Composite pipe concrete composite structure

A combined structure and concrete technology, applied in the direction of columns, piers, pillars, etc., can solve problems such as high yield load, and achieve the effect of high yield load, increased bearing capacity, and increased yield load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

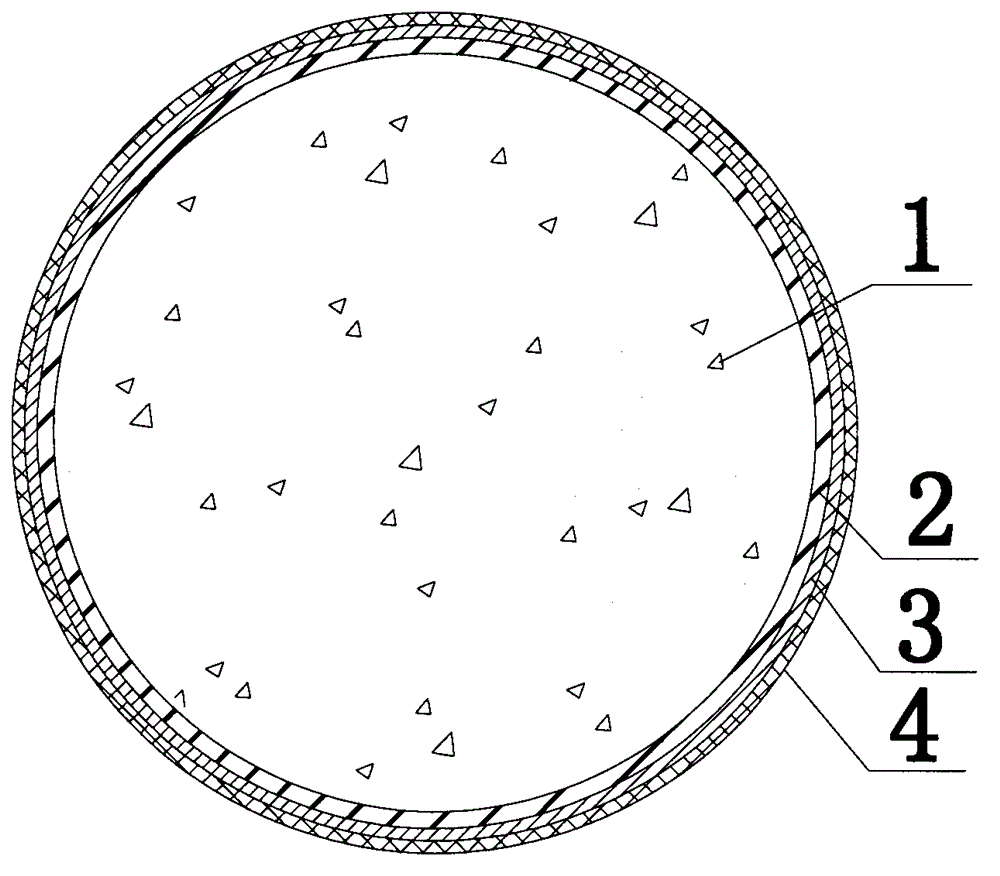

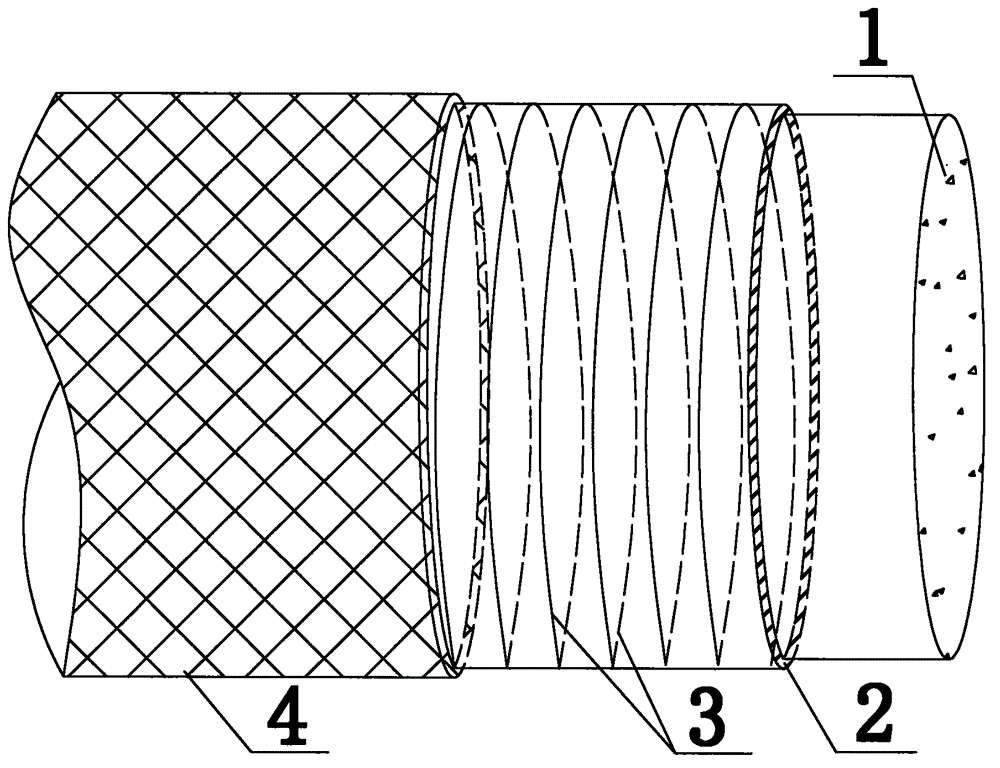

[0035] Such as figure 1 , figure 2 , a composite tubular concrete composite structure, comprising internal concrete 1, steel pipe 2, transverse prestressed steel wire 3, and fiber-reinforced plastic 4; wherein, the transverse prestressed steel wire 3 is continuously and uniformly wound on the outer wall of the steel pipe 2 by applying prestress to the steel wire , the fiber reinforced plastic 4 is pasted on the outer surface of the transverse prestressed steel wire 3, the internal concrete 1 is filled in the interior of the steel pipe 2, and the transverse prestressed steel wire 3 and the fiber reinforced plastic 4 are each one layer.

