Patents

Literature

126results about How to "Anti-friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

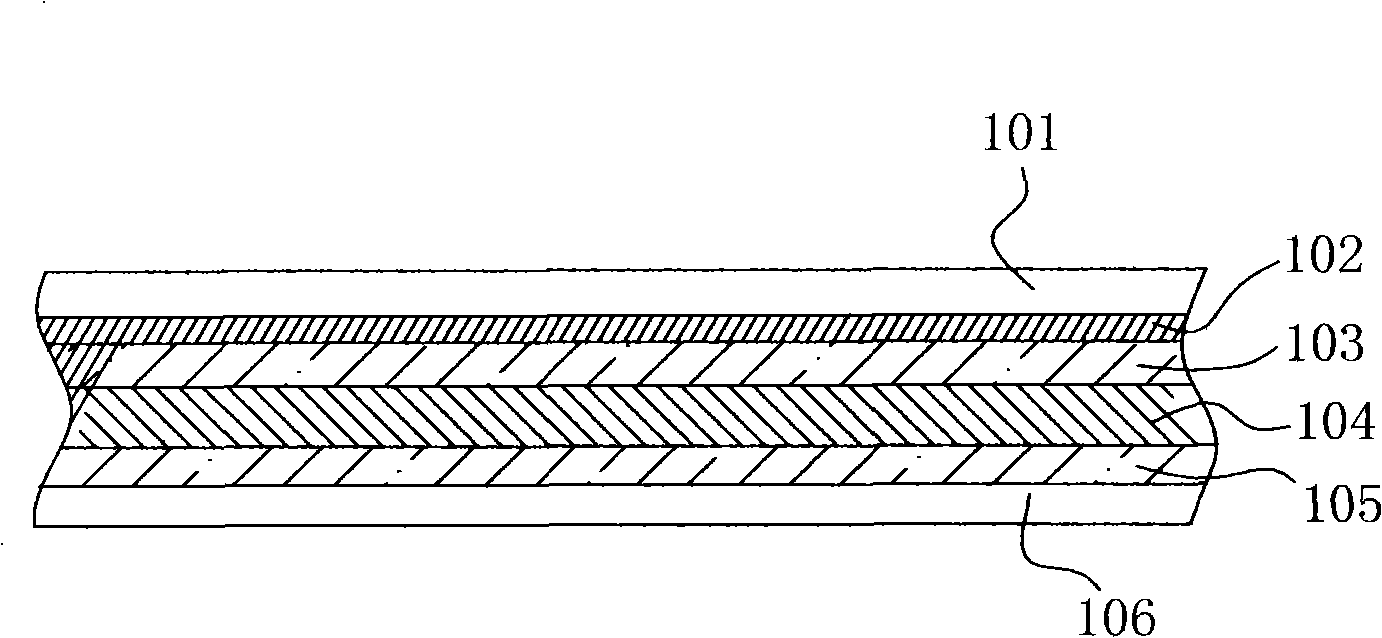

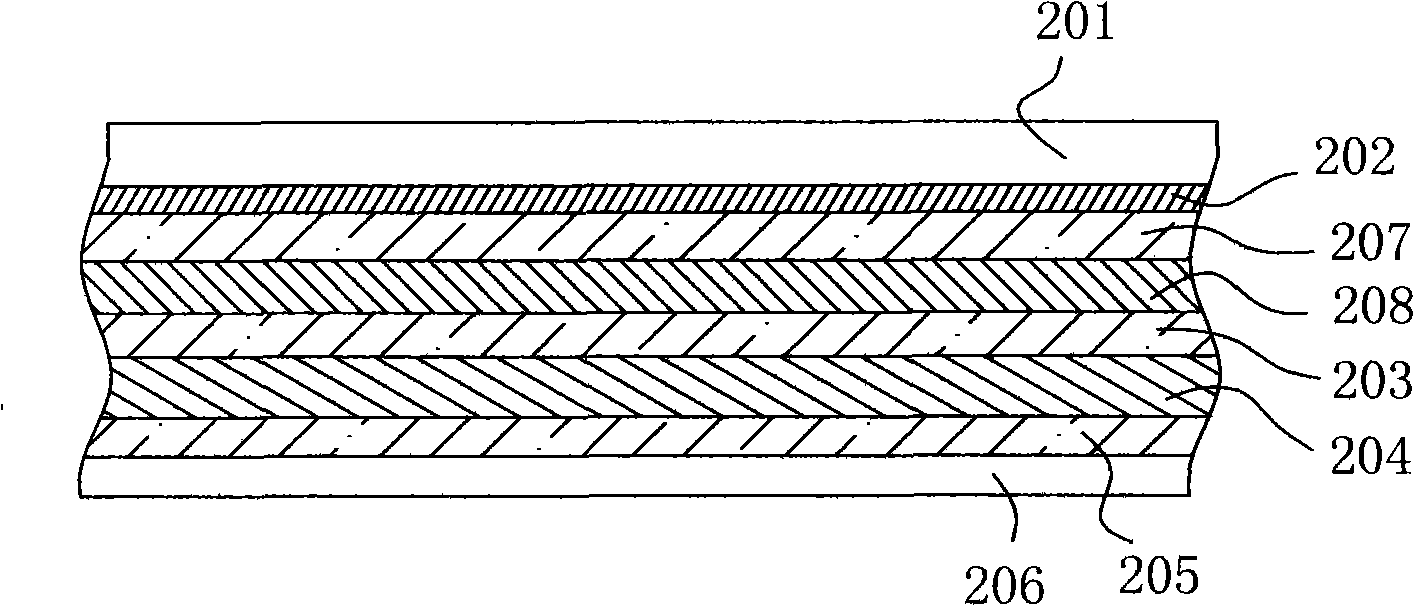

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

Nano-silver porous silicone rubber/polyurethane-containing double-layer artificial skin and preparation method thereof

InactiveCN103948960ACapable of absorbing effusionWaterproofAbsorbent padsProsthesisFoaming agentSolvent

The invention discloses a nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin and a preparation method thereof. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin is characterized in that the artificial skin contains a dermis and epidermis double-layer structure; a dermis layer is prepared from loose porous polyurethane; an epidermis layer is prepared from antibacterial agent-containing silicone rubber. A preparation method of the dermis layer comprises the following steps: dissolving the polyurethane, adding a pore-foaming agent, defoaming, carrying out curtain coating so as to form a film, volatilizing a solvent, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a porous polyurethane film. A preparation method of the epidermis layer comprises the following steps: dissolving a silicone rubber precursor, carrying out ultrasonic dispersion on a nano-silver solution, adding the pore-foaming agent, defoaming, carrying out blade coating or curtain coating so as to form a film, volatilizing a solvent, curing so as to obtain an embryonic film, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a silicone rubber microporous film. The preparation method of the double-layer artificial skin comprises the following steps: coating the polyurethane film with polyvinyl alcohol, acid liquor and a crosslinking agent, then covering the polyurethane film by using the silicone rubber film, volatilizing a solvent, and carrying out heat treatment so as to obtain the double-layer artificial skin. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin has the effects of water resistance, air permeability, bacterial inhibition, virus killing and effective absorption of hydrops.

Owner:SICHUAN UNIV +1

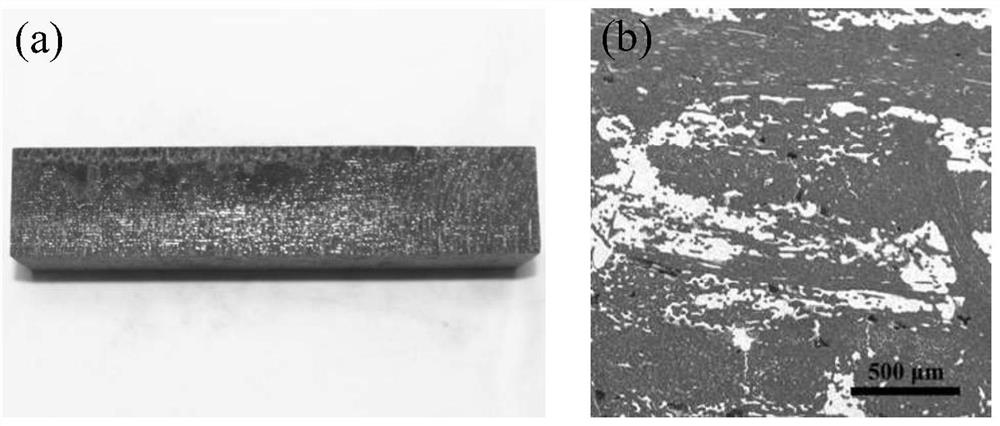

Nitrogen and boron alloying high tenacity hardfacing flux-cored wire

ActiveCN102886620AImprove impact toughnessImprove plasticityWelding/cutting media/materialsSoldering mediaNiobiumRare earth

The invention relates to a nitrogen and boron alloying high tenacity hardfacing flux-cored wire. The skin of the nitrogen and boron alloying high tenacity hardfacing flux-cored wire adopts a mild-carbon steel strip, and the core part is filled with alloy or mineral powder, and is pulled into a wire. The nitrogen and boron alloying high tenacity hardfacing flux-cored wire is characterized in that nitrogen and boron compounds, such as NaN3, BN and the like and a rear earth oxide are added into flux-cored powder to realize the surfacing metal nitrogen and boron alloying. The flux-cored wire comprises chemical components (weight percentage) including 1.0-3.0 % of carbon, 35-40% of chromium, 1.0-2.0% of niobium, 3.0-8.0% of boron, 2.0-5.0% of nitrogen, 1.0-2.0% of molybdenum, 1.0-2.5% of rare earth oxide, and the balance of iron or other impurities. Because the flux-cored wire adopts nitrogen and boron to replace part of carbon alloying surfacing metal, the hardness of a surfacing layer is high, and the highest hardness can reach HRC 66-69. The nitrogen and boron alloying high tenacity hardfacing flux-cored wire has the advantages of favorable toughness and outstanding wear resistance. The nitrogen and boron alloying high tenacity hardfacing flux-cored wire can be mainly used for the surfacing repair and the composite manufacturing of easily-damaged parts of ferrous metallurgy equipment, building machinery and the like.

