Insulated rail with nano-ceramic coating

A technology of nano-ceramic and steel rail, applied in the field of rail transit, can solve the stray problems of the rail system, and achieve the effect of eliminating stray current, ensuring the insulation performance of the rail, operating efficiency and safety, and simplifying the laying process of the rail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

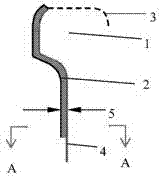

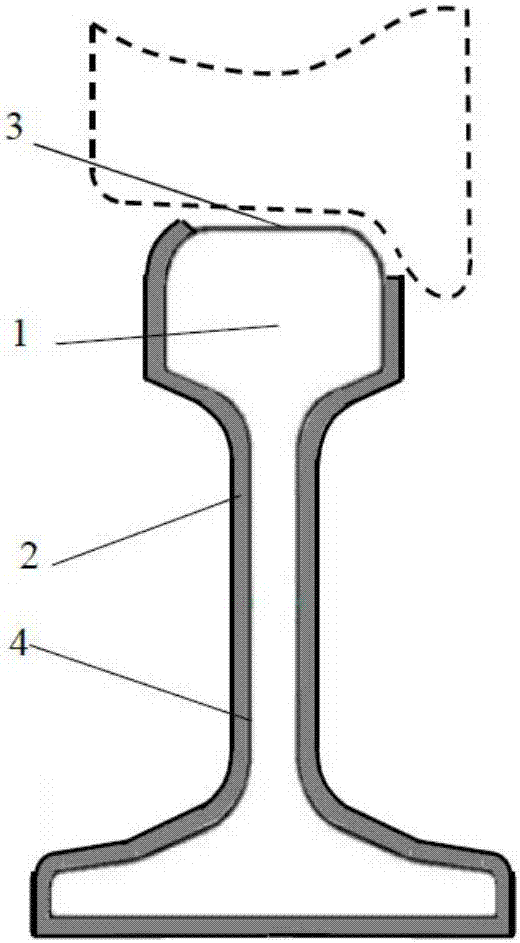

[0048] Such as Figure 1a Shown, a kind of nano-ceramic insulating steel rail is coated with nano-ceramic insulating coating 2 on the surface of general track rail 1; Nano-ceramic insulating coating 2 is evenly covered on the surface of rail 1; The surface of rail 1 includes rail top surface 3 and other rail outer surfaces 4, the rail outer surface 4 includes the upper and lower sides of the rail bottom, the two sides of the rail waist, and the upper and lower sides of the rail head along the longitudinal direction of the rail; the top surface of the rail 3 is the rolling contact surface of the wheel and the adjacent In the 50mm wide area of the upper surface, the top surface of the rail 3 is not regarded as the must-coated area, that is, the non-coated area, and the non-coated area of the rail 1 is used to install tooling during coating to support or hang the rail; nano-ceramic insulating coating The material of 2 adopts two-component alcohol system nano-ceramic coating mo...

Embodiment 2

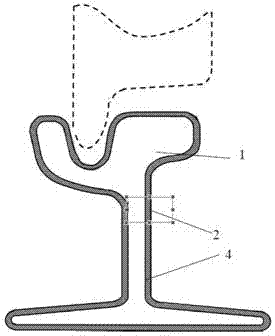

[0059] Such as Figure 1b As shown, a grooved nano-ceramic insulating steel rail is coated with a nano-ceramic insulating coating 2 on the surface of the grooved track rail 1; the surface of the rail 1 includes a rail top surface 3 and other rail outer surfaces 4, and the nano-ceramic insulating coating 2 is evenly covered on the outer surface 4 of the rail; the outer surface 4 of the rail includes the upper and lower sides and sides of the rail bottom, the two sides of the rail waist, and the upper and lower sides of the rail head along the longitudinal direction of the rail; but the top surface 3 of the rail is the rolling contact surface of the wheel And the 50mm wide area of the adjacent upper surface is not regarded as the must-coated area, that is, the non-coated area. The non-coated area of rail 1 is used to install tooling during coating to support or hang the rail; nano-ceramic insulating coating The materials include bonding materials, reinforcing materials, acti...

Embodiment 3

[0068] The coating process of nano-ceramic insulating coating, such as Figure 5a-5d As shown, the rail is supported by special tooling, and the contact surface between the special tooling 16 and the rail 1 does not hinder the coating of the nano-ceramic insulating coating. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Abrasion | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com