Embodiment 2

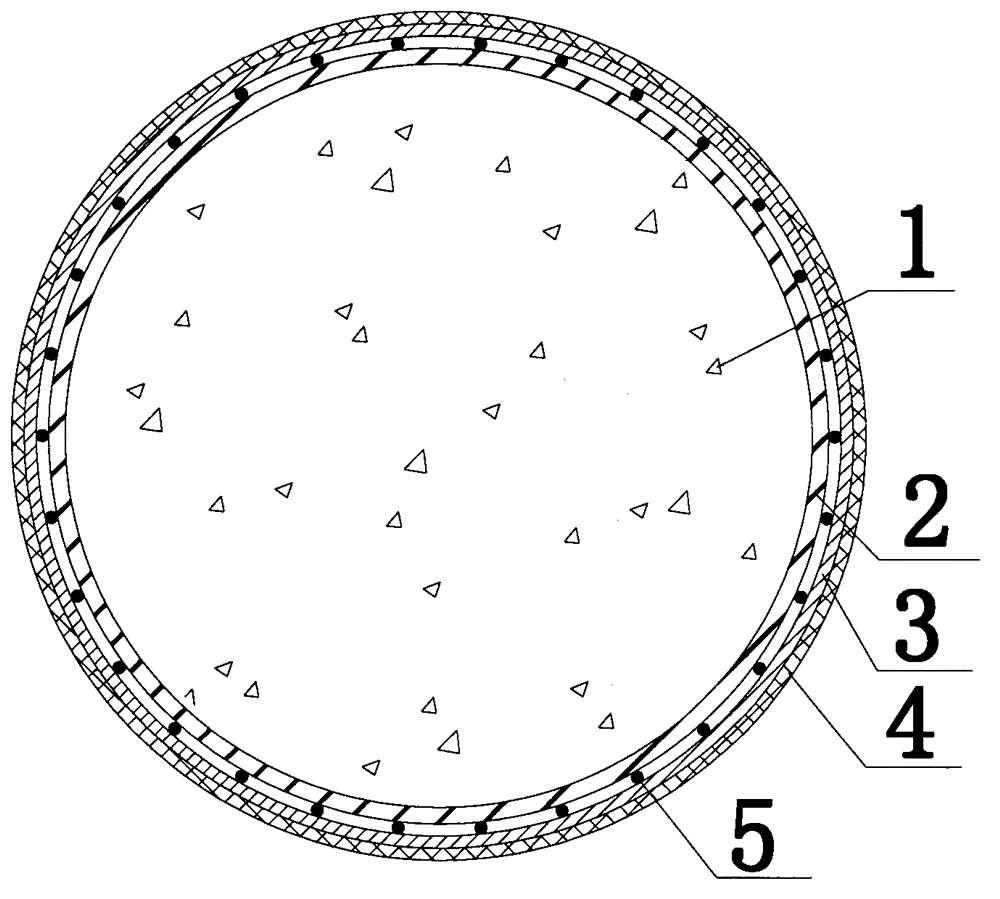

[0037] Such as image 3 , Figure 4 , a composite tubular concrete composite structure, comprising internal concrete 1, steel pipes 2, transverse prestressed steel wires 3, fiber reinforced plastics 4, and longitudinal steel wires 5; wherein, the transverse prestressed steel wires 3 are wound horizontally and uniformly by applying prestress to the steel wires On the outer wall of the steel pipe 2, the fiber reinforced plastic 4 is pasted on the outer surface of the transverse prestressed steel wire 3, and the internal concrete 1 is filled in the interior of the steel pipe 2, and the transverse prestressed steel wire 3 and the fiber reinforced plastic 4 are each one layer. At the same time, a layer of longitudinal steel wires 5 is arranged between the transverse prestressed steel wires 3 and the steel pipe 2. During specific implementation, the longitudinal steel wires 5 are evenly arranged around the steel pipe 2 along the axial direction of the steel pipe 2, and are temporari...

Embodiment 3

[0039] Such as Figure 5 , Figure 6 , a composite tubular concrete composite structure, comprising internal concrete 1, steel pipes 2, transverse prestressed steel wires 3, fiber reinforced plastics 4, and longitudinal steel wires 5; wherein, the transverse prestressed steel wires 3 are wound horizontally and uniformly by applying prestress to the steel wires On the outer wall of the steel pipe 2, the fiber reinforced plastic 4 is pasted on the outer surface of the transverse prestressed steel wire 3, and the internal concrete 1 is filled in the interior of the steel pipe 2. The transverse prestressed steel wire 3 has two layers, and the winding distances of the two layers are different. The fiber reinforced plastic 4 is 1 layer. At the same time, between the transverse prestressing steel wire 3 and the steel pipe 2 and between the two layers of transverse prestressing steel wire 3, a layer of longitudinal steel wire 5 is respectively arranged. During specific implementation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com