Owner:HUNAN UNIV OF TECH

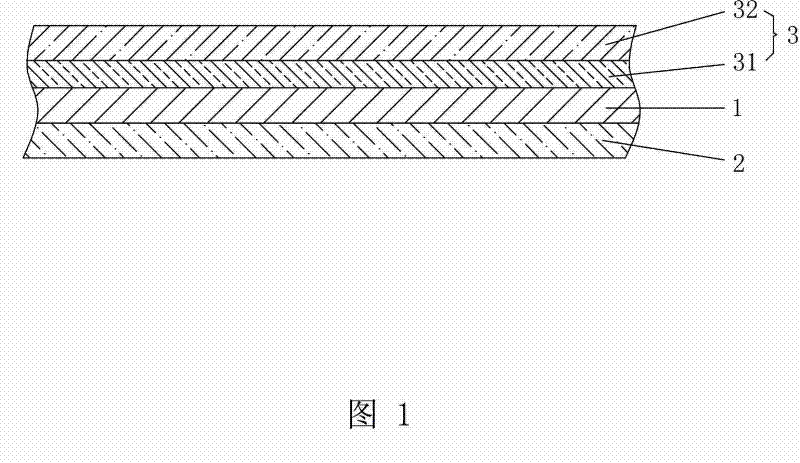

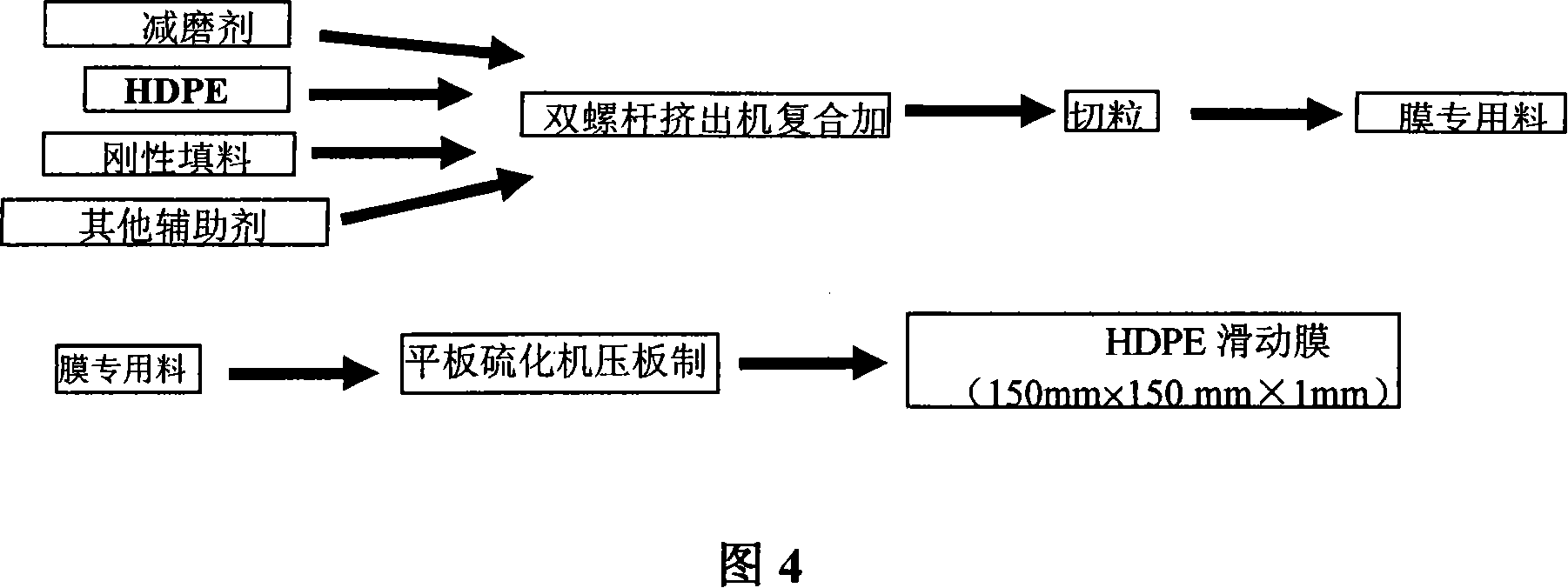

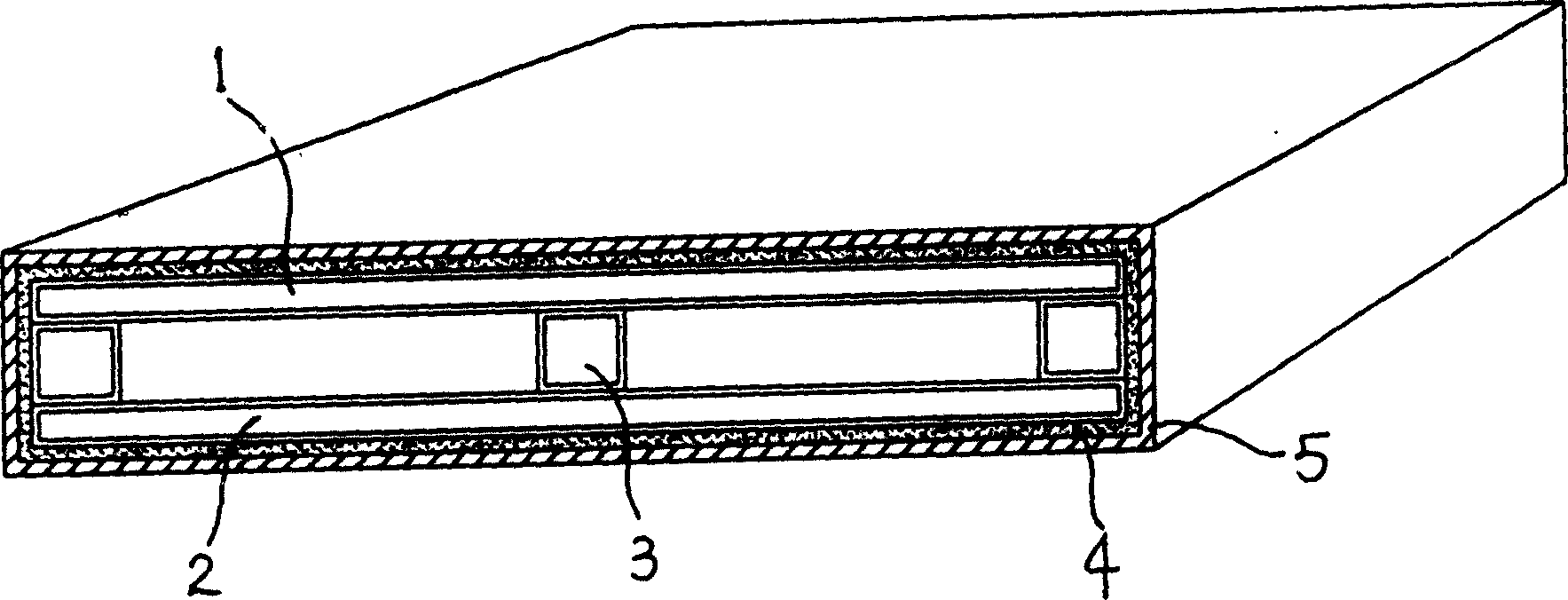

Sliding layer for bridge trackway longitudinal spacer assembly

ActiveCN101139817AReduce coefficient of frictionReduce frictionBridge structural detailsTrackwayEngineering

The invention provides a slide layer for longitudinal isolation devices on bridge tracks. The slide layer is arranged below a longitudinal partition wall between a track and a bridge; the slide layer is positioned in the direction of the bridge length; both ends of the slide layer can be expanded to limit table across an abutment; the width of the slide layer is bigger than that of the track; the slide layer comprises an top-arranged film layer, an intermediate sliding film and a bottom-arranged film layer; the top face of the top-arranged film layer of the slide layer is adhered to the bottom face of the longitudinal partition wall; the bottom face of the bottom-arranged film layer is stuck to the top face of the bridge beam body. The invention has advantages of anti-friction, tensile resistance, anti-freezing, creep-resisting, anti-corrosion and having weather ability performances; meanwhile, the invention can meet the requirements for lower friction factor and low friction loss. Besides, the invention also has advantages of perfect processing performance, being economic and practical and low price. Therefore, the invention meet requirements of bridge track longitudinal isolation devices for slide layers.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

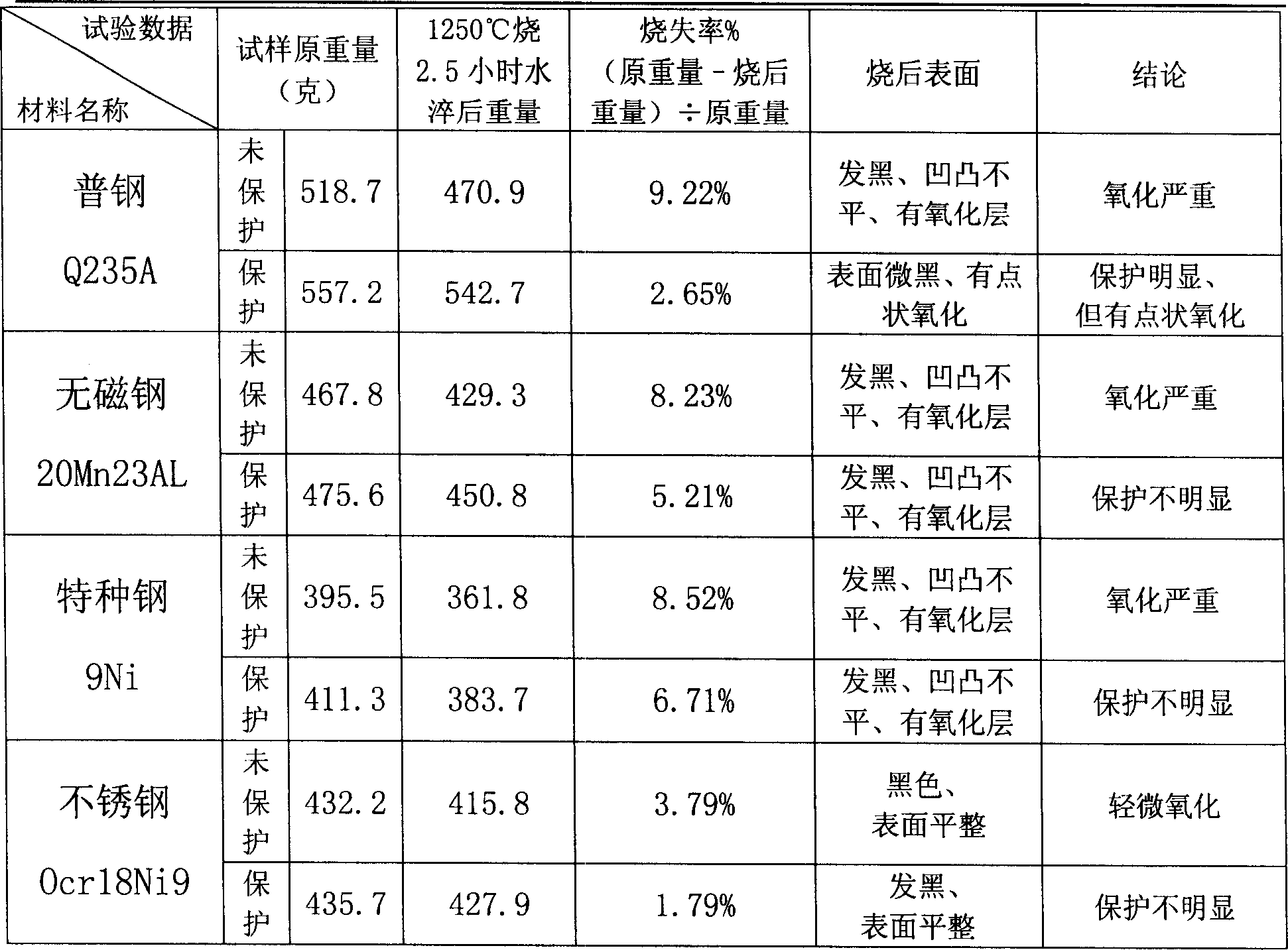

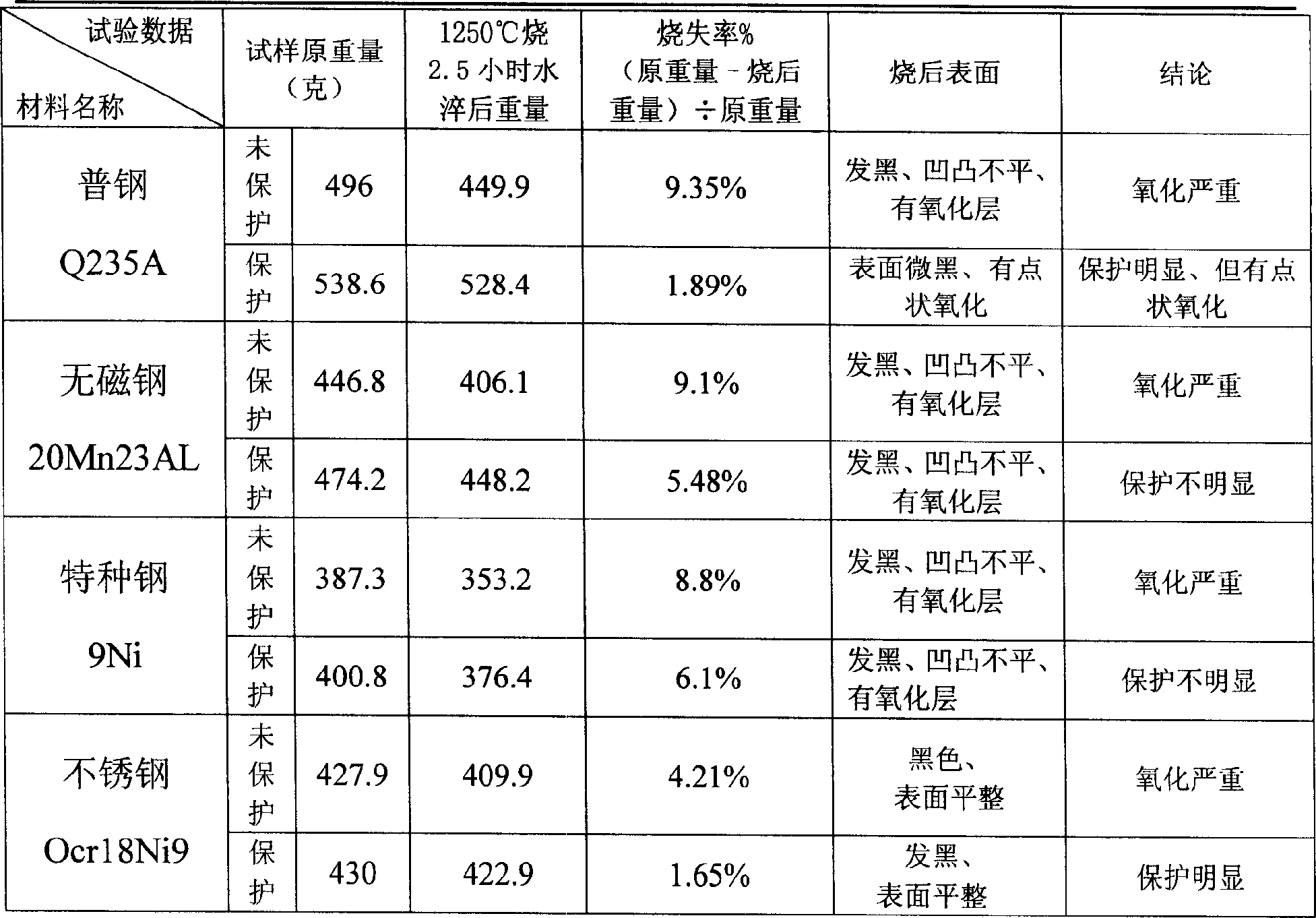

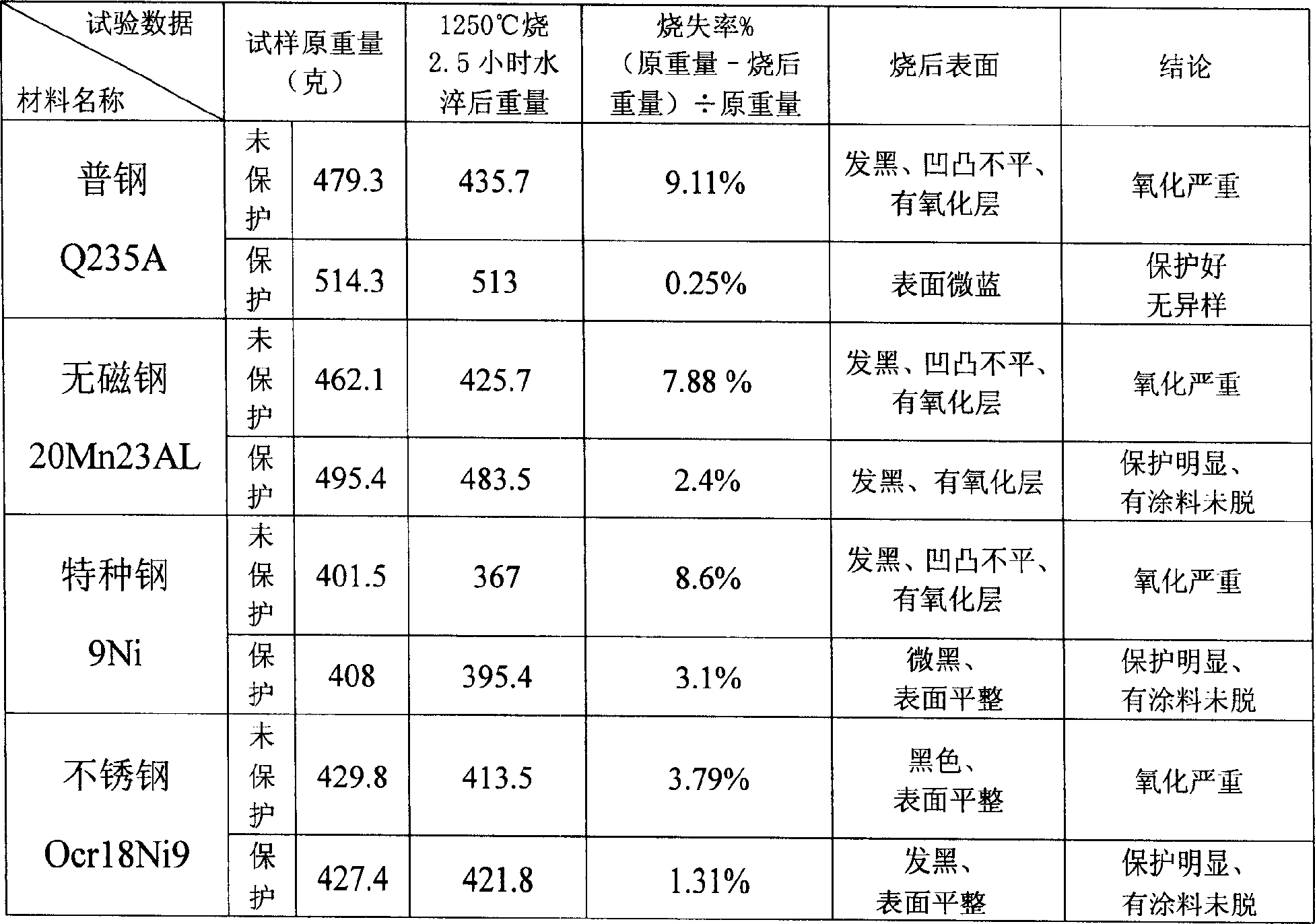

Antioxidation coating material of Nano silicate in use for annealing billet in series

