Patents

Literature

33results about How to "Simple laying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bearing plate screw adjusting method construction process

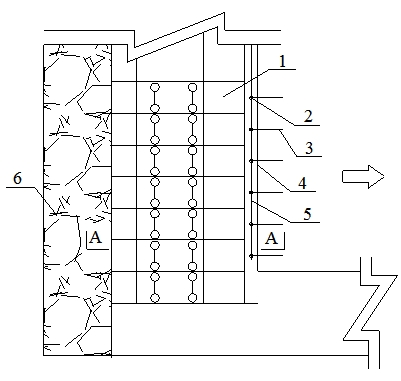

InactiveCN1966869AFast constructionSimple laying processFoundation engineeringSpecial foundation layoutGroutBuilding construction

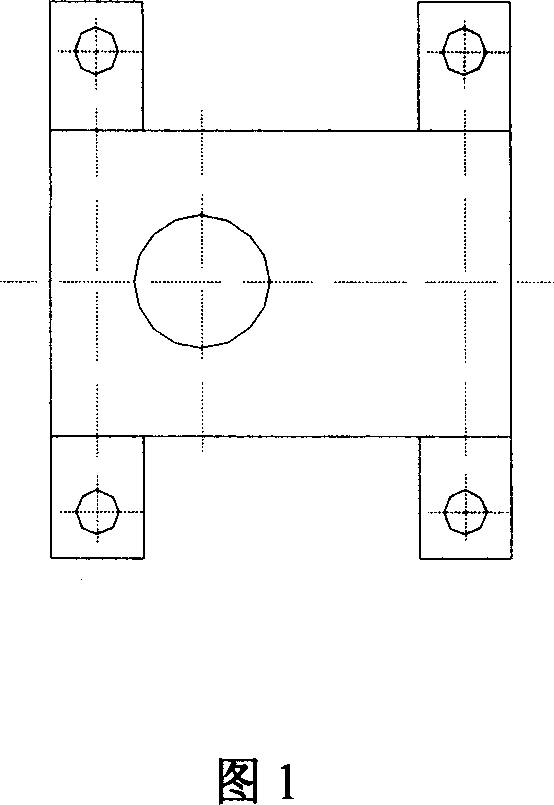

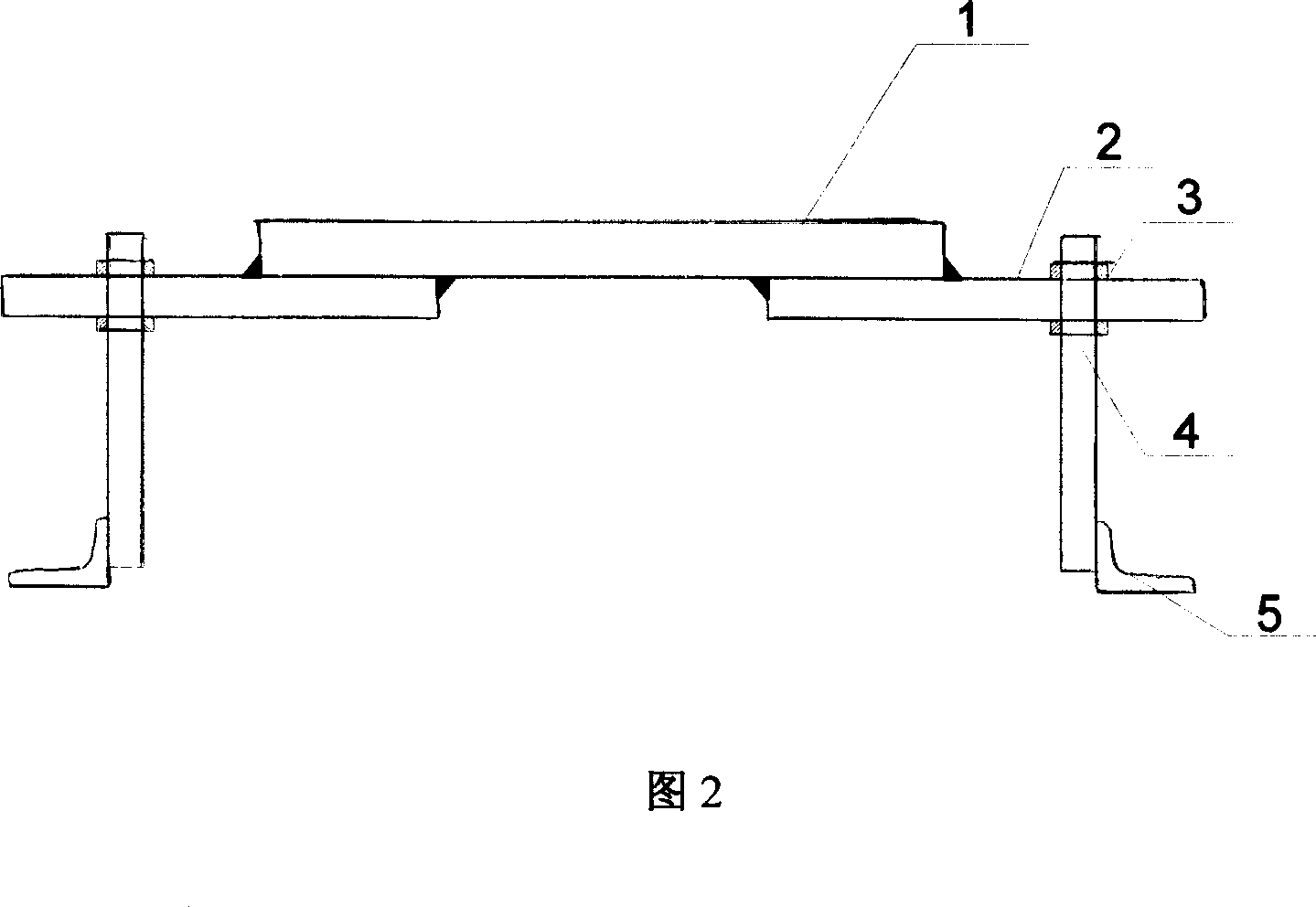

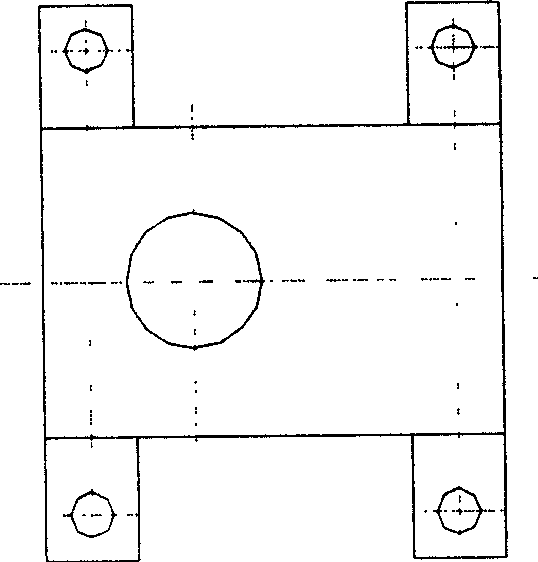

It relates to the close binding of the bottom plate and the base of equipments in installation and maintenance. The screw adjusting method for basic overlay plate goes like this: a. overlay plate processing by welding a piece of steel plate for each of the four corners of the selected qualified flat overlay plate with holes in the middle of the steel plates. B. determining the height mark. c. inspect the basics by eliminating the original secondary grout blanket with the backbone of the first layer exposed and the distance between the lower surface of the flat overly plate and the original concrete layer 120-180mm. d. install the overlay plate by welding the angle steel to the backbone of the basics and welding the bolts on the flat overly plate after positioning based on the technical specifications of the flat overlay plate. E. installs the equipment. It can work a lot of work with simple process and within short time.

