Floating semi-submersible oil production and storage arrangement

An oil storage, semi-submerged technology, applied in the affected field, can solve the problems of raised center of gravity, limited number of processing equipment, etc., to achieve the effect of increasing anti-overturning force and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

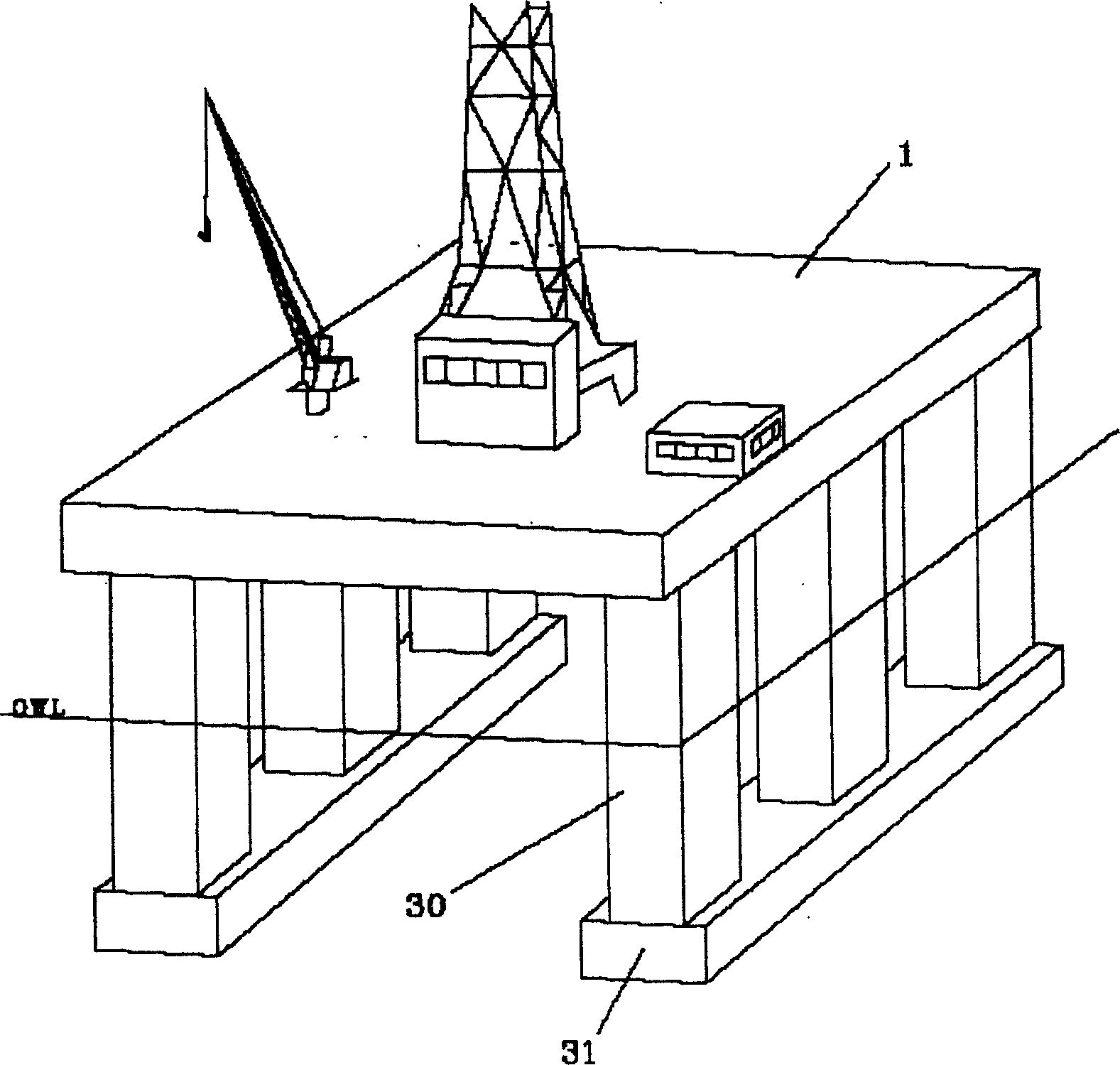

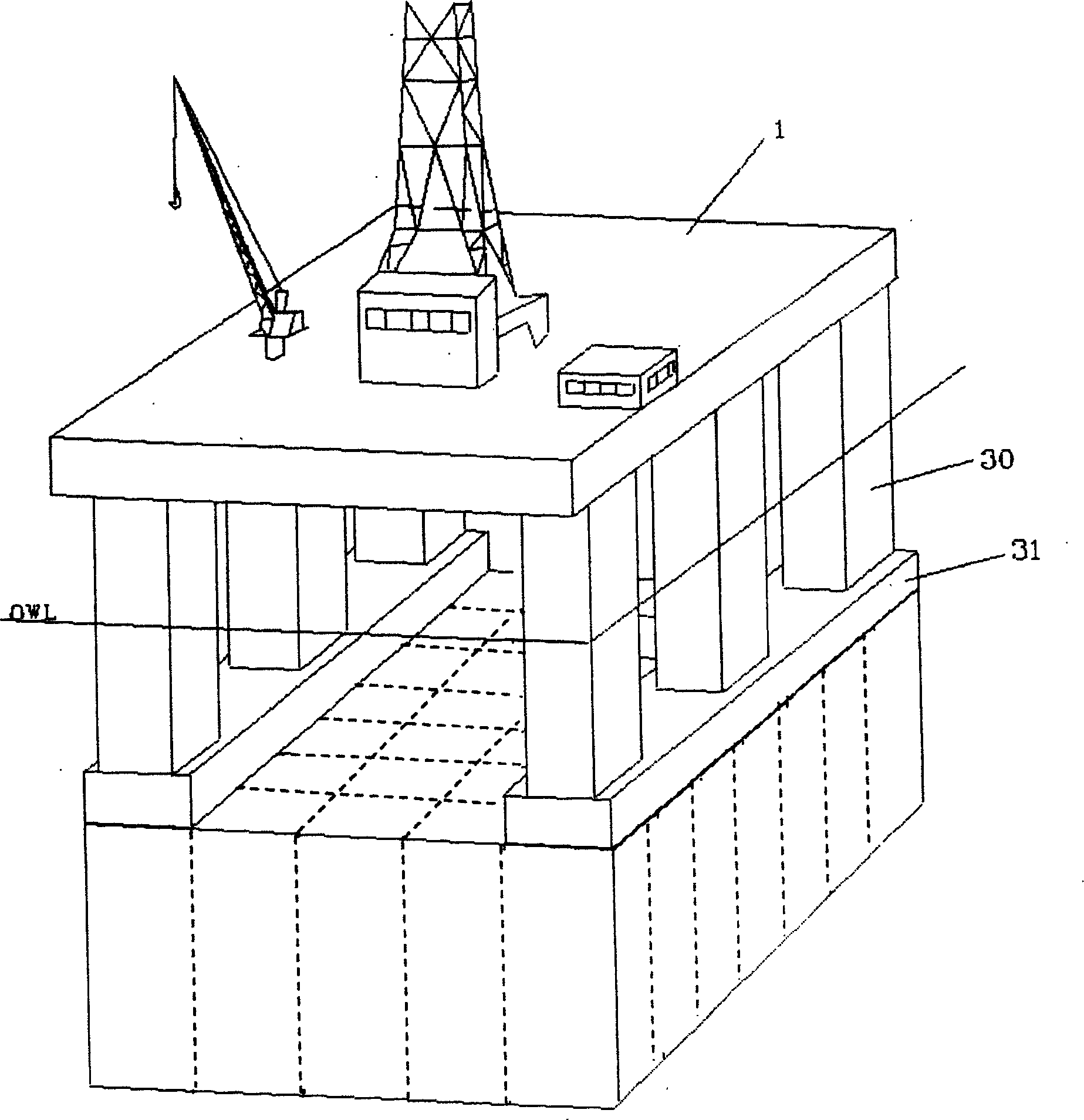

[0028] See figure 2 , the drilling rig 1 has a concrete tank 2 connected under a column 30 and a buoy 31 .