This invention relates to nanoscale silicate anti-oxidation coating for steel billet annealing. The coating is composed of: composite binder 20-30 wt.%, composite phosphate curing agent 8-12 wt.%, and composite aluminosilicate filler 58-72 wt.%. The coating can resist 1500 deg.C high temperature. The coating does not need any surface treatment, and can be directly sprayed onto the surface of steel billet, and cured at normal temperature for 10 min. Before annealed and hot-rolled, the coated steel billet is water-quenched for several seconds so that the coating layer is removed without any trace, and the surface quality is improved. The coating can reduce the loss-on-ignition of various steels, thus can be used for surface protection of refractory materials used as furnace kiln lining. Besides, the coating can also be used as inner and outer wall coating, and metal surface (bridge, bridge pier and dam) coating with water, corrosion and oxidation resistance.

Owner:沁阳市皇甫喷射防腐技术有限公司

Lubricating oil composition

One lube oil compound with the quality of oxidation resistance, abrasive resistance, and anti-attrition, based on total weight of the compound, includes the following components: (a) zinc salt, ntoquita nantokite, magnesium salts, calcium salt and barium salt of dialkyl phosphorodithioic acid, the content is 0.1-3.5%; (b) compound antioxidant of amine antioxidant and phenolic ester antioxidant, the content is 0.2-3.0%; (c) molybdenum salt of dialkyl dithioic organic acid, the content is 0.05-1.5%; (d) monohydric or polyhydric alcohol ester with abrasive resistance and anti-attrition produced by monohydric alcohol or diatomic alcohol and alkyl, arene or alkyl phenol in place of carboxylic acid, the content is 0.05-1.5%; (e) zinc salt, sodium salt, magnesium salts, calcium salt and barium salt dialkyl dithiocarbamate or dialkyl dithiobenzoic acid, the content is 0.05-1.5%; (f) grease oil, the residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep punching stewing-resistant transparent aluminum lid gloss oil and preparation method thereof

The invention relates to light industry aluminum and iron printing coating, in particular to deep punching stewing-resistant transparent aluminum lid gloss oil which is prepared by following steps: polyester resins is taken as basal materials, right amount of methyl etherified tripolycyanamide and butyl etherified benzoguanamine is taken as a cross linking agent, also right amount of closed type polymeric isocyanate and epoxide resins is taken as an additive in an auxiliary way, an auxiliary agent,is added, right amount of acid catalyst is induced, and reserved carboxyl of the basal materials and a small quantity of hydroxide radical are carried out cross linking solidifying reaction under set temperature and time with activated functional groups of epoxide resin carboxyl, a cross linking resin and the acid catalyst. The invention adopts the maximum basal materials-polyester resins, adopts the butyl etherified benzoguanamine, the closed type polymeric isocyanate and the polyester resins to be matched with the polyester resins to be used and has optimized mixture ratio among the composites, thereby reaching the reasonable cross linking density, reducing the internal stress and enhancing the stretchability resistance, the flexible property and the water and stewing resistant property.

Owner:无锡市太湖防腐材料有限公司

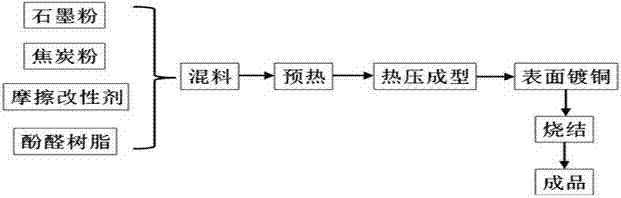

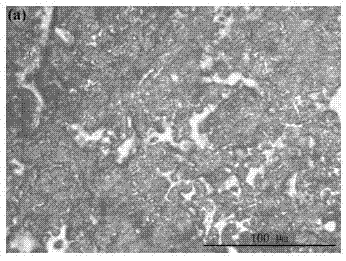

Carbon based sliding plate material of high speed railway pantograph and preparation method thereof

The invention provides a carbon based sliding plate material of a high-speed railway pantograph and a preparation method thereof. The carbon based sliding plate material is composed of graphite, powdered coke, thermosetting phenol resins, aluminum oxide and glass powder. The preparation method of the carbon based sliding plate material comprises the steps of mixing the materials in a dry basis state, wherein a base body is formed by the graphite and the powdered coke, the thermosetting phenol resins serve as binders, and the mixture of the aluminum oxide and the glass powder serves as friction modifier; performing hot press molding; plating copper on the surface of the base body in an electric spark mode under the nitrogen atmosphere; and performing high-temperature diffusion in a plasma vacuum sintering device to obtain the carbon based sliding plate material with a surface modified layer. The carbon based sliding plate material has good lubricating performance of a pure carbon sliding plate and good conductivity of a pure metal sliding plate, and is low in cost, less in consumed energy, simple in preparation process, short in production period and suitable for manufacturing a slide plate of an electric locomotive pantograph of a high-speed railway.

Owner:TAIYUAN UNIV OF TECH

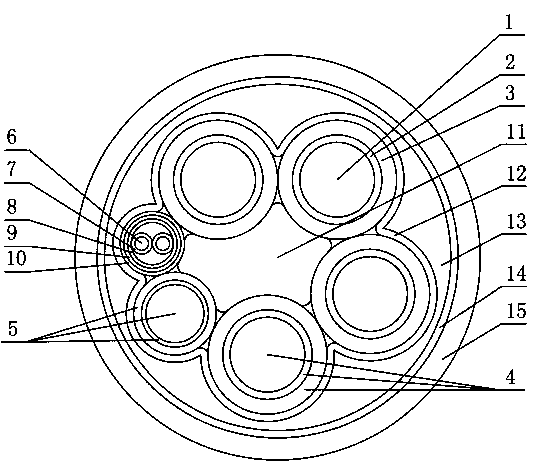

Cable for electric automobile alternating current charging system and manufacturing method of cable

InactiveCN103971848ACompact structureReasonable structureInsulated cablesInsulated conductorsInsulation layerElectrical conductor

The invention relates to a cable for an electric automobile alternating current charging system and a manufacturing method of the cable. The cable comprises a cable core, the cable core is formed by twisting a three-phase power wire core, a grounded wire core, an auxiliary wire core and a signal transmission unit, the single three-phase power wire core structurally comprises a three-phase wire core conductor, and the periphery of the three-phase wire core conductor is wrapped by a three-phase wire core insulation layer through a three-phase wire core isolation layer. The grounded wire core and the auxiliary wire core are of the structure the same as the three-phase power wire core. The signal transmission unit structurally comprises a signal control wire core conductor, and the periphery of the signal control wire core conductor is wrapped by a signal control insulation layer, wrapping tape, a signal control unit shielding layer and a wrapping layer. A gap in the middle of the twisted cable core is filled with a hemp rope, and the periphery of the cable core is wrapped by a reinforced non-woven fabric belt, an inner protective layer, a shielding layer and an outer protective layer in sequence. The cable is compact and reasonable in structure, convenient to manufacture, excellent in performance, low in cost, strong in function and good in use reliability.

