Manufacturing process of one-piece Chinese-style tile

A production process, small blue tile technology, applied in the field of small blue tile production technology, can solve the problems of inconvenient maintenance, high consumption cost, complicated process, etc., achieve the effect of easy hanging, large coverage area, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

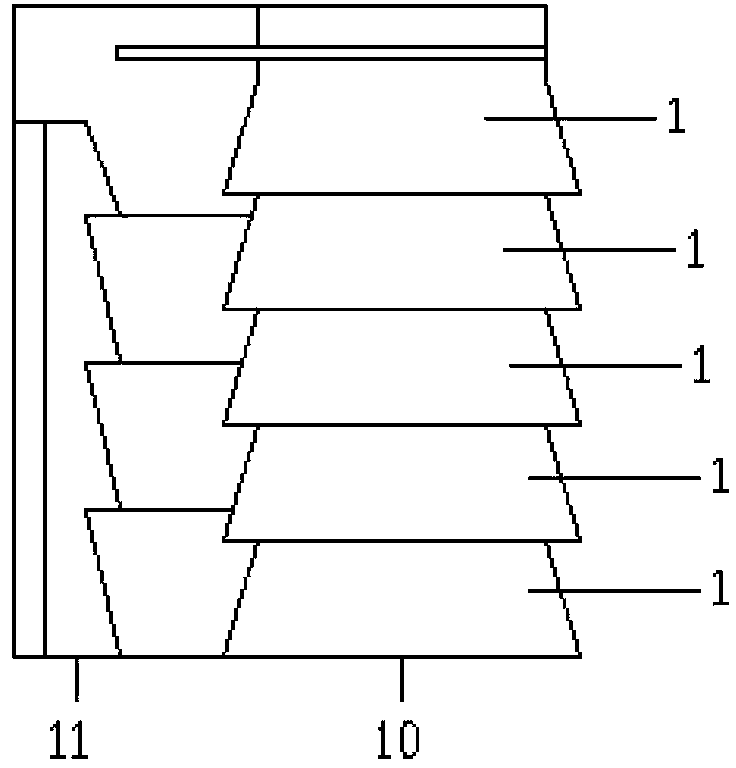

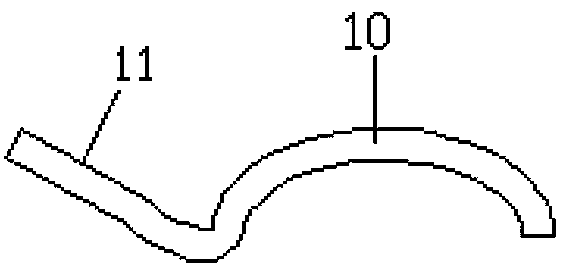

[0017] Combine below figure 1 with figure 2 The specific structure of the conjoined small green tile of the present invention is described. It includes at least two tiles 1, the tiles are overlapped in the form of bottom tiles and cover tiles, and the small green tiles are integrally formed by a mould. The cross-sectional profile of the tile includes an arc bulge 10 and an upward warping edge 11 connected to the left side of the arc bulge. The width of the top of the arc raised part of the tile gradually narrows from front to back, and the width of the bottom of the warped part gradually widens from front to back.

[0018] And the small green tile raw material of the present invention is mixed and formulated by cement, washing river sand, additive, reinforcing fiber. The mass ratio of main components in the raw materials is cement:washed river sand=1:1.2-1.8. The mass ratio of main components in the raw materials is cement:washed river sand=1:1.5. The additive or reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com