Owner:MCC BAOSTEEL TECH SERVICE

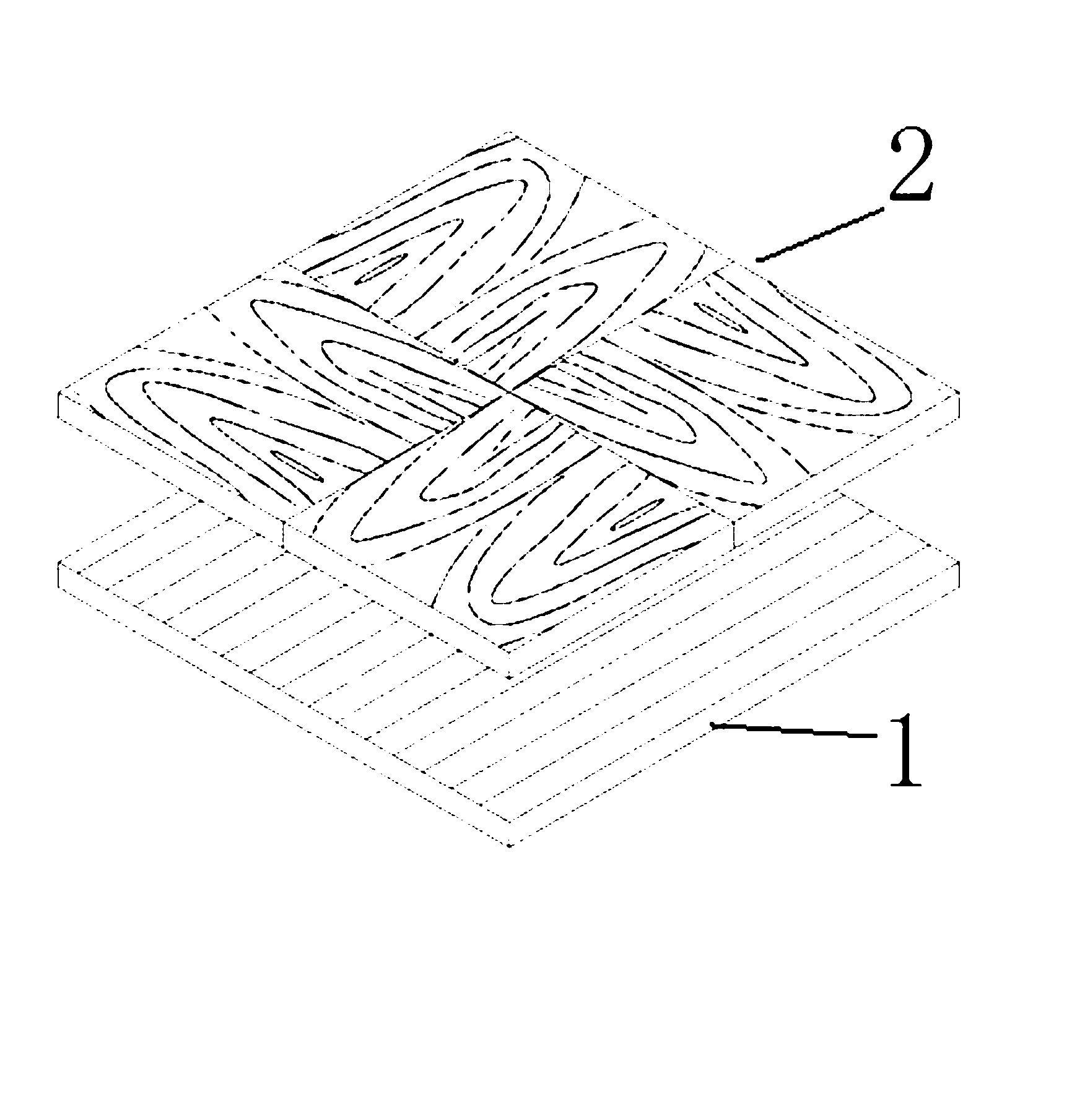

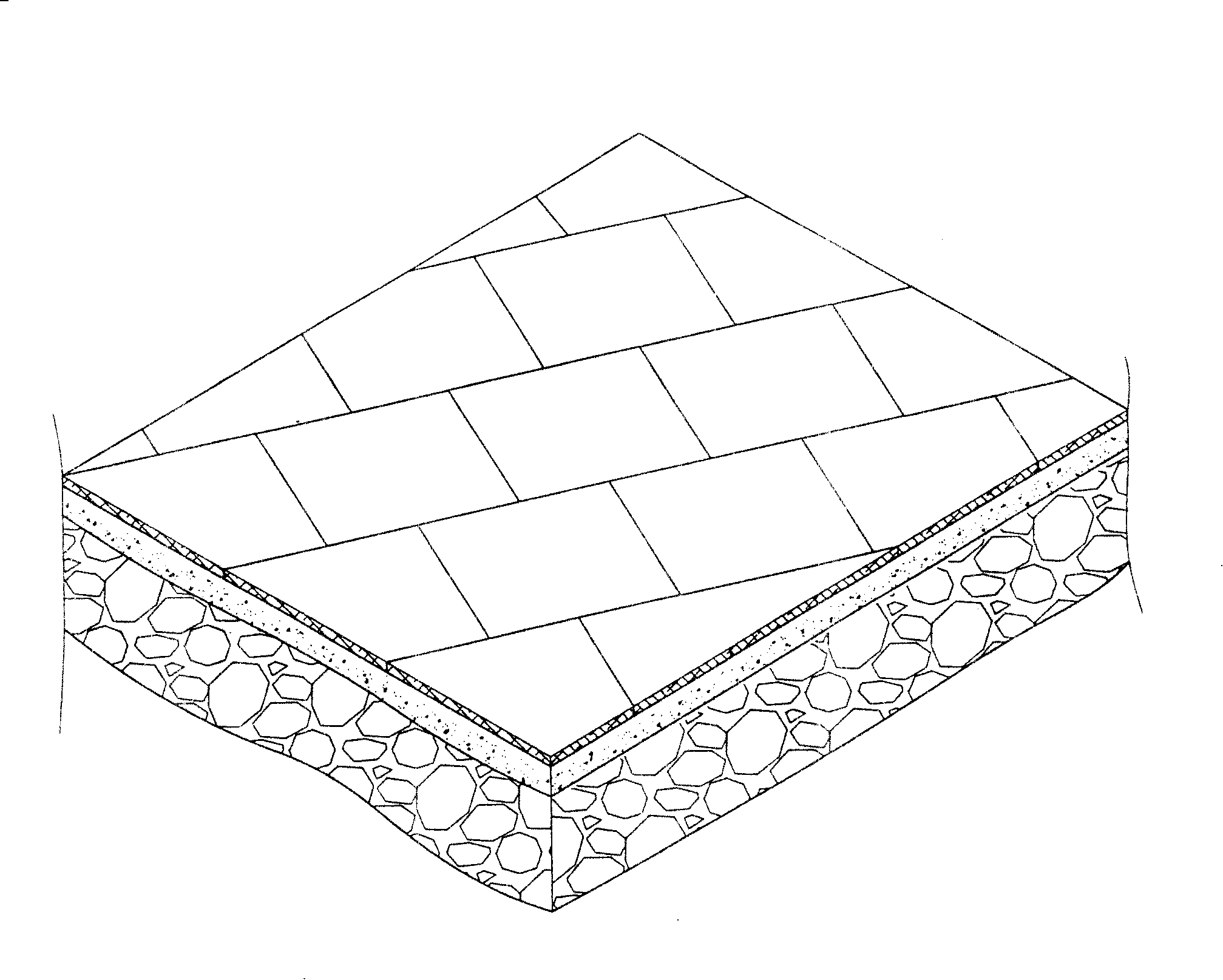

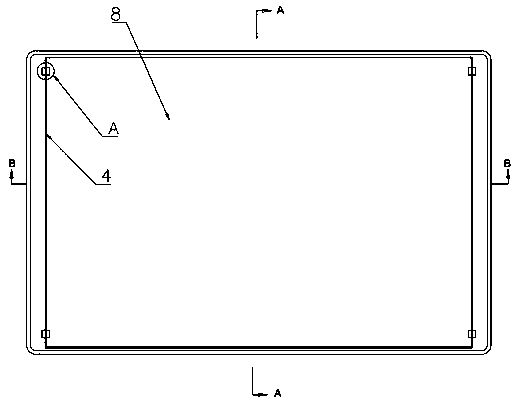

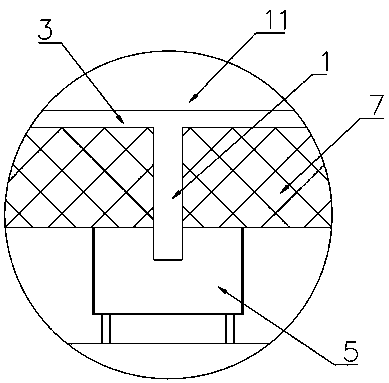

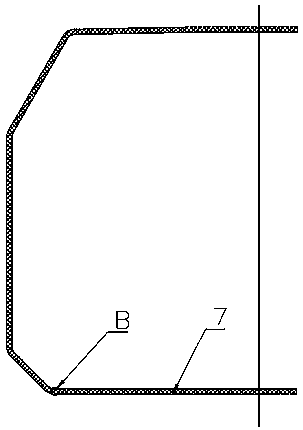

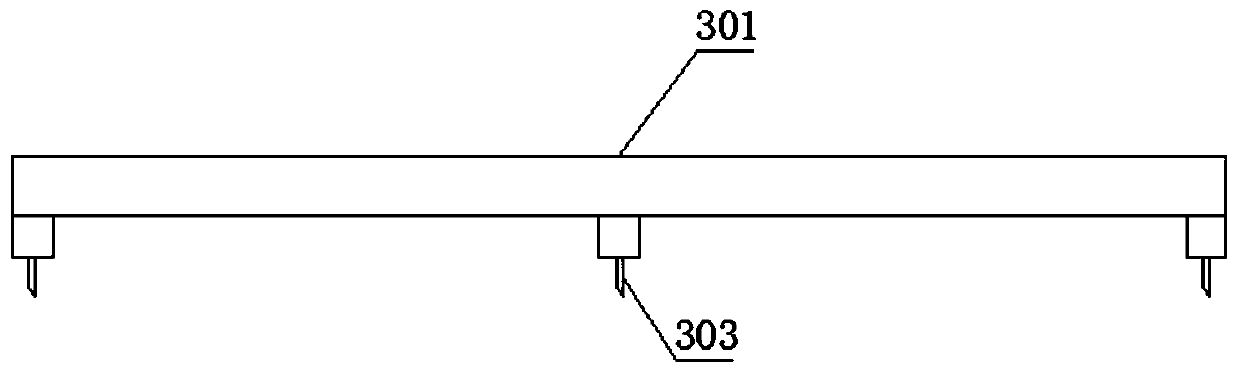

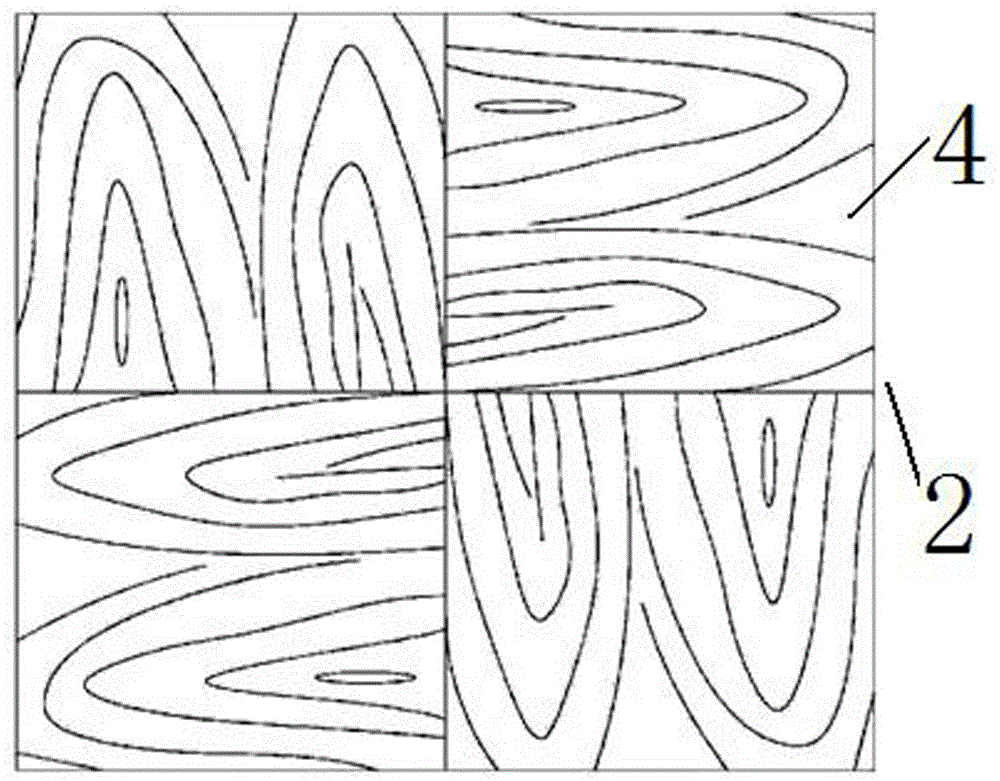

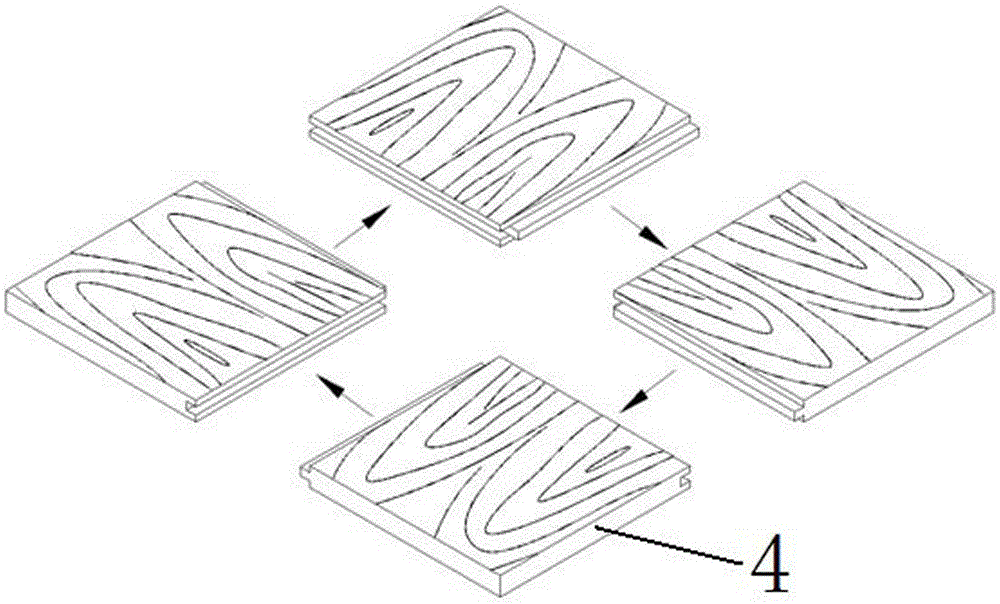

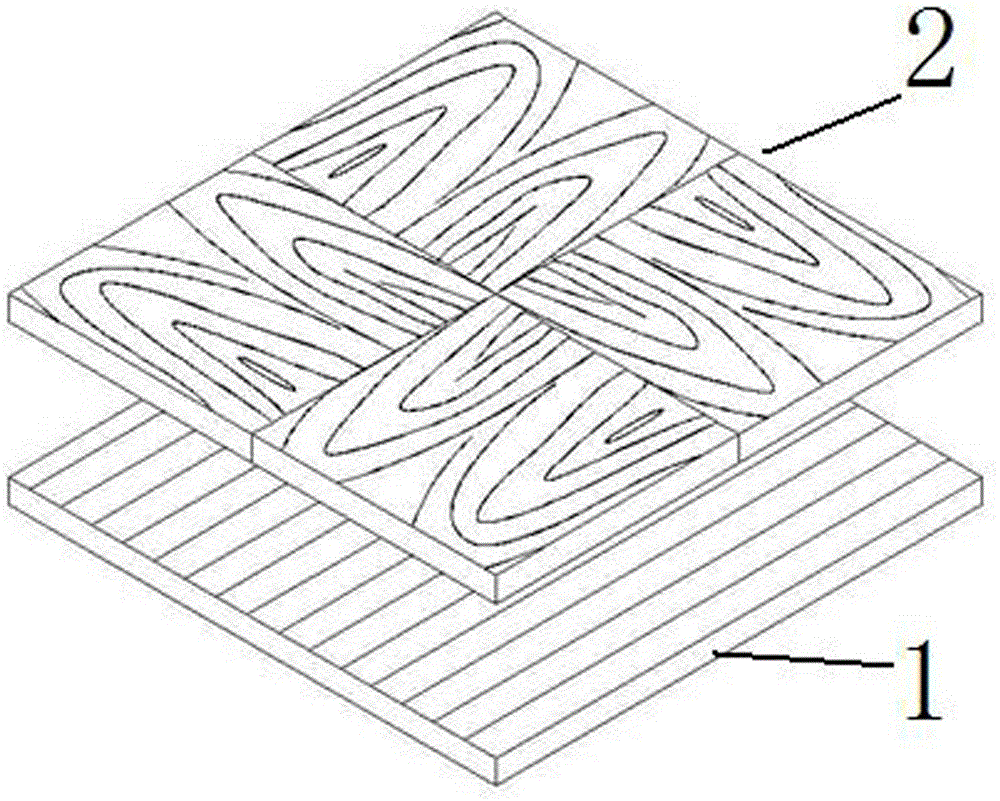

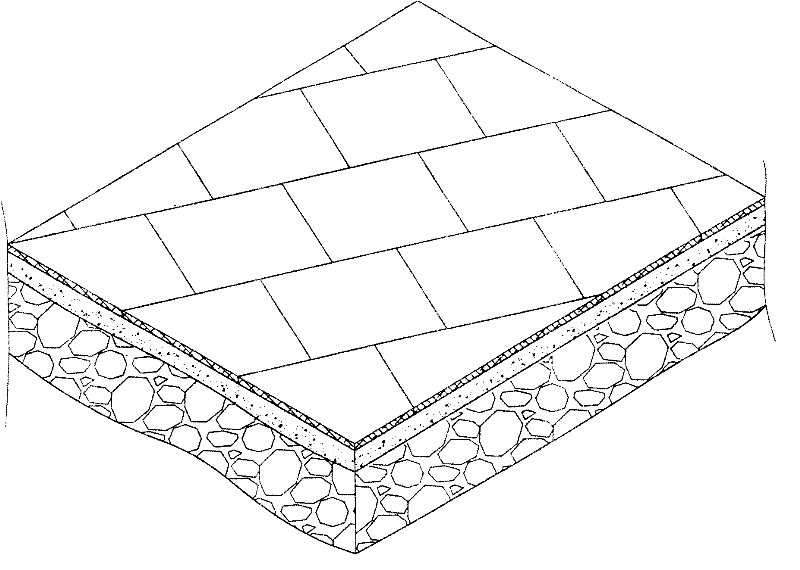

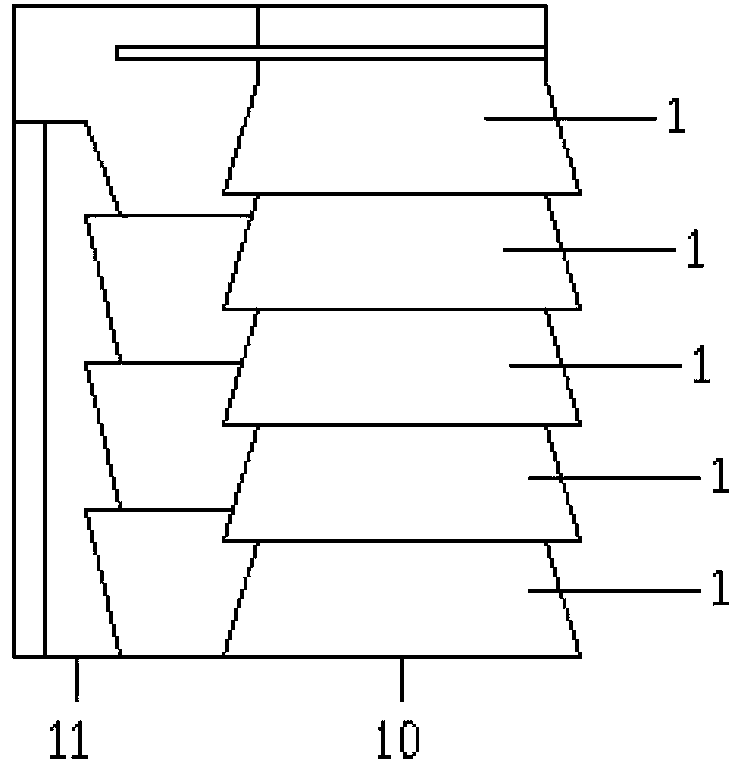

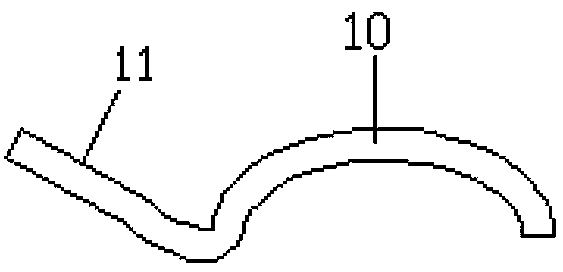

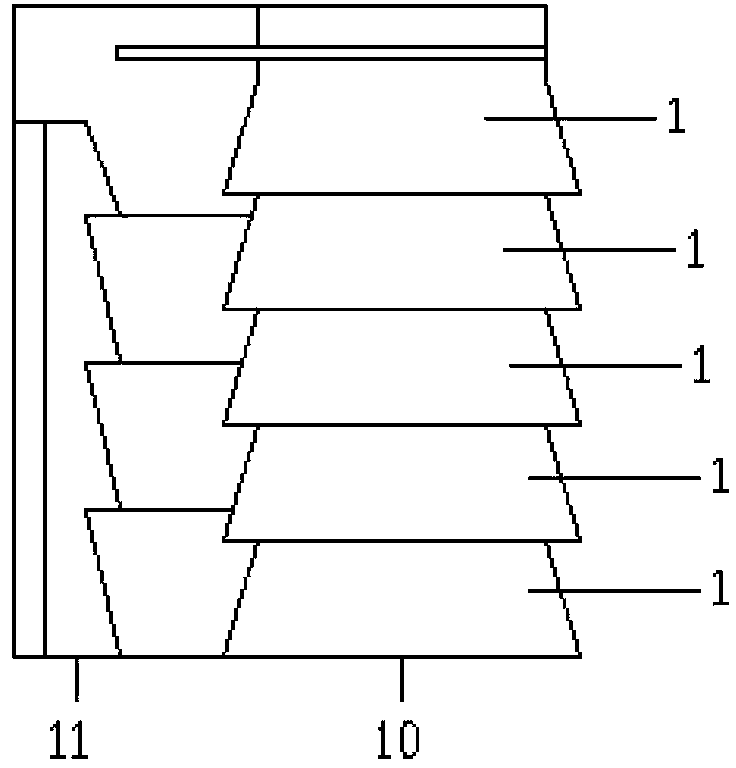

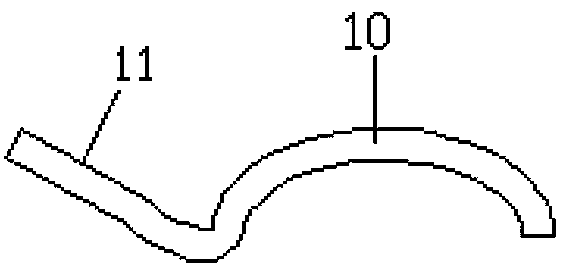

Three-layer-timber-structure solid wood floor and installment method of the same

InactiveCN103161294AImprove moisture resistanceImprove the anti-deformation effectWood layered productsFlooringSolid woodKeel

The invention relates to a three-layer-timber-structure solid wood floor. The three-layer-timber-structure solid wood floor is characterized in that a middle plate and a panel are sequentially arranged on a bottom plate, the middle plate is formed by splicing at least two floor blocks, the texture of timbers between neighboring floor blocks is criss-cross, and an included angle is arranged between the timber texture direction of the bottom plate and the timber texture direction of the floor block of the middle plate. Meanwhile, the three-layer-timber-structure solid wood floor is simple in pavement technology. Neighboring square floors are connected through U-shaped metal buckles. Keels do not need additionally arranging, and materials and manpower are saved to provide convenience for disassembling, assembling and maintenance in the future. A fixing mode is a dynamic fixing mode, and no matter a solid wood floor expands or contracts in the using process, the solid wood floor can automatically digest and absorb stress deformation of expansion and stress deformation of contraction, and accordingly the problems such as deformation and cracking can not happen in the using process of the solid wood floor.

