Planetary rotor engine

A rotary engine and planetary technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as low efficiency, unreasonable structure, and large weight, and achieve high efficiency, low mechanical vibration and wear, and power consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

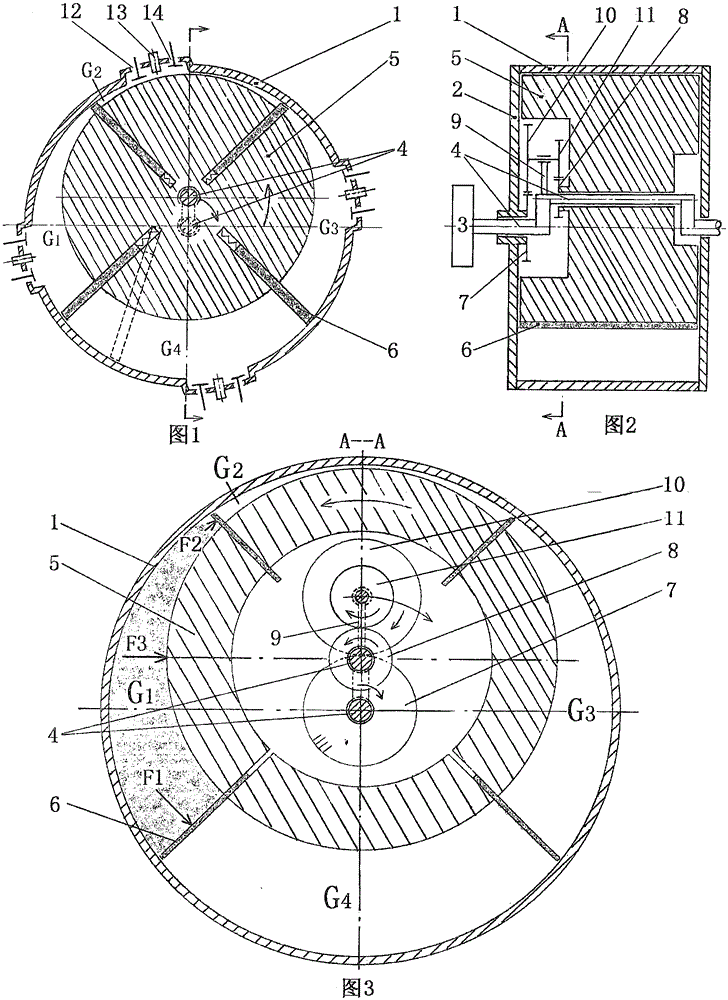

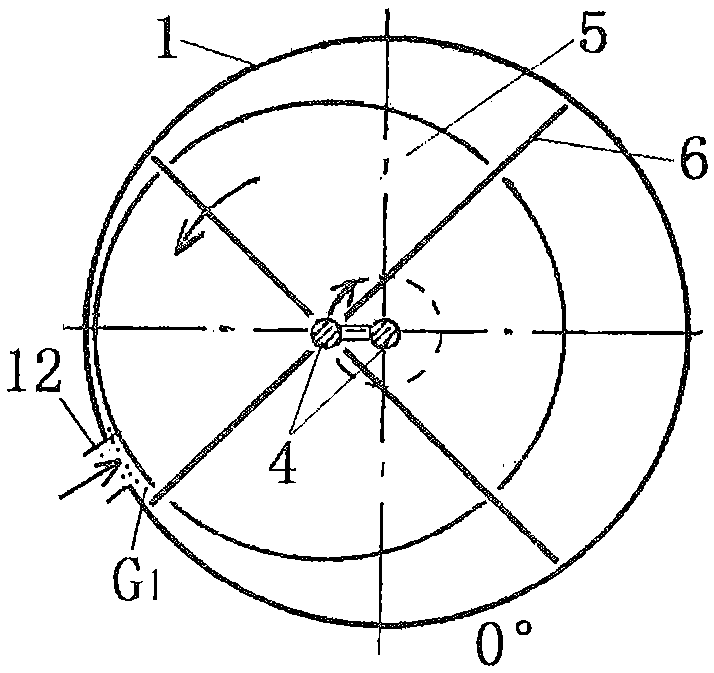

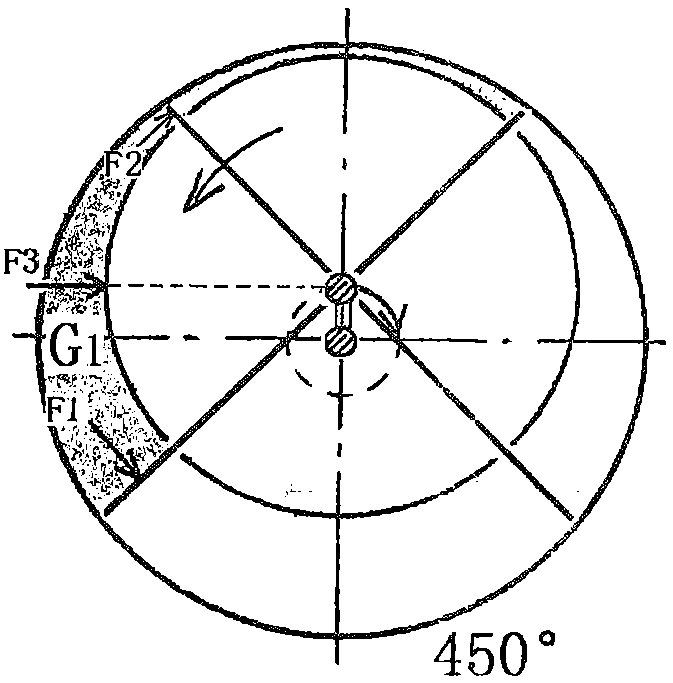

[0023] Such as figure 1 , 2 , 3, the planetary rotor engine of the present invention, the two ends of the tubular stator 1 are closed by the end cover 2, and the crankshaft 4 connecting the flywheel 3 is arranged inside, the main journals at the two ends of the crankshaft are supported at the center of the end cover, and the middle section of the crankshaft is The planetary journal and the support are equipped with a planetary column 5 for rotation fit. There are more than two radial slots on the planetary column. Each slot is inserted with a blade 6 for telescopic sliding and sealing fit. The inner side of the blade and the bottom of the groove Springs are interposed so that the outer side is close to the inner wall of the stator, and the left and right sides of the planetary column and blades are in sliding and sealing cooperation with the inner wall of the end cover. Each blade divides the inner cavity of the stator into a closed space with the same number of blades as the ...

Embodiment 2

[0035] Such as figure 1 As shown by the dotted line in the center, the slots on the planetary column 5 and the blades 6 are inclined in the radial direction, so that they are inclined to the inner wall of the stator 1, so as to reduce the pressure and friction caused by the centrifugal force of the blades on the inner wall of the stator.

Embodiment 3

[0037] Such as Figure 16 As shown, the end cap on one side has a groove to accommodate the crank arm and gear train, and the end cap on the other side has a groove to accommodate the other crank arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com