Equipment and method for preparing high-performance modified pitch particles through abandoned clothing fibers

A technology of modified asphalt and asphalt granules, which is applied in the direction of solid waste management, sustainable waste treatment, and climate sustainability. It can solve the problems of reducing the quality of modified asphalt and high viscosity of asphalt, and achieves convenient transportation, simple laying process, Avoid the effect of uneven mixing of short fibers and asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

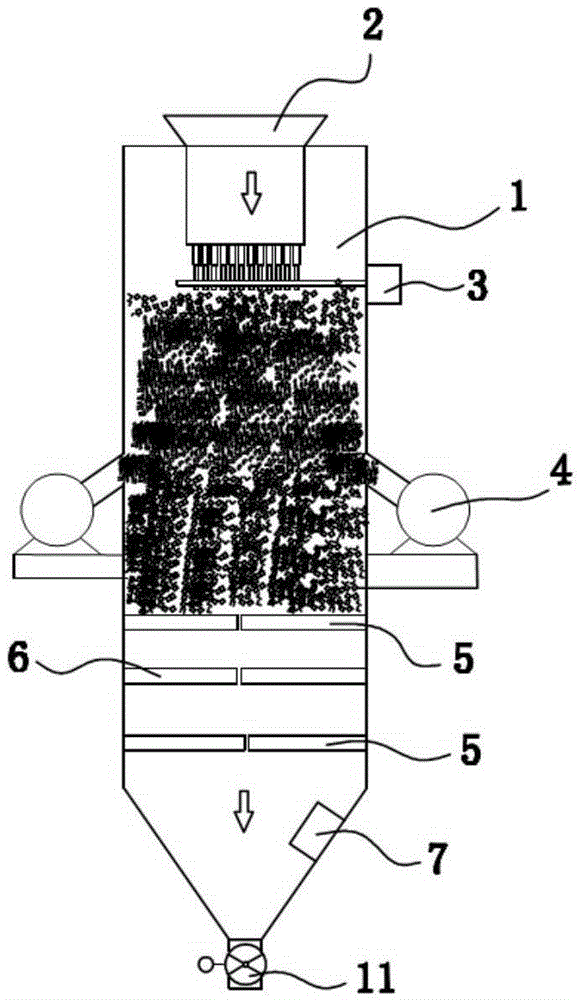

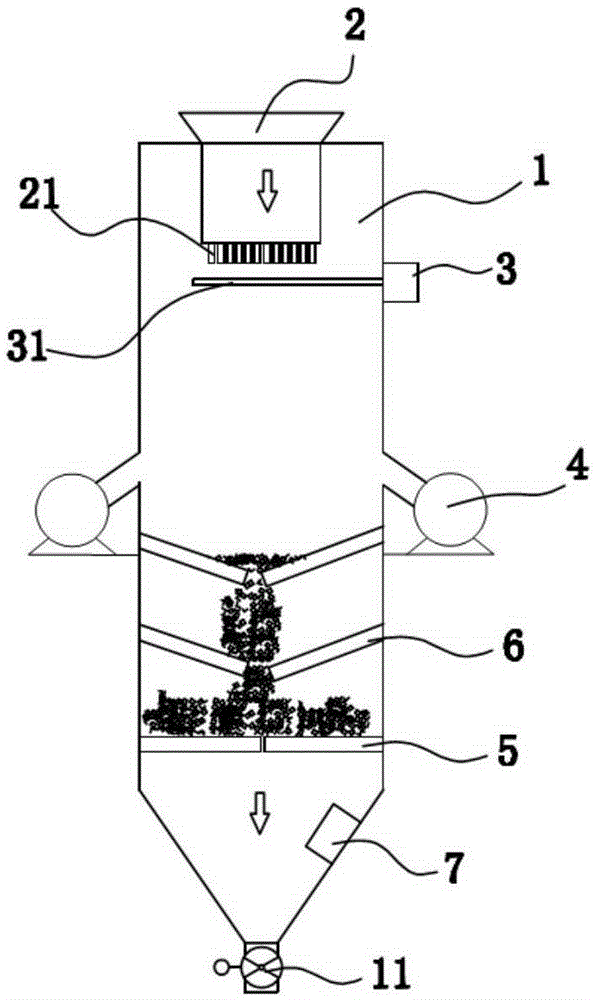

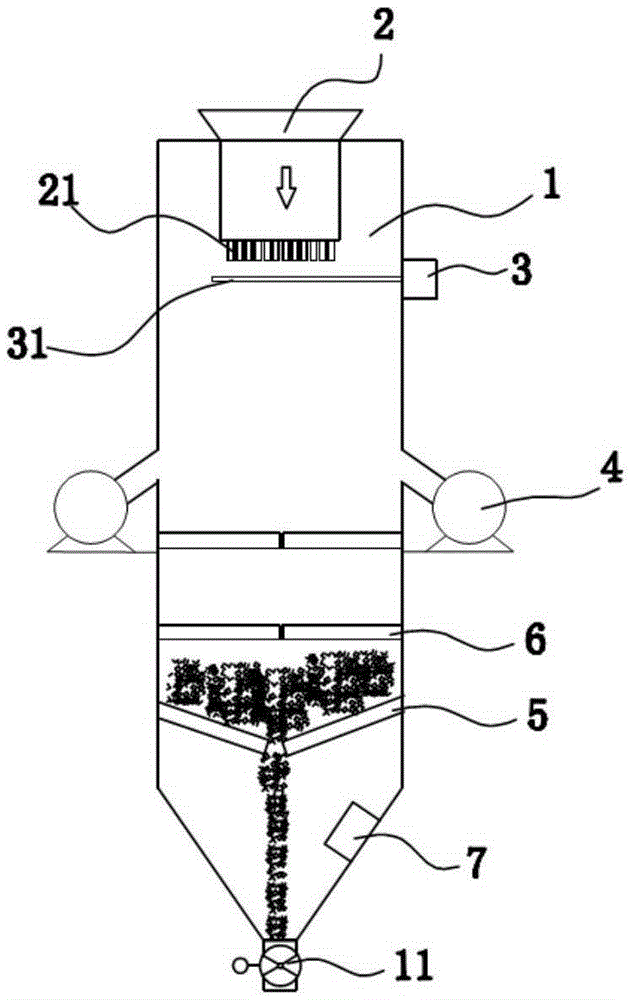

[0027] Such as Figure 1-3 As shown, a device for preparing modified asphalt granules by using waste clothes includes a mixing chamber 1, a high-pressure jet mechanism or a high-pressure extrusion mechanism 2 is arranged above the mixing chamber 1, and the jet port or high-pressure jet of the high-pressure jet mechanism The extrusion port 21 of the extrusion mechanism communicates with the mixing chamber, and the jet port or the extrusion port is provided with a cutting mechanism 3 for transversely cutting the linear asphalt ejected from the jet port or extruded from the extrusion port. Both sides of the bottom are provided with blowing mechanism 4, and described blowing mechanism is used for blowing short fiber upwards from the bottom of the mixing chamber.

[0028] Preferably, a vibrating screen 5 is provided at the bottom of the mixing chamber, and the asphalt granules wrapped in short fibers fall into the vibrating sieve, so that the short fibers are further uniformly and ...

Embodiment 2

[0034] A method for preparing modified asphalt granules from waste clothes, comprising the steps of:

[0035] S1. Remove the buttons, zippers and other accessories from the waste cotton or chemical fiber clothing, and then pulverize them into short fibers of 3-6mm through a pulverizer;

[0036] S2, softening the asphalt into a molten state through high temperature;

[0037] S3. In a mixing chamber, short fibers are blown upward from the bottom of the mixing chamber, and molten linear asphalt is sprayed downward from the upper part of the mixing chamber. The linear asphalt is cut into short asphalt particles by a cutting mechanism, and the rising short fibers are combined with short asphalt particles. The outer surface is in contact with the surface of the asphalt particles under the action of viscosity, and the asphalt particles wrapped with short fibers fall to the bottom of the mixing chamber. A vibrating screen is installed at the bottom of the mixing chamber. Under the vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com