Owner:上海筑邦木业有限公司

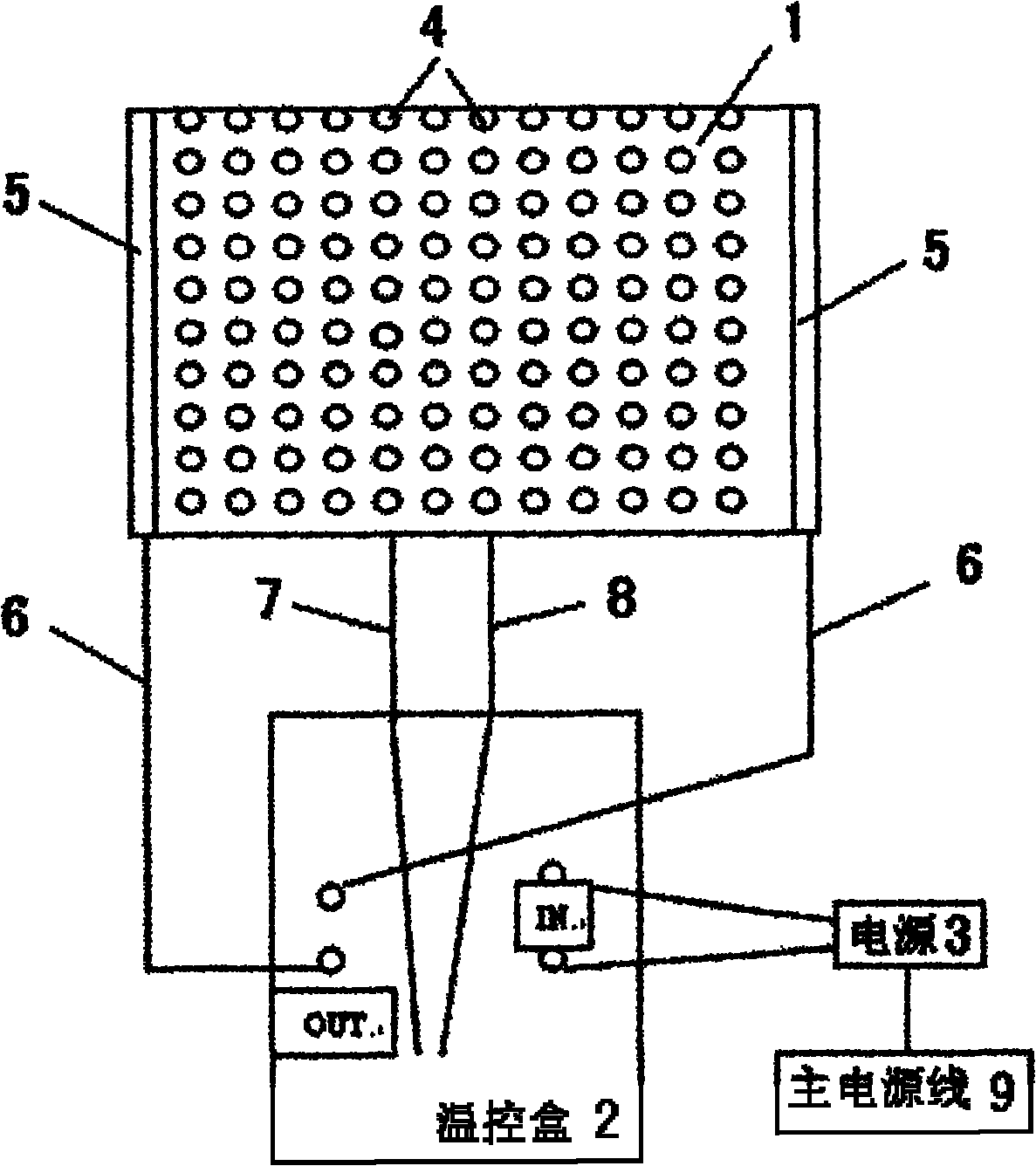

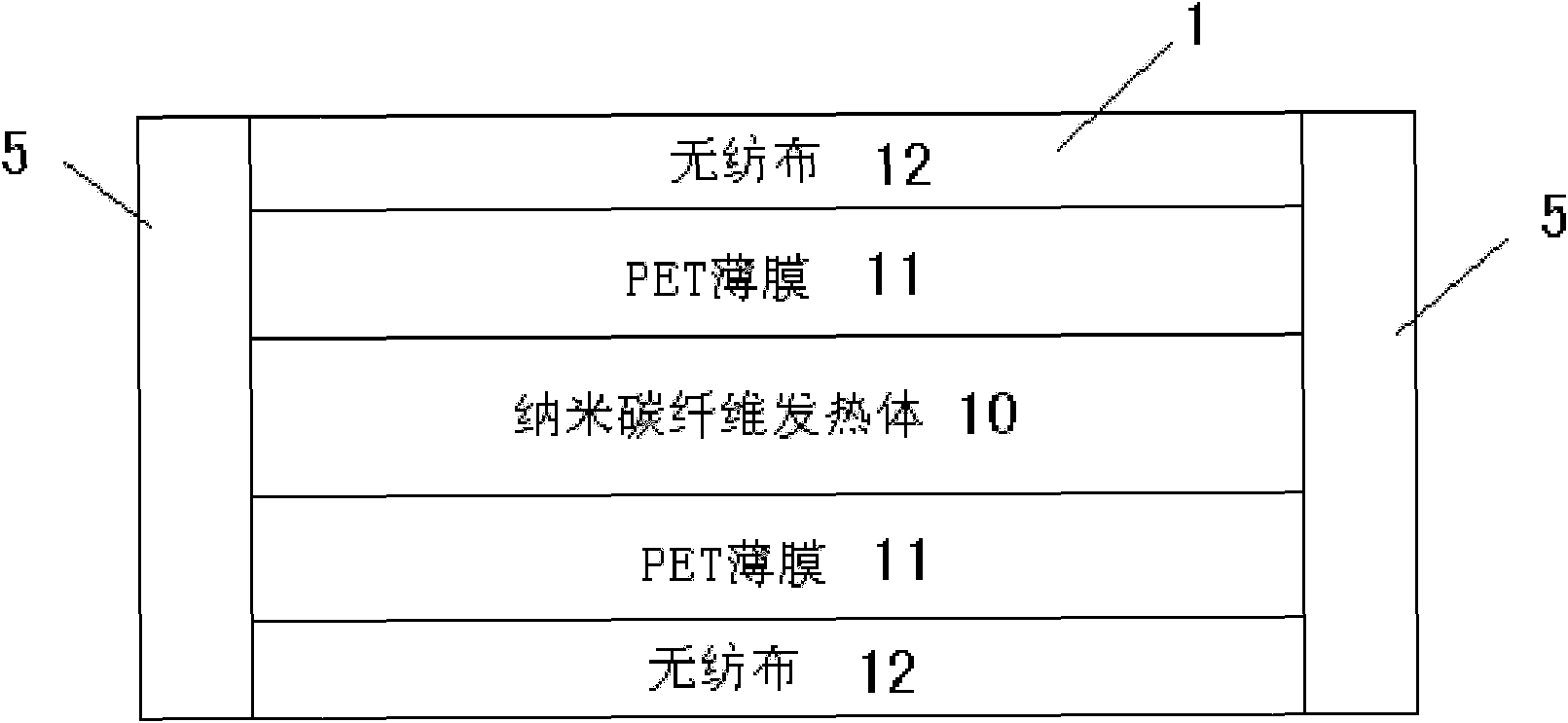

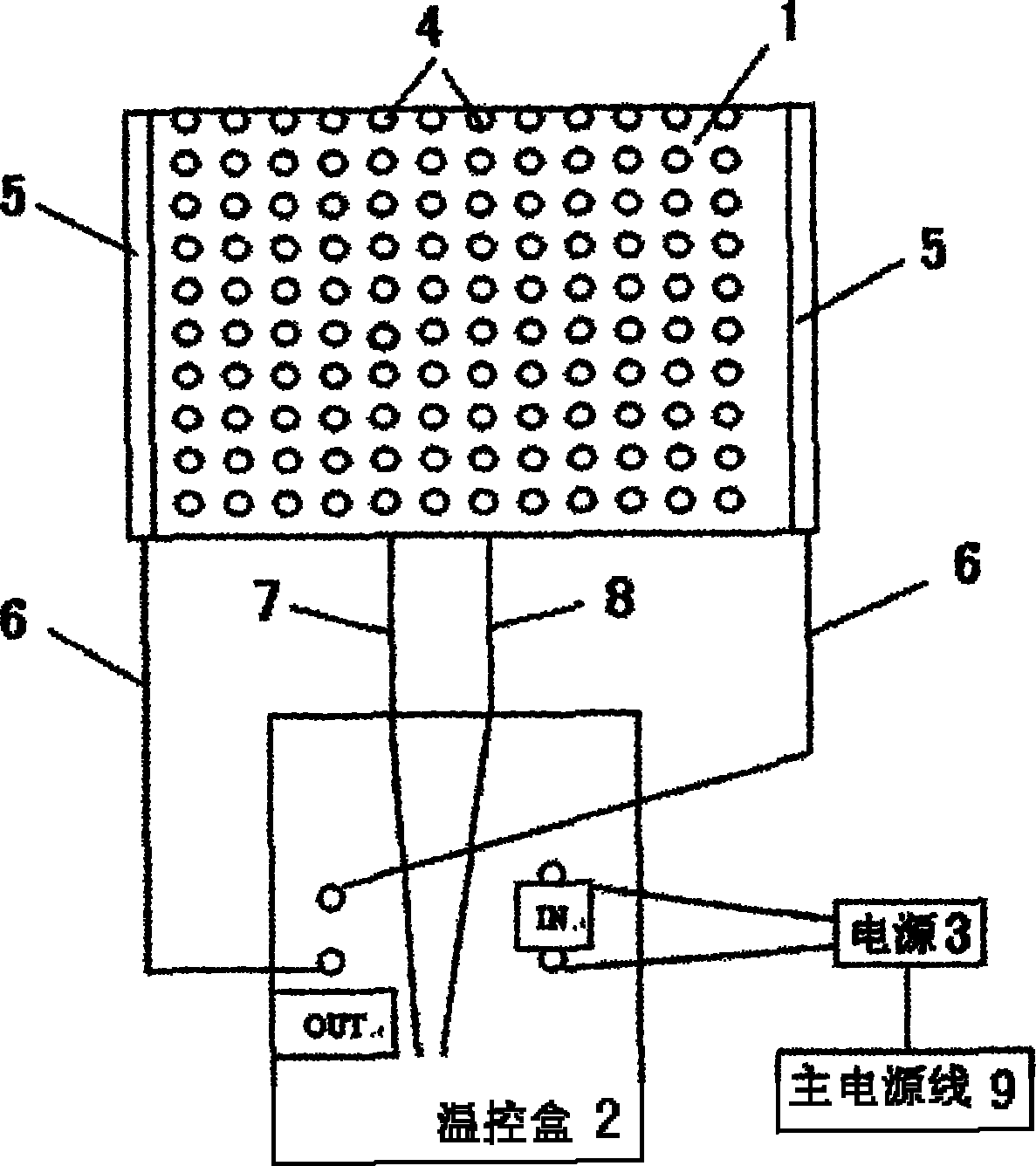

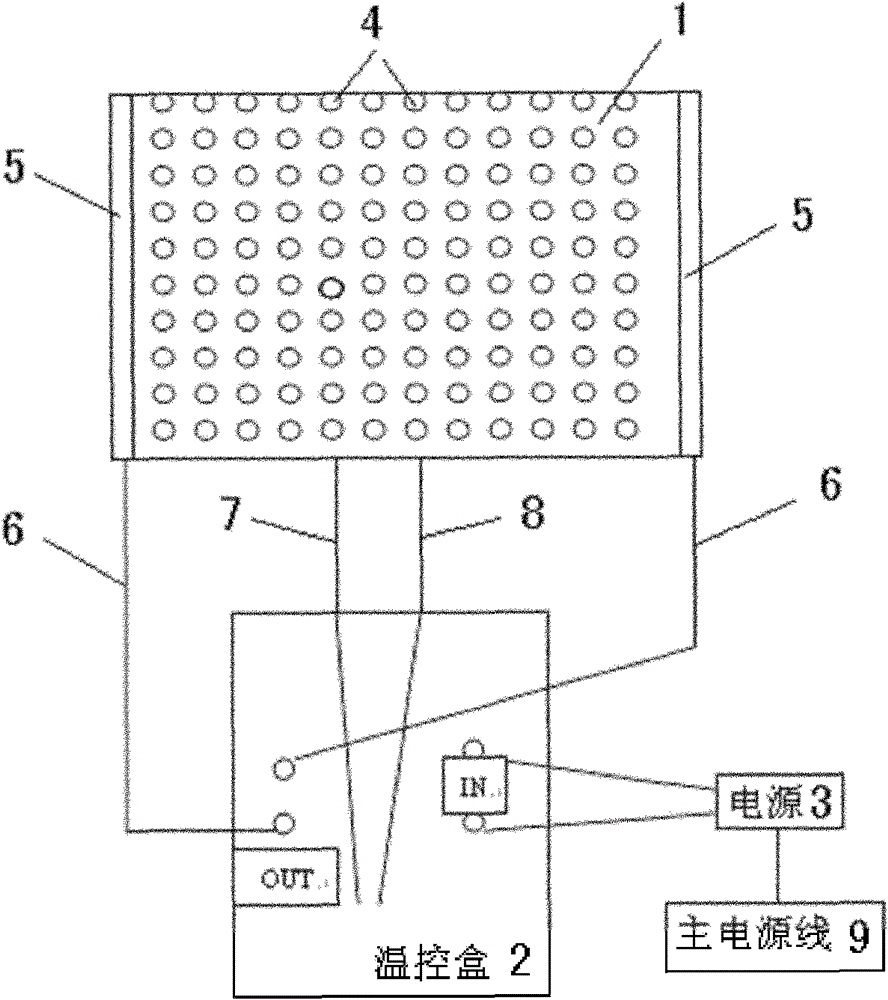

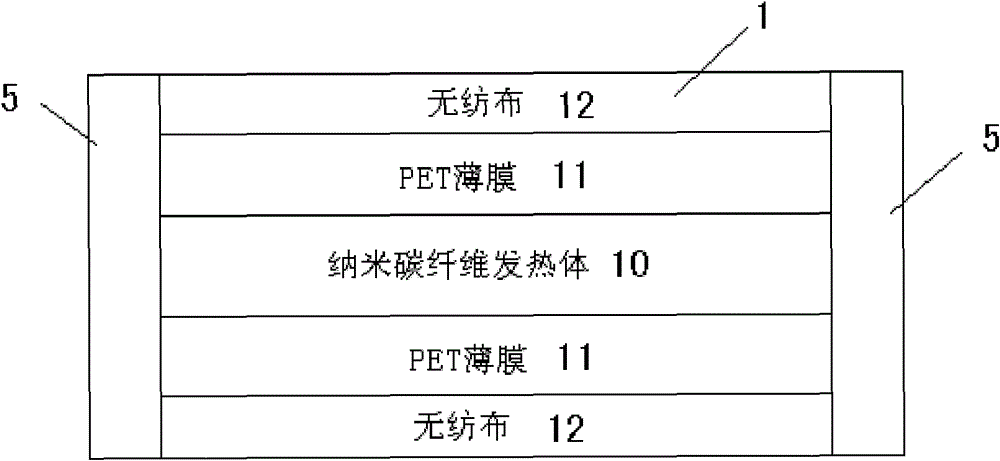

Heating layer for megawatt wind turbine blade auxiliary mould and manufacturing method thereof

The invention relates to a heating layer for a megawatt wind turbine blade auxiliary mould and a manufacturing method thereof. The heating layer comprises at least one heating area, wherein each heating area comprises 5-15 nanometer carbon heating films, a temperature-controlled box, a power supply and a plurality of copper nets; each nanometer carbon heating film is provided with a plurality of small holes; each nanometer carbon heating film is paved on an inner structural layer of the blade auxiliary mould; each copper net is paved between adjacent nanometer carbon heating films; electrodesare arranged at two ends of each nanometer carbon heating film; two electrodes are respectively connected to the temperature-controlled box by power lines; a temperature-limiting line and a temperature-sensing line pre-embedded in each nanometer carbon heating film are connected to the temperature-controlled box; the power lines of the nanometer carbon heating films are in parallel connection with the temperature-controlled box; the temperature-controlled box is used for controlling the temperature of the corresponding heating area; the temperature-control box for each heating area is connected to an externally connected power supply; and all power supplies are in parallel connection and then are connected to a main power line. The heating layer for a megawatt wind turbine blade auxiliarymould can be used for ensuring that the blade auxiliaries are uniformly heated in the process of being solidified in the blade auxiliary mould. The heating layer for a megawatt wind turbine blade auxiliary mould can be widely applied to the field of wind power.

Owner:GUODIAN UNITED POWER TECH

Ground surface finishing method

The invention discloses a method for floor decoration, which includes the following steps: mixing self-leveling mortar with water by the ratio of 5:1, churning up the mixture, applying the mixture evenly on the ground to form a bottom layer, coating the bottom layer with a shaping layer, and finally mixing solvent-free epoxy resin with curing agent according to the weight percentage of 2:1 and spreading the mixture on the shaping layer with a trowel to form a wear-resistant and transparent surface layer. The method of decoration has the advantages of safety, environment-friendliness, no seam, various shapes, easy revamping and rapid construction.

Owner:厦门哈德新型建材有限公司

Preparing method for cable embedded composite material shell

ActiveCN107676814ASimple laying processReduce negative qualityContinuous combustion chamberFiberConductor Coil

The invention discloses a preparing method for a cable embedded composite material shell. The preparing method comprises the following steps that firstly, a heat insulation structure is manufactured;secondly, the shell is manufactured through fiber wet process winding; thirdly, cable pavement is conducted; and fourthly, demoulding is conducted. A cable cover is not needed for pavement of a cableon the shell, the passive mass of the shell is reduced, the cable pavement technology is simplified, and the machining efficiency is improved. The cable is embedded between carbon fiber composite material layers of the shell, the cable can well adapt to stress deformation of the shell, the two outermost sides of the cable are filled with light foam materials, and the structure coordination of a winding layer is guaranteed.

Owner:湖北三江航天江北机械工程有限公司

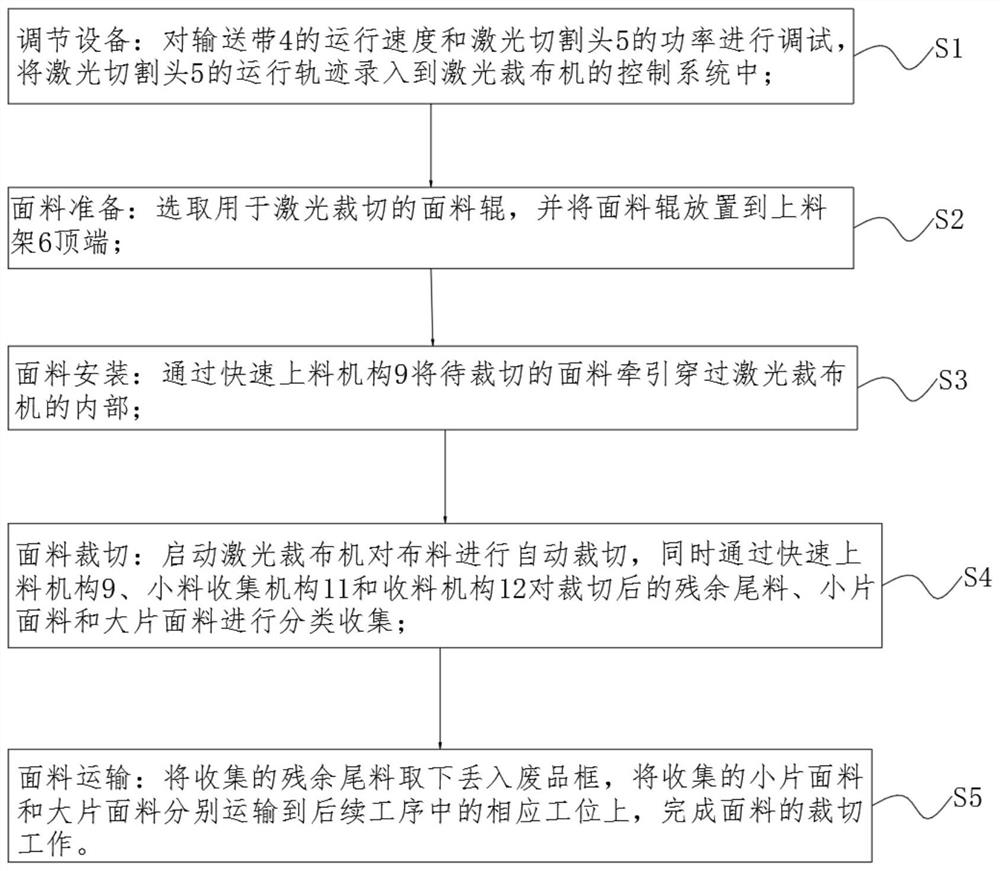

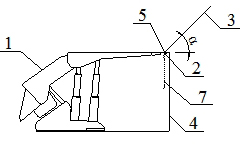

Laser cutting method for garment production

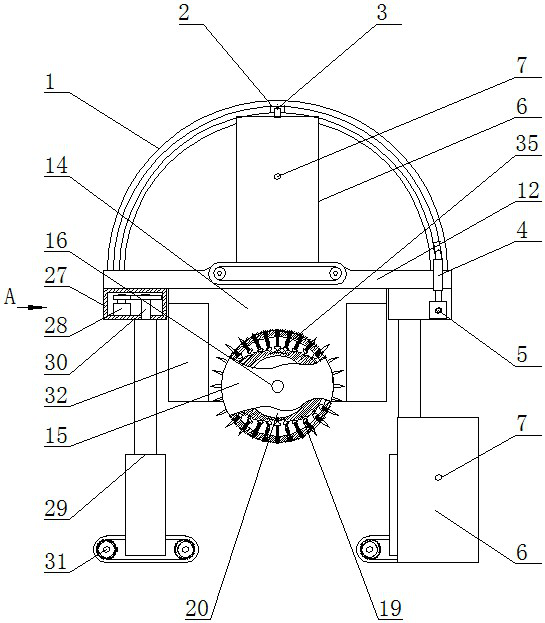

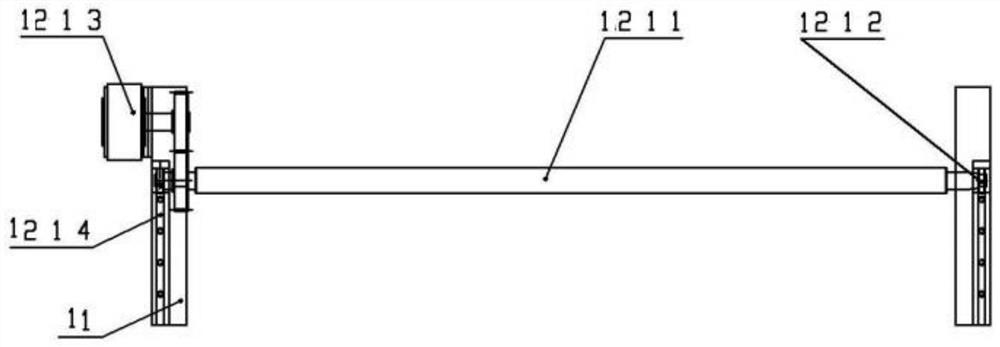

InactiveCN112008254AScientific and reasonable structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention discloses a laser cloth cutting method for garment production. A cutting box is welded to the top end of a machine tool base; one end of the top of the cutting box is movably connected with a protective cover; a conveying belt is movably connected into the machine tool base; laser cutting heads are fixedly connected to the positions, corresponding to the top of the conveying belt, ofthe two sides of the top end of the machine tool base; and a synchronous flattening mechanism is arranged at the top end, corresponding to the inner position of the cutting box, of the machine tool base. According to the laser cloth cutting method, a pair of movable cross bars and a scraper blade move from the middle to two ends of a bidirectional lead screw to gradually smooth a fabric from themiddle to two ends, and meanwhile the area swept by the scraper blade is the machining area of the laser cutting head, so that flatness of the fabric in a processing area is guaranteed, residual wrinkles on cloth are prevented from influencing normal processing of the laser cutting head, and cutting precision of the cloth is effectively improved. Meanwhile, a mechanical mode is adopted for flattening, so that the flattening process of the cloth is more convenient, and cutting efficiency of the fabric is effectively improved.

Owner:李永庆

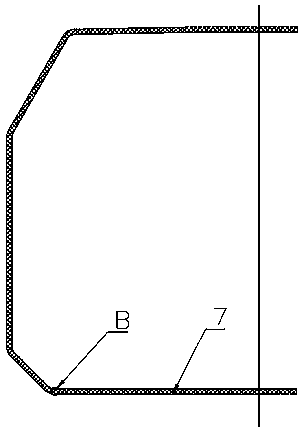

Leakage guiding device of a B-type enclosure system of an LNG ship

ActiveCN108974259APrevent leakageAvoid stockpilingVessel partsFor bulk goodsInsulation layerEngineering

The invention discloses a leakage guiding device of a B-type enclosure system of an LNG ship, belongs to the technical field of ship construction. The device comprises a guide mechanism, flow-guidingtube, lap plate and support mechanism, the deflection mechanism comprises a plurality of deflection plates with deflection grooves, A plurality of deflector plates are connected to the upper surface of the insulating layer of the B-type enclosure system of the LNG ship to form an annular liquid collecting tank, the annular liquid collecting tank is communicated with the collecting device of the LNG ship through a diversion pipe, two adjacent delfection plates are connected through transition plates; A low surface of that flow guiding mechanism is connected with an upper surface of an insulation layer of a B-type enclosure system of an LNG ship, two sides of the flow guiding mechanism are connected with a splash screen through an overlapping plate, and the upper surface of the flow guidingmechanism is connected with a bottom plate of a liquid cargo tank of the LNG ship through a support mechanism, wherein the upper surface of the flow guiding mechanism is connected with the bottom plate of the liquid cargo tank of the LNG ship through a support mechanism. The diversion device can timely divert the leaked LNG out of the gap between the cargo tank and the splash screen, can effectively prevent the LNG from accumulating in large quantities, and can prevent the LNG from damaging the structure of the cargo tank and the splash screen.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

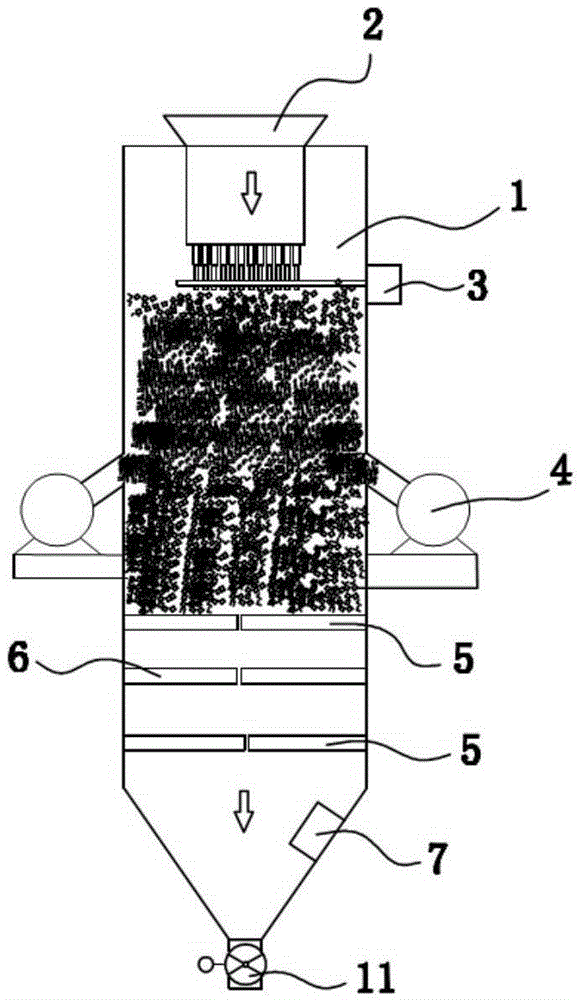

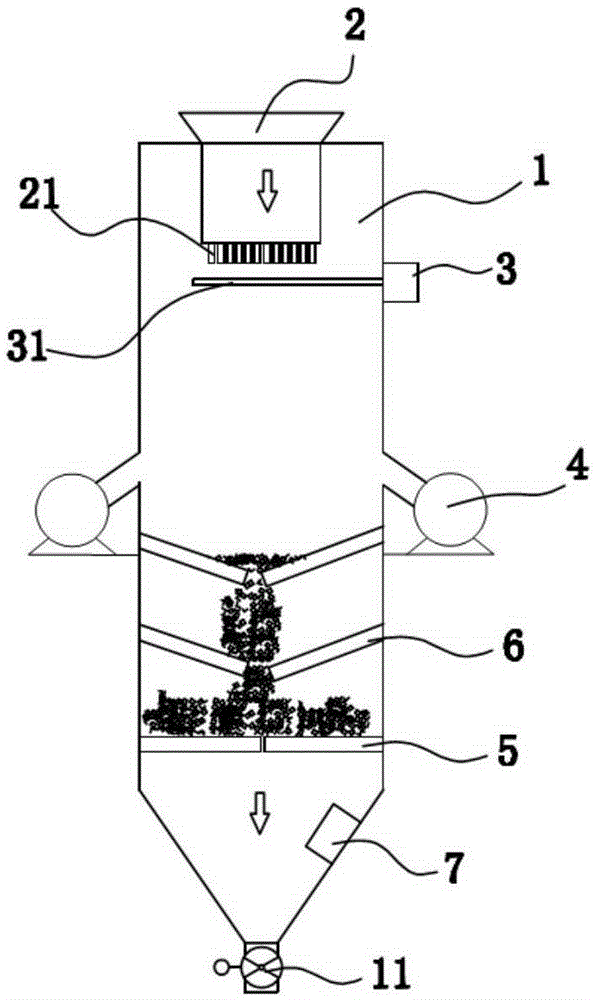

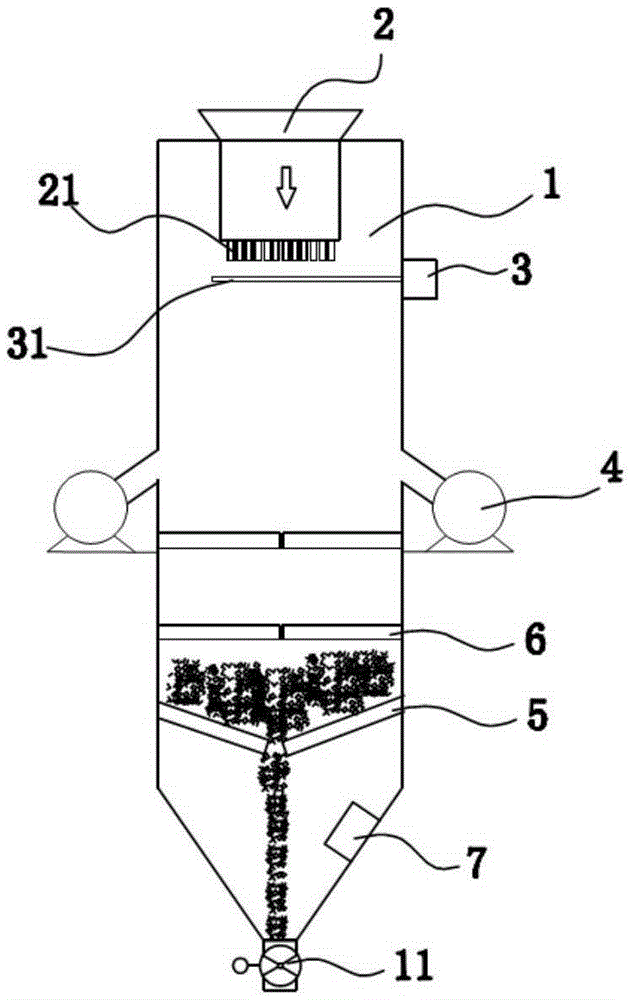

Equipment and method for preparing high-performance modified pitch particles through abandoned clothing fibers

The invention provides equipment and method for preparing high-performance modified pitch particles through abandoned clothing fibers. The equipment comprises a mixing cavity, a high-pressure jet flow mechanism or a high-pressure extrusion mechanism, a cutting mechanism and short fiber blowing mechanism. The method includes the steps that firstly, abandoned clothing is crushed into short fibers ranging from 3 mm to 6 mm in size, and pitch is softened into a melt shape; then, the short fibers are blown upwards from the bottom of the mixing cavity, melt line-shaped pitch is sprayed downwards from the upper portion of the mixing cavity, the line-shaped pitch is cut into short pitch particles through the cutting mechanism and is in full contact with the sticky surfaces of the ascending short fibers in the descending process, the short fibers are arranged on the surfaces of the pitch particles in a wrapping mode, and the modified pitch particles can be obtained after vibration with a vibrating screen and cooling. By means of the equipment and the method, the problem that the short fibers and the pitch are not evenly mixed due to high adhesion of the pitch particles can be effectively avoided, the produced pitch particles are convenient and fact to transport, the laying process is simple, and the problem that the short fibers are distributed unevenly due to secondary melting of pitch laid in a road can be effectively avoided.

