Hydrogen fluoride heater

A heater, hydrogen fluoride technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem of waste materials, unsatisfactory heat exchange effect, and heat resistance of Monel400 nickel-copper alloy. Not ideal and other problems, to achieve the effect of obvious heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

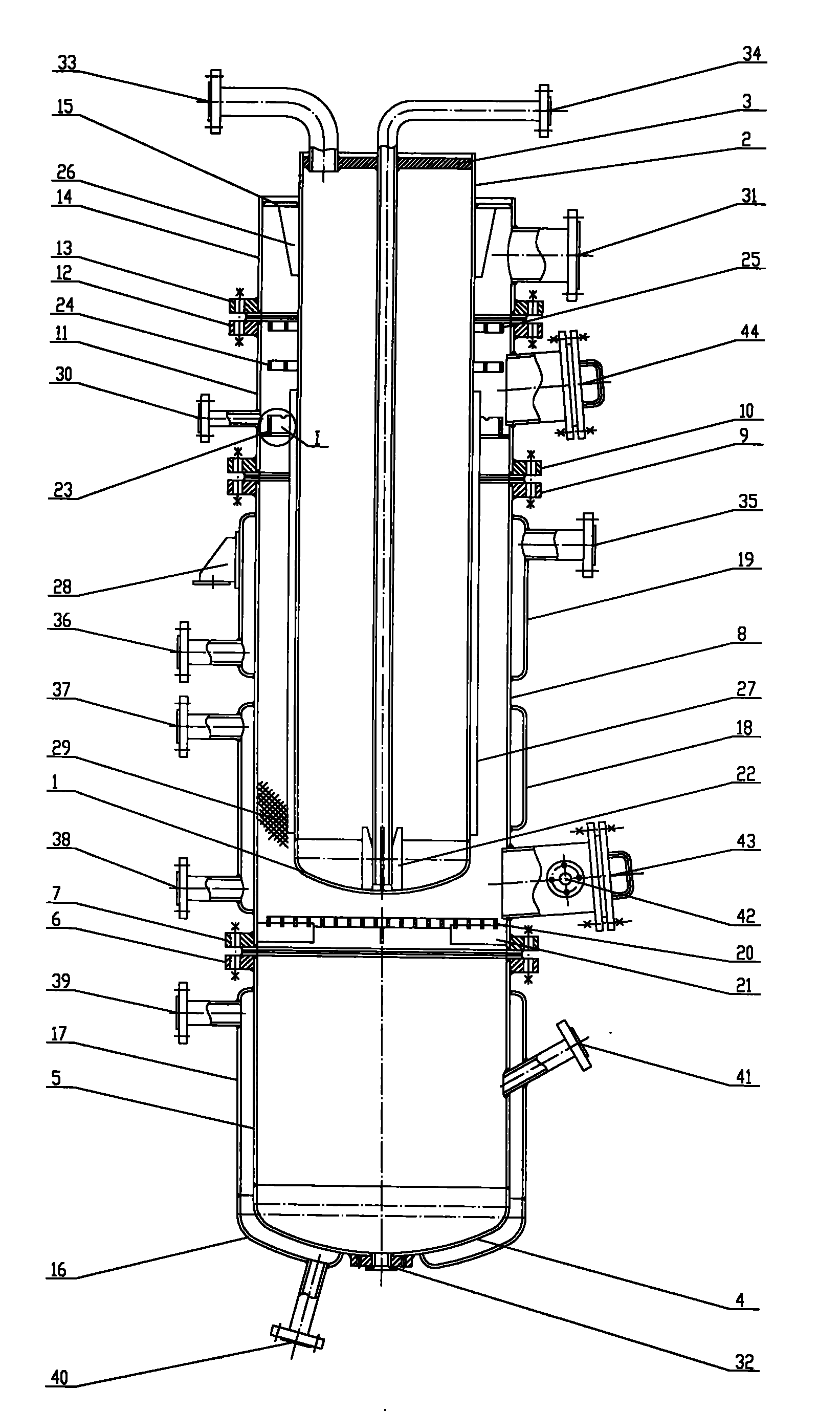

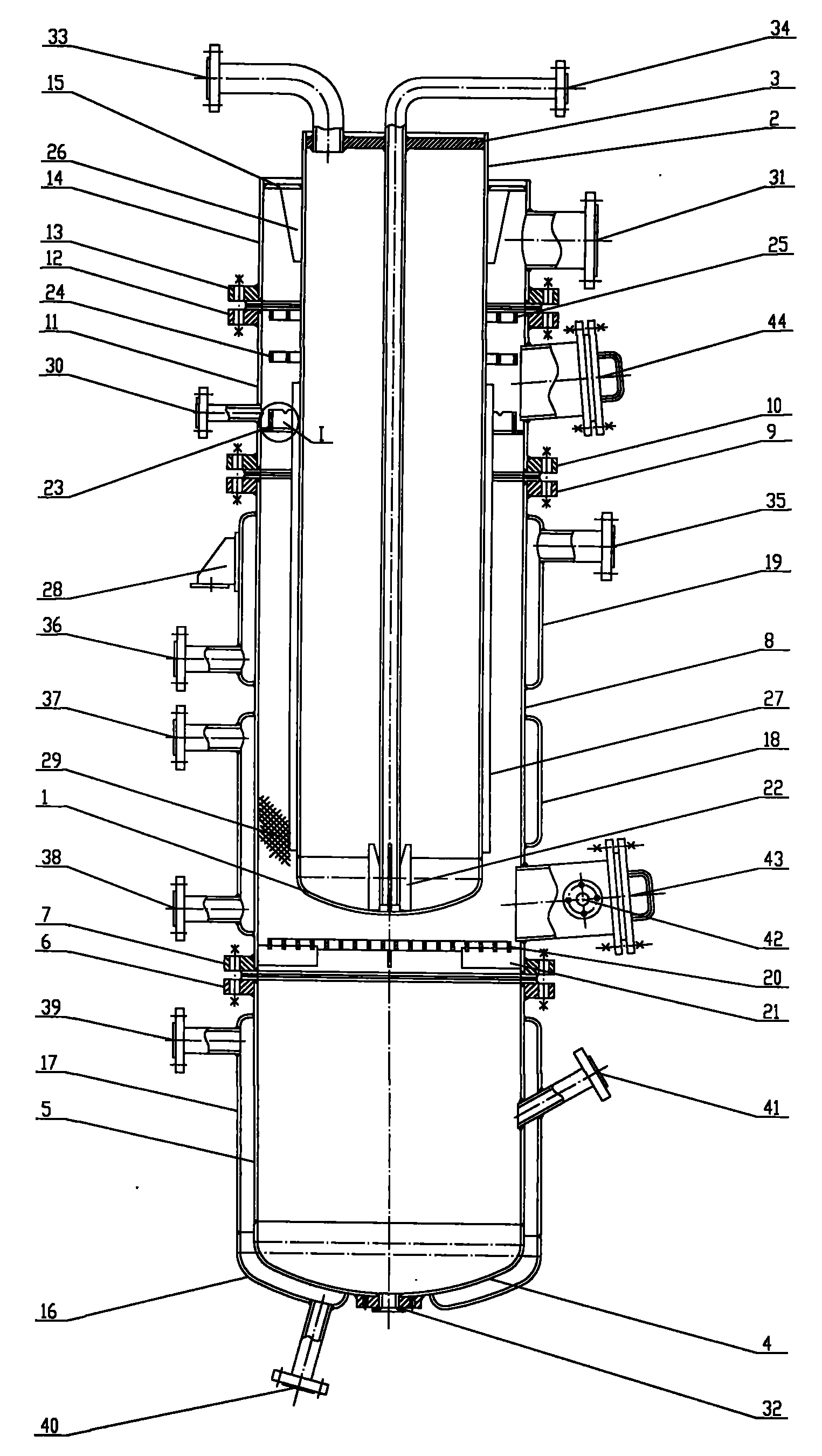

[0023] Such as figure 1 As shown, a hydrogen fluoride heater: consists of three parts: an inner tube, a container and a jacket;

[0024] The inner cylinder is: the inner cylinder head (1) is connected with the inner cylinder body (2), the inner cylinder body (2) is connected with the flat cover (3), and the inner bottom of the inner cylinder head (1) is provided with ( 4) A fixed rib (22), one end of the condensate outlet pipe (34) is connected with the fixed rib (22), and the other end passes through the flat cover (3) and extends out of the inner cylinder. The flat cover (3) is provided with a steam inlet A (33), there are several supporting ribs B (26), several reinforcing ribs (27), grid A (24) and grid B (25) on the outside of the inner cylinder body (2);

[0025] The container is: the container head (4) is connected with the container cylinder A (5), the container cylinder A (5) passes through the equipment flange F (6), the equipment flange A (7) and the container cylinder B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com