Bearing plate screw adjusting method construction process

A construction technology and basic technology, applied in the direction of basic structure engineering, special foundation layout, supporting machines, etc., can solve the problems of incomplete joint surface, affecting the stability of the foundation, rework, etc., to achieve short maintenance engineering time, simplified laying process, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

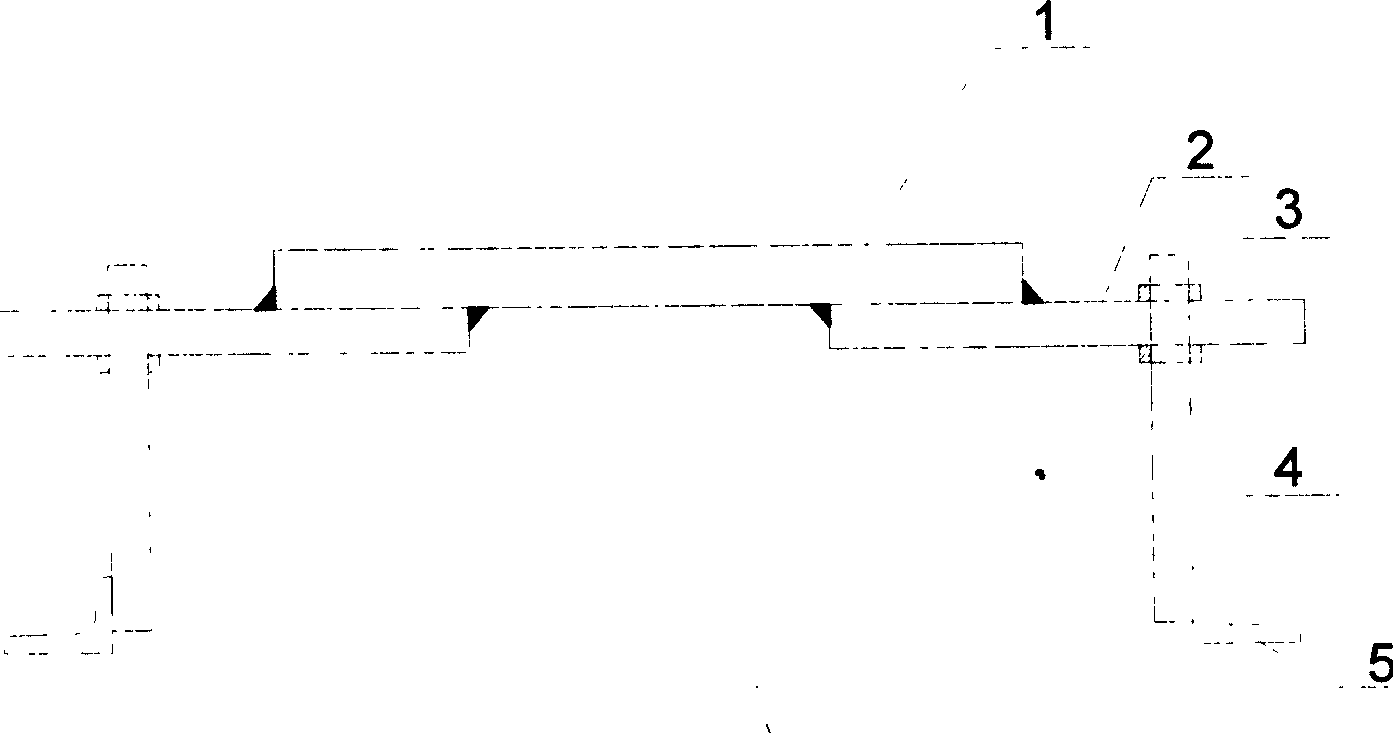

[0019] The rapid construction method of the foundation backing plate according to the present invention will be specifically described below in conjunction with the accompanying drawings.

[0020] 1. Construction preparation

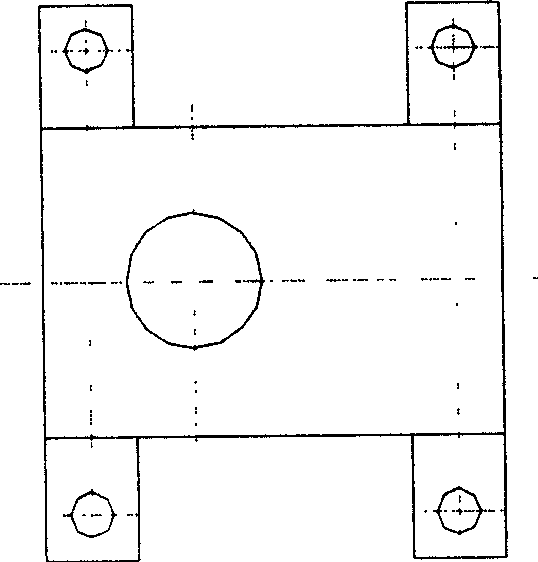

[0021] 1) Flat backing plate processing: Prepare necessary grouting materials, auxiliary materials and tools according to the size of the project and equipment installation requirements, select a flat backing plate that meets the specifications, and weld a piece of size on the four corners of the flat backing plate as required About 120*60*10mm steel plate, open a φ18mm round hole in the center of the steel plate, see figure 1 . The size of the steel plate used for the lower bolts can also be determined according to the actual size of the flat backing plate.

[0022] 2) Determination of elevation: It is directly related to the installation height of the flat backing plate and the coordinate position of the equipment, and it is required to be easy to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com