Owner:ZHONGGUAN CABLE CO LTD

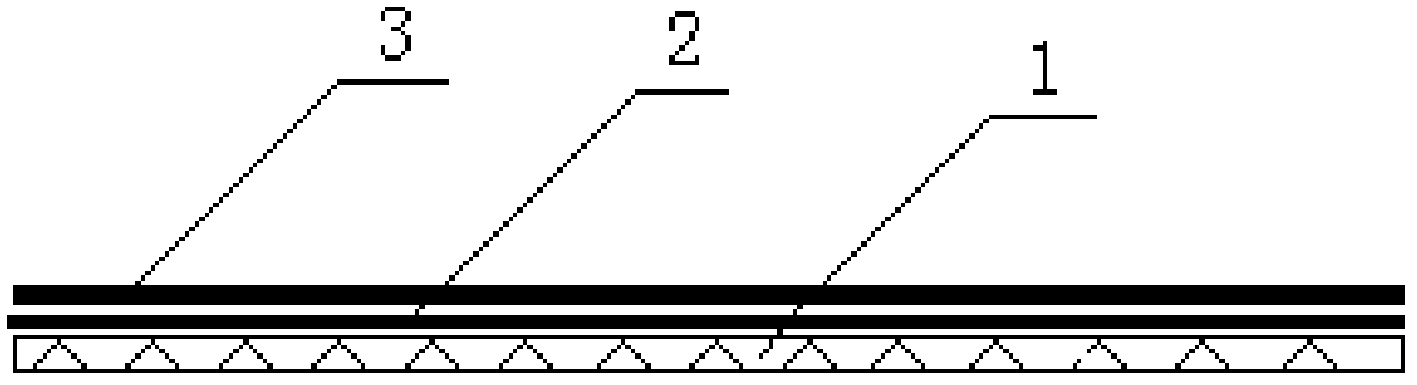

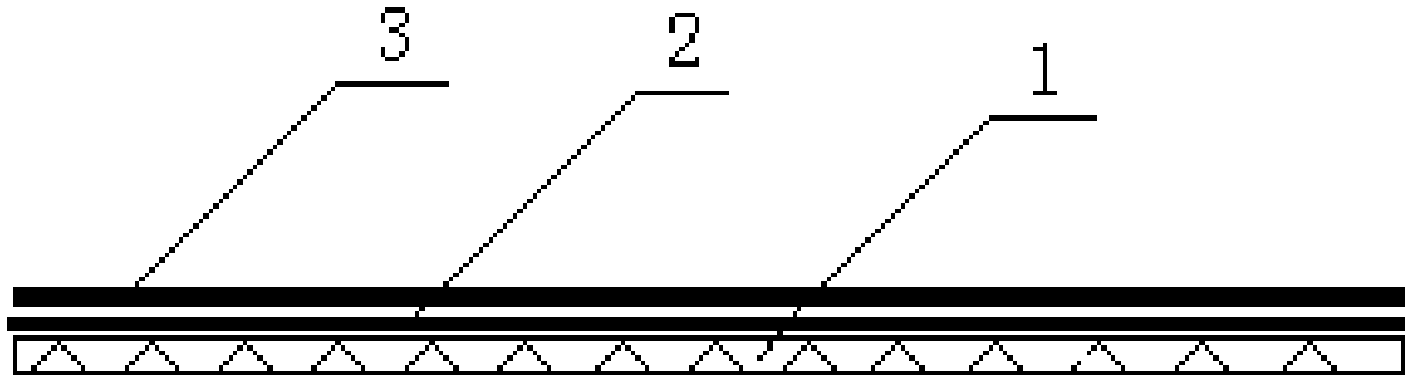

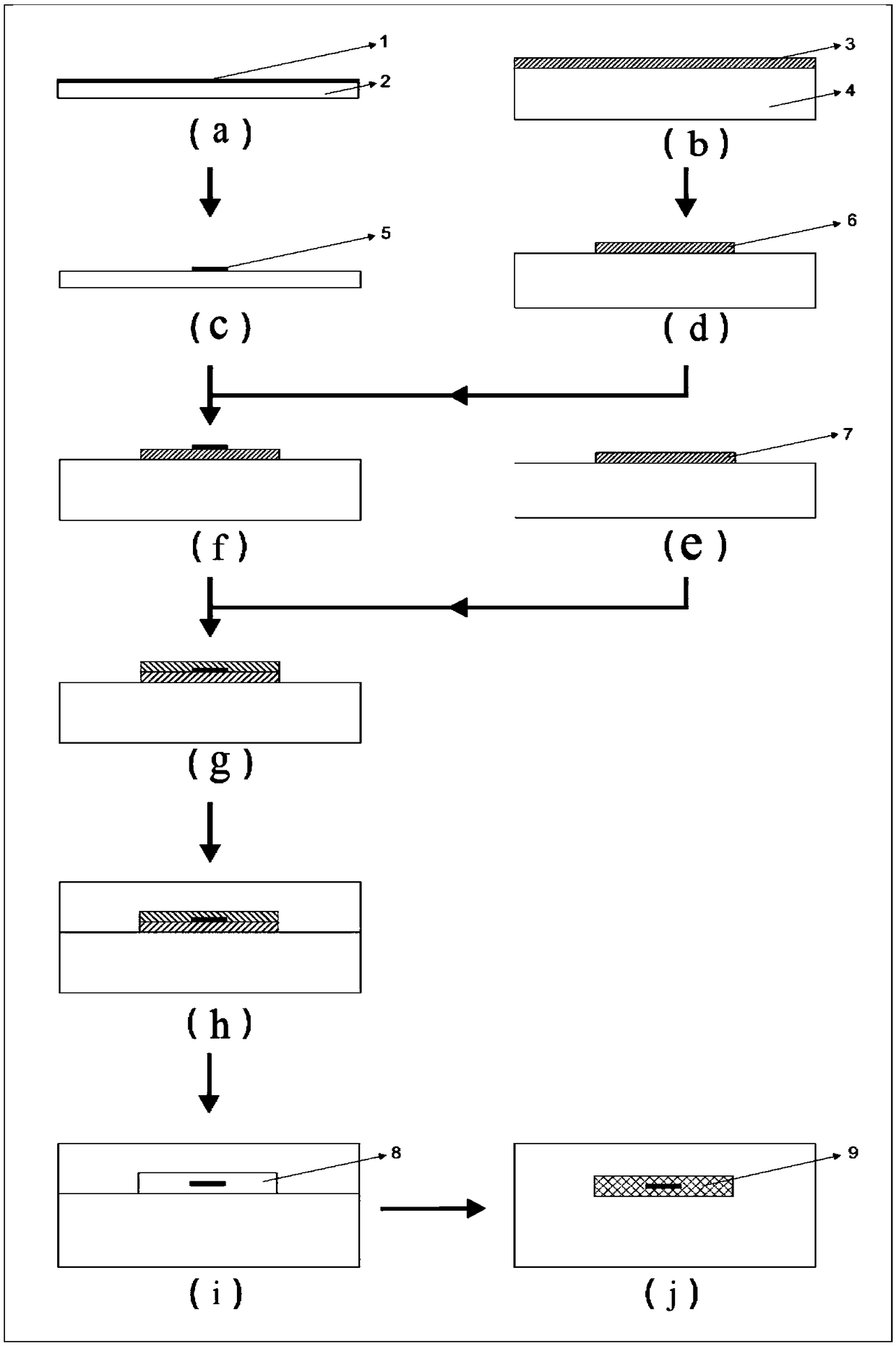

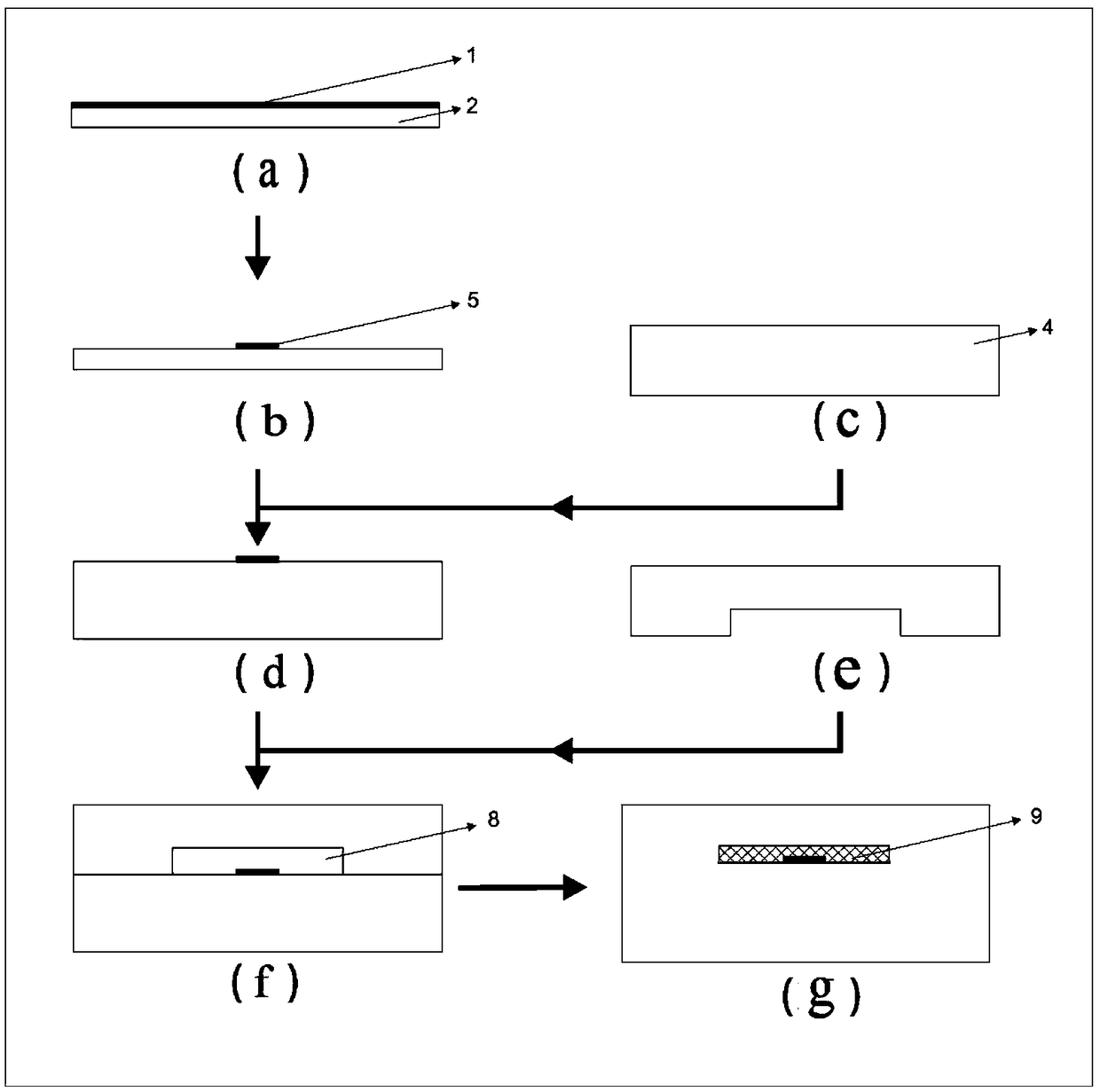

Biologically degradable pre-coating film

The invention relates to a biologically degradable pre-coating film, which comprises a substrate, an intermediate layer and a hot melt adhesive layer. The intermediate layer is arranged between the substrate and the hot melt adhesive layer, the substrate is a cellulose acetate film, the intermediate layer is made of polyethylenimine, and the hot melt adhesive layer is made of ethylene-vinyl acetate hot melt adhesive. The thickness of the substrate is 12-25 microns, the thickness of the intermediate layer is 0.01-0.03 micron, and the thickness of the hot melt adhesive layer is 12-40 microns. Since the cellulose acetate film is biologically degradable, the biologically degradable pre-coating film can be completely decomposed into CO2 and H2O under effects of microorganisms in the nature, such as bacteria, fungi and algae, and can also be used with waste paper into a pulp forming procedure to produce recycled paper. Therefore, the film is an environmentally friendly green plastic packaging material.

Owner:KANGDE XIN COMPOSITE MATERIAL CO LTD

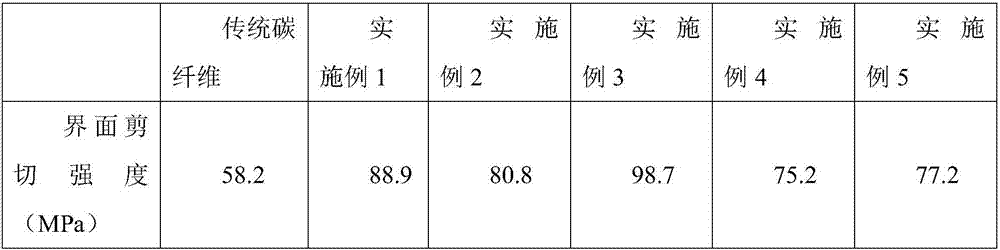

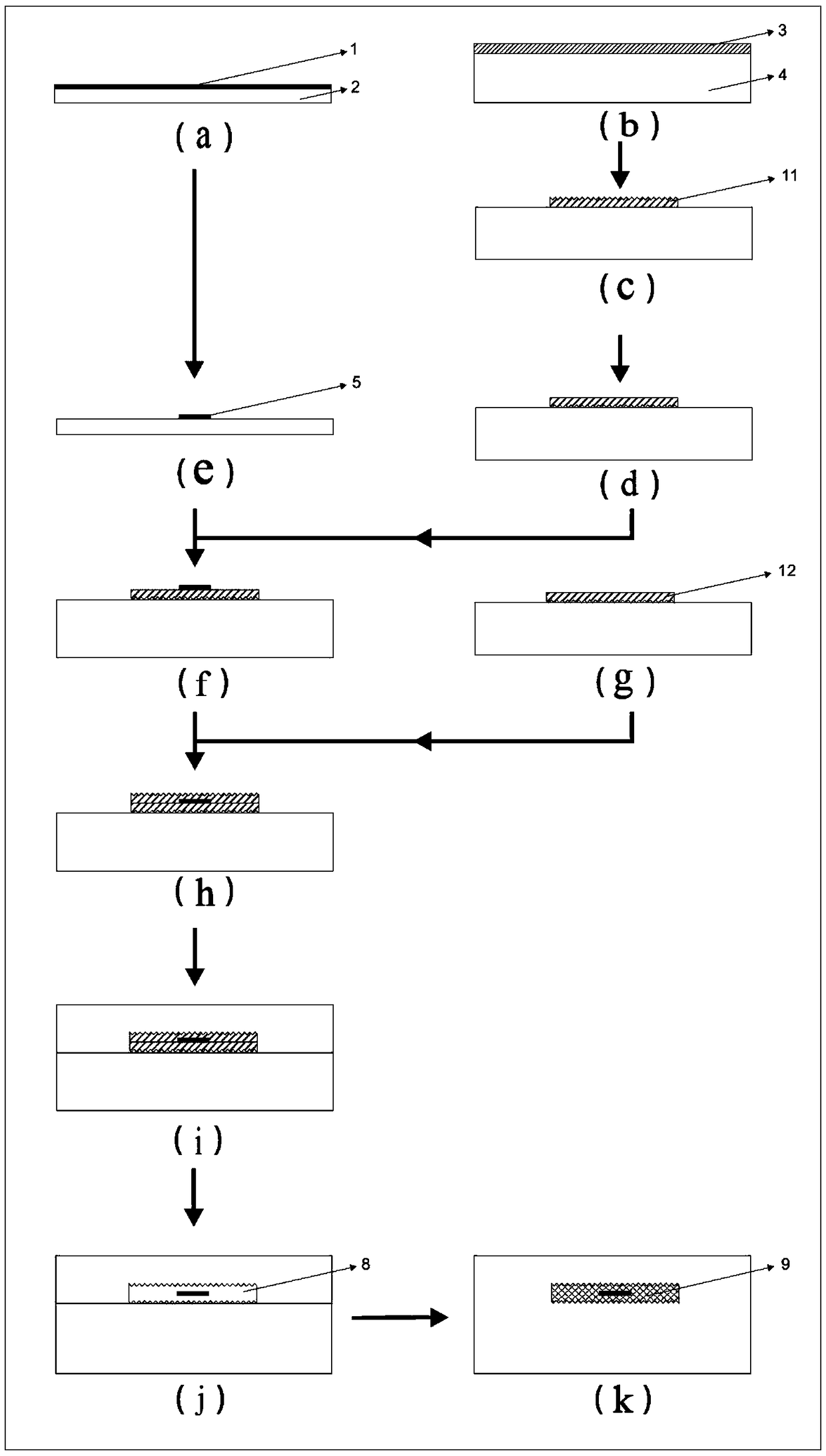

Preparation method of graphene/carbon nano tube-reinforced and toughened carbon fiber composite material

ActiveCN107059403AFew preparation stepsSimple processCarbon fibresGrapheneModified carbonStrong acids

The invention provides a preparation method of a graphene / carbon nano tube-reinforced and toughened carbon fiber composite material. The method comprises the steps of preparing a three-dimensional graphene floccule and a surface-modified carbon nano tube by using a strong acid and a breaker under the action of an oxidizing agent separately; then, carrying out high-speed shear mixing and ultrasonic dispersing processes to obtain a graphene / modified carbon nano tube sizing agent; and preparing the graphene / carbon nano tube-reinforced and toughened carbon fiber composite material through a sizing process. The prepared graphene / carbon nano tube-reinforced and toughened carbon fiber composite material has the characteristics of conductivity and thermal conductivity, high strength, high modulus, rubbing resistance and corrosion resistance of a carbon fiber, the characteristics of the tensile strength, the bending strength and the interfacial shear strength are significantly improved, the cycling processability of the carbon fiber is effectively improved, and the composite material has reinforcing and toughening characteristics.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

