Inserting plate rotor engine

A technology of rotor engine and plug-in plate, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc. It can solve the problems of heavy pollution, heavy weight, and poor sealing, and achieve low wear and power consumption, simple structure, and tightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

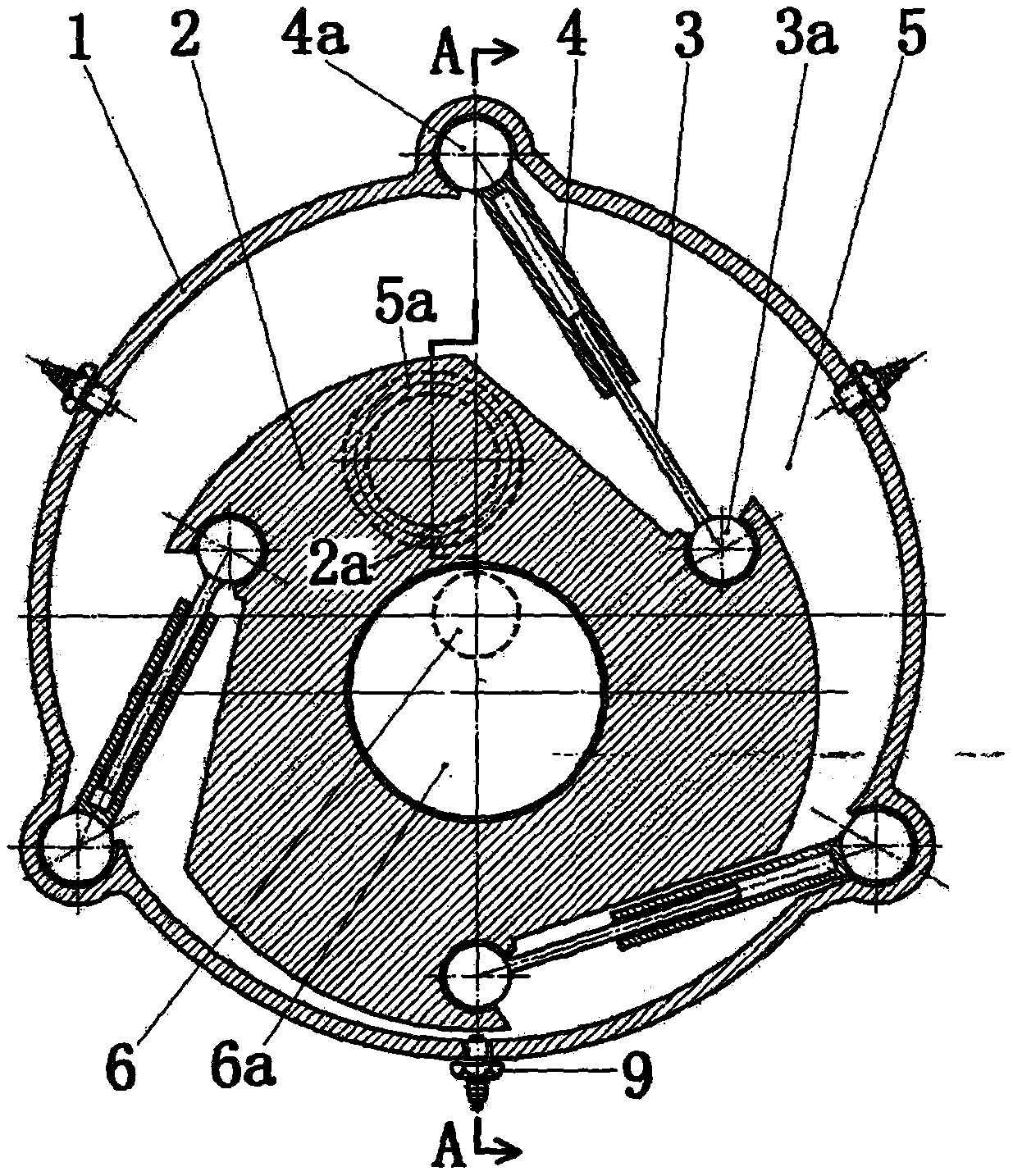

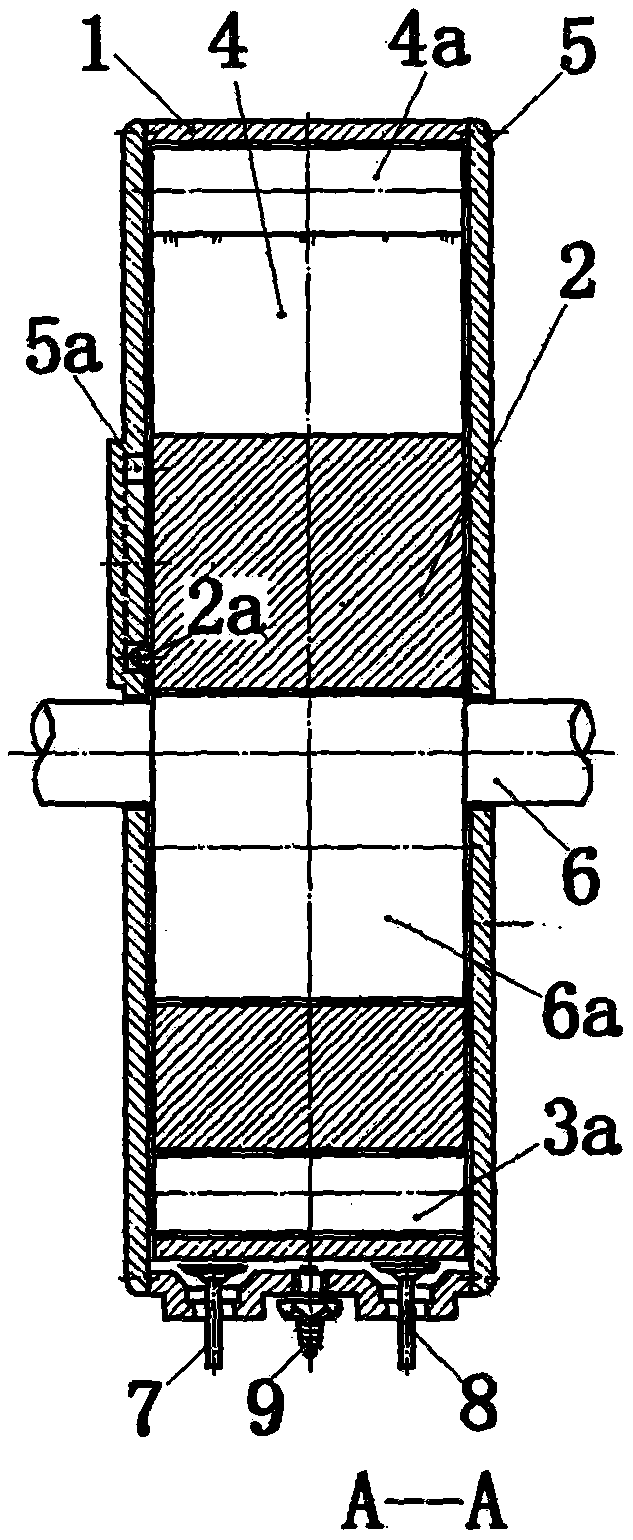

[0015] Such as figure 1 , 2 As shown, a plug-in rotor engine mainly includes a casing 1 , a rotor 2 , a plug-in plate 3 and a slot 4 . The two ends of the fixed cylindrical casing are closed by end covers 5, and a main shaft 6 is located at the axis of the casing, and the main journals at both ends are respectively supported on the end covers on both sides, and are located between the inner walls of the two end covers. The first section of the main shaft is the eccentric shaft 6a, on which the rotor with a cylindrical appearance is set. Both ends of the eccentric shaft and the rotor are close to the inner wall of the end cover for sliding and sealing fit. On the inner wall of the casing, use the slotted shaft 4a Evenly distributed hinged There are three axially long slots for swinging, the slots are inwards, and both ends of the slots are open, and on the outer wall of the rotor, they are hinged outwards evenly by the inserting plate shaft 3a There are three axially long ins...

