A circular rotating "receiving-returning" system suitable for rail transit

A rail transit and circular technology, applied in vehicle components, electric vehicles, transportation and packaging, etc., can solve the problems of insufficient utilization of carbon skateboard materials, untouched areas of carbon skateboards, etc., to save operating costs and eliminate stray Current, effect of preventing stray current corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

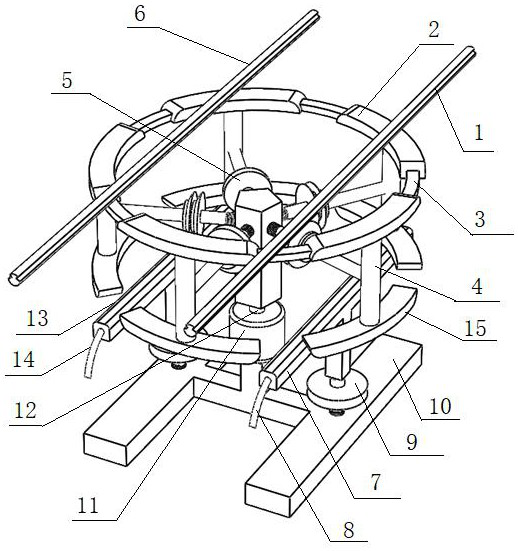

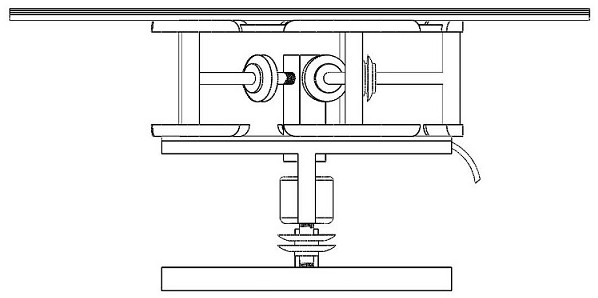

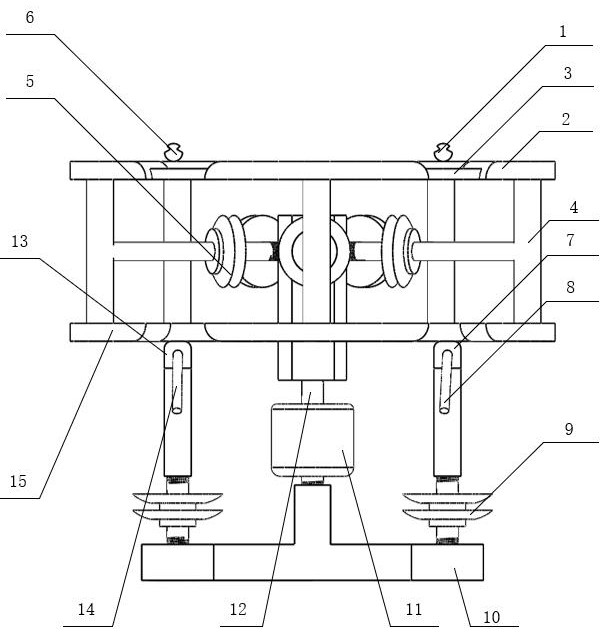

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, the present invention is applicable to the annular rotation "receiving-returning" system of rail transit, including the upper carbon slider 2 and the lower carbon slider 15; the upper carbon slider 2 and the lower carbon slider 15 include multiple sizes and The arc-shaped carbon sliders with equal radii, the upper carbon sliders 2 are arranged in a ring shape and separated from each other; the lower carbon sliders 15 are connected to the upper carbon sliders one by one through the carbon slider metal bracket 4 Below the block 2, each carbon slider metal bracket 4 is connected to the rotating shaft 12 through the carbon slider insulator 5; the rotating shaft 12 passes through the center of the ring and is connected to the output end of the rotating motor 14; it also includes The power supply line 6 and the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com