A combined floor slab, building and construction method

A combined type and floor slab technology, which is applied in the direction of building structure, building, floor slab, etc., can solve the problems of inability to ensure the passage of installation equipment such as pipelines, long construction period and complicated process, so as to simplify the laying process, shorten the construction period, Strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] This embodiment discloses a combined floor slab. The only difference from Embodiment 1 is that prestressed steel bars are embedded in the mortar of the second steel pipe, which further enhances the strength and bending rigidity of the second steel pipe. Other structures and embodiments 1 is the same and will not be repeated here.

Embodiment 3

[0045] This embodiment discloses a building, which is provided with the combined floor slabs described in Embodiment 1 or 2, and other structures of the building adopt existing structures, which will not be described in detail here.

Embodiment 4

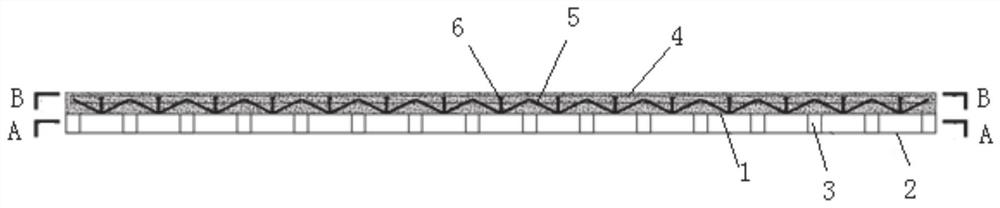

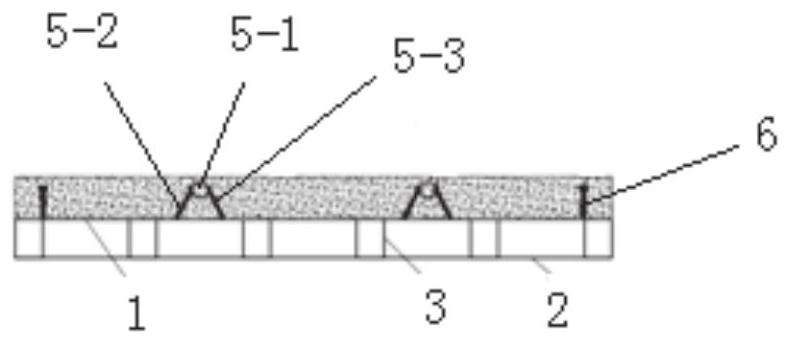

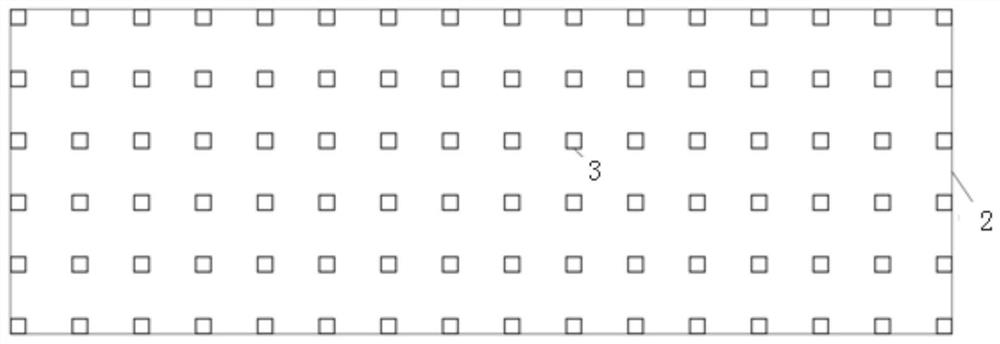

[0047] This embodiment discloses a construction method of the combined floor slab described in Embodiment 1. The bottom ends of a plurality of vertical columns are welded and fixed to the lower steel plate by high-frequency welding, and the top ends of the plurality of vertical columns are welded and fixed by high-frequency welding. The method is welded and fixed with the upper steel plate.

[0048] The second steel pipe is poured with mortar, the first and second steel bars that are pre-bent in a wave-like structure are welded and fixed to the second steel pipe respectively, and the wave crest positions of the first and second steel bars are welded and fixed to the second steel pipe to form In the truss structure, the trough positions of the first steel bar and the second steel bar are welded and fixed with the upper surface of the upper steel plate.

[0049] Weld studs on the upper surface of the upper steel plate.

[0050] After the welding of the welding nails, concrete is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com