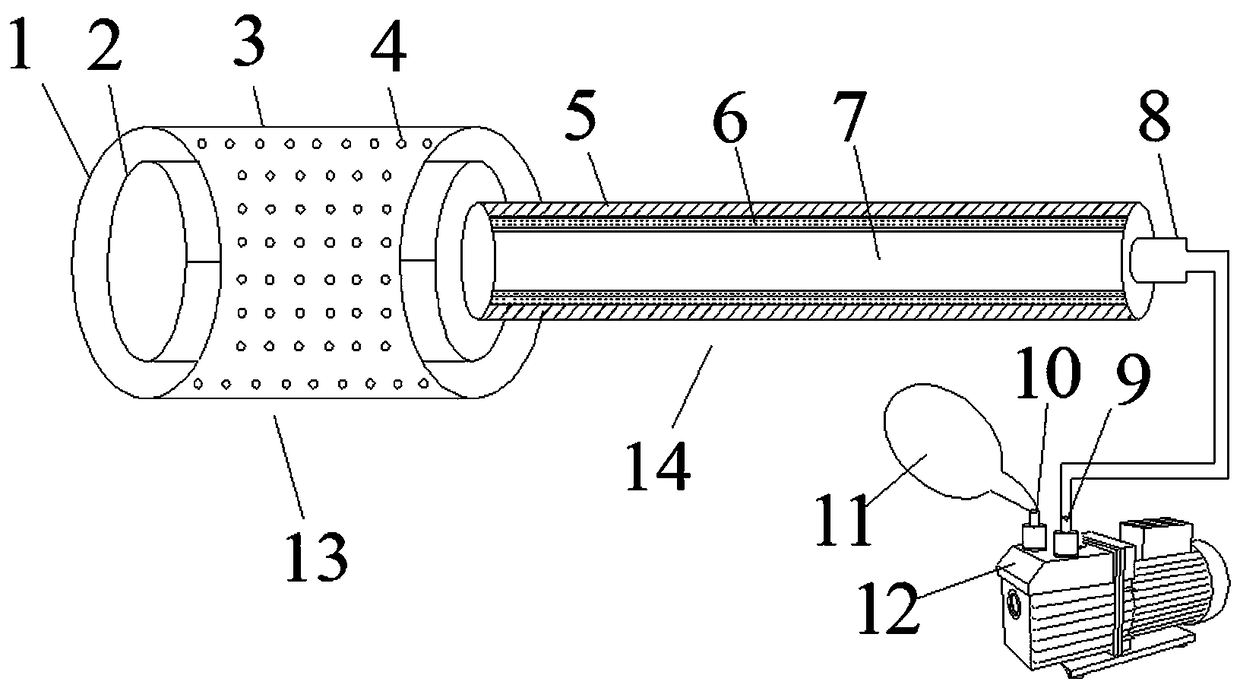

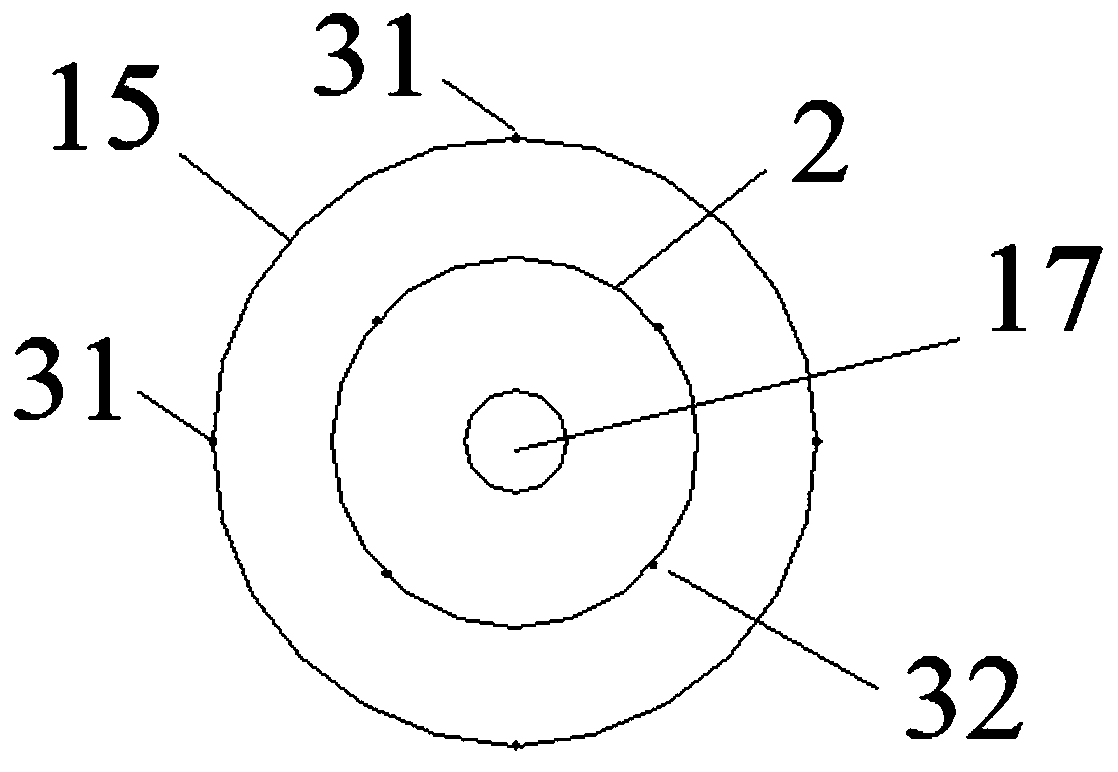

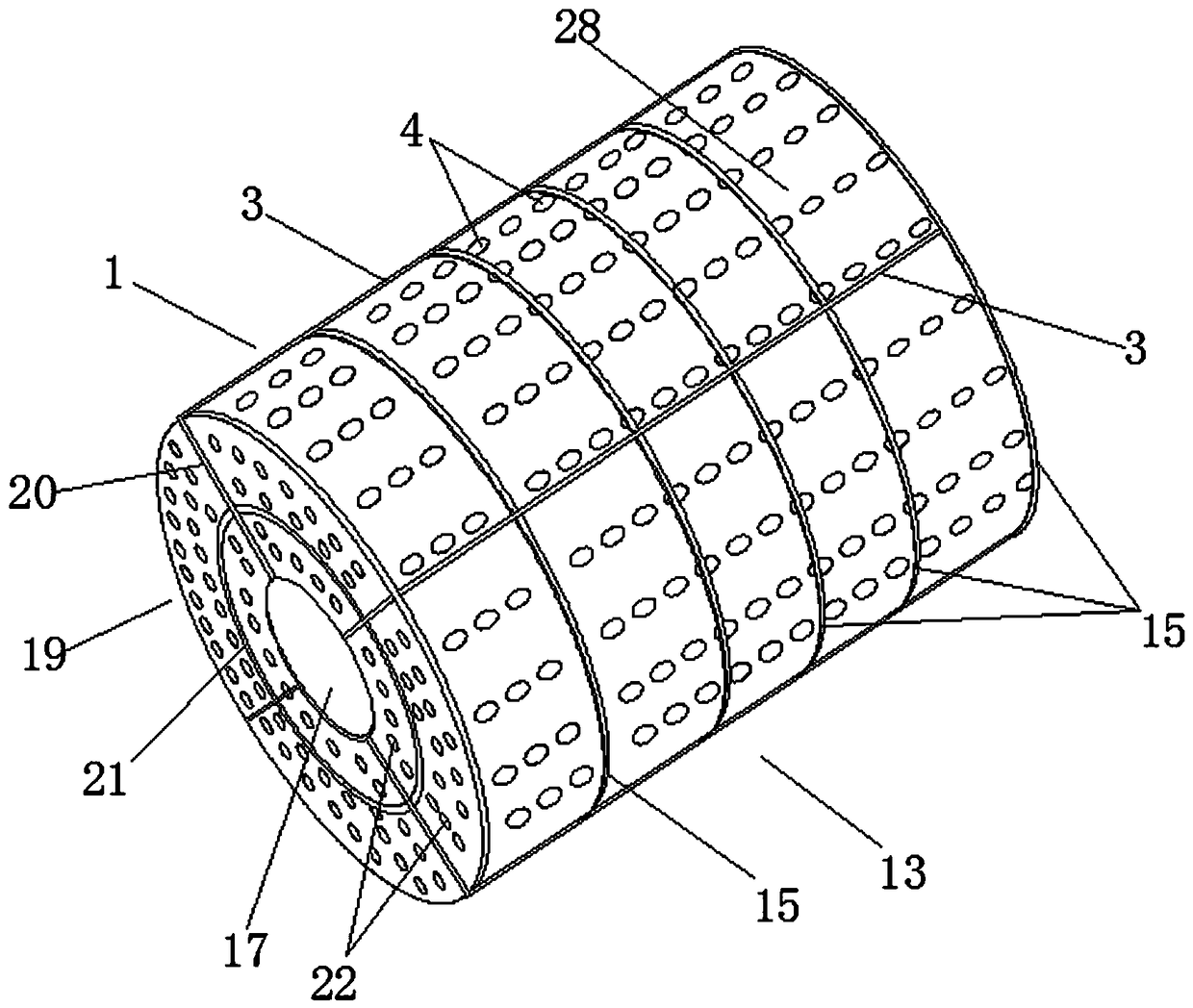

Goaf gas detection equipment and gas extraction device thereof

ActiveCN108825295ANot easy to be affected by air intakeNot easy to be blockedMining devicesGas removalEngineeringProtection layer

The invention relates to goaf gas detection equipment and a gas extraction device thereof. The gas extraction device comprises a far-end sampling gas extraction pipe. A gas extraction end head is arranged at an air inlet of the far-end sampling gas extraction pipe, and the gas extraction end head comprises an inner protective layer and an outer protective layer, wherein the inner protective layerand the outer protective layer are arranged at intervals inside and outside, and the inner protective layer and the outer protective layer are of cylindrical structures. An inner cavity of the inner protective layer communicates with the air inlet, and a plurality of radial air inlet holes penetrating through the corresponding protective layers in the radial direction are formed in the outer peripheral surfaces of the inner protective layer and the outer protective layer. The gas extraction device is provided with a sampling opening not prone to being covered and blocked by rocks, and goaf gasdetection equipment using the gas extraction device is provided.

Owner:HENAN INST OF ENG +1

Protective coating liquid of engine

The invention discloses protective coating liquid of an engine, and a preparation method and application of the protective coating liquid. The protective coating liquid is prepared from polytetrafluoroethylene, a dispersing agent, base oil, viscosity index improver and an adhesive. The protective coating liquid is mixed with lubricating oil for protecting the engine. The protective coating liquid has the advantages that pits are filled, worn parts are repaired, lubrication and wear resistance are achieved, the cylinder pressure is recovered, the oil consumption is lowered, tail gas emission is optimized, the repair effect and the lubrication effect are good, and the overall performance of vehicles can be improved.

Owner:山东山河环保科技有限公司

Modified nano material lubricating oil

InactiveCN105886080AIncrease motivationReduce equipment failure rateBase-materialsChemistryPetroleum

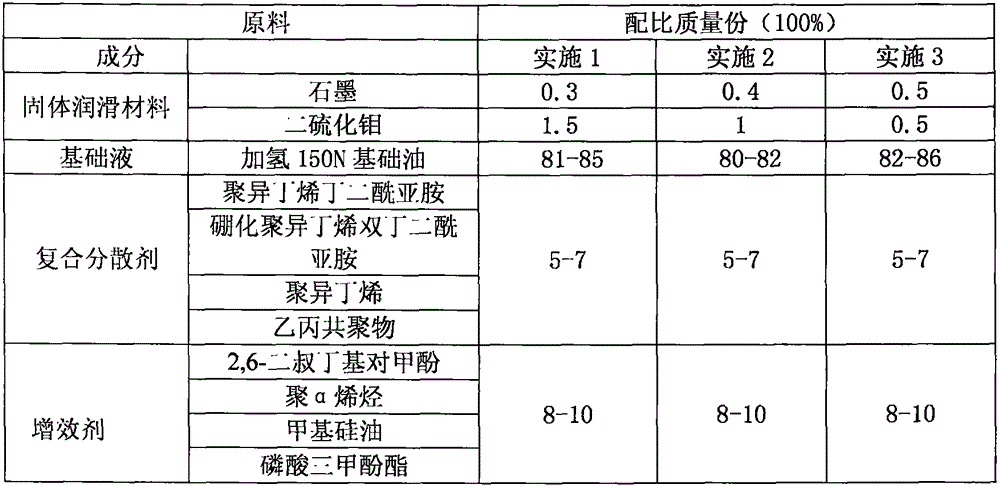

The invention relates to modified nano material lubricating oil which is prepared from hydrogenated base oil, a compound dispersant, a solid lubricant agent and a synergist. The hydrogenated base oil is 150 N or 250 N base oil, the solid lubricant agent is prepared from graphite below 3 um and molybdenum disulfide, the compound dispersant is prepared from polyisobutylene succinimide, boronized polyisobutylene-bis-succinimide, polyisobutylene, an ethylene-propylene copolymer, synthetic petroleum sodium sulfonate, polymethacrylate and poly-alpha olefin through compounding, and the synergist is an extreme-pressure agent, an oxidation and corrosion inhibitor, a defoaming agent or a tackifier. The lubricating oil contains, in percentage, 50-80% of the hydrogenated base oil, 0.5-1% of graphite, 1-5% of molybdenum disulfide, 6-12% of the compound dispersant and 6-15% of the synergist. The product can reduce the mechanical friction, repair abraded portions and prolong the service life of equipment, and the lubricating oil has the good effect of oil saving rate up to 5-15% when applied to a vehicle engine.

Owner:SHANGHAI RUNLIDE MATERIAL TECH CO LTD

Silicon nitride circuit substrate material and preparation method thereof

ActiveCN110395989AHigh temperature resistantImprove thermal shock resistanceSemiconductor/solid-state device detailsSolid-state devicesFiberCompression molding

The invention discloses a silicon nitride circuit substrate material and a preparation method thereof and belongs to the technical field of circuit substrate materials. The silicon nitride circuit substrate material is prepared from the following raw materials in parts by weight: 50-60 parts of silicon nitride, 15-25 parts of a carbon fiber, 5-8 parts of a dispersant, 6-10 parts of a surfactant, 10-15 parts of a sintering aid, 3-8 parts of a coupling agent and 160-200 parts of absolute ethyl alcohol. The silicon nitride circuit substrate material is prepared from silicon nitride and the carbonfiber as raw materials which are compounded with the dispersant, the surfactant, the sintering aid, the coupling agent and the like through process steps of mixing, soaking, stirring, spray granulation, compression molding, sintering, vacuum thermal treatment, and the like, and the material has good comprehensive properties; the bending strength is 23.2MPa or greater, the impact strength is 17.3KJ / cm<3>, the heat conduction coefficient is 95.8W / (m*K) or greater, and the heat conduction coefficient is up to 98.9W / (m*K) at most; and by adopting the process disclosed by the invention, the pass percent is up to 96.3%, the pass percent of the material is remarkably increased, the raw materials are saved, and the production cost can be lowered.

