Device for weighing liquid with viscosity being 4mPa.S

A technology for weighing devices and liquids, which is used in measurement devices, weighing, weighing devices for materials with special properties/forms, etc. High speed, improved weighing accuracy, and reduced negative mass effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

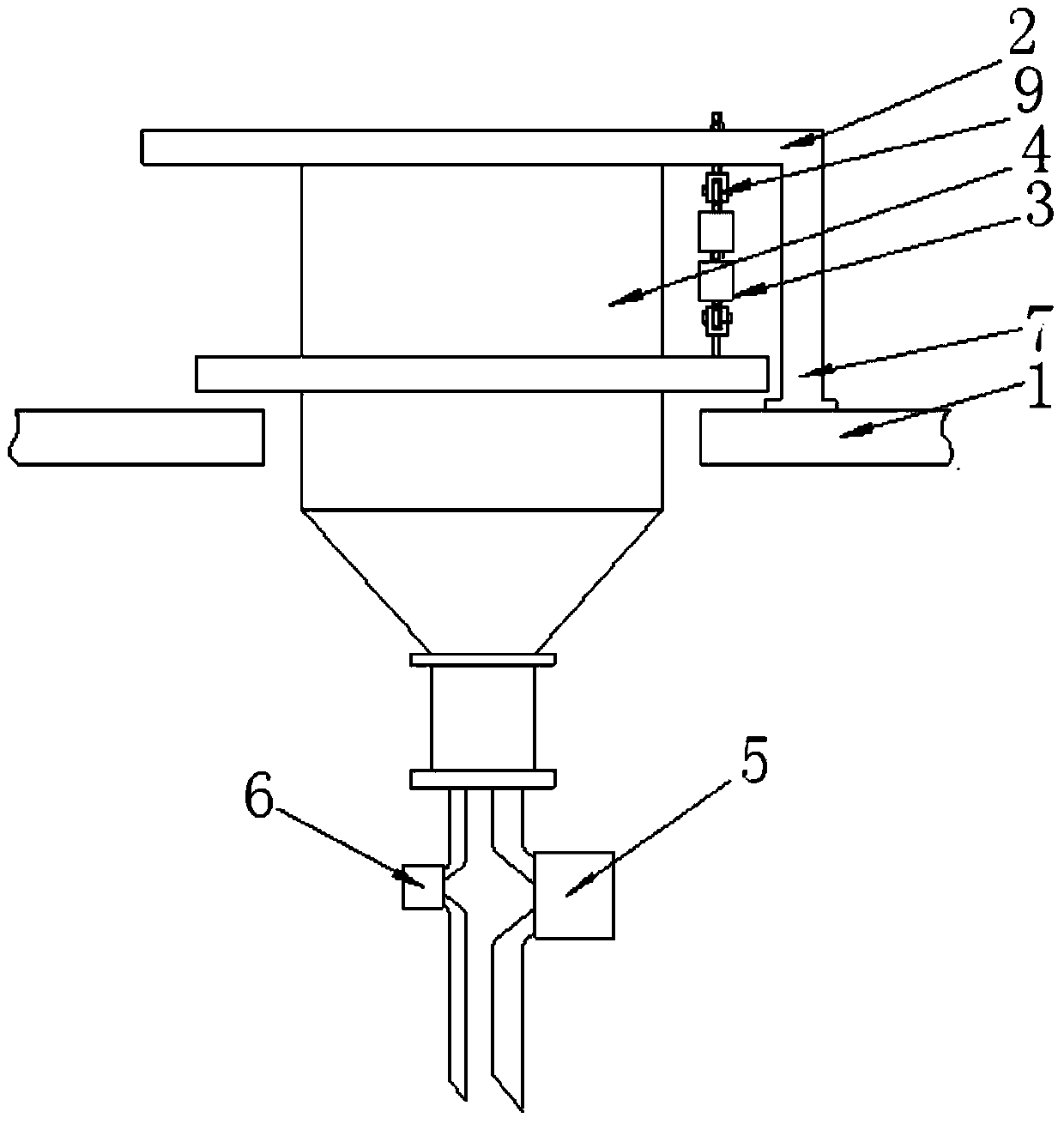

[0036] This embodiment is an automatic weighing device for mucus, which includes a support platform 1, an annular support 2, three sensor components 3, a mucus hopper 4, a fast discharge valve 5 and a slow discharge valve 6, and the data is processed by an industrial control computer And management, and control the fast loading valve, slow loading valve, fast unloading valve 5, and slow unloading valve to complete the weighing of each material.

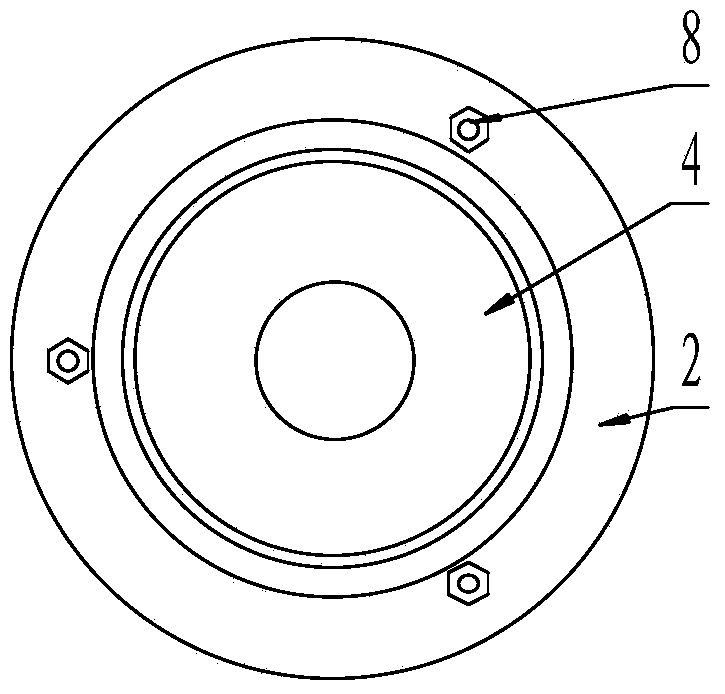

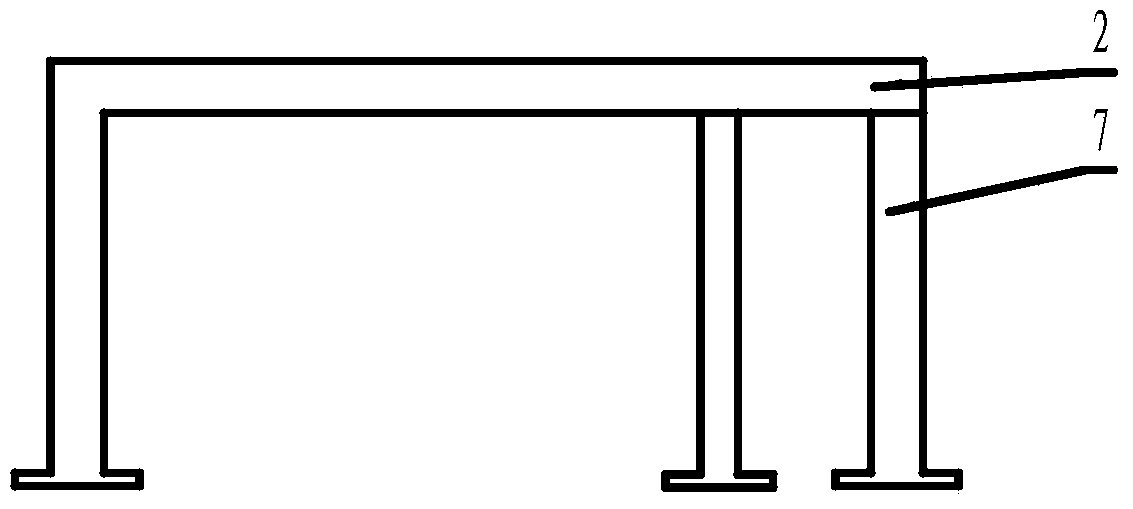

[0037] Such as Figure 1 ~ Figure 3 As shown, the support platform 1 is the support carrier of this embodiment. The panel of the annular support 2 is set on the circumference of the upper end of the mucus hopper 4 with a distance of 50 mm from the mucus hopper 4 . The three poles of the annular support 2 are placed on the supporting platform 1 . Three sensor assemblies are evenly distributed on the periphery of the mucus hopper 4 . The upper ends of the three sensor assemblies are respectively fixedly connected with the ring support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com