Owner:JIESHOU YIMIN CHEM TECH CO LTD

Leakage guiding device for B type enclosure system of LNG ship

ActiveCN109606567APrevent large stockpilesAvoid damageVessel partsFor bulk goodsMarine engineeringGuide tube

The invention, which belongs to the technical field of ship construction, discloses a leakage guiding device for a B type enclosure system of an LNG ship. The device comprises a flow guiding mechanism, guiding tubes, lap plates and a supporting mechanism. The flow guiding mechanism includes a plurality of guiding plates with guiding slots; the multiple guiding plates are connected in an end-to-endmanner on the upper surface of an insulating layer of an LNG ship B type enclosure system to form an annular liquid collecting tank; and the annular liquid collecting tank and an LNG ship collectiondevice are communicated through the guiding tube. The every two adjacent guiding plates are connected by a transition plate; the lower surface of the flow guiding mechanism is connected with the uppersurface of the insulating layer of the LNG ship B type enclosure system; the two sides of the flow guiding mechanism are connected with an anti-splash screen through the lap plates; and the upper surface of the flow guiding mechanism is connected with a bottom plate of an LNG ship liquid cargo hold by the supporting mechanism. The flow guiding mechanism can guide the leakage LNG out of the gap between the liquid cargo hold and the anti-splash screen timely, thereby preventing the accumulation of lots of LNG effectively and protecting the structures of the liquid cargo hold and the anti-splashscreen from being damaged by the LNG.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

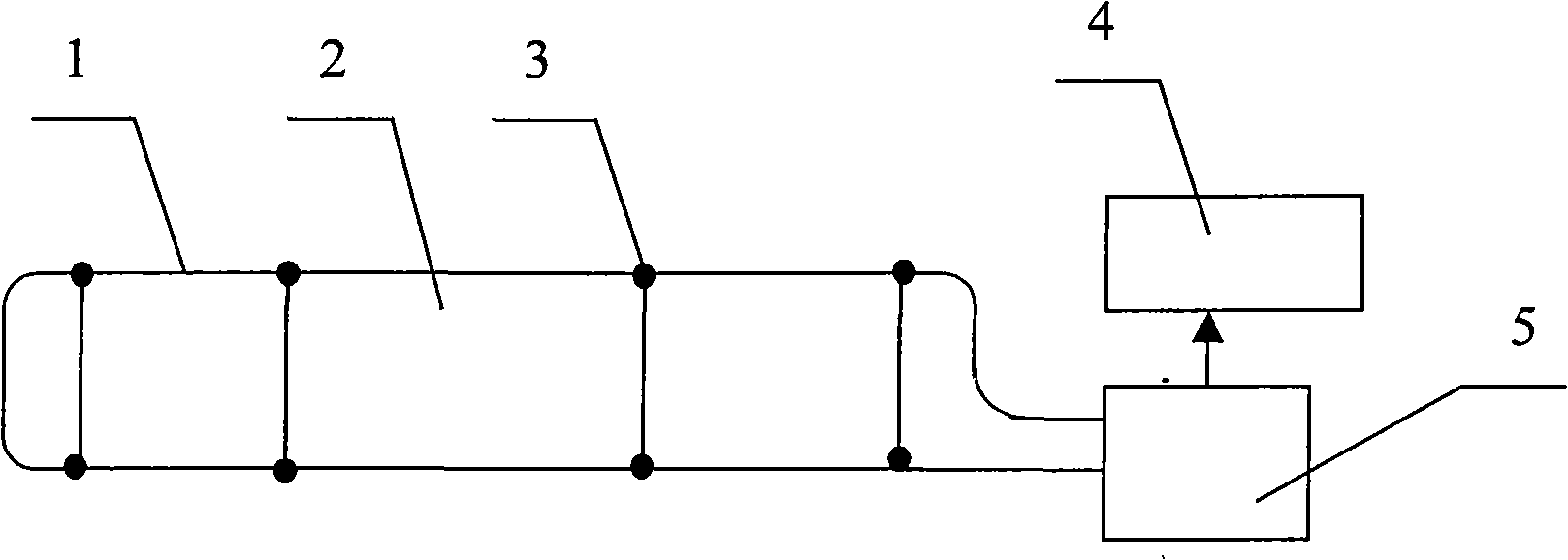

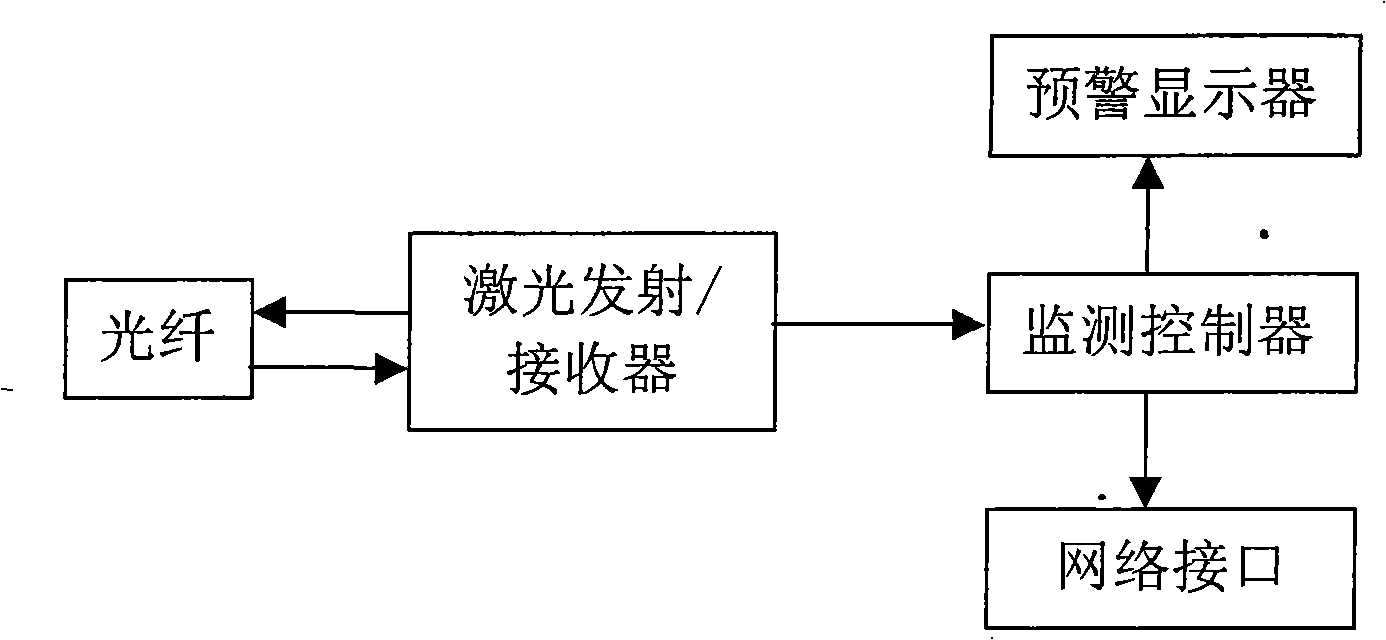

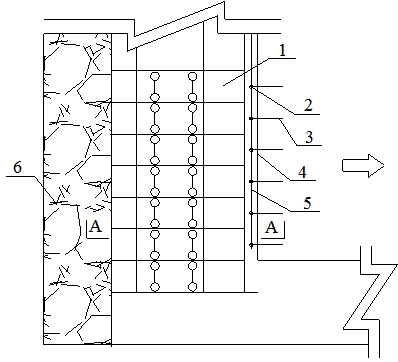

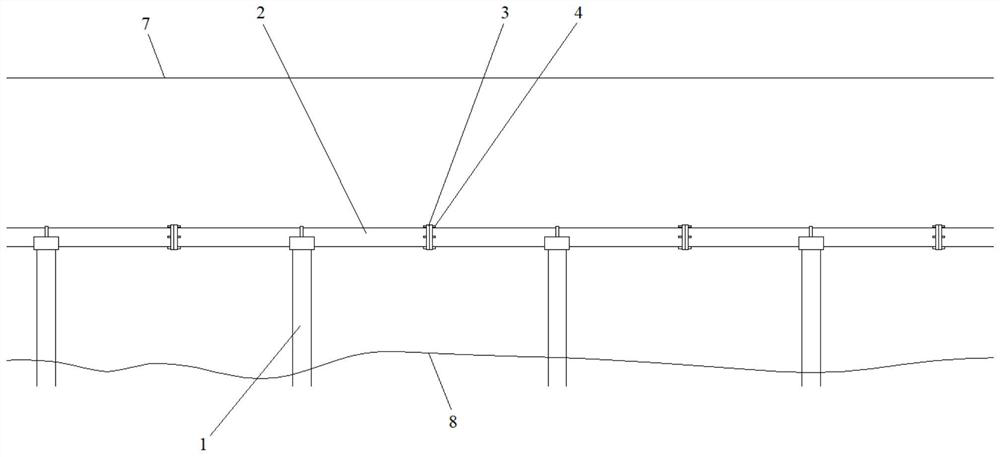

Structure safety optical fiber intelligent test and early-warning system

InactiveCN101303242AAvoid lostStrong interference abilityNon-electrical signal transmission systemsConverting sensor output opticallyEarly warning systemTransceiver

The invention discloses an optical fiber intelligent detecting and early warning system with a safe structure, particularly a detecting and early warning system with simple laying process, high reliability and strong anti-interference ability. The system comprises optical fiber, an optical fiber light path monitor and an early warning display, wherein the optical fiber light path monitor is configured by connecting a detection signal output end of a laser transceiver with a monitoring controller, one end of the optical fiber is connected with the transmitting end of the laser transceiver and the other end is connected with the receiving end of the laser transceiver, and the monitoring controller is connected with the early warning display. The detecting and early warning system according to the invention performs judgement by on-off detection of the optical fiber light path, has strong anti-electromagnetic interference ability, can effectively realize safe detection of building structures, and automatically gives the early warning. The invention has advantages of low cost and simple laying process.