Owner:国网河南省电力公司方城县供电公司

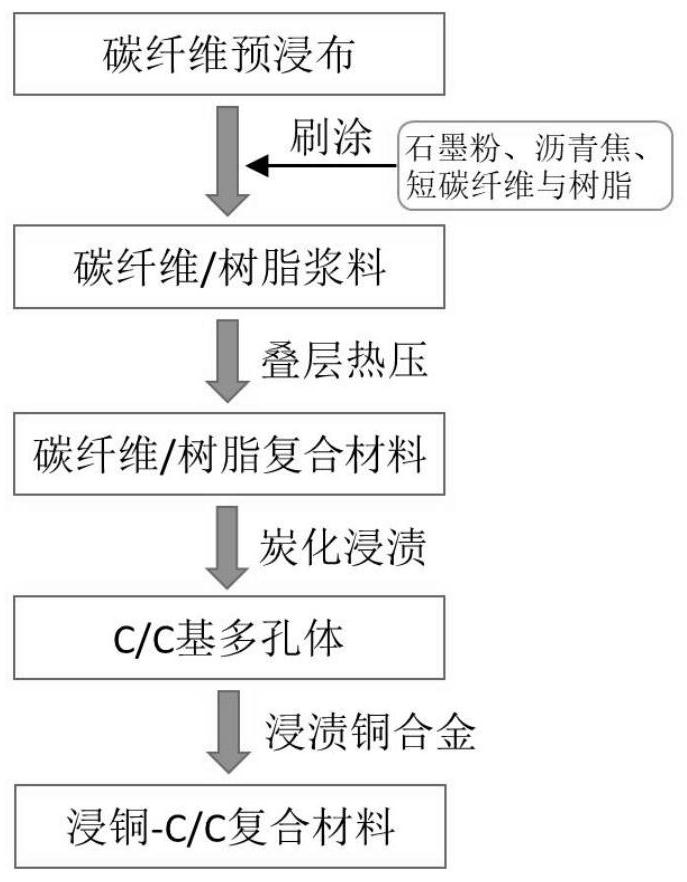

Preparation method of pantograph slide plate for high-speed train

ActiveCN111960839AImprove performancePrevents clogging effectsCeramicwarePower current collectorsCarbon compositesFiber

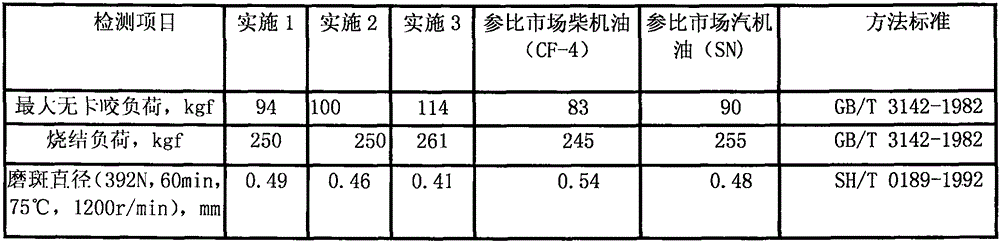

The invention relates to a preparation method of a pantograph slide plate for a novel low-cost copper-carbon / carbon-impregnated composite material. The material is a high-conductivity high-strength self-lubricating material. The preparation method comprises the following steps: designing slurry with special components, then brushing the modified carbon fiber prepreg cloth with the modified carbonfiber prepreg cloth in a brushing manner, then performing hot pressing to prepare a C / C porous body, and finally, dipping the copper alloy so that the copper leaching C / C composite material is obtained. Vapor deposition densification does not need to be carried out, and the obtained product has excellent performance, and especially has much better wear resistance than the existing product.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

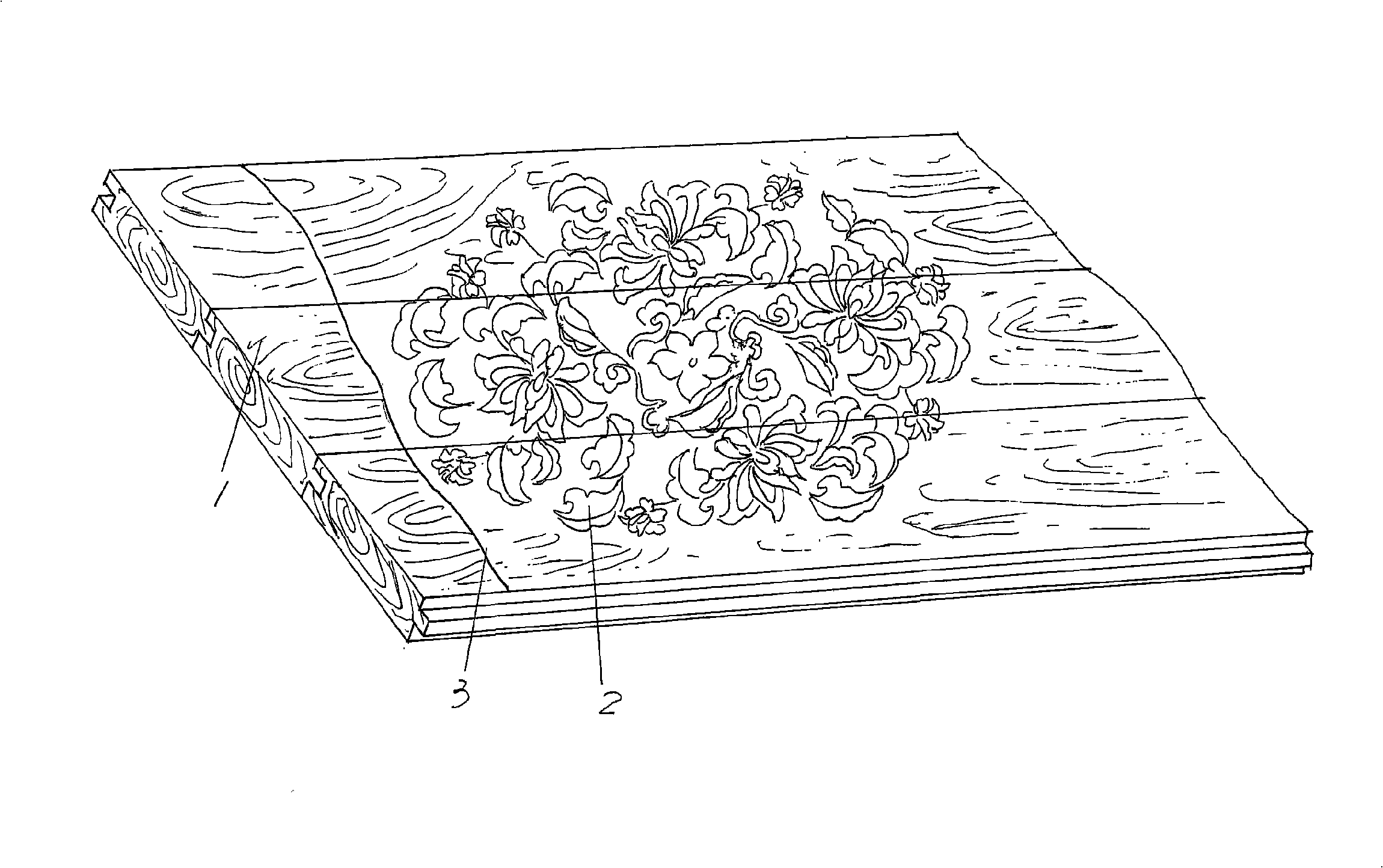

Ironing picture wooden floor and its manufacturing technique

InactiveCN101307639AFix boring colorsAvoid dullnessDecorative surface effectsWood working apparatusSolid woodEngineering

The invention relates to purography solid wood flooring and a technique for producing the same, belonging to the solid wood flooring used for architectural decoration and the technique for producing the same. The purography solid wood flooring comprises a solid wood base plate and is characterized in that: a purography paper pattern layer is printed on the surface of the solid wood base plate by means of transfer printing, and an abrasion resistant protective layer is coated on the surface of the solid wood base plate which is provided with the purography paper pattern layer by means of transfer printing. The purography solid wood flooring and the technique have the advantages that: the technique can partially preserve the natural beauty of the texture and the color of the solid wood flooring, simultaneously solves the problem of monotonous color and wood grain of the prior solid wood flooring and solves the problem of stiffness and debility of printed flooring as well, and makes the pattern have bright color and rich hierarchy; due to the high abrasion resistance of aluminum trioxide abrasion-resistant impregnated paper, the purography solid wood flooring can effectively play a part in antifriction and is very favorable for cleaning during the use process.

Owner:陆旻

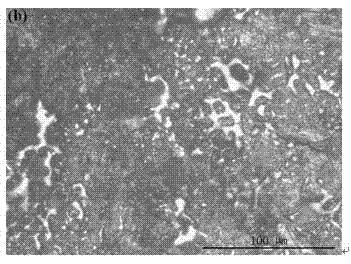

Nitralloy cast iron air cylinder sleeve and preparing method thereof

The invention belongs to a nitralloy cast iron air cylinder sleeve produced through centrifugal casting and a preparing method thereof. The air cylinder sleeve is prepared from, by weight, 3.0%-3.6% of C, 2.2%-2.8% of Si, 0.1%-0.4% of P, 0.12% or less of S, 0.5%-1.0% of Mn, 0.2%-0.5% of Cu, 0.06% or less of Ti, 0.04% or less of V, 0.006%-0.015% of N and the balance Fe. According to the air cylinder sleeve prepared through the method, the metallographic structure is composed of flake graphite, pearlite (the amount is larger than 95%), a small amount of ferrite and a small amount of dispersely-distributed carbide; the tensile strength is larger than 300 Mpa, and the elasticity modulus is larger than 100 GPa; compared with an ordinary gray cast iron air cylinder sleeve, the dimension is more stable, and the strength performance is higher; the nitralloy cast iron air cylinder sleeve has the advantages of being good in abrasion resistance, wear resistance, wear reduction performance and cutting performance and the like.

Owner:ZYNP GRP

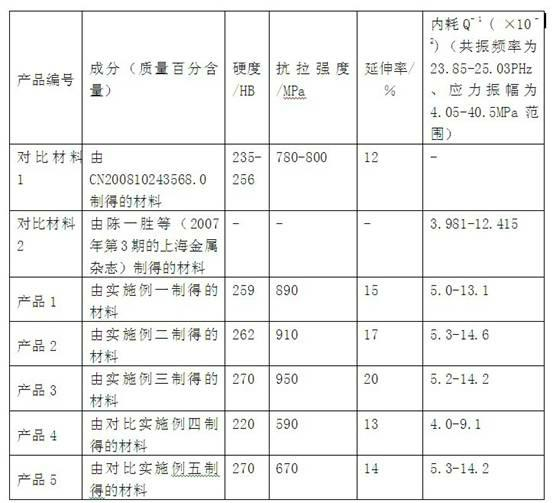

Damping wear-resistant aluminum alloy material and preparation method thereof

InactiveCN102051554AEasy to enhance and toughenImprove the strengthening and toughening effectFiberCarbon fibers

The invention discloses a damping wear-resistant aluminum alloy material and a preparation method thereof. In the damping wear-resistant aluminum alloy material, aluminum alloy serves as a matrix; steel wire rolls and carbon fibers are distributed in the matrix; the diameter of each steel wire roll is 10 to 15 centimeters; each steel wire has a rectangular section and the section size is 0.1-0.4 mm*0.5-1.5 mm; the weight ratio of the steel wires to the carbon fibers is 25-30:1; and the steel wires and the carbon fibers account for 20 to 40 percent of the volume of the material. The damping wear-resistant aluminum alloy material prepared by the method has high toughness, wear resistance, a simple process and low production cost.

Owner:金湖中博物联网科技有限公司

Technique for jet printing long term anti-corrosive paint on cable bridge rack

InactiveCN101097036AExtended service lifeSave human effortCorrosion preventionPipe protection against corrosion/incrustationFluorocarbonLife length

The invention discloses a method to spray long period anticorrosion paint for cable crane span structure, which is characterized by the following: basing on original cable crane span structure spraying paint craft; spraying fluorocarbon resin substratum, mesosphere and surface course. This invention possesses the advantages of high brightness, high strength and long durability.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Preparation method for high-temperature-resistant insulation paper

InactiveCN111088715ASmall water absorptionImprove radiation resistancePlastic/resin/waxes insulatorsSpecial paperFiberCarbon fibers

The invention relates to a preparation method for high-temperature-resistant insulation paper, belonging to the technical field of insulation paper materials. The preparation method comprises the following steps: blending polyimide with silicon nitride, and carying out electrostatic spinning so as to prepare polyimide fibers; with propylene as a carbon source and FeCl3.6H2O as a catalyst, carryingout in-situ vapor deposition on the polyimide fibers by adopting a chemical vapor deposition method so as to grow carbon fibers, mixing the carbon fibers with softwood kraft pulp, and carrying out pulping and wet molding so as to prepare the high-temperature-resistant insulation paper. The polyimide fibers have high strength, high modulus, low water absorption property, high-temperature resistance, excellent radiation resistance, excellent oxidation resistance, excellent acid corrosion resistance and excellent dielectric property; the carbon fibers have the characteristics of high temperatureresistance, friction resistance, electric conduction, heat conduction, corrosion resistance and the like, is fibrous and soft in appearance, and can be processed into various fabrics; the graphite microcrystalline structure of the carbon fibers has preferred orientation along a fiber axis, so the carbon fibers have high strength and modulus along a fiber axis direction; thus, the prepared insulation paper has good high-temperature resistance and strength performance.

Owner:李可禛

Shielding material

InactiveCN101513783AGood physical propertiesSelf-degradingSynthetic resin layered productsProtective garmentEngineeringPhysical property

The present invention relates to a shielding material and also relates to a shielding cloth material. The shielding material has a laminar structure and comprises conductive cloth, TPU film and release material layer. The TPU film and release material layer are adhibited on two surfaces of conductive cloth through two adhesive layers. The TPU film is provided with a printing layer which is installed on the surface that faces to the conductive cloth. The shielding cloth material comprises the conductive cloth. The surface of conductive cloth is attached with the TPU film which is provided with the printing layer that is installed on the surface facing to the conductive cloth. Because the TPU has excellent air permeability and is water-proof, the people feel comfortable when the TPU is used as clothes and the dirt is easily eliminated. The shielding material is suitable for the group with shielding requirement, and is especially suitable for the group with electromagnetic wave shielding requirement. The present invention provides an electromagnetic wave shielding material with the advantages of excellent physical property and environment protection. The invention also provides the shielding cloth material which is suitable for environment protection.

Owner:DONGGUAN WANFENG NANOMETER MATERIALS

A preparation method and a product of a fatigue-resistant flexible electronic device

ActiveCN109231149AIncrease deformation spaceReduce stress concentrationDecorative surface effectsChemical vapor deposition coatingFlexible electronicsFilm structure

The invention belongs to the technical field of flexible electronic devices, and particularly discloses a preparation method and a product of a fatigue-resistant flexible electronic device. The methodcomprises the following steps: S1, engraving the shape structure of the electrode material on the auxiliary substrate to obtain the electrode patterned film structure; S2, constructing a movable channel of an electrode material around that electrode patterned film structure; S3, injecting a flexible material into that movable channel, and packaging the inlet and outlet of the movable channel to obtain a fatigue-resistant flexible electronic device. The product comprises a flexible cladding layer, a movable channel arranged inside the flexible cladding layer, a flexible material filled in themovable channel and an electrode material arranged inside the movable channel. The invention provides the movable space of the flexible electrode when stretching by embedding a channel when packaging,reduces the constraint of the packaging layer, improves the tensile property and fatigue resistance of the flexible electronic device, and has long service life.

