Prestress anchor cable buttress-type parapet suitable for rock substrate

A technology of prestressed anchor cable and rock foundation, applied in sheet pile wall, foundation structure engineering, water conservancy engineering and other directions, can solve the problems of the ultimate anti-sliding force and anti-overturning performance of buttress retaining wall, etc. Anti-sliding and anti-overturning ability, reducing adverse effects, reducing design thickness and the effect of steel reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

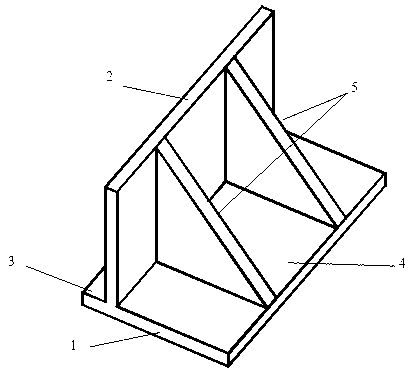

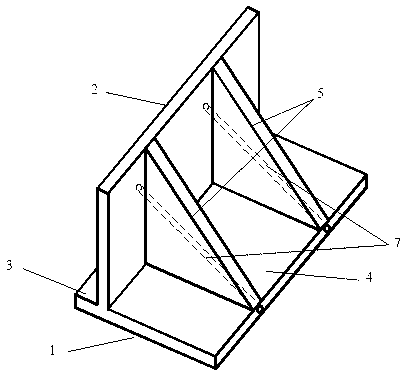

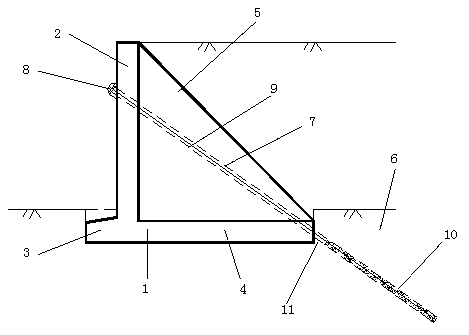

[0036] The technical scheme of the present invention will be further described in conjunction with the accompanying drawings. Figure 2 ~ Figure 6 Shows the basic structure of the prestressed anchor-cable buttress retaining wall applicable to the rock foundation and the setting state in the rock foundation.

[0037] As shown in the figure, the prestressed anchor cable buttress type retaining wall applicable to the rock foundation 6 according to the present invention includes a retaining wall foundation 1, a retaining wall panel 2, a buttress plate 5 and a prestressed anchor cable. The retaining wall foundation 1 is in the shape of a horizontal plate, the retaining wall panel 2 and the buttress plate 5 are placed on the retaining wall foundation 1, the retaining wall panel 2 is perpendicular to the retaining wall foundation 1, and the buttress plate 5 in the form of a right triangle is placed on the retaining wall panel 2 inside. The retaining wall panel 2 divides the retainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com