Owner:MILITARY TRANSPORTATION UNIV PLA

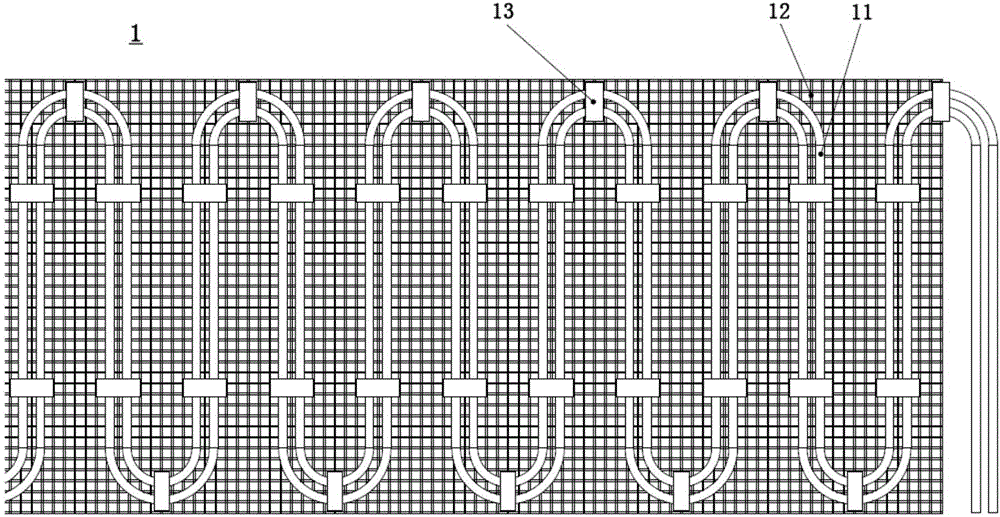

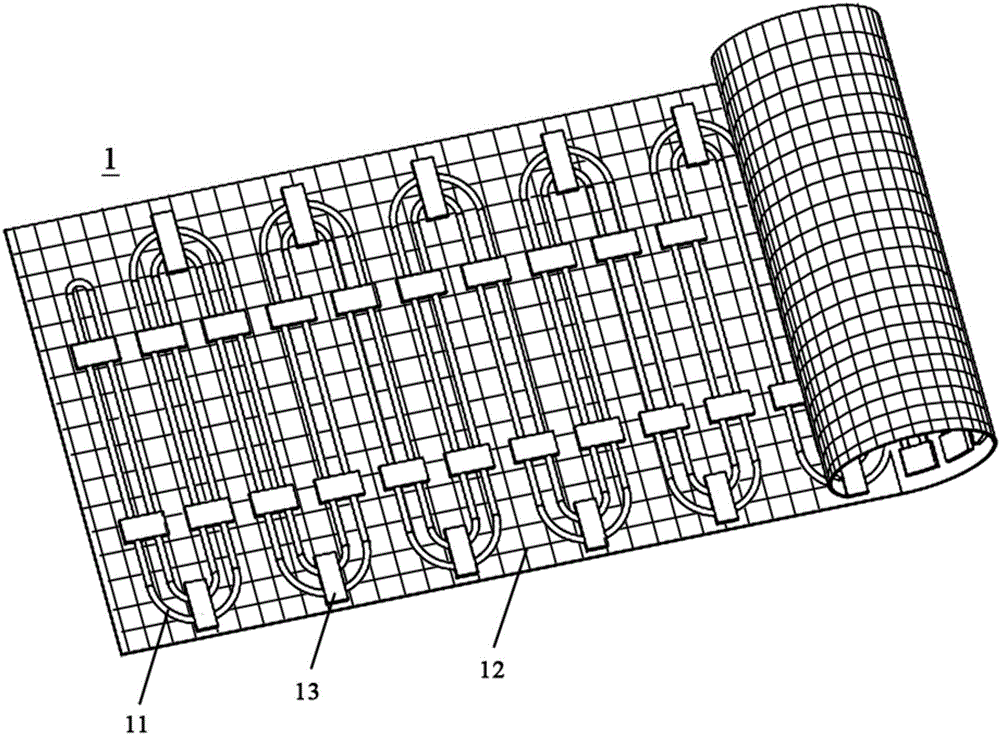

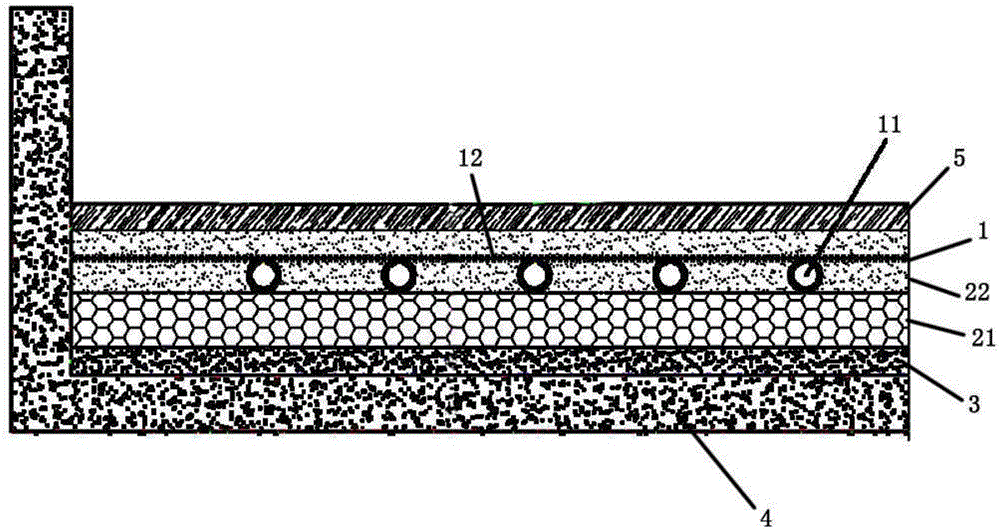

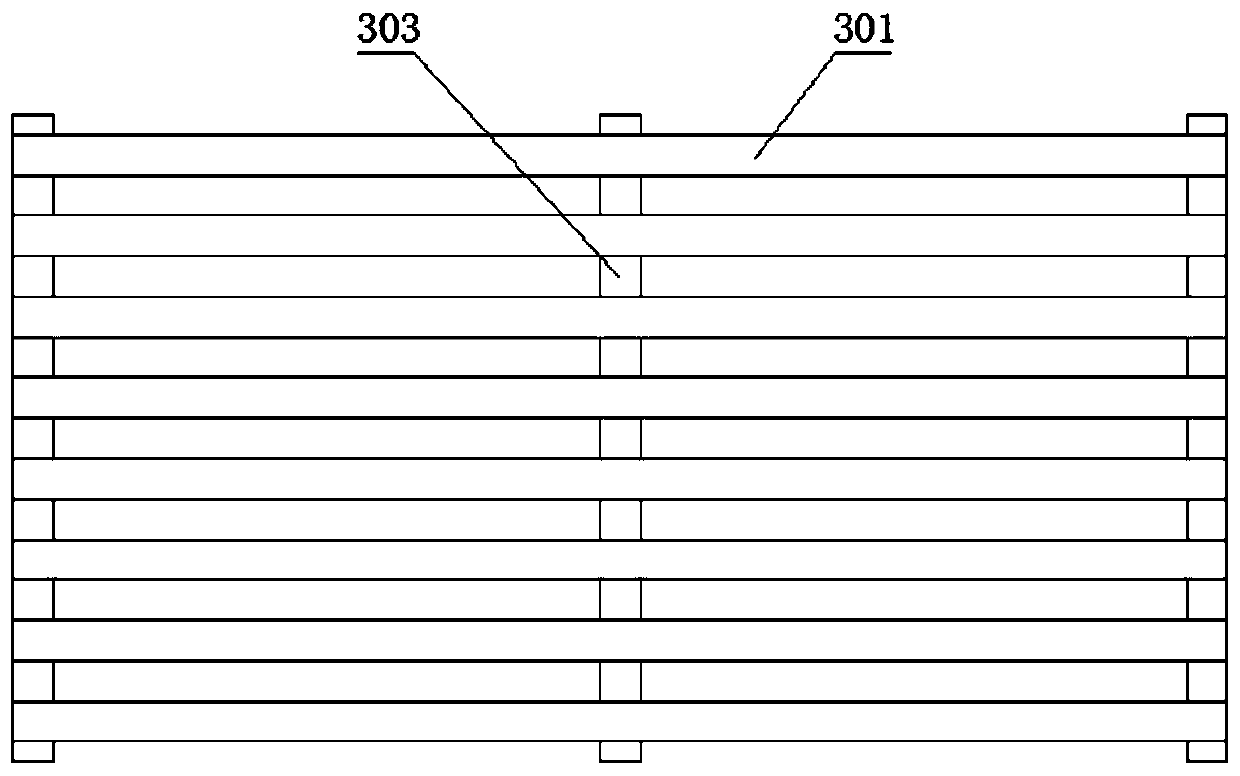

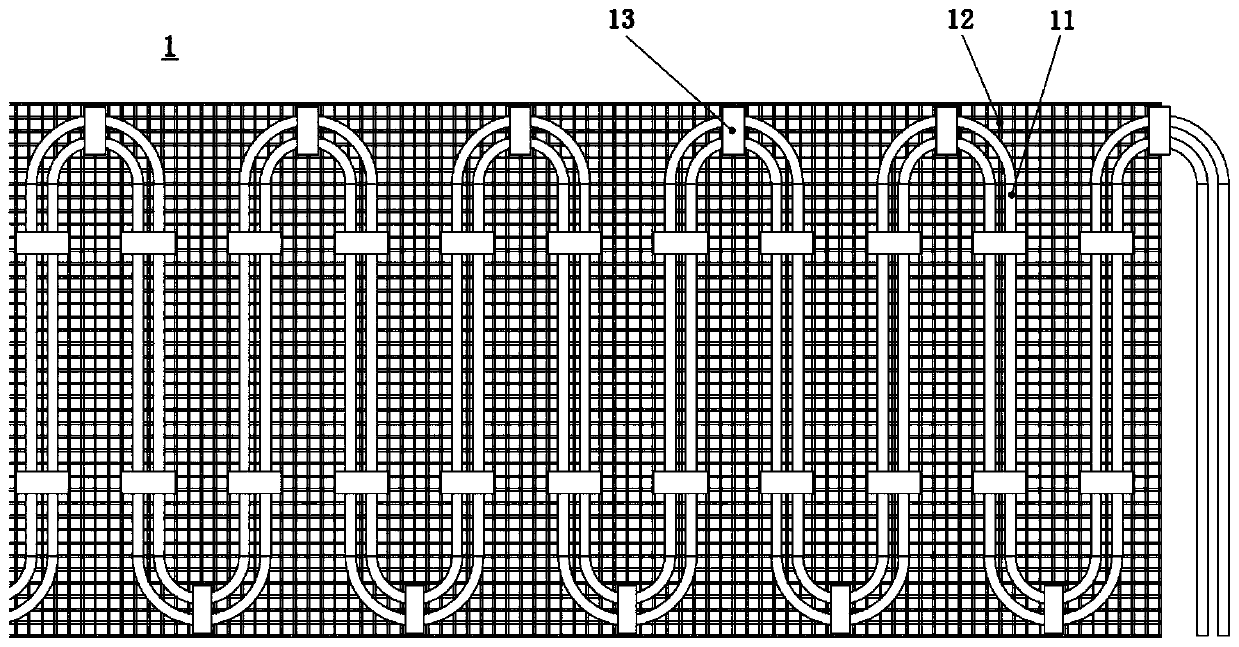

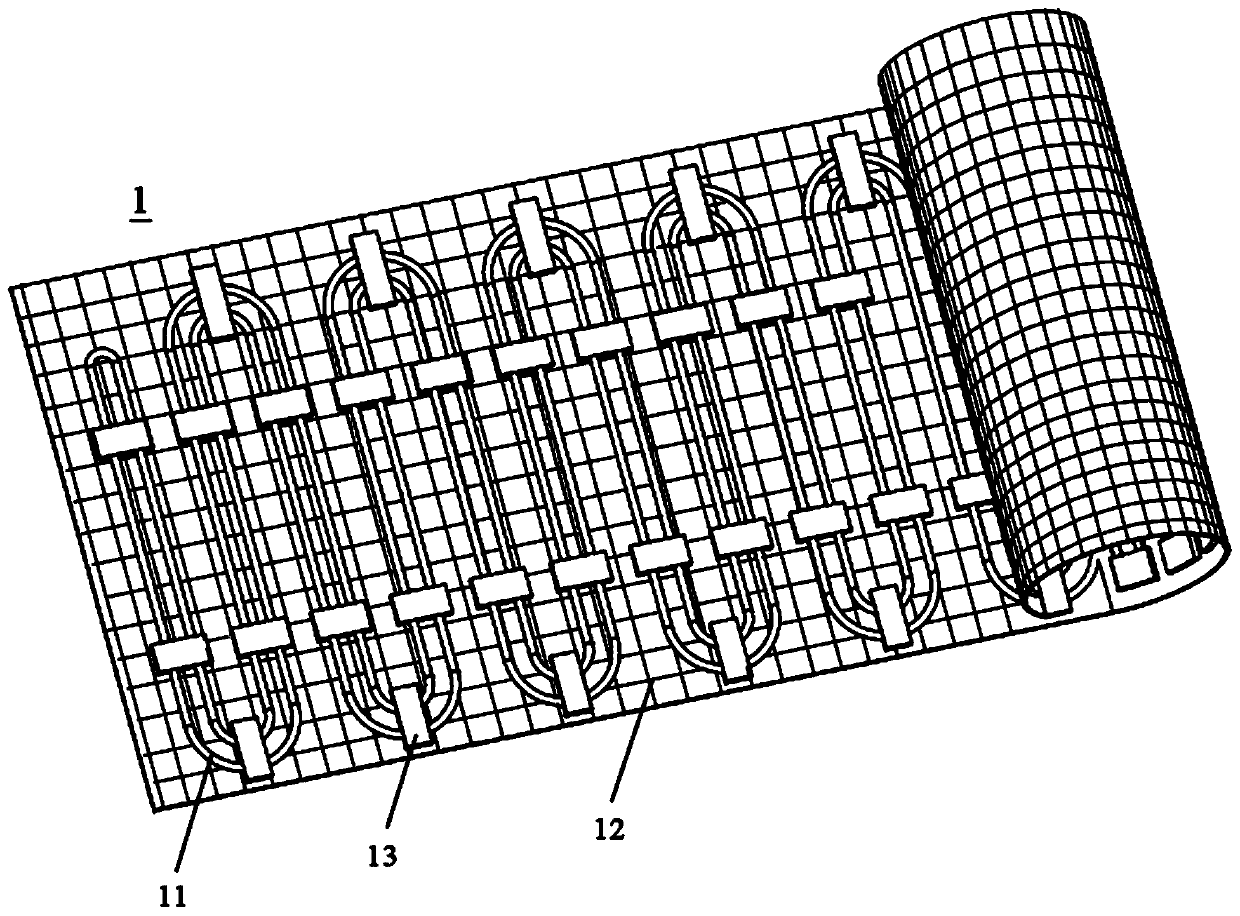

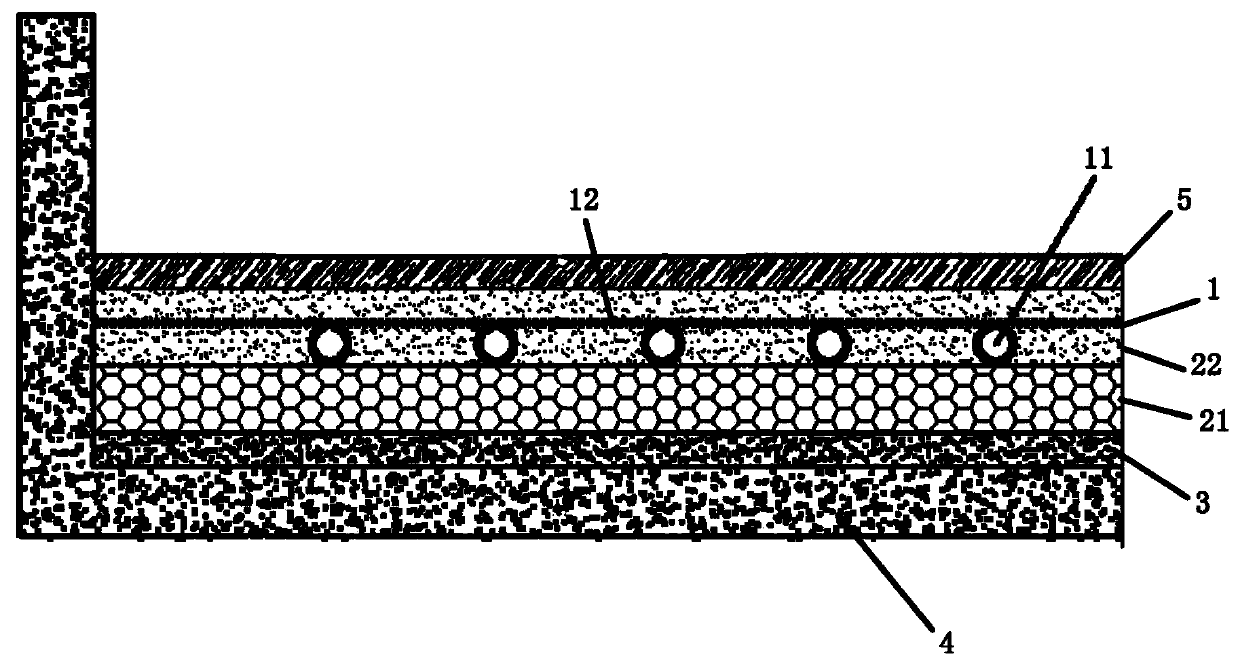

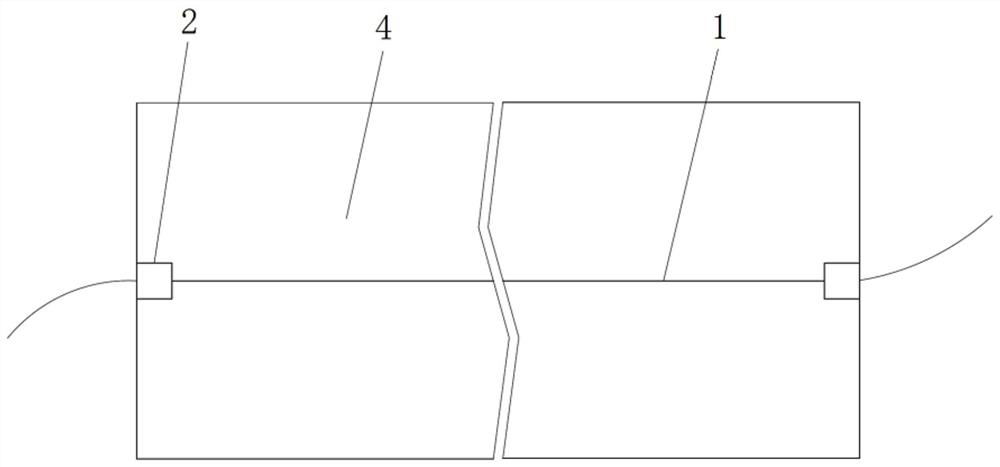

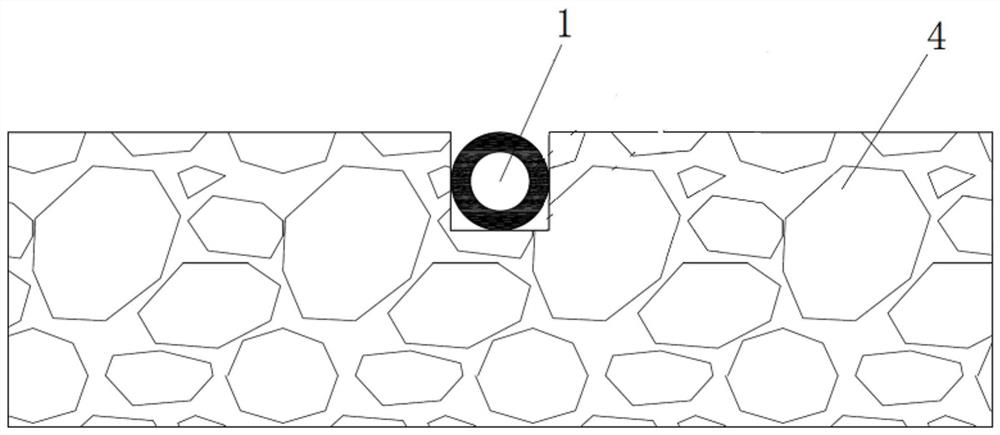

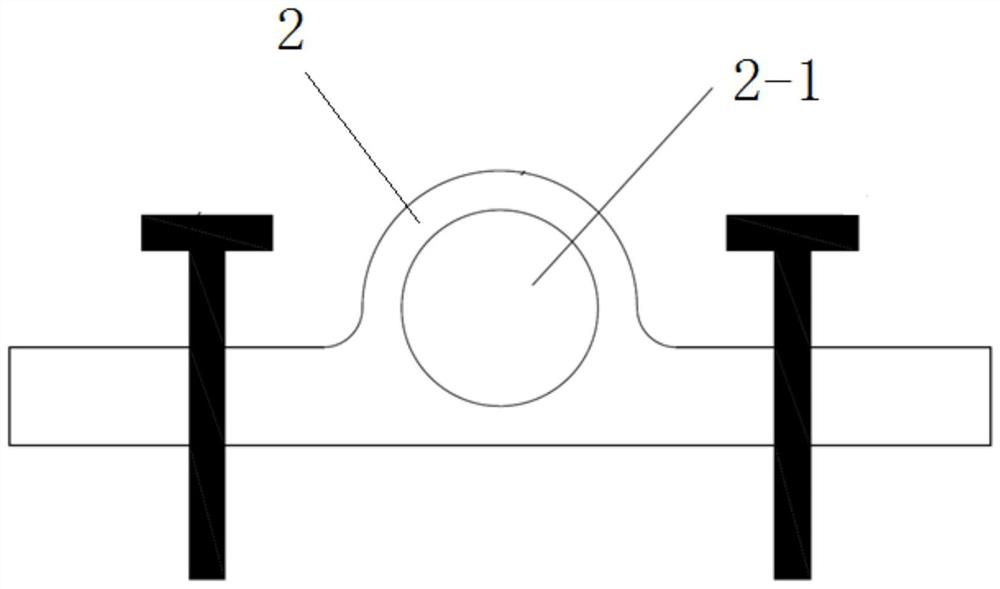

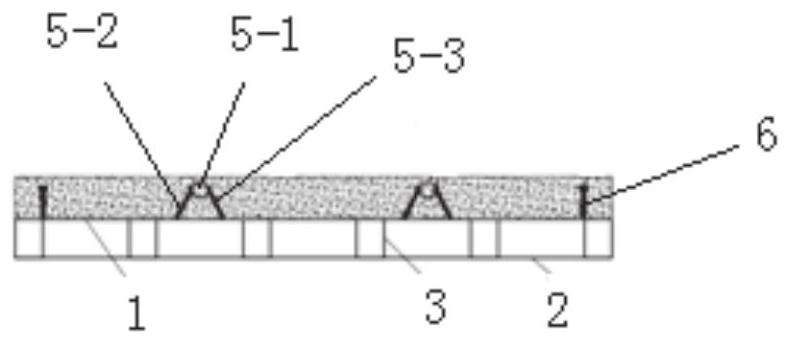

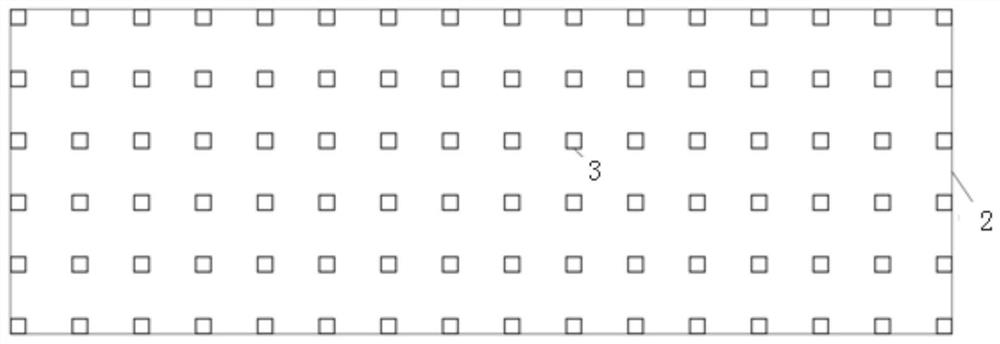

Grid cloth floor heating pipe and grid cloth quick-release floor heating as well as mounting method of grid cloth quick-release floor heating

ActiveCN106193522AReduce installation thicknessAdapt to laying needsCovering/liningsLighting and heating apparatusService efficiencyPrefabrication

A grid cloth floor heating pipe comprises grid cloth, floor heating pipe bodies and fixing clips, wherein the floor heating pipe bodies are laid on the grid cloth in a zigzag manner; the fixing clips are mounted in the extending direction of the floor heating pipe bodies at intervals; the floor heating pipe bodies are fixed on the grid cloth; the grid cloth floor heating pipe is laid in a floor heating. The invention further discloses a grid cloth quick-release floor heating and a mounting method thereof. Therefore, factory prefabrication modularization of floor heating materials is realized to facilitate transportation and mounting, the mounting efficiency of the floor heating is improved obviously, and the service efficiency and life of the floor heating are further improved and prolonged.