Owner:HUAZHONG UNIV OF SCI & TECH

High-temperature-resistant anti-corrosive coating and preparation method

InactiveCN105295462AAnti-frictionImpact resistantAlkali metal silicate coatingsAnti-corrosive paintsLithium hydroxideSports equipment

Provided are a high-temperature-resistant anti-corrosive coating and a preparation method. The high-temperature-resistant anti-corrosive coating comprises, by weight parts, 812 parts of potassium silicate solution, 32 parts of lithium hydroxide solution, 337 parts of CH3Si (OCH3), 68 parts of water, 139 parts of wollastonite, 37 parts of boron nitride, 41 parts of fine grain aluminum oxide, 35 parts of superfine zinc oxide and 38 parts of titanium oxide. The high-temperature-resistant anti-corrosive coating can be used for base layer painting of automobiles, aerospace, toys and outdoor sports equipment. The high-temperature-resistant anti-corrosive coating has the advantages of being convenient to transport and construct and non-toxic, having no foreign smell and being free of pollution and has the advantages of being high in coating hardness and resistant to friction, impact, high temperature, corrosion, aging, weather, radiation, salt fog and water.

Owner:景晓丽

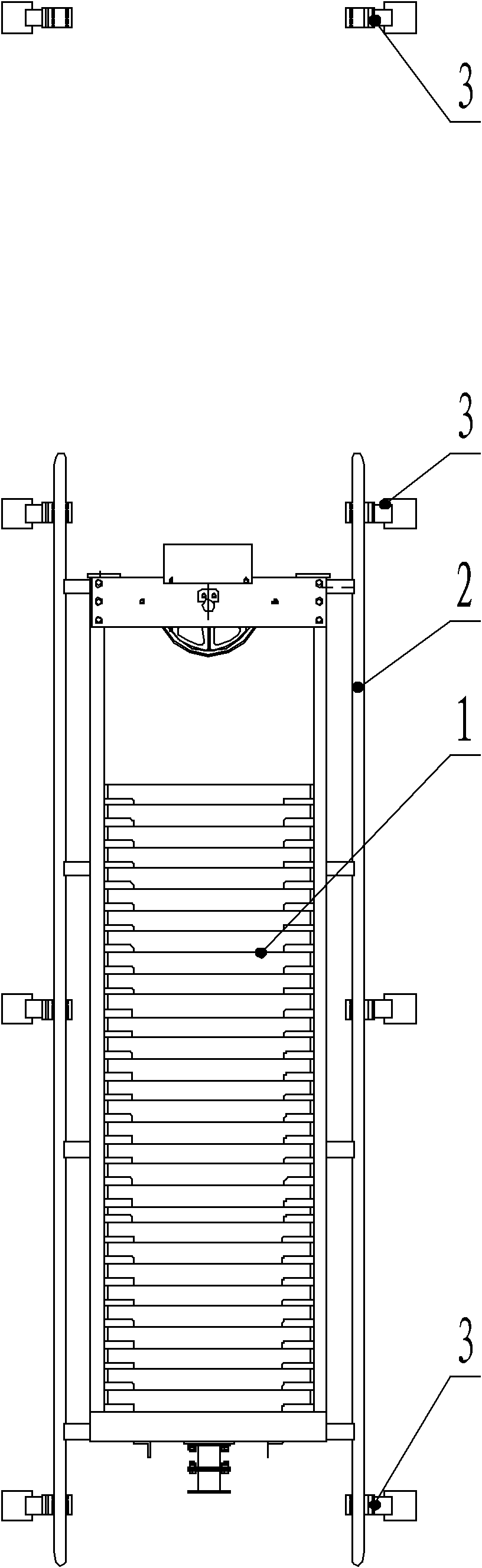

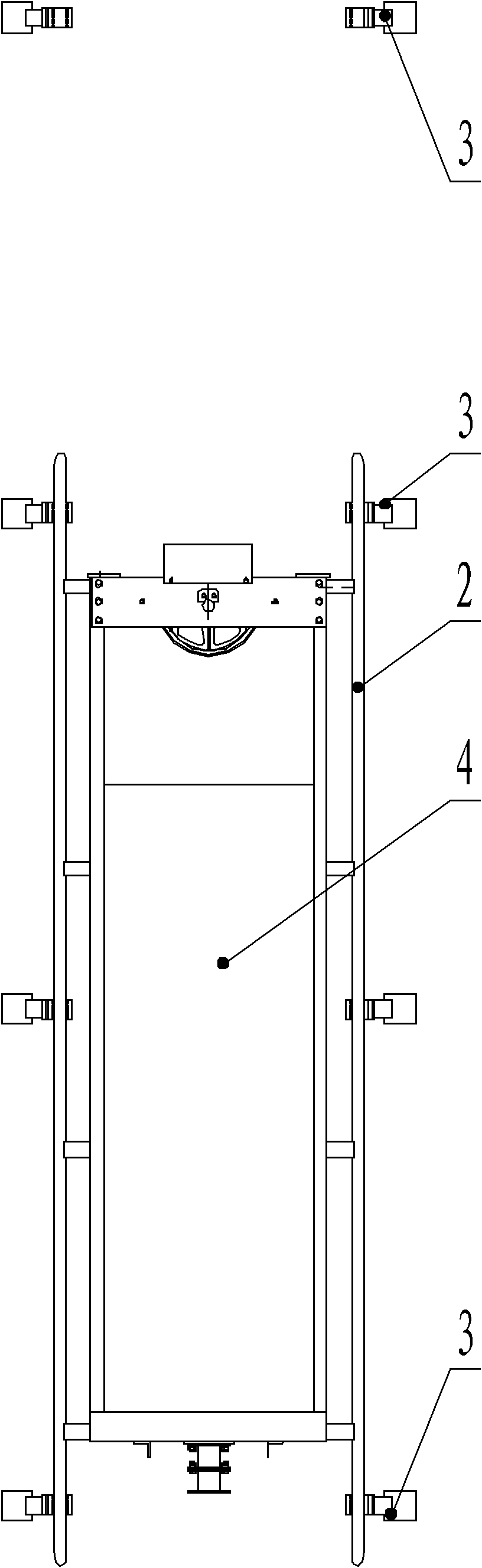

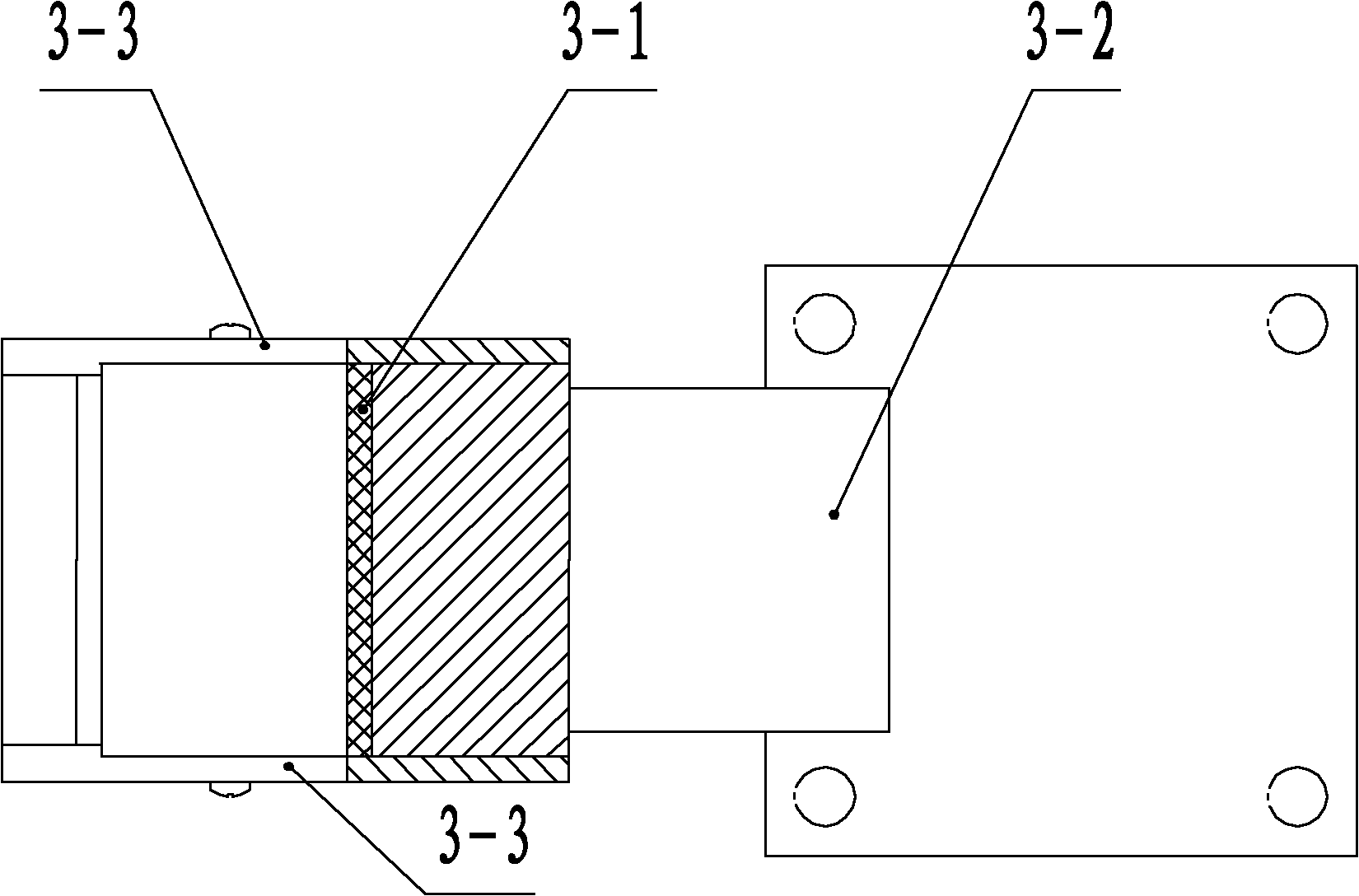

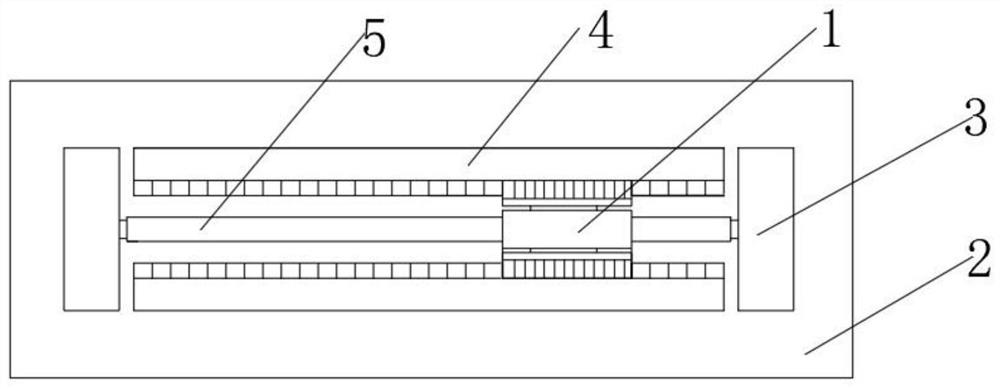

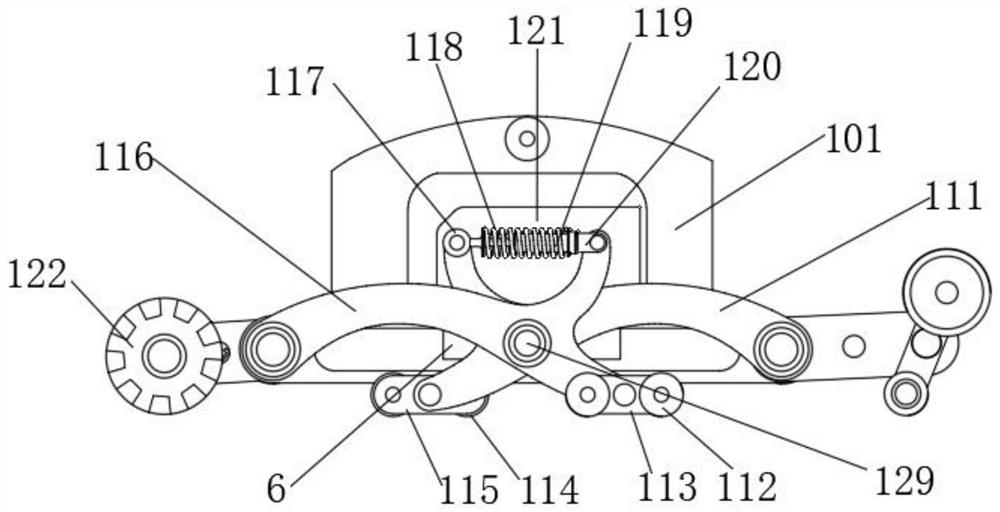

Trackless counter weight assembly and trackless lift car

InactiveCN102126663ASimple structureReduce length dimensionElevatorsBuilding liftsEngineeringMechanical engineering

The invention discloses a trackless counter weight assembly and a trackless lift car. The trackless counter weight assembly comprises a counter weight housing assembly, wherein a guide rod used for guiding is respectively arranged at the two sides of the counter weight housing assembly, and a plurality of guide sleeve assemblies which are in a sliding fit with the guide rods are arranged on the side wall of an elevator. The trackless lift car comprises a lift car assembly, wherein the guide rod used for guiding is respectively arranged at the two sides of the lift car assembly, and a plurality of guide sleeve assemblies which are in a sliding fit with the guide rods are arranged on the side wall of the elevator. By adopting the trackless counter weight assembly and the trackless lift car in the technical scheme in the invention, a counter weight assembly and a lift car move up and down along a straight lie by utilizing the sliding fit between the guide rods and the guide sleeve assemblies, each guide rod is short, the processing process is simple, and linear error is small, thus bump and noise produced during the process that the counter weight assembly and the lift car are lifted as a track is long and joints are excessive can be avoided, the trackless counter weight assembly and the trackless lift car are convenient to transport and mount, components such as a special track, track support, special track pressure guide plate and the like can be saved, and the product cost can be reduced.

