Axial sliding type partition plate suitable for multi-pulse solid rocket engine

An axial sliding, solid rocket technology, applied in rocket motor units, machines/engines, mechanical equipment, etc., can solve the problems of charge type design limitations, poor mechanical properties of soft partition structures, etc., to achieve optimal management, reduction of negative quality, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

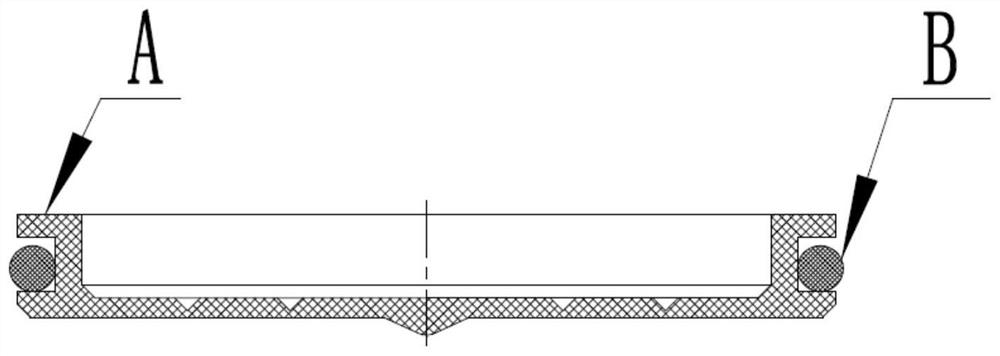

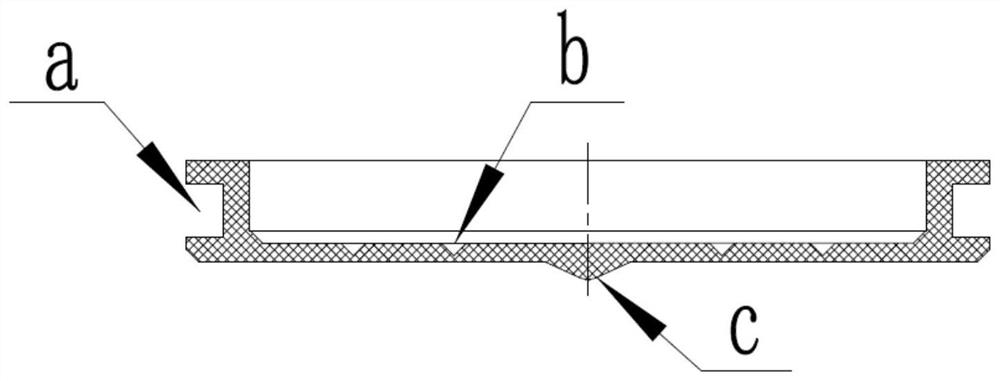

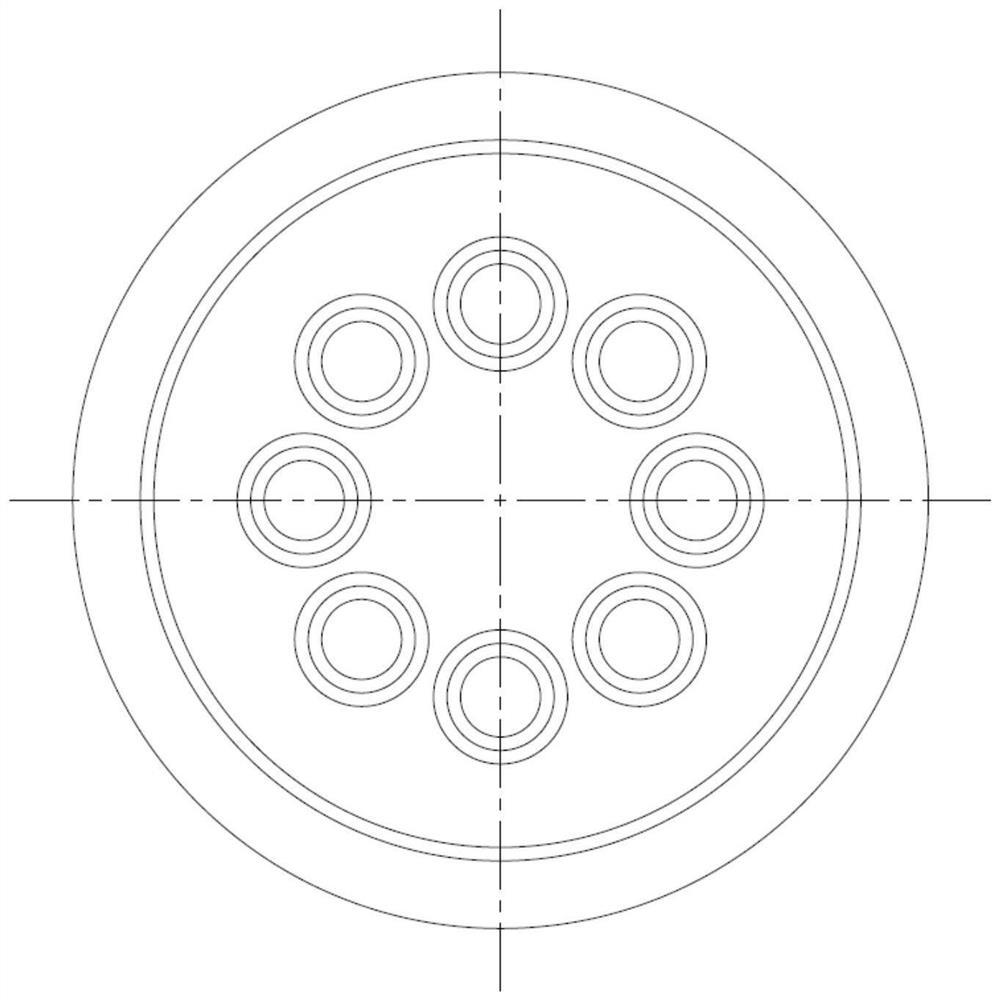

[0027] Such as Figure 4 As shown, an axially sliding diaphragm type solid rocket double-pulse motor disclosed in this embodiment includes a second pulse igniter 1, a front head 2, an elastic pad 3, a motor casing 4, a pine bar 5, a second Pulse charge 6, partition seal ring 7, partition 8, first pulse charge 9, backstop drug plate 10, rear seal ring 11, first pulse igniter 12, nozzle 13, nozzle plug 14. The second pulse igniter 1 is arranged near the end of the second pulse charge 6 , and is screwed in and fixed by the front head 2 . The elastic pad 3 is placed between the front head 2 and the second pulse charge 6 to reduce the vibration of the second pulse charge 6 . The pine bar 5 is placed between the engine casing 4 and the second pulse charge 6 and the first pulse charge 9 to limit the radial movement of the engine charge. The lower surface of the partition 8 is pre-adhered to the second pulse charge 6 , and the partition sealing ring 7 is placed in the lateral groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com