Owner:明德倍适(天津)科技有限公司

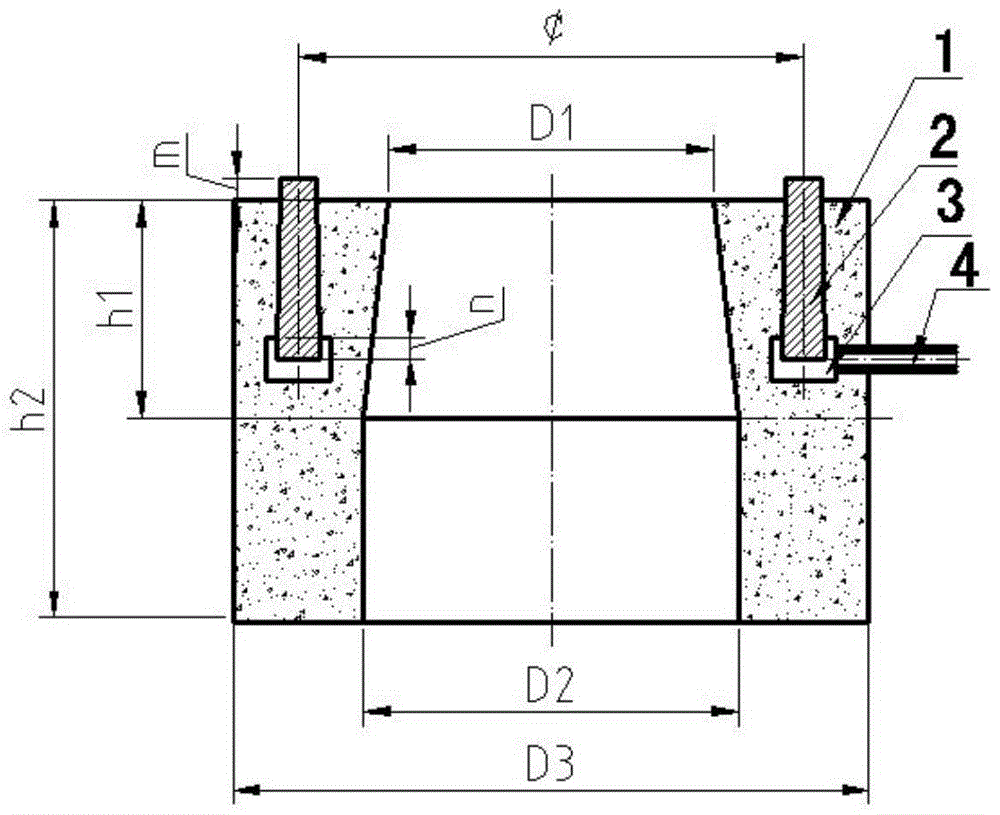

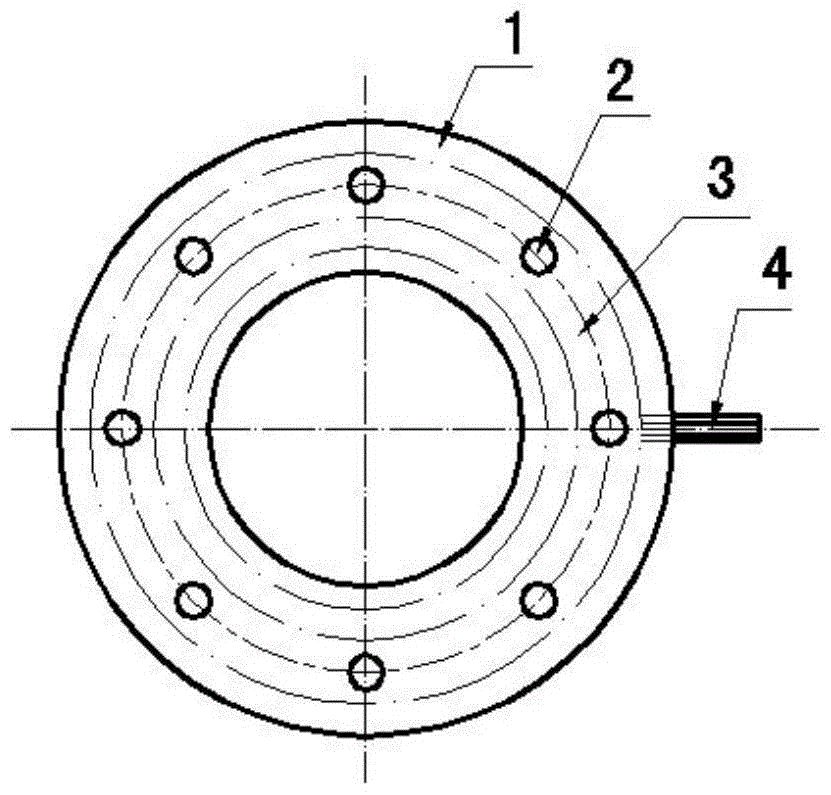

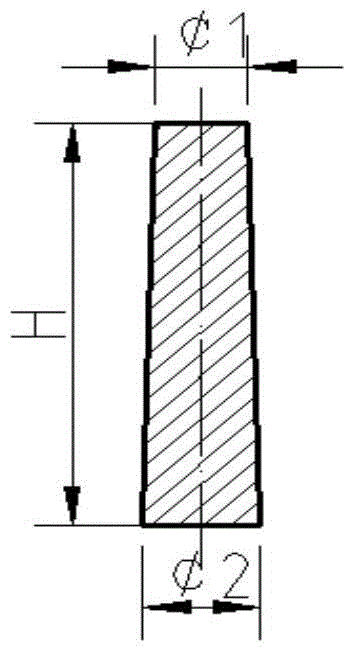

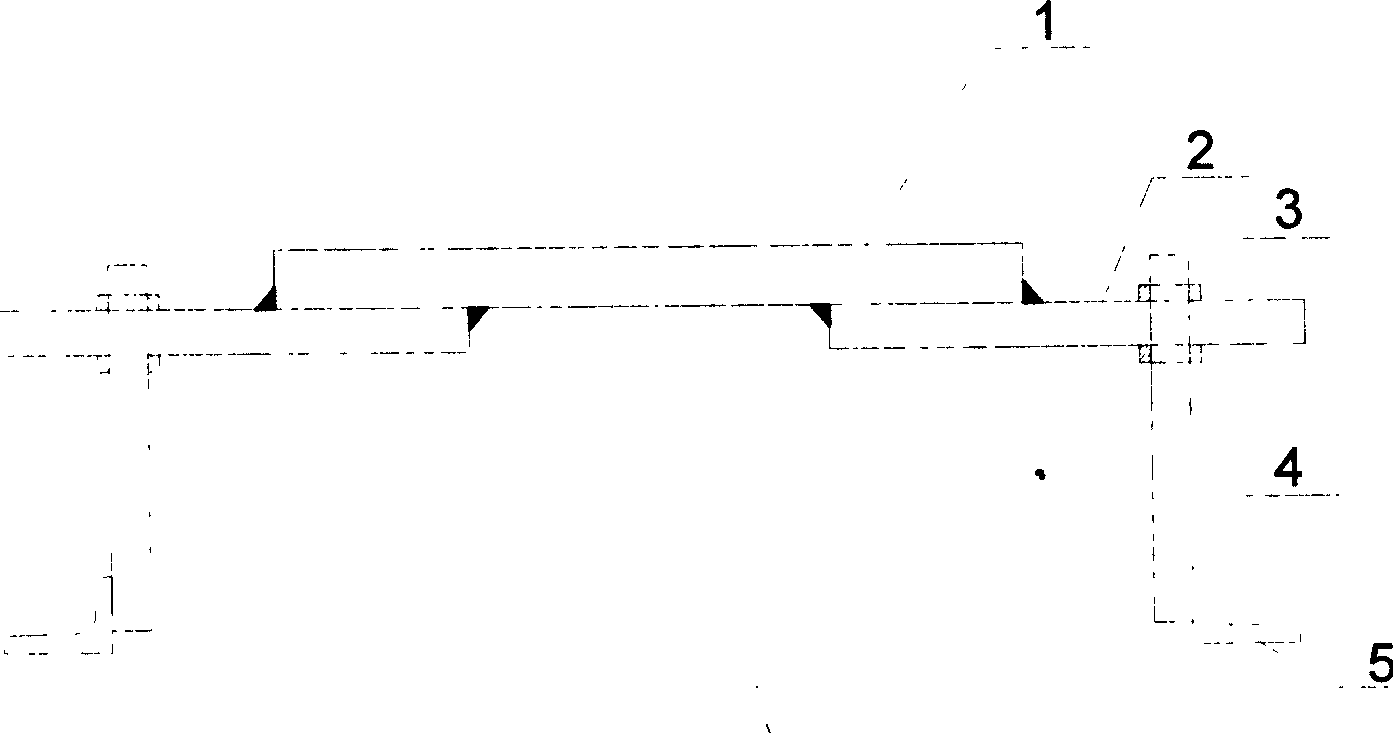

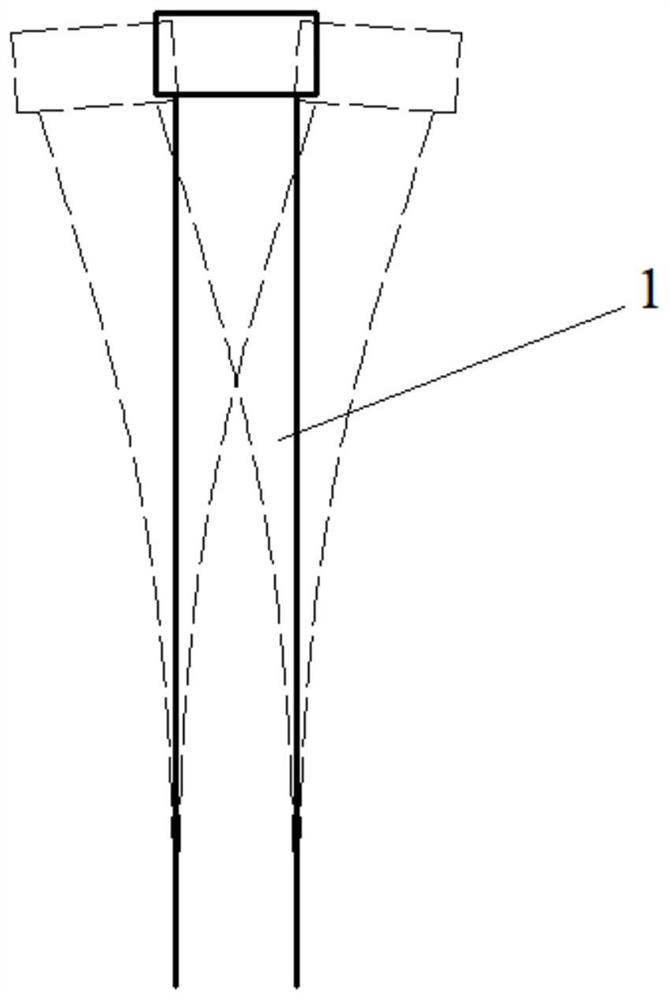

A continuous casting tundish argon-blowing upper nozzle seat brick and its installation method and application

ActiveCN104028740BControl and solve the problem of eddy current slag entrainmentImprove cleanlinessMelt-holding vesselsBrickSlag

Owner:LAIWU IRON & STEEL GRP

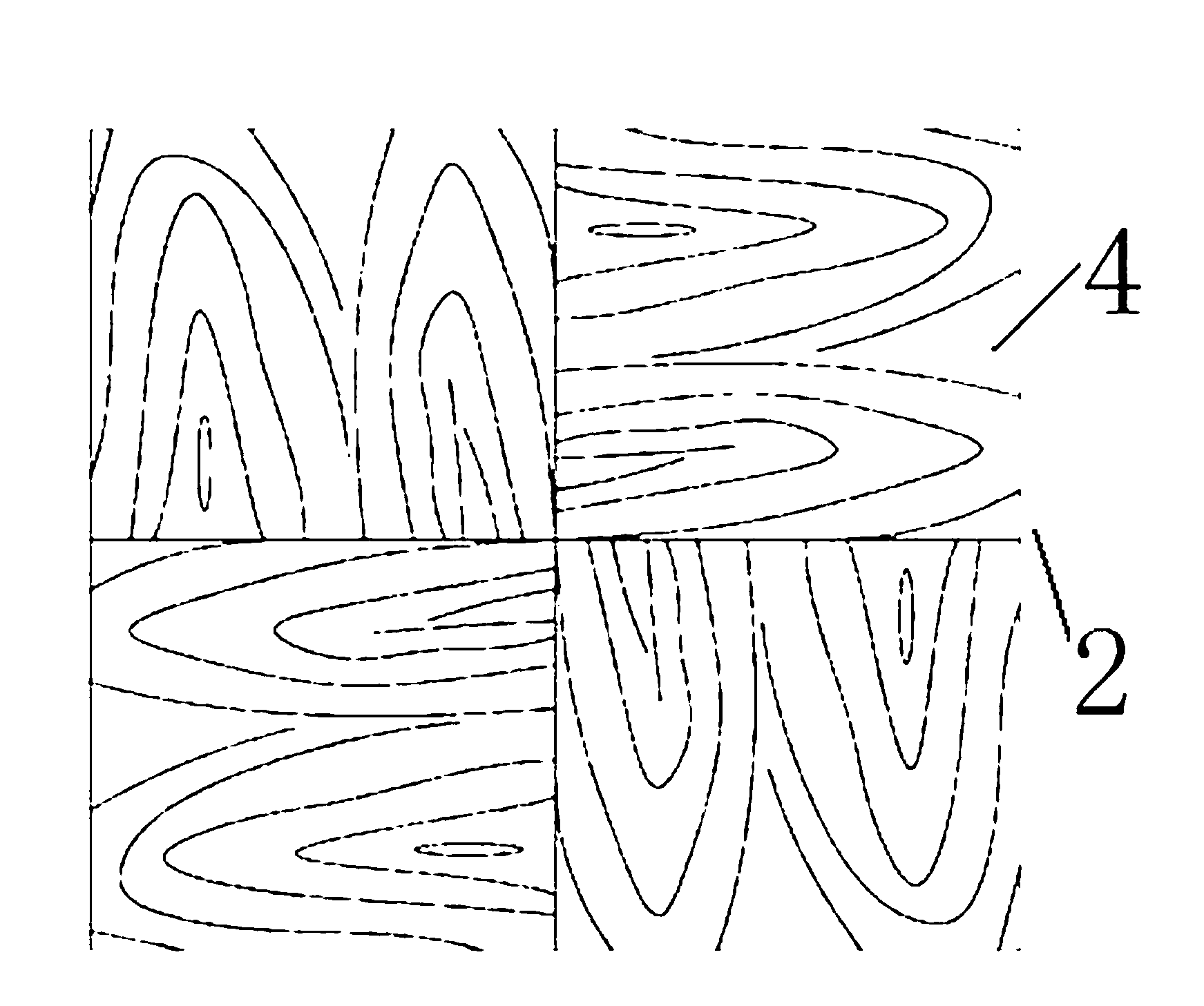

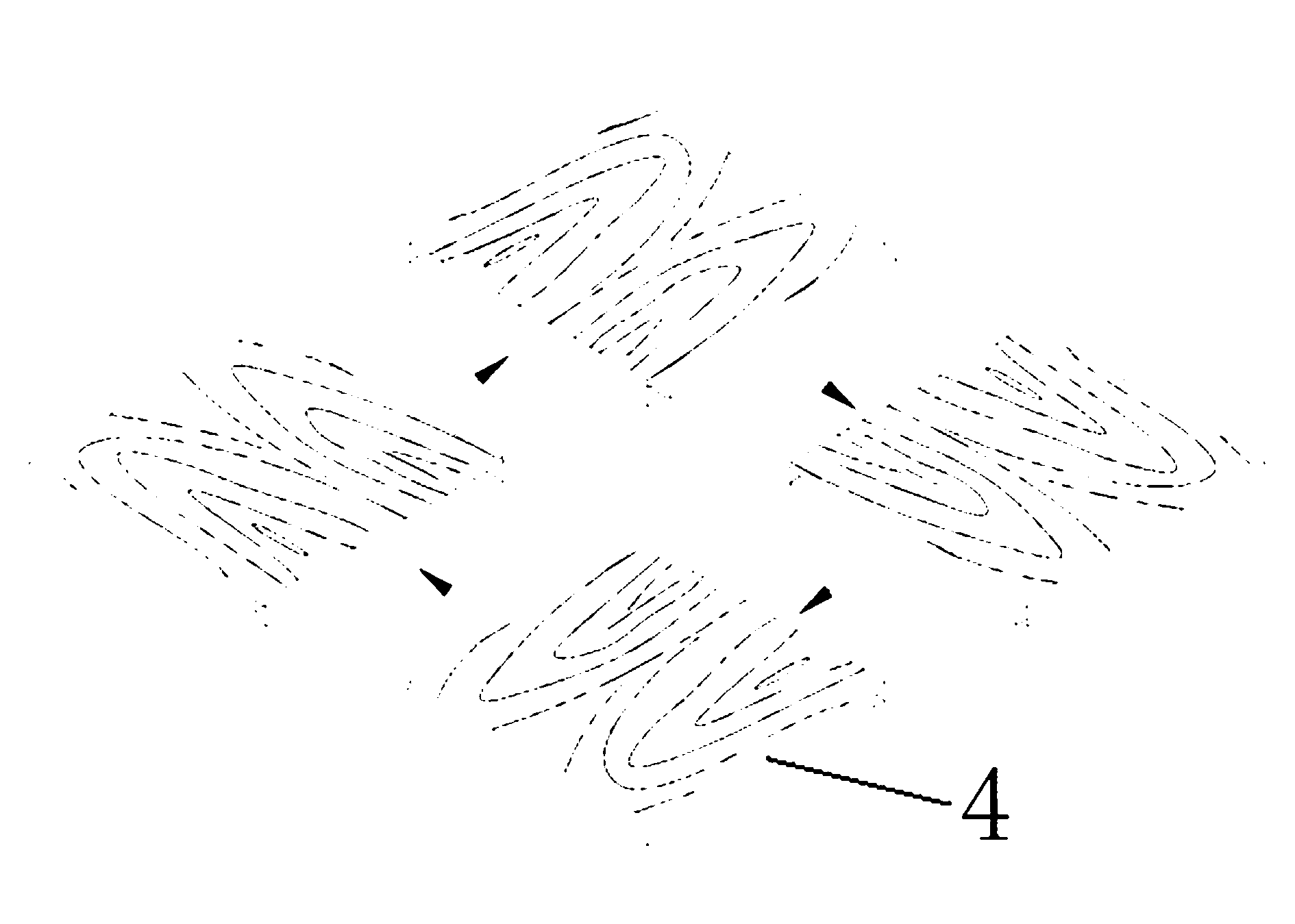

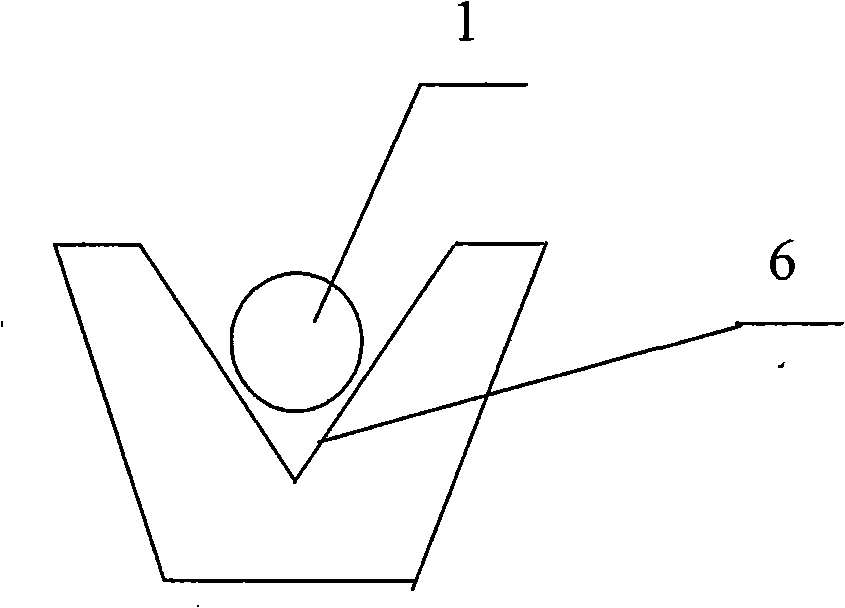

Insulated rail with nano-ceramic coating

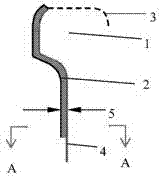

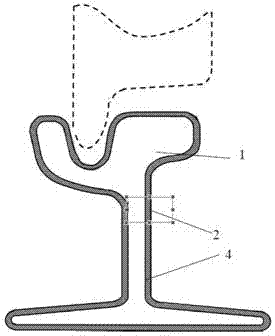

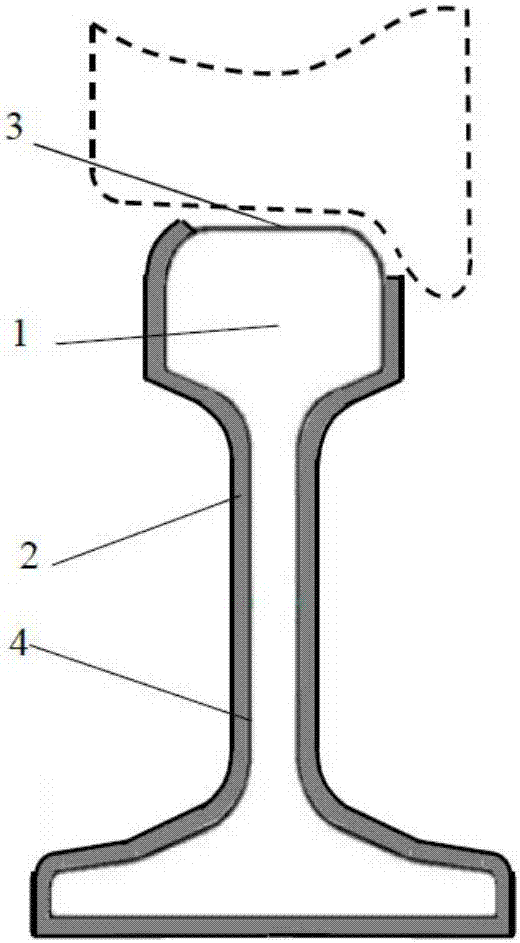

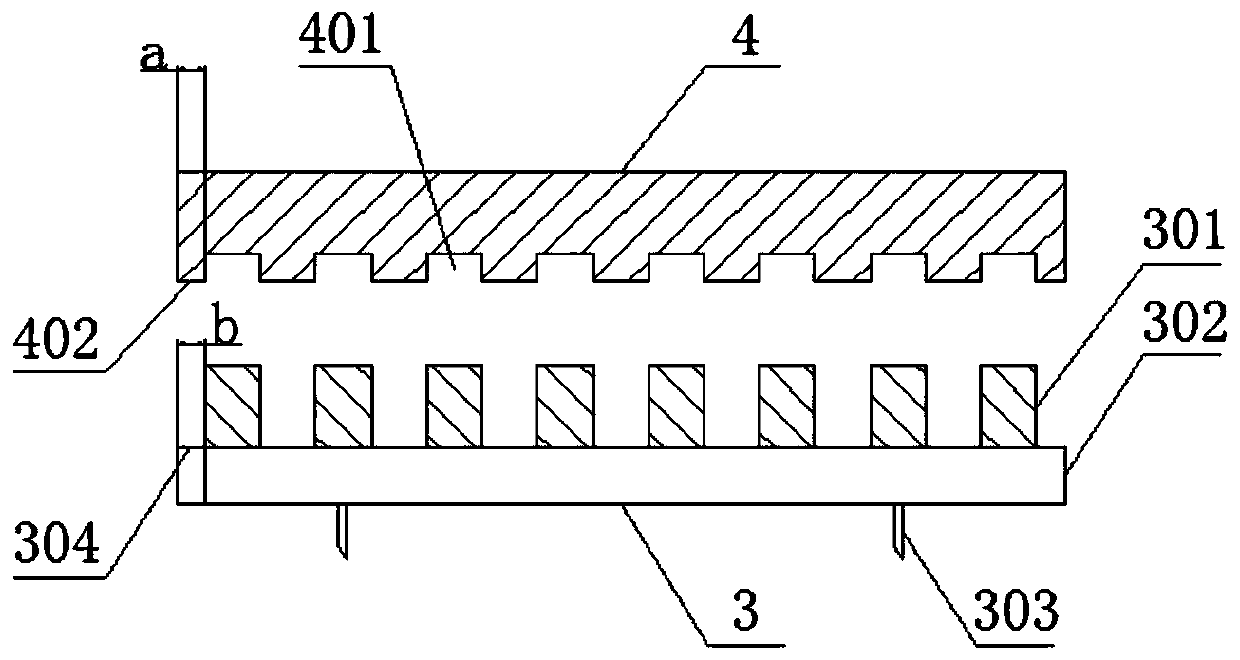

InactiveCN106939534AEliminate stray currentSimplify track laying processRailsInsulation resistanceNanometre

The invention relates to an insulated rail with a nano-ceramic coating. The surface of a rail (1) comprises a rail top surface (3) and rest rail outer surfaces (4), wherein the rail top surface (3) refers to the surface in contact with the rolling of wheels and the nearby upper surface part; the rest rail outer surfaces (4) comprise the upper, lower and side surfaces of a rail foot, the two side surfaces of a rail web and the upper, lower and side surface of a rail head along the longitudinal direction of the rail; a nano-ceramic insulated coating (2) is evenly coated on the rest rail outer surfaces (4); and the materials of the nano-ceramic insulated coating (2) comprise an adhesive material, a reinforcing material and an active hardener. Compared with the prior art, the insulated rail with the nano-ceramic coating has the functions of high insulation resistance, corrosion resistance, water resistance, aging resistance, friction resistance, damp and heat resistance, atmospheric aging resistance and strong adhesion; in addition, the insulated rail with the nano-ceramic coating has the advantages of fundamentally eliminating the occurrence of stray currents of a rail system and avoiding the electrochemical corrosion, and the cost is low.