Owner:邬建勋 +1

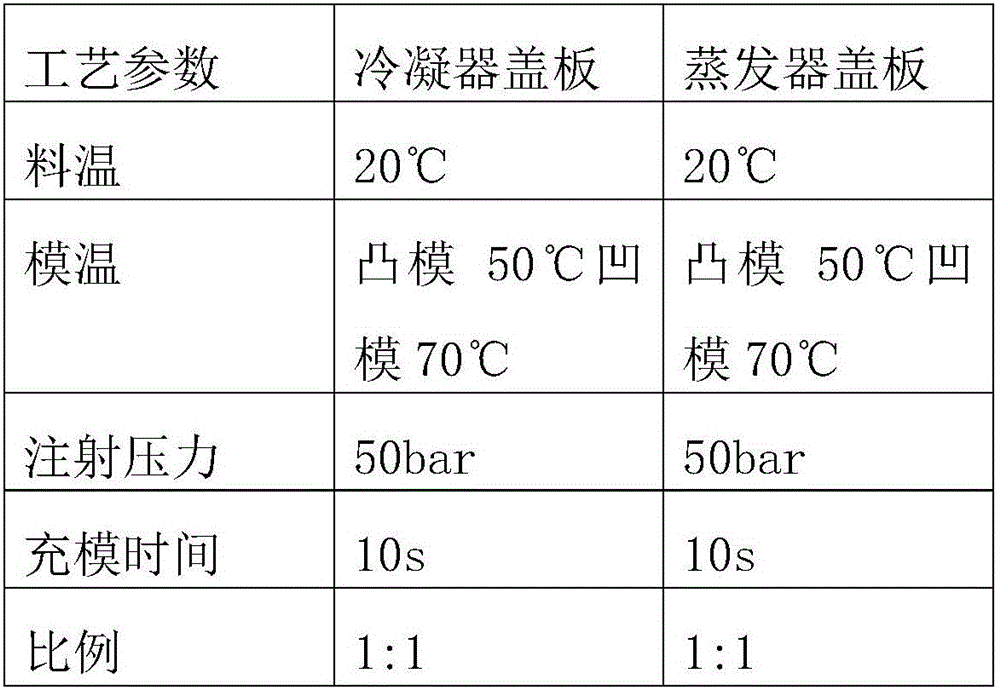

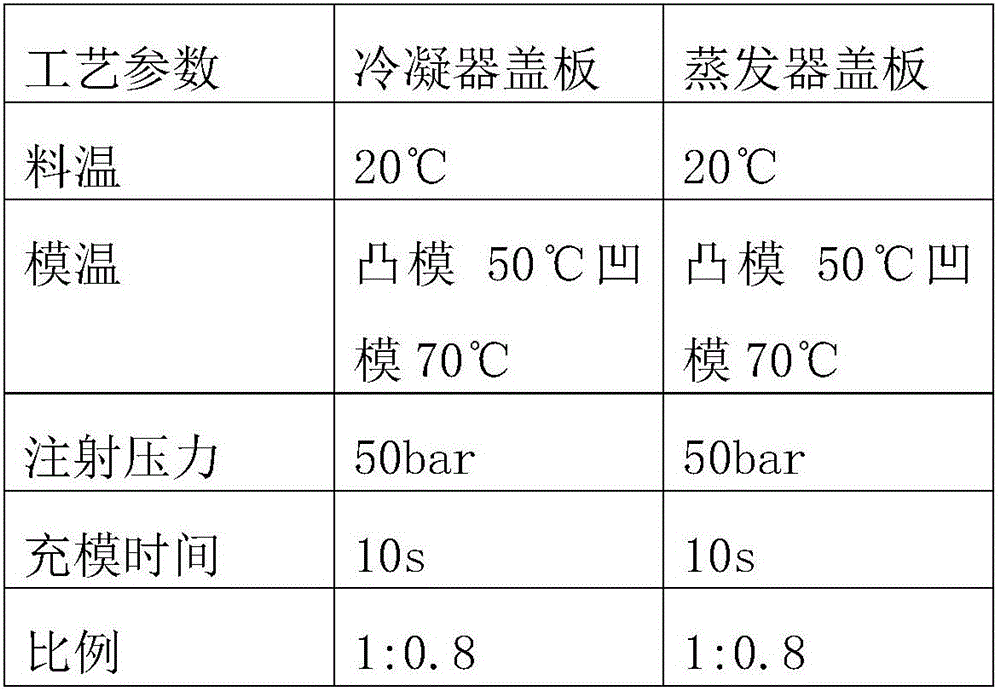

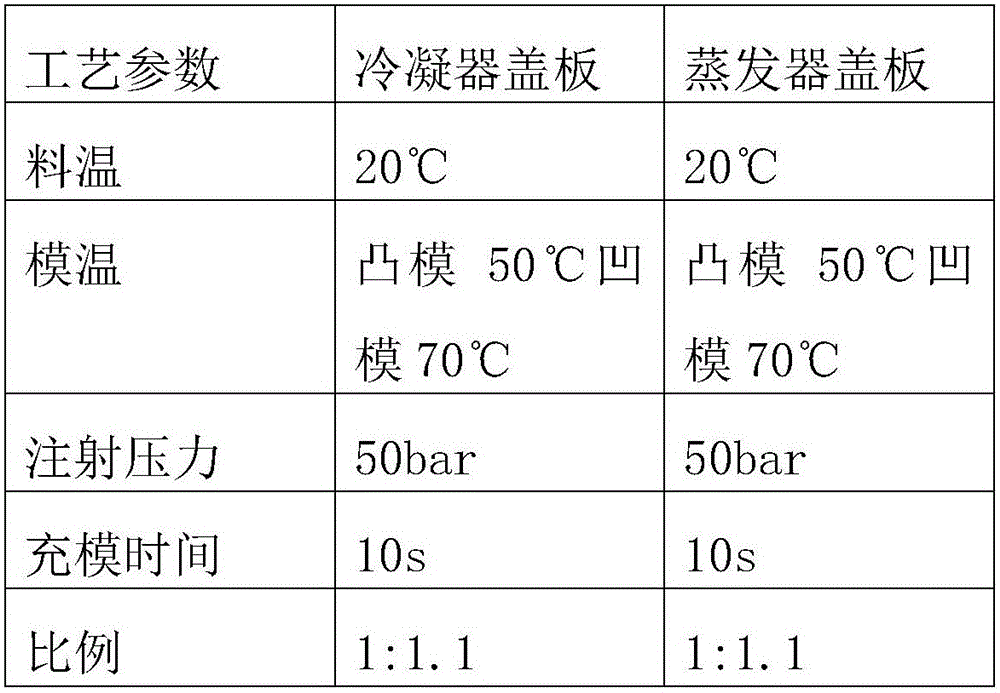

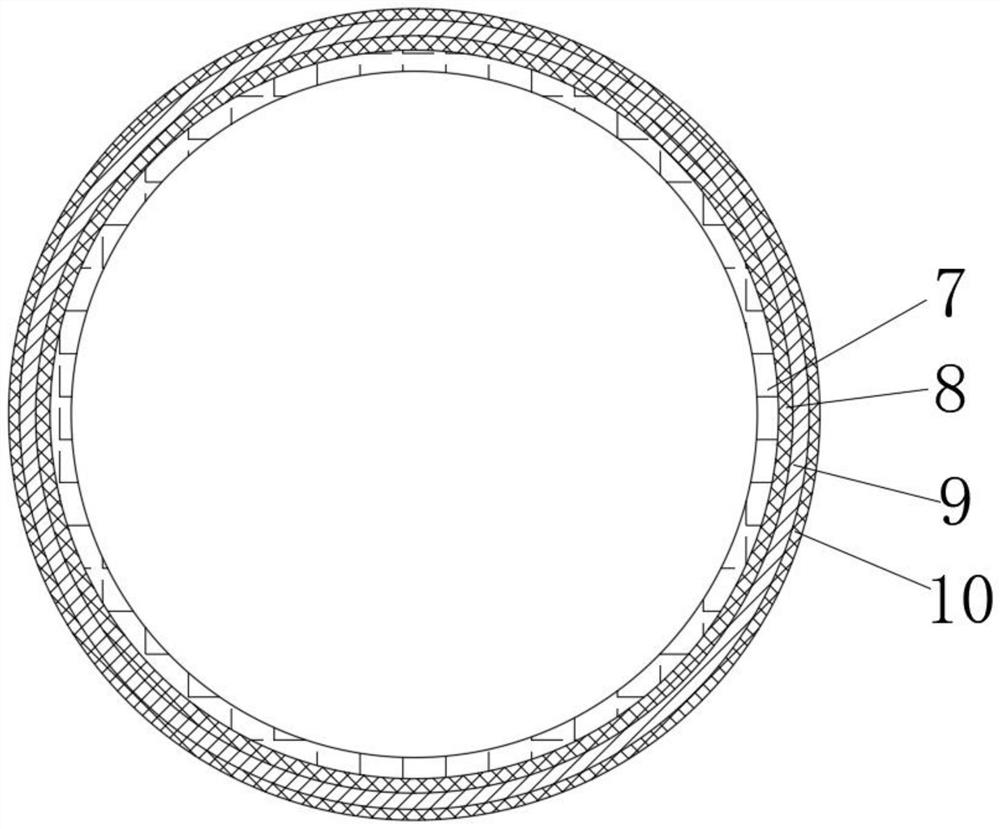

DCPD (dicyclopentadiene) composite material for cover plates of air conditioners for vehicles

InactiveCN106397741AHeat resistantHas acid and alkali resistanceAir-treating devicesVehicle heating/cooling devicesHeat resistanceMass ratio

The invention relates to air conditioner accessories for vehicles, in particular to a DCPD (dicyclopentadiene) composite material for cover plates of air conditioners for vehicles. According to the scheme, the DCPD composite material is prepared by mixing a material A and a material B according to a mass ratio that the A to the B is equal to 0.5 to 1.5, wherein the material comprises the following components in parts by weight: 85 to 98 parts of DCPD, 1 to 8 parts of a catalyst, 0.1 to 4 parts of a stabilizer and 0.1 to 4 parts of an additive; and the material B comprises the following components in parts by weight: 85 to 98 parts of DCPD, 5 to 10 parts of an activating agent and 0.5 to 5 parts of a regulator. The DCPD composite material for the automobile air conditioner cover plates, provided by the invention, has excellent performance, such as heat resistance, acid and alkali resistance, friction resistance and the like, has high insulativity, and can be used for manufacturing the cover plates of the air conditioners for the vehicles, wherein the cover plates include cover plates for automobile air conditioners, cover plates for train air conditioners, cover plates for subway air conditioners and the like.

Owner:HUNAN VAQOUNG ELECTRIC

Slurry containing natural stone powder as well as preparation method and application of slurry

InactiveCN107325671AHeat resistantBeautiful and elegantFireproof paintsRosin coatingsEmulsionCombustion

The invention relates to slurry containing natural stone powder as well as a preparation method and an application of the slurry. The slurry comprises raw materials in parts by weight as follows: 40-50 parts of the natural stone powder, 20-30 parts of a tackifying emulsion, 4-6 parts of silica sol, 35-45 parts of modified acrylic resin and 5-10 parts of triisopropanolamine. When the slurry prepared from the natural stone powder and other components through scientific proportioning is applied to a wall surface, the wall surface can have the excellent properties of heat resistance, sound insulation, friction resistance, corrosion resistance, waterproofing, dampproofing, non-combustion, environmental protection and the like, and the slurry can be applied to decoration of various wall surfaces.

Owner:北京弘信润达装饰有限公司

Continuous carbon fiber winding composite reinforced MPP electric power pipe and preparation method thereof

The invention discloses a continuous carbon fiber winding composite reinforced MPP electric power pipe and a preparation method thereof. The continuous carbon fiber winding composite reinforced MPP electric power pipe comprises an inner pipe, an insulating layer, an outer pipe and a carbon fiber layer, the insulating layer is arranged between the inner pipe and the outer pipe, the outer surface of the outer pipe is wrapped by the carbon fiber layer, and the outer pipe is prepared from, by weight, , 60-80 parts of isotactic polypropylene resin, 5-10 parts of block copolymerized polypropylene, 3-5 parts of olefin block copolymerized elastomer OBC, 0.5-2 parts of heat-resistant insulating orange master batch and 10-20 parts of ultra-high molecular weight polyethylene resin. The inner pipe is prepared from, by weight, 50-65 parts of modified polypropylene, 3-4 parts of a compatilizer, 2-3 parts of a stabilizer and 1.5-3 parts of a flame retardant, the inner pipe is obtained through extrusion of an extruder, the outer layer of the inner pipe is coated with waterproof glue so that the insulating layer can be bonded, the outer surface of the insulating layer is covered with the outer pipe, the carbon fiber layer is wound on the surface of the outer pipe through a carbon fiber winding machine, and a finished product is obtained.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Damping wear-resistant copper alloy material and preparation method thereof

The invention discloses a damping wear-resistant copper alloy material and a preparation method thereof. In the damping wear-resistant copper alloy material, copper alloy serves as a matrix; steel wire rolls and carbon fibers are distributed in the matrix; the diameter of each steel wire roll is 10 to 15 centimeters; each steel wire has a rectangular section and the section size is 0.1-0.4 mm*0.5-1.5 mm; the weight ratio of the steel wires to the carbon fibers is 25-30:1; and the steel wires and the carbon fibers account for 20 to 40 percent of the volume of the material. The damping wear-resistant copper alloy material prepared by the method has high toughness and wear resistance, and is simple in process and low in production cost.

Owner:金湖中博物联网科技有限公司

Fork truck stack board and its manufacturing method

InactiveCN1597455AHigh strengthEnvironmentally friendlyFlexible coversWrappersGlass fiberWear resistant

Pallets for fork vehicle are produced by: using honeycomb paperboards as substrates, binding a paper surface on the substrates and then binding glass fibres on them, coating with a layer of chemical resin, finally, assembling into pallets. The products are waterproof and corrosion-resistant and wear-resistant due to their glass fiber and a resin layer, and have good strength and environmental protection effect.

Owner:张源锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com