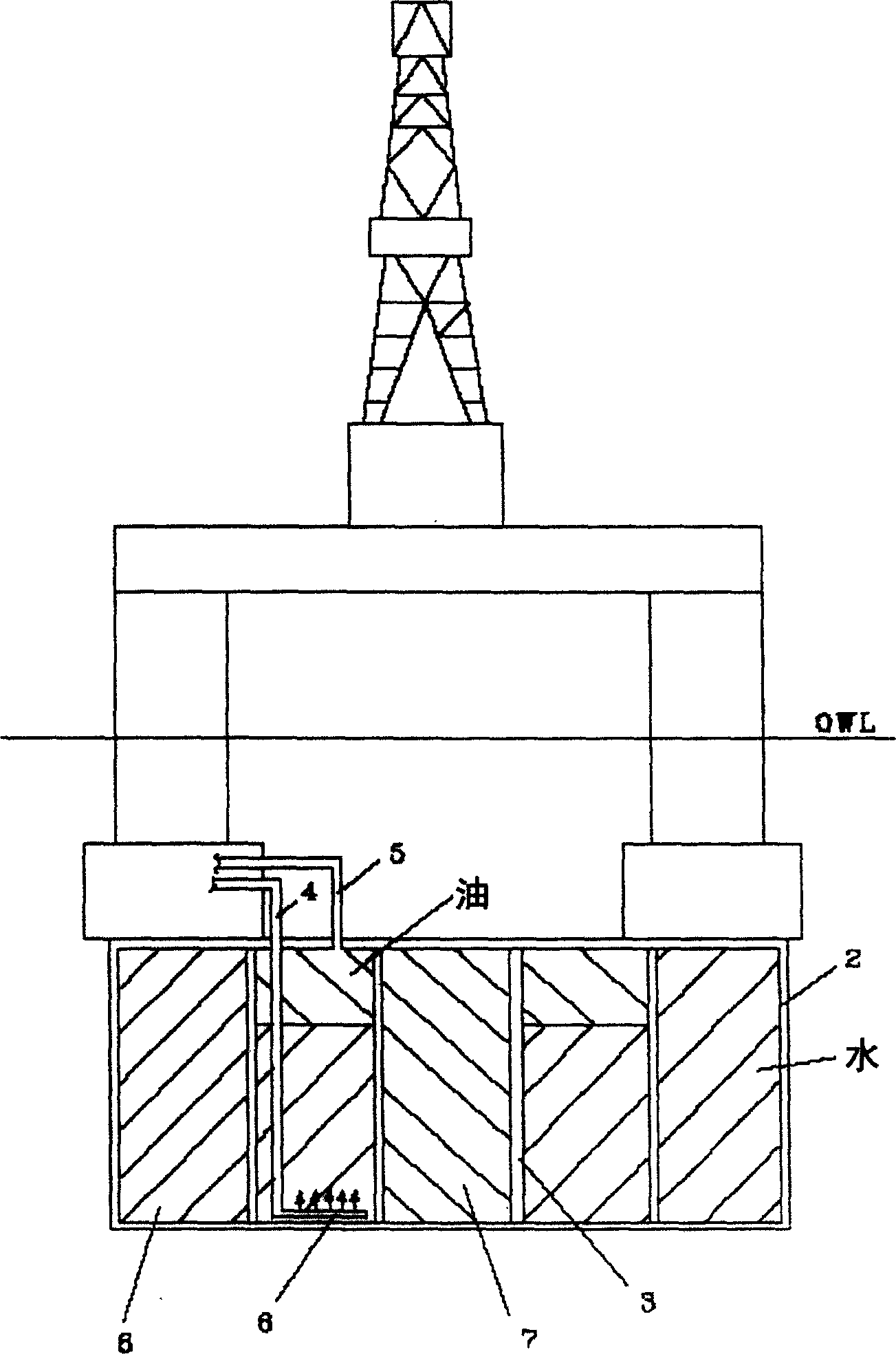

[0029] Such as image 3As shown in , the concrete boxes are separated by fluid-tight partitions in the form of inner concrete walls 3 . At least one cell in the center of the concrete box is configured to be open at the top and bottom to create a hole through the center of the concrete box whereby drilling equipment can perform drilling or well servicing operations with the box attached.

[0030] image 3 and 5 Also shown are water inlet / outlet pipes 4 and oil inlet / outlet pipes 5 of one chamber. The water pipe terminates in a diffuser tube 6 near the bottom of the chamber which minimizes mixing of oil and water as water is pumped in. The tubing terminates on the inside face of the upper surface to avoid the possibility of air bubble formation. To keep the mass of the concrete tank and contents constant when producing or unloading oil, only 4 / 5 of the chamber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com