Owner:SHANGHAI UNIV OF ENG SCI

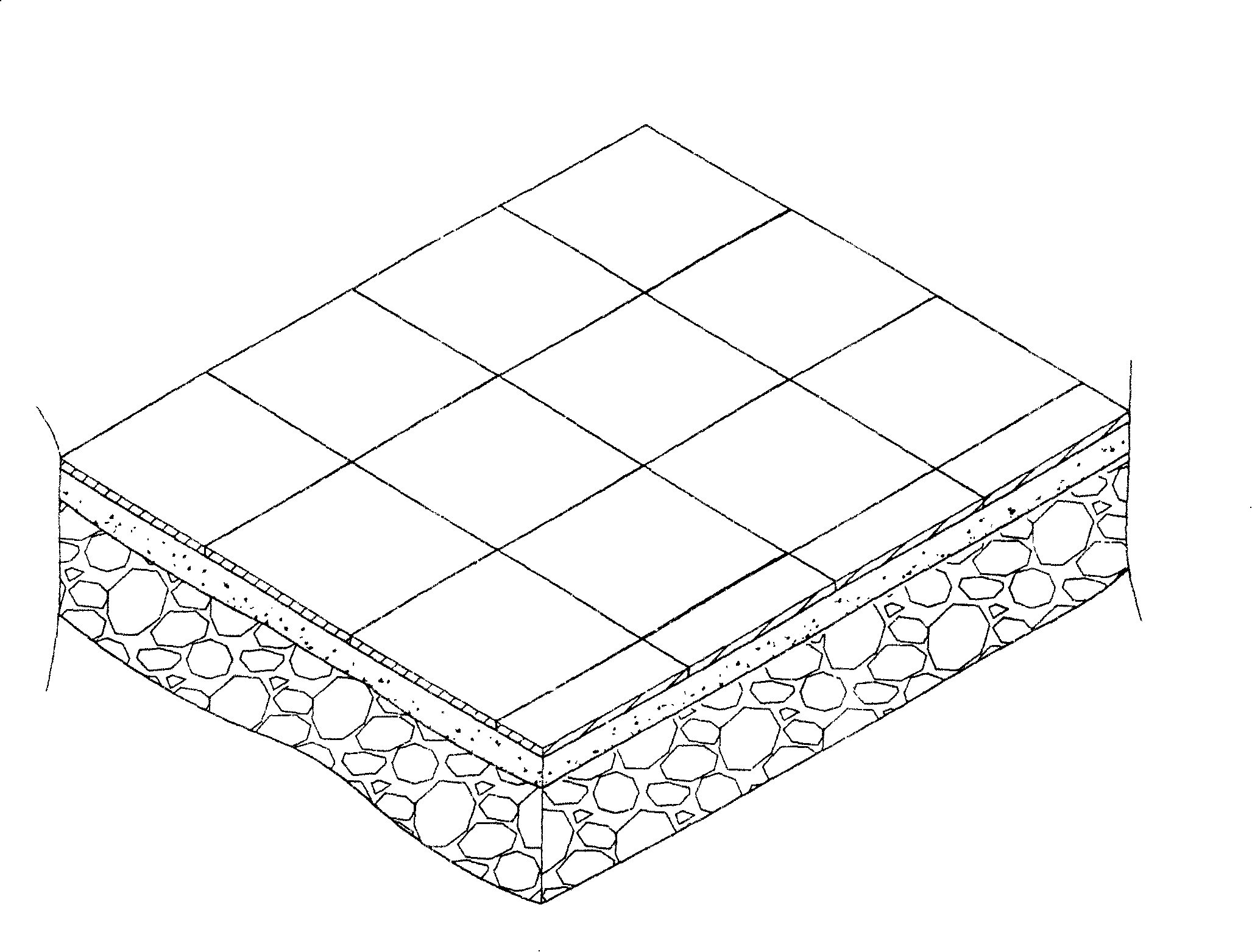

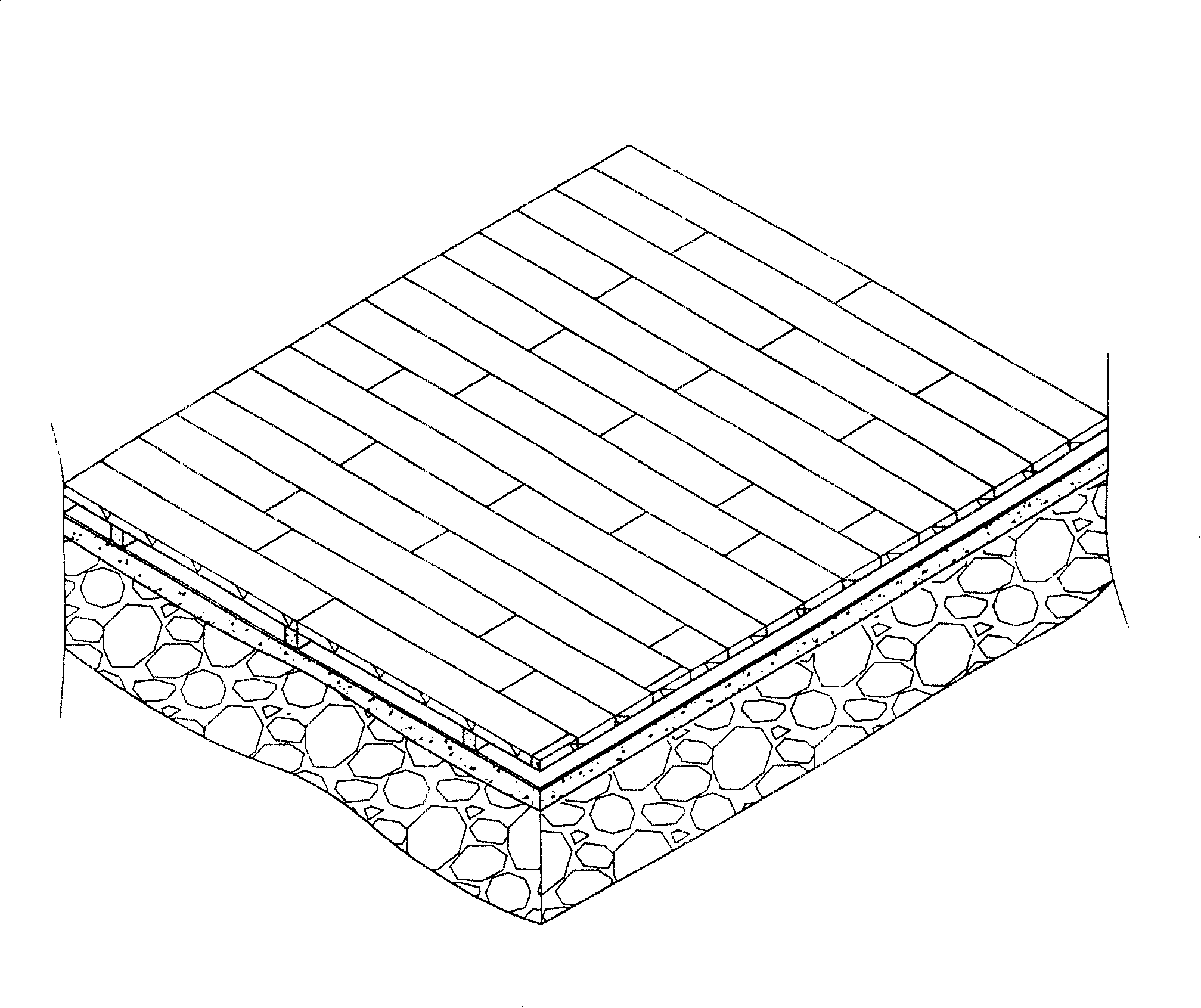

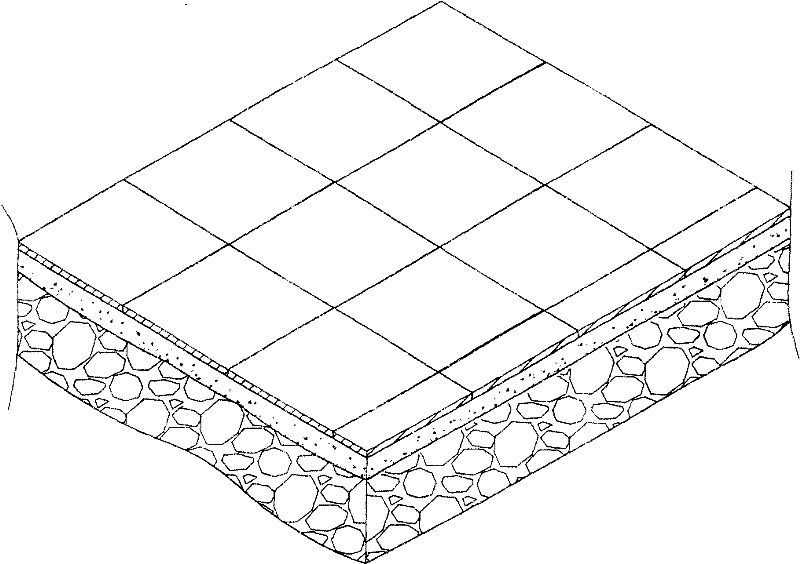

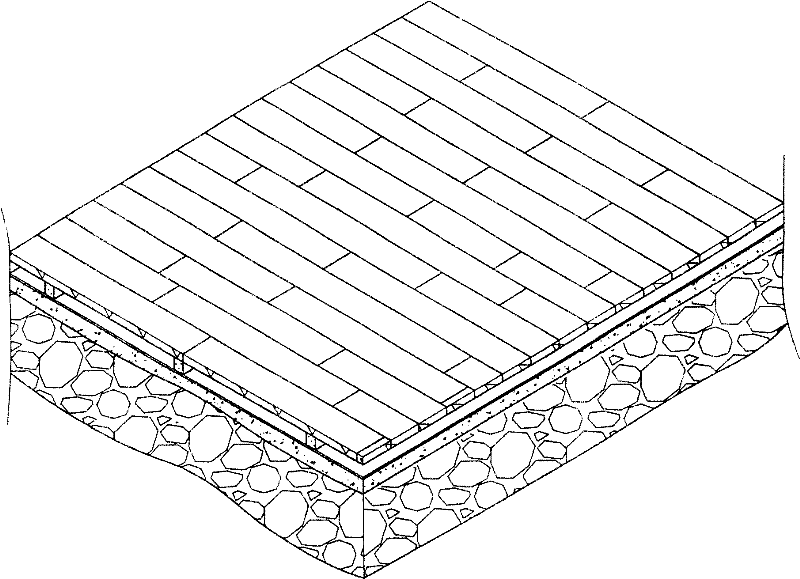

Sidewalk floor tile composite structure and laying construction method thereof

InactiveCN110820458ASimplify the laying processSmall support surfaceSingle unit pavingsPaving gutters/kerbsComposite structureStructural engineering

The invention discloses a sidewalk floor tile composite structure, and belongs to the technical field of municipal facilities. The sidewalk floor tile composite structure comprises a framework and a tile body, wherein the framework comprises an upper supporting part and a lower supporting part, the lower supporting part is of a plurality of long-strip-shaped structures, and the plurality of long-strip-shaped structures are neatly arranged side by side at equal intervals; the upper supporting part is of the plurality of long-strip-shaped structures, the plurality of long-strip-shaped structuresare neatly arranged on the upper surface of the lower supporting part side by side at equal intervals and are intersected with the lower supporting part in a perpendicular mode, and the upper supporting part is fixedly connected with the lower supporting part; and the lower surface of the tile body is provided with strip-shaped grooves, and the strip-shaped grooves are in one-to-one correspondence with the long-strip-shaped structures of the upper supporting part. According to the technical scheme, a space under the tile body is supported through the framework structure, a continuous space isformed below the tile body, only a rubble layer is laid down under the space, and a soil layer is arranged below the rubble layer, so that the infiltration of accumulated water is facilitated, wateris not prone to accumulate inside the space, a road surface can be kept free from water accumulation under most conditions, and development planning and requirements of the nation of " construction ofthe sponge city "are conformed.

Owner:贵州筑信达创科技有限公司

Method for preventing hydraulic bracket in large inclined angle workface from collapsing

InactiveCN102322280APrevent dumpingImprove the state of supportMine roof supportsAnchoring boltsEngineeringCoal

A method for preventing a hydraulic bracket in a large inclined angle working face from collapsing comprises the steps of obliquely driving an anchor rod in the middle of each hydraulic bracket in the working face along direction of from the top plate to the coal wall; connecting exposed ends of anchor rods in series by using steel wire ropes and hanging a metal net on the connected steel wire ropes; when the hydraulic brackets move forward, jacking the hung metal net to attach front beams of the hydraulic brackets; with advancing of the mining working face, enabling the hydraulic brackets to move forward, splicing and lengthening the metal net till the metal net is paved on the whole hydraulic bracket or stopping splicing the metal net after the top plate is stable and does not collapse. The method has the advantages of simple operation, safety, reliability and high efficiency, and effectively prevents the hydraulic bracket in the large inclined angle working face from collapsing under a condition that the top plate is crushed.

Owner:CHINA UNIV OF MINING & TECH

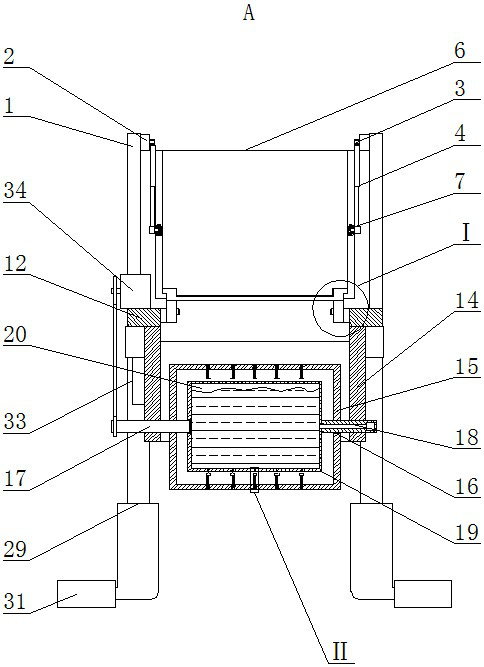

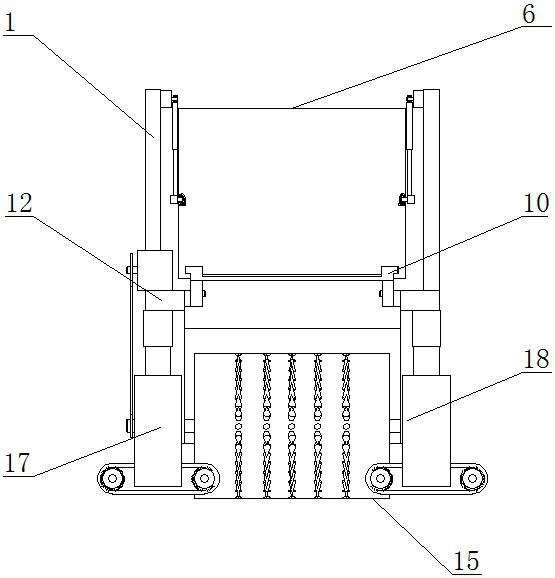

Greening turf laying device for landscaping construction

ActiveCN114271148AReduce labor intensityHigh degree of automationHops/wine cultivationTurf growingMaterials preparationArchitectural engineering

The invention relates to the technical field of garden construction equipment, in particular to a greening turf laying device for garden greening construction, which comprises two cross beams, the two cross beams are horizontally arranged in parallel, and the two end parts of the upper side surfaces of the cross beams are provided with material preparation mechanisms for automatically loading and unloading external box bodies for storing turf; turf discharging devices coupled with the turf preparation mechanism are installed in the middles of the opposite inner side faces of the two cross beams, vertical plates fixedly connected with the cross beams are arranged on the lower side faces of the middles of the cross beams in the length direction of the cross beams, and a turf laying mechanism is arranged between the opposite inner side faces of the two vertical plates and located below the turf discharging devices. The turf laying mechanism can bear and fix turf thrown by the turf discharging device when working, and laying of the turf is automatically completed when the hollow roller rotates. According to the automatic turf laying device, automatic turf laying is achieved in the turf laying process, the labor intensity of workers is greatly reduced, the laying efficiency is improved, and the automatic turf laying device is quite suitable for turf laying during large-area landscaping construction.

Owner:赵梅

Bearing plate screw adjusting method construction process

InactiveCN100473789CFast constructionSimple laying processFoundation engineeringSpecial foundation layoutGroutBuilding construction

Owner:MCC BAOSTEEL TECH SERVICE

Mesh cloth floor heating pipe, mesh cloth quick-installation floor heating and installation method thereof

ActiveCN106193522BReduce installation thicknessAdapt to laying needsCovering/liningsLighting and heating apparatusService efficiencyPrefabrication

A grid cloth floor heating pipe comprises grid cloth, floor heating pipe bodies and fixing clips, wherein the floor heating pipe bodies are laid on the grid cloth in a zigzag manner; the fixing clips are mounted in the extending direction of the floor heating pipe bodies at intervals; the floor heating pipe bodies are fixed on the grid cloth; the grid cloth floor heating pipe is laid in a floor heating. The invention further discloses a grid cloth quick-release floor heating and a mounting method thereof. Therefore, factory prefabrication modularization of floor heating materials is realized to facilitate transportation and mounting, the mounting efficiency of the floor heating is improved obviously, and the service efficiency and life of the floor heating are further improved and prolonged.

Owner:明德倍适(天津)科技有限公司

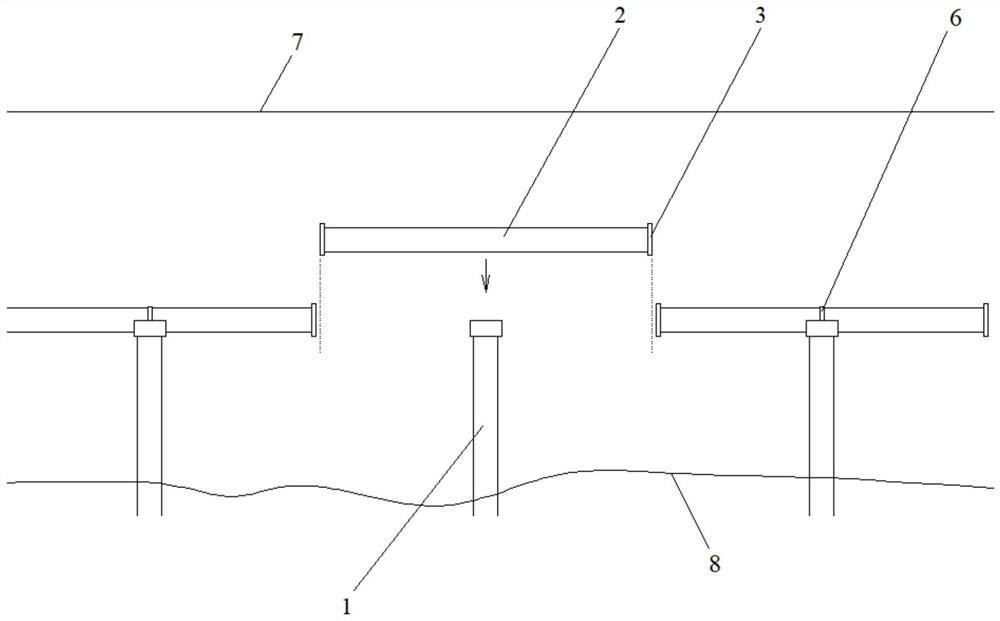

Arrangement method of a distributed optical fiber sensor

ActiveCN110424229BSlow down the pace of on-site deploymentImprove layout effectMeasurement apparatus componentsRoads maintainenceRoad surfaceMechanical engineering

Owner:HARBIN INST OF TECH

Preparation method of composite material shell for embedded cable

ActiveCN107676814BSimple laying processReduce negative qualityContinuous combustion chamberFiberElectric cables

Owner:湖北三江航天江北机械工程有限公司

Ground surface finishing method

The invention discloses a method for floor decoration, which includes the following steps: mixing self-leveling mortar with water by the ratio of 5:1, churning up the mixture, applying the mixture evenly on the ground to form a bottom layer, coating the bottom layer with a shaping layer, and finally mixing solvent-free epoxy resin with curing agent according to the weight percentage of 2:1 and spreading the mixture on the shaping layer with a trowel to form a wear-resistant and transparent surface layer. The method of decoration has the advantages of safety, environment-friendliness, no seam,various shapes, easy revamping and rapid construction.

