Mesh cloth floor heating pipe, mesh cloth quick-installation floor heating and installation method thereof

An installation method and mesh cloth technology, applied in the field of floor heating structure, can solve the problems that affect the installation operation and use effect and safety of floor heating, the distance between pipe arrangement is large, and the pipe is not fixed firmly, so as to reduce the laying strength and difficulty, The effect of shortening the construction period and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

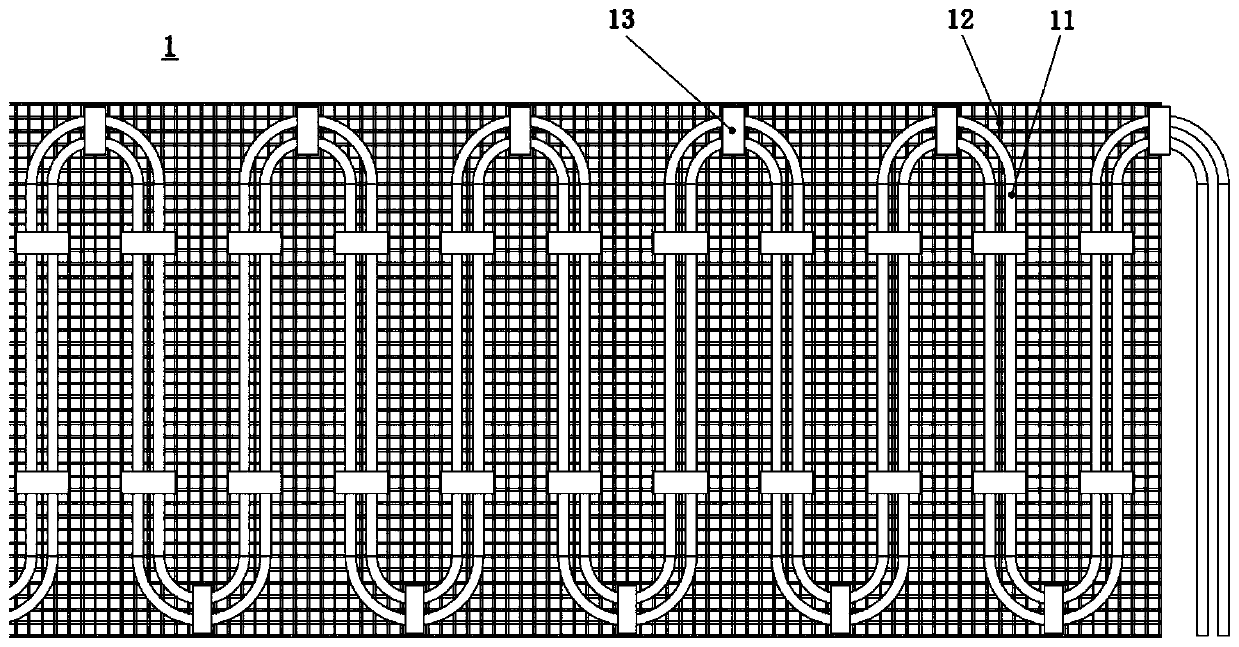

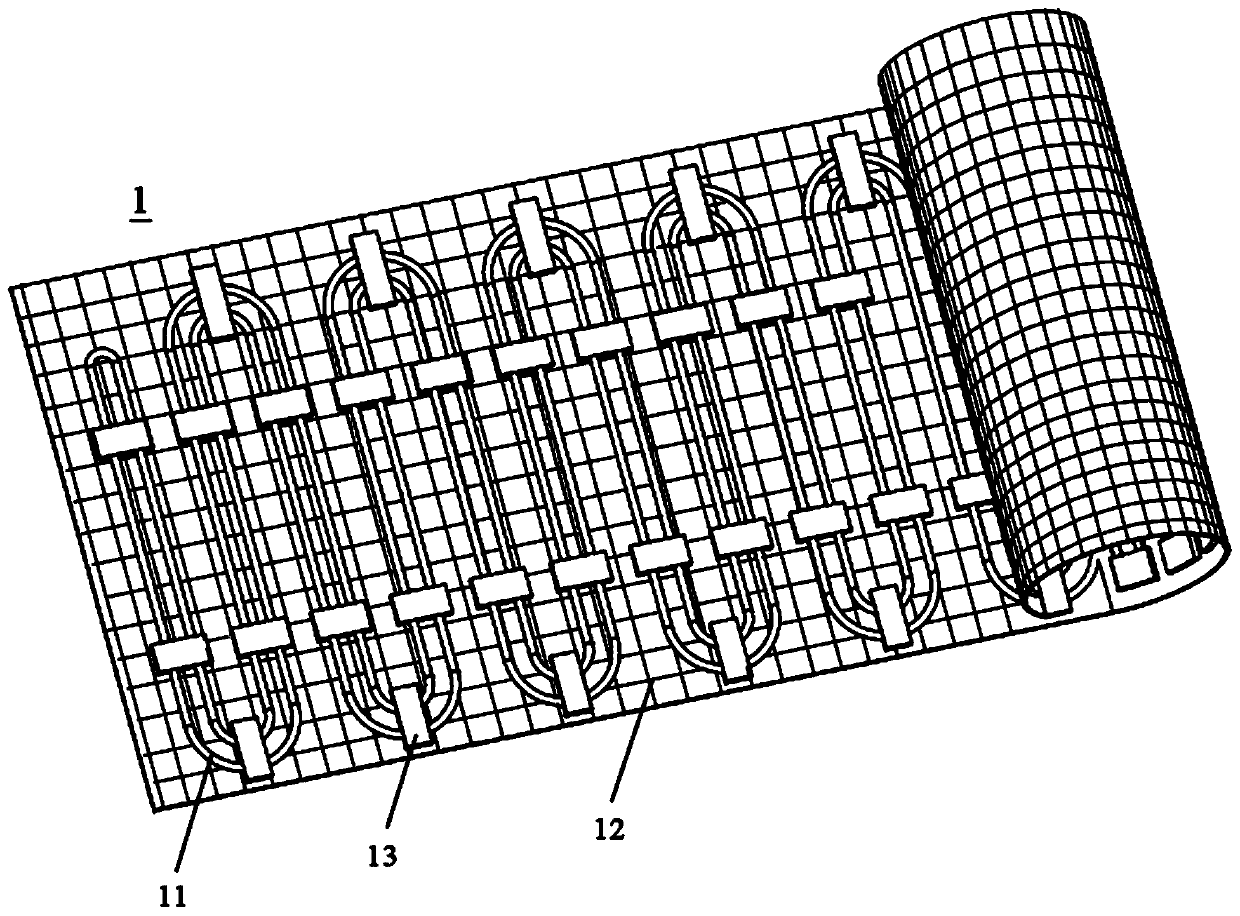

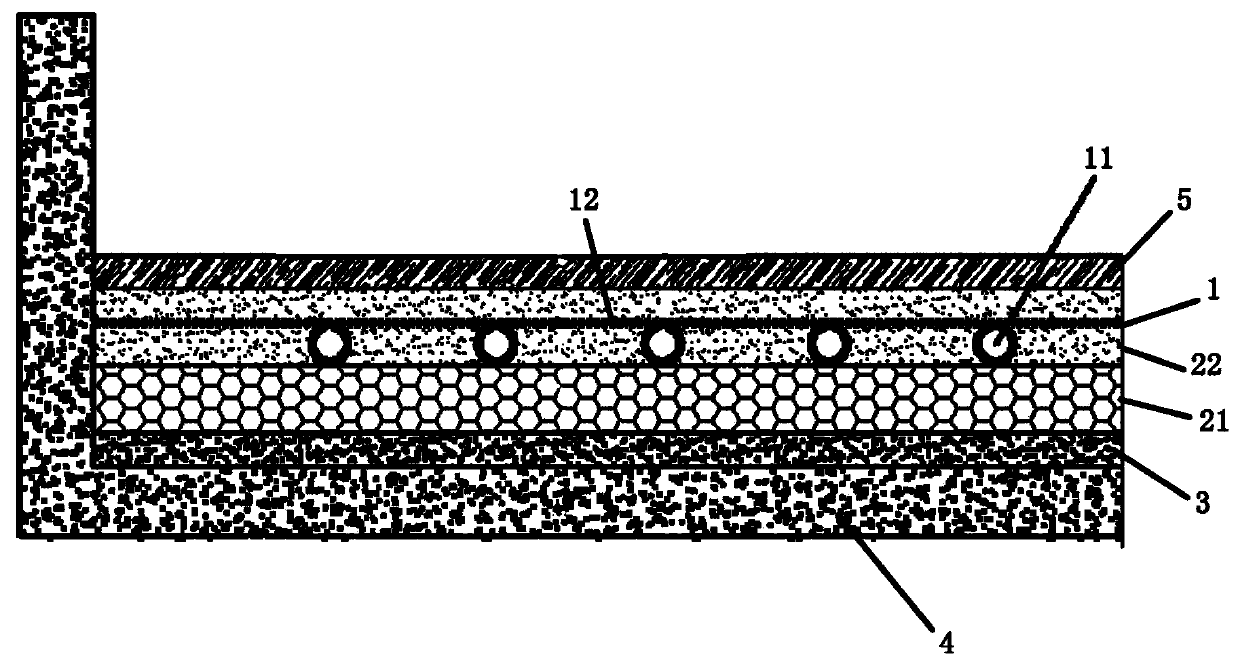

[0031] See figure 1 and figure 2 As shown, it is a partial structural diagram of a preferred embodiment of a grid cloth floor heating pipe of the present invention. Wherein the grid cloth floor heating pipe 1 includes a grid cloth 12, a floor heating pipe 11 and a fixing clip 13; the floor heating pipe 11 is laid on the grid cloth 12 in a meandering manner; the fixing clip 13 runs along the The floor heating pipes 11 are installed at intervals in the extending direction, and the floor heating pipes 11 are fixed on the grid cloth 12, and the grid cloth floor heating pipe 1 is laid inside the floor heating. In the present invention, the grid cloth 12 and the floor heating pipe 11 are pre-fixed by the fixing clip 13, so as to realize a simple and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com