Projectile base separation mass reduction extended-range projectile

A technology of projectile bottom and projectile, which is applied in the field of projectile bottom separation, mass reduction and range extension projectile, can solve the problem of reducing negative mass and extending range that has not been found, and achieves the effect of reducing negative mass, low use requirements and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

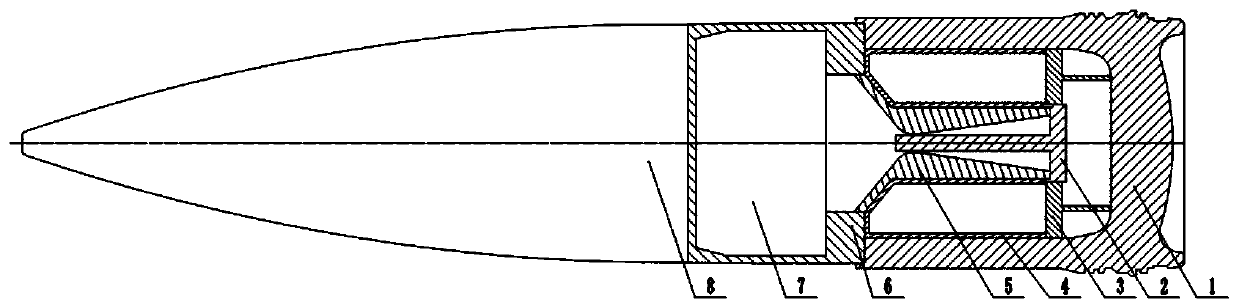

[0019] refer to figure 1 , the present embodiment provides a kind of ammunition with bottom separation, mass reduction and range extension, which includes warhead 8, solid motor and separation bottom mechanism in turn; The nozzle 5 of the product and the solid hair igniter 2; the solid motor cartridge 7 is arranged inside the solid motor housing 6 .

[0020] The separation bomb bottom mechanism includes a bomb bottom 1, a bottom row casing 4 and a bottom row igniter 3; the outlet of the nozzle 5 and the bottom row casing 4 are both arranged inside the bomb bottom 1; the bottom row casing 4 is arranged on the nozzle pipe 5 Between the bomb bottom 1. The inside of the bottom row housing 4 is provided with a charge column for containing propellant; one side of the solid motor housing 6 is fixedly connected to the combat part 8, and the other side of the solid motor housing 6 is sleeved on the inner side of the bullet bottom 1, and The bottom end of the solid motor housing 6 is ...

Embodiment 2

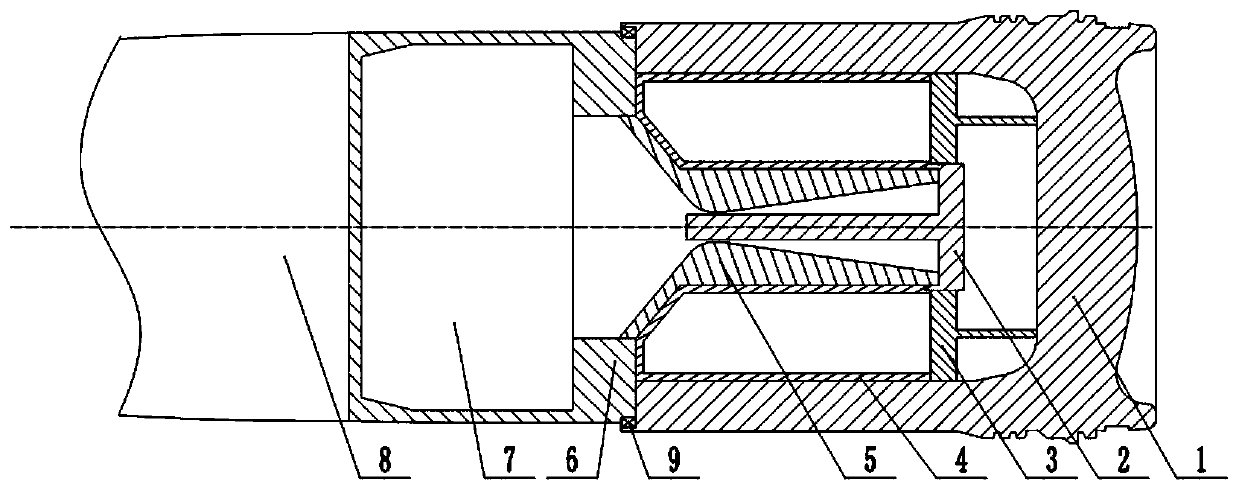

[0023] refer to figure 2 , the present embodiment provides a projectile shell with bottom separation, reduced mass and extended range. The difference between this embodiment and Embodiment 1 is that a bearing 9 is arranged between the solid motor casing 6 and the projectile bottom 1, and the bearing 9 is fixedly arranged on On the solid motor case 6. During the launch of the projectile, the separation bottom mechanism rotates at high speed, and the projectile and the separation bottom mechanism are connected by bearings. The radial force on the projectile is small, so the projectile rotates at a low speed due to inertia, which effectively reduces the impact of the projectile cannon. The mouth speed is conducive to the control of the projectile in the later stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com