Owner:厦门哈德新型建材有限公司

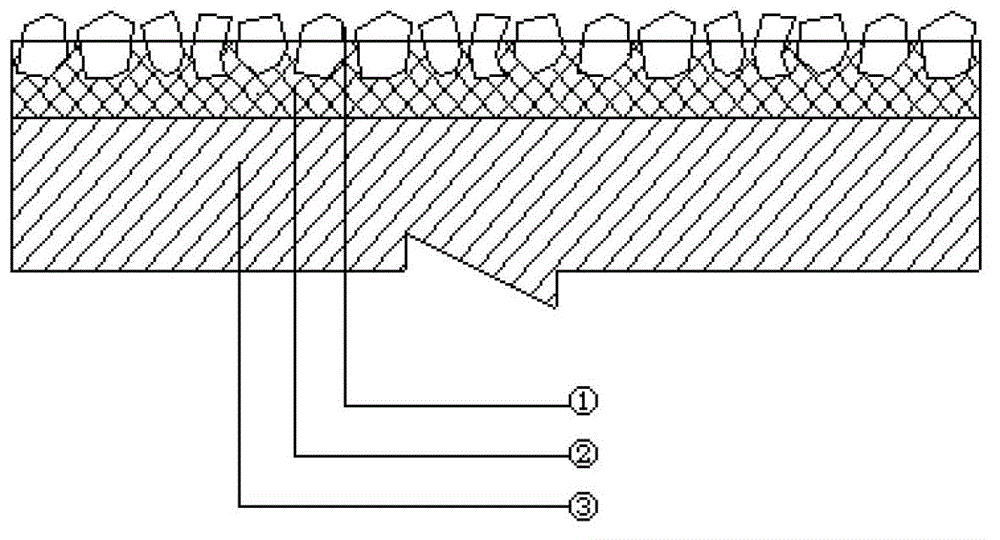

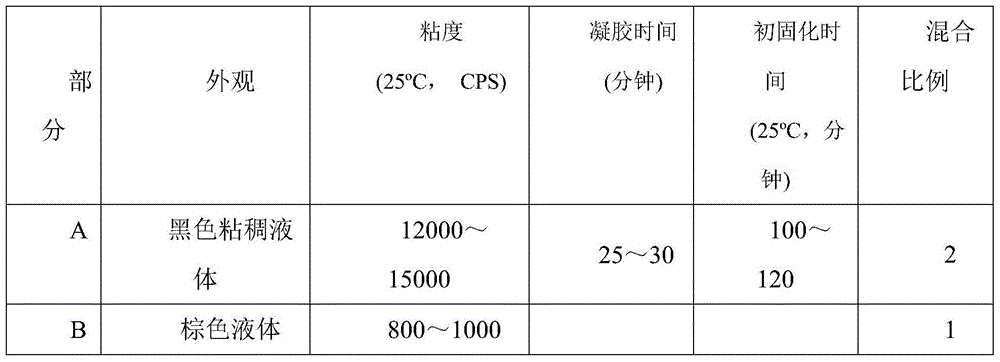

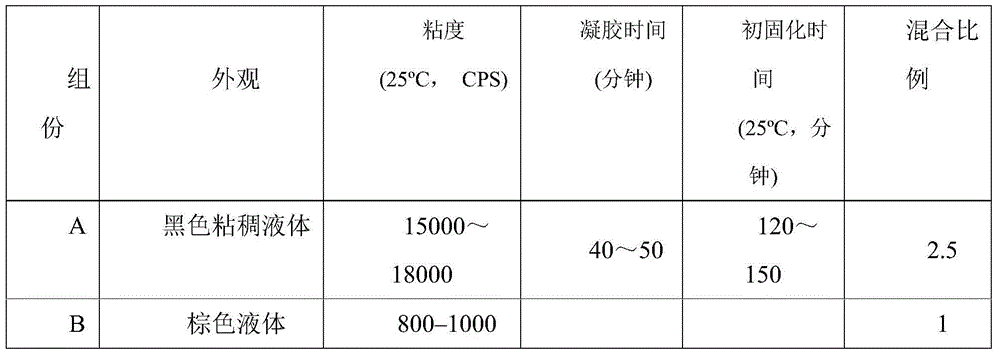

Cold-coating asphalt, and preparation method and construction method thereof

ActiveCN102816446BSimple laying processLaying speed is fastIn situ pavingsPaving detailsWear resistantRoad surface

Disclosed are a cold-coating asphalt paved on an anti-skid wear-resistant road surface, and a preparation method and use thereof. The cold-coating asphalt comprises a part A and a part B. The part A is prepared from the following components in parts by weight: 10-30 parts of asphalt, 10-30 parts of active modifier and 10-60 parts of reactive resin; the part B is a curing agent; and the weight ratio of the part A to the part B is (1-5):1. According to the cold-coating asphalt, the petroleum asphalt, the reactive resin and the active modifier are used as the part A and the part A is prepared into a homogeneous-phase liquid mixture; and the curing agent is proportionally added into the part A to prepare the cold-coating asphalt which does not need hot stirring in construction. The cold-coating asphalt can be used as a new material in place of the conventional hot-stirring asphalt for repairing and reconstructing road surfaces and paving high-strength thin functional road surfaces, such as high-anti-skid road surfaces, wear-resistant anti-greasy-dirt road surfaces, draining road surfaces and the like.

Owner:GUANGZHOU THE BOND CHEM

Conjoined Chinese-style tile

InactiveCN103352542AReduce use costSimple laying processRoof covering using tiles/slatesLap jointManufacturing engineering

The invention discloses a conjoined Chinese-style tile which comprises at least two tile pieces which are in lap joint through a base-tile and cover-tile mode, and the Chinese-style tile is of an integrally formed structure through a mold. According to the paving effect of the conjoined Chinese-style tile, the integral conjoined structure is formed by connecting the base tile and the cover tile, and therefore multiple Chinese-style tiles made of earth can be replaced by one conjoined Chinese-style tile. Using cost is reduced, the paving technology is simplified, hanging is simple and convenient, effective covering area is large, and the waterproof performance and the wind-resistant performance are better.

Owner:ZHEJIANG HENGDIAN CONSTR ENG CO LTD

Pre-tension seabed vacuum pipeline structure and stretching method thereof

ActiveCN112878373AHas elastic strengthReduce vibrationArtificial islandsUnderwater structuresAbutmentUltimate tensile strength

The invention discloses a pre-tension seabed vacuum pipeline structure and a stretching method thereof. The rigidity of a seabed vacuum pipeline can be improved, drooping of the middle of a suspended span pipeline is minimized, and driving stability and safety are guaranteed. The structure comprises the seabed vacuum pipeline and a plurality of abutments; the seabed vacuum pipeline is fixedly supported on the tops of the abutments; the abutments have elastic strength; the seabed vacuum pipeline comprises a plurality of vacuum pipeline sections which are sequentially arranged; the vacuum pipeline sections have tensile strength; flanges are arranged at the opposite ends of every two adjacent vacuum pipeline sections; gaps are formed between the flanges of every two adjacent vacuum pipeline sections at intervals; and the flanges of every two adjacent vacuum pipeline sections are connected through a tensioning mechanism. The stretching method comprises the steps that the plurality of vacuum pipeline sections are locally grouped and then stretched through a sequencing stretching method, each vacuum pipeline section is stretched step by step through a step-by-step stretching method, and the gaps between the flanges of every two adjacent vacuum pipeline sections are stretched and closed step by step.

Owner:XIJING UNIV

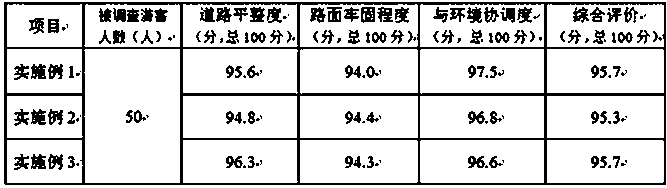

A laying method of an electric car lane

The invention provides a laying method of an electric car lane, which comprises the following steps: (1) scraping the floating soil piled on the shallow surface of the ground along the left and rightsides of the terrain, controlling the width to be 3.0-6.0 m, scraping the floating soil, spraying water and rolling to form a route; (2) laying sand stone with the thickness of 15-20 cm on the route,scraping, sprinkling water and rolling, and spreading the sand stone deposited on both sides along the terrain to form a roadbed; (3) laying a layer of rice stone with a diameter less than 5 mm on theroadbed, and sprinkling water and rolling to form a pavement after the laying is completed. The invention adopts the rice grained stone with the diameter less than 5mm as the pavement paving material, has good evenness, strong porcelain, can resist the erosion of the 30mm heavy rainstorm, and has high coordination degree with the site body and the surrounding environment, and has broad popularization prospect; The roadbed is paved with sandstone which is made of stone with the diameter of 10-50 mm, fine sand and clay. The roadbed has excellent robustness and durability.

Owner:瓜州县文物局

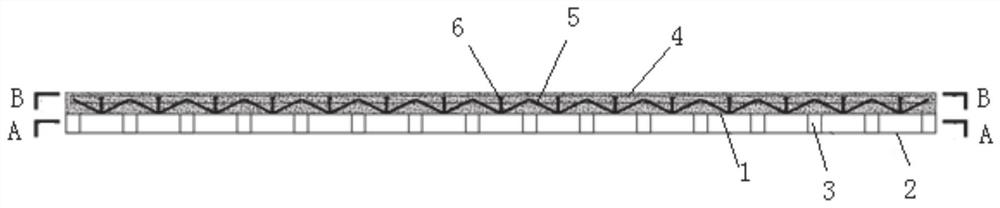

A combined floor slab, building and construction method

The invention relates to a combined floor slab, a building and a construction method, comprising an upper steel plate and a lower steel plate, a plurality of columns are fixed between the upper steel plate and the lower steel plate, a concrete slab is poured on the upper surface of the upper steel plate, and a concrete slab is embedded in the concrete slab There are multiple rows of truss structures, and the truss structures are fixed with the upper steel plates. The combined floor slab of the present invention is light in weight and convenient for later installation of pipelines.

Owner:SHANDONG JIANZHU UNIV

Heating layer for megawatt wind turbine blade auxiliary mould and manufacturing method thereof

The invention relates to a heating layer for a megawatt wind turbine blade auxiliary mould and a manufacturing method thereof. The heating layer comprises at least one heating area, wherein each heating area comprises 5-15 nanometer carbon heating films, a temperature-controlled box, a power supply and a plurality of copper nets; each nanometer carbon heating film is provided with a plurality of small holes; each nanometer carbon heating film is paved on an inner structural layer of the blade auxiliary mould; each copper net is paved between adjacent nanometer carbon heating films; electrodes are arranged at two ends of each nanometer carbon heating film; two electrodes are respectively connected to the temperature-controlled box by power lines; a temperature-limiting line and a temperature-sensing line pre-embedded in each nanometer carbon heating film are connected to the temperature-controlled box; the power lines of the nanometer carbon heating films are in parallel connection with the temperature-controlled box; the temperature-controlled box is used for controlling the temperature of the corresponding heating area; the temperature-control box for each heating area is connected to an externally connected power supply; and all power supplies are in parallel connection and then are connected to a main power line. The heating layer for a megawatt wind turbine blade auxiliary mould can be used for ensuring that the blade auxiliaries are uniformly heated in the process of being solidified in the blade auxiliary mould. The heating layer for a megawatt wind turbine blade auxiliary mould can be widely applied to the field of wind power.

Owner:GUODIAN UNITED POWER TECH

Manufacturing process of one-piece Chinese-style tile

The invention discloses a manufacturing process of a one-piece Chinese-style tile. The one-piece Chinese-style tile comprises at least two tiles which are lapped with each other in forms of concave tile and convex tile, and the Chinese-style tile has an integrally molded structure formed by a die. The manufacturing method comprises the following steps: firstly, preparing raw materials, wherein the raw material is formed by mixing cement, washed river sand, additive, reinforced fiber and pigment powder, then, conducting compression moulding, and finally demoulding for curing, and coating encaustic tile paint on the surface of the Chinese-style tile after natural curing is completed. Based on the pavement effect of the Chinese-style tile, the invention adopts a one-piece structure with the concave tile and the convex tile integrated into a whole, so that one piece of Chinese-style tile can replace multiple traditional earthen Chinese-style tiles, the production cost is lowered, and the pavement process is simplified; in addition, the Chinese-style tile is a coating type tile; after natural curing of the tile is completed, the surface of the tile is sprayed with dedicated encarpus tile paint; the whole roof after pavement is uniform in color and rich in expression.

Owner:ZHEJIANG HENGDIAN CONSTR ENG CO LTD

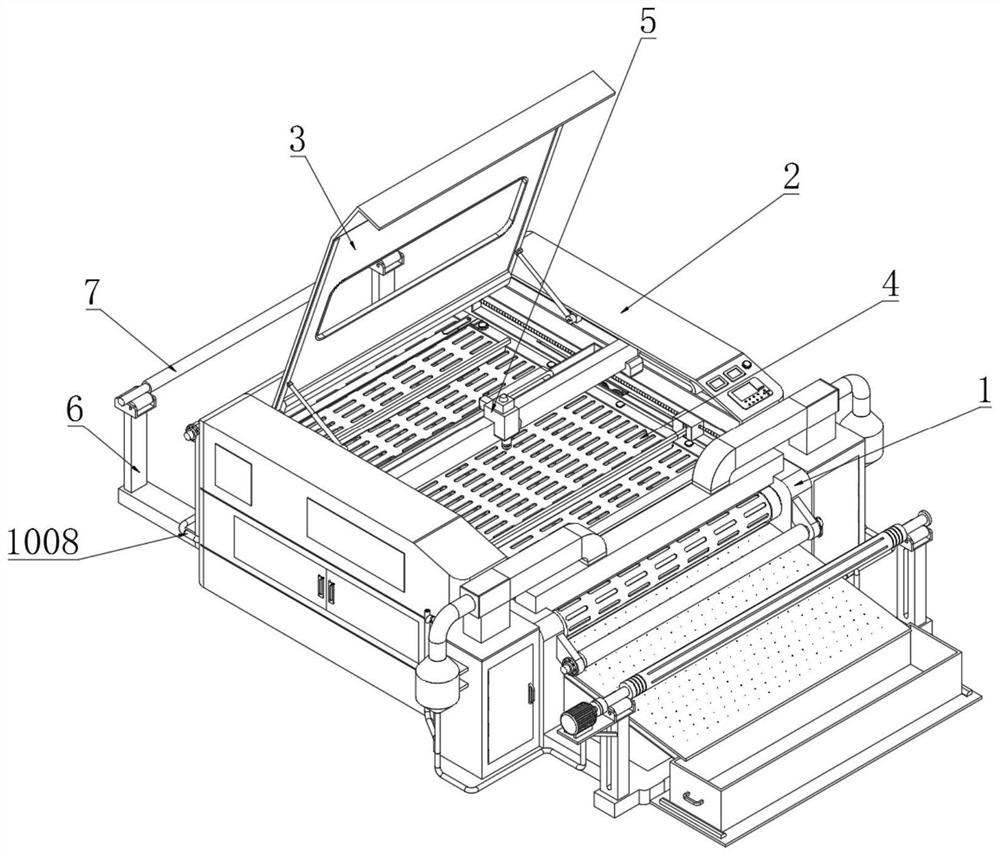

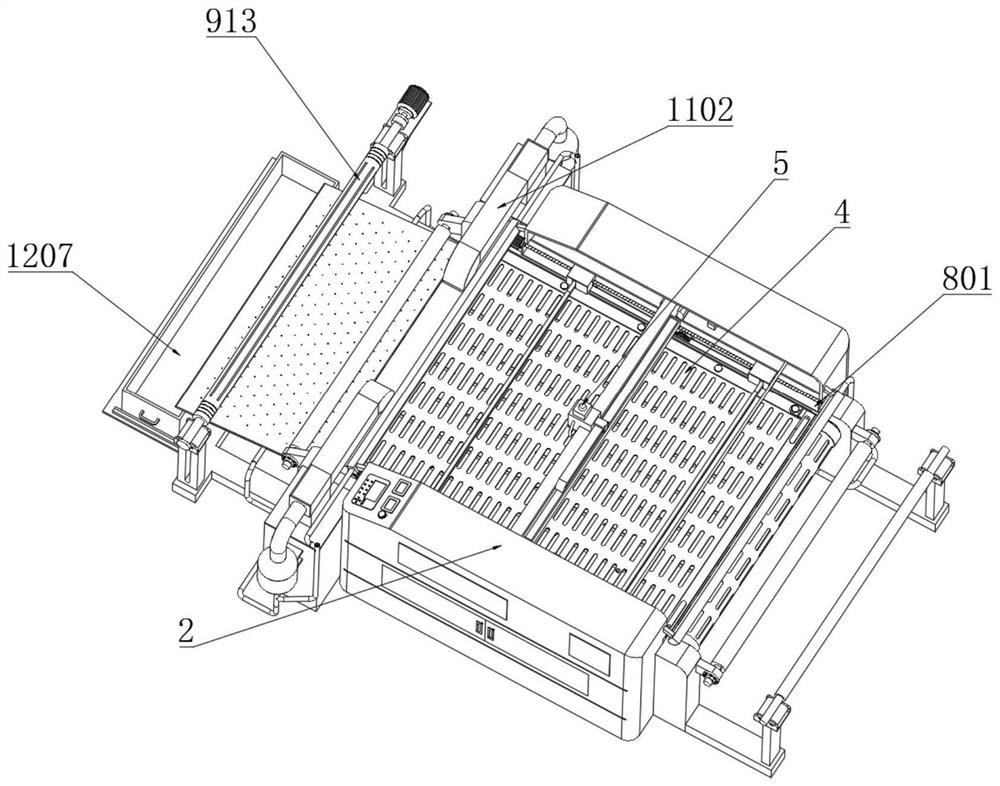

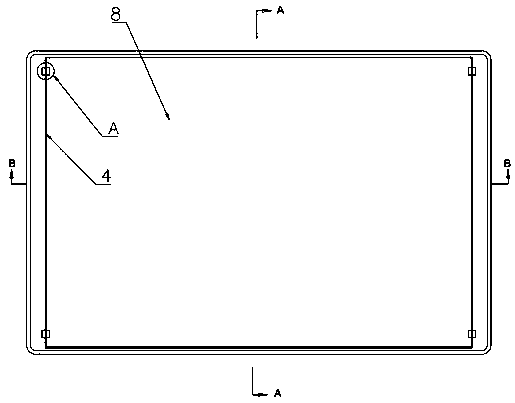

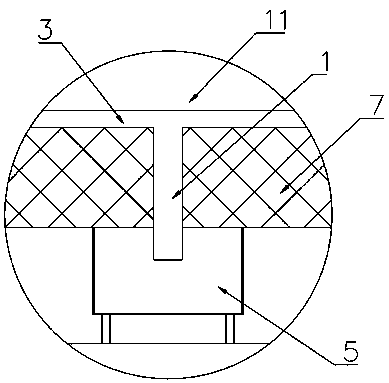

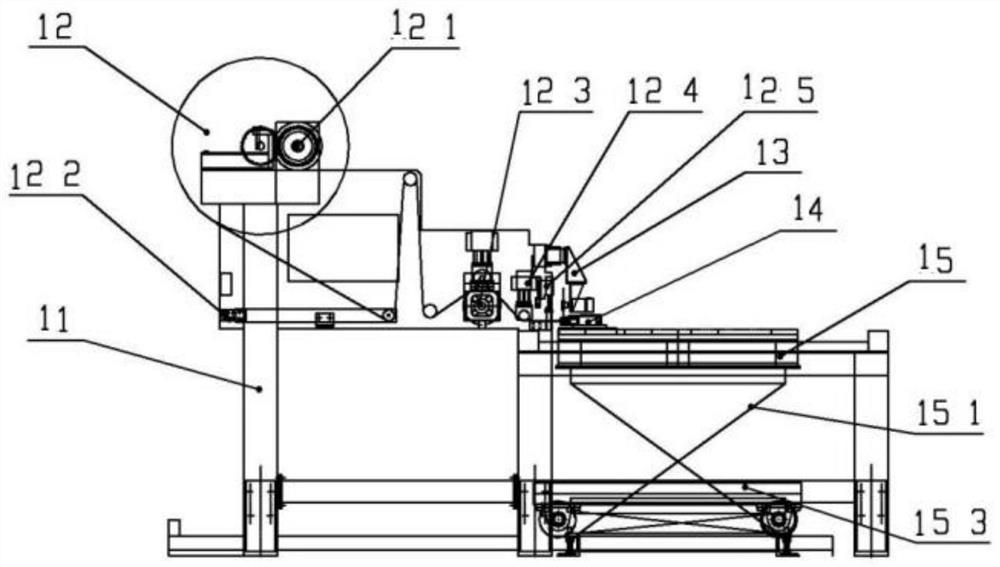

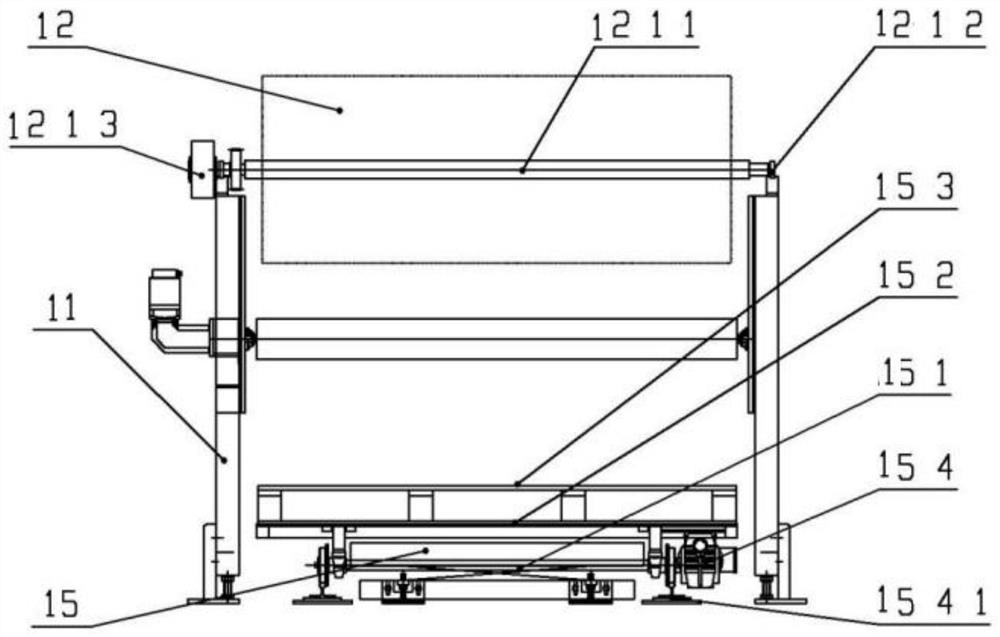

a paper laying machine

ActiveCN110255277BSimple laying processEfficient laying processCharge manipulationUnfolding thin materialsIndustrial engineeringPaper sheet

The invention discloses a paper spreading machine and relates to the technical field of glass surface paper spreading. The paper spreading machine comprises a paper spreading machine rack, an unwinding device, a cutting device, a dragging device, a stacking device and a controller, wherein the unwinding device, the cutting device and the dragging device are fixedly arranged on the paper spreading machine rack in sequence. The stacking device is used for carrying glass. The unwinding device is used for mounting a paper roll and releasing paper. The dragging device is used for dragging the paper. The cutting device is used for cutting the paper to obtain fixed-length paper sheets. The unwinding device, the cutting device, the dragging device and the stacking device are all electrically connected with the controller. Accordingly, the defects that a paper spreading machine is complex in operation and low in efficiency in the paper spreading process in the prior art are overcome. The paper spreading machine provided by the invention is easy to operate and high in efficiency.

Owner:中建材智能自动化研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com