A laying method of an electric car lane

A laying method and lane technology, which can be applied to cohesive pavement paved on site, roads, roads, etc., can solve problems such as incompatibility, and achieve the effect of regular roads, broad promotion prospects, and smooth driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

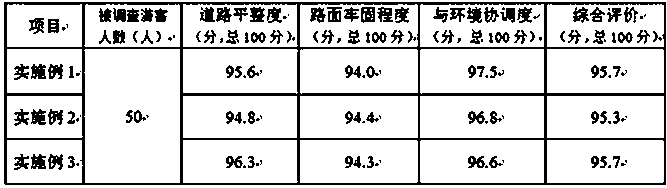

Embodiment 1

[0021] Embodiment 1: A kind of laying method of storage battery driveway

[0022] (1) Scrape the floating soil accumulated on the shallow surface of the ground from left to right along the terrain, and control the width to 3.0 m. After scraping, sprinkle water and roll it to form a route; when forming a route, avoid the plants on the ground, the body of the ruins and other related areas. For relevant cultural information, choose low-lying places with wide plants to avoid; set transfer points at intervals of 600m, the width of the transfer point route is 8 m, and the length is 10 m;

[0023] (2) Lay sand and stones with a thickness of 15 cm on the route, and sprinkle water and roll them after scraping, and spread the sand and stones accumulated on both sides along the terrain to form a roadbed; the composition and weight percentage of the sand and stones are : 20% of stones with a diameter of 10-50 mm, 45% of fine sand, and 35% of clay;

[0024] (3) Lay a layer of rice grain s...

Embodiment 2

[0025] Embodiment 2: A kind of laying method of storage battery driveway

[0026] (1) Scrape the floating soil accumulated on the shallow surface of the ground from left to right along the terrain, and control the width to 4.5 m. After scraping, sprinkle water and roll it to form a route; when forming a route, avoid plants on the ground, the body of the ruins and their For relevant cultural information, choose low-lying places where the plants are far apart; set transfer points every 700m, the width of the transfer point route is 9 m, and the length is 20 m;

[0027] (2) Lay sand and stones with a thickness of 17.5 cm on the route, and sprinkle and roll them with water after scraping, and spread the sand and stones accumulated on both sides along the terrain to form a roadbed; the composition and weight percentage of the sand and stones are : 25% of stones with a diameter of 10-50 mm, 50% of fine sand, and 25% of clay;

[0028] (3) Lay a layer of rice stones with a thickness ...

Embodiment 3

[0029] Embodiment 3: a kind of laying method of storage battery driveway;

[0030] (1) Scrape the floating soil accumulated on the shallow surface of the ground from left to right along the terrain, and control the width to 6.0 m. After scraping, sprinkle water and roll it to form a route; when forming a route, avoid plants on the ground, the body of the ruins and other related areas. For relevant cultural information, choose low-lying places with wide plants to avoid; set transfer points at intervals of 800m, the width of the transfer point route is 10m, and the length is 30m;

[0031] (2) Lay sand and gravel with a thickness of 20 cm on the route, after scraping and watering and rolling, spread the sand and gravel accumulated on both sides along the terrain, and form a regular shape to form a roadbed; the composition and weight percentage of the sand and gravel are : 30% of stones with a diameter of 10-50 mm, 55% of fine sand, and 15% of clay;

[0032] (3) Lay a layer of ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com