design requirements.

[0047] Follow the steps below to manufacture the inner insulation layer of the front head:

[0048] Step 1: Make an alloy aluminum mold according to the inner surface structure of the inner heat insulation layer, and spray polytetrafluoroethylene on the surface of the mold; the outer surface of the alloy aluminum mold is the same as the inner surface of the heat insulation layer to be formed;

[0049]Step 2: Sand blast the inner wall of the front head to make the inner surface rough, so as to improve the bonding performance between the inner insulation layer and the metal front head, and ensure reliable bonding and no debonding;

[0050] Step 3: preparing a thermal insulation layer in a liquid state;

[0051] Butyl hydroxyl agent: 100 parts, carbon fiber filler 4 parts, boron phenolic resin filler 50 parts, DEHP plasticizer 8 parts, HB crosslinking ...

Embodiment 2

[0058] The front head 1 is made of high-strength steel 30Cr3SiNiMoVA material, which is machined according to design requirements.

[0059] Follow the steps below to manufacture the inner insulation layer of the front head:

[0060] Step 1: Make an alloy aluminum mold according to the inner surface structure of the inner heat insulation layer, and spray polytetrafluoroethylene on the surface of the mold; the outer surface of the alloy aluminum mold is the same as the inner surface of the heat insulation layer to be formed;

[0061] Step 2: Sand blast the inner wall of the front head to make the inner surface rough, so as to improve the bonding performance between the inner insulation layer and the metal front head, and ensure reliable bonding and no debonding;

[0062] Step 3: preparing a thermal insulation layer in a liquid state;

[0063] HTPB base agent: 100 parts, carbon fiber filler 5 parts, boron phenolic resin filler 55 parts, DEHP plasticizer 8 parts, HB crosslinking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com