Embodiment 2

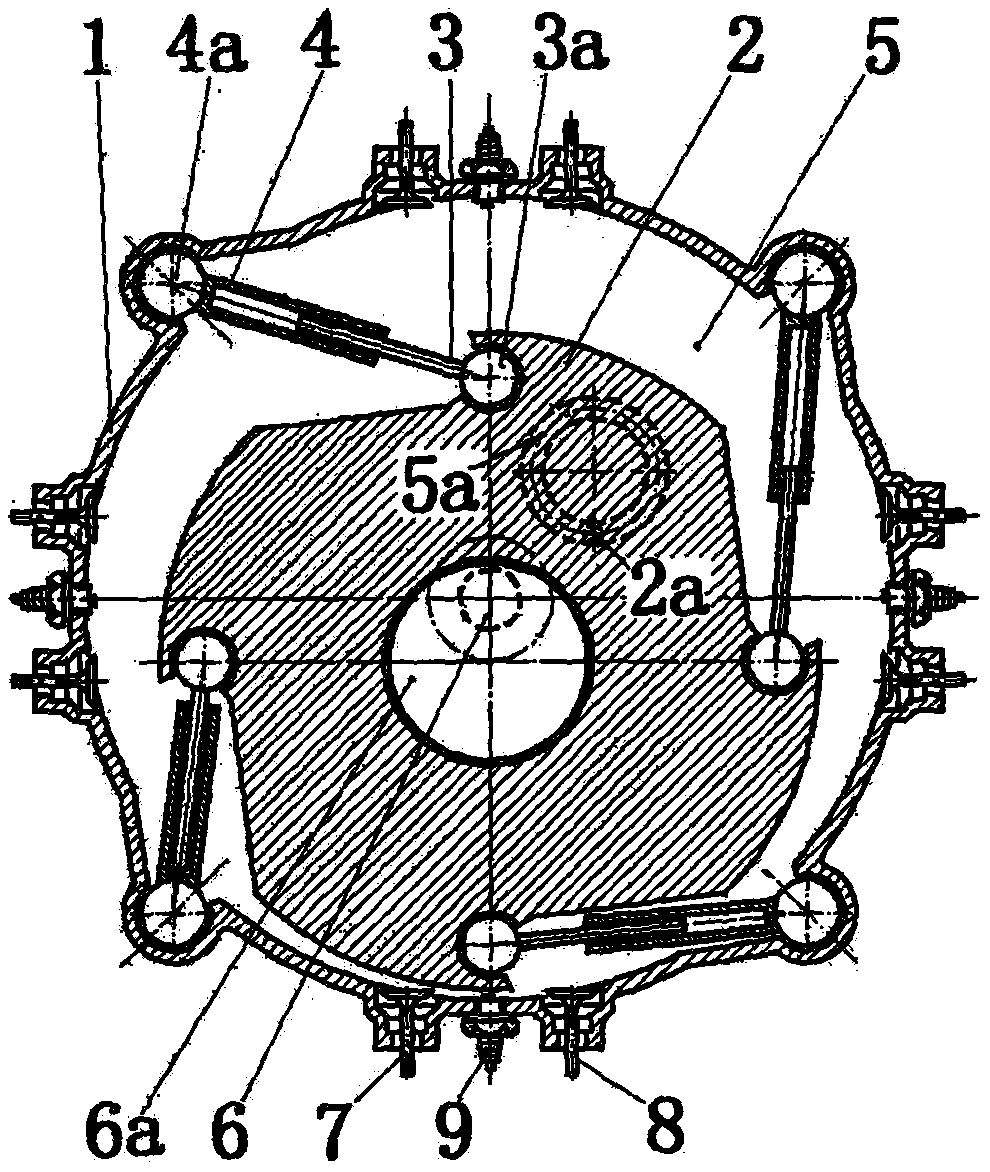

[0028] Such as image 3 As shown, four pairs of plugboards 3 and slots 4 are provided in the plugboard rotor engine, and four sets of intake valves 7, exhaust valves 8 and spark plugs 9 are correspondingly provided. Part and its working principle are all the same as in Embodiment 1.

Embodiment 3

[0030] Such as Figure 4 As shown, there are six pairs of plug-in plates 3 and slots 4 in the plug-in rotor engine, and correspondingly there are six sets of intake valves 7, exhaust valves 8 and spark plugs